Mobile phone glass cover plate 3D arc edge defect detection method

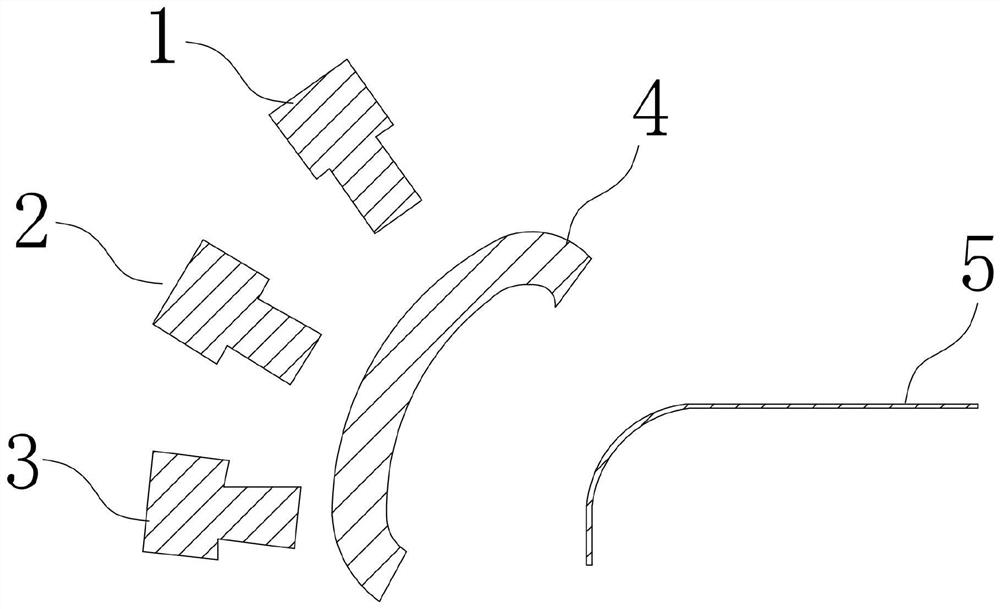

A technology for glass cover and defect detection, applied in computer parts, image data processing, instruments, etc., can solve the problems of difficult 3D curved surface detection technology, difficult optical imaging technology to meet the detection technical requirements, large curved surface and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

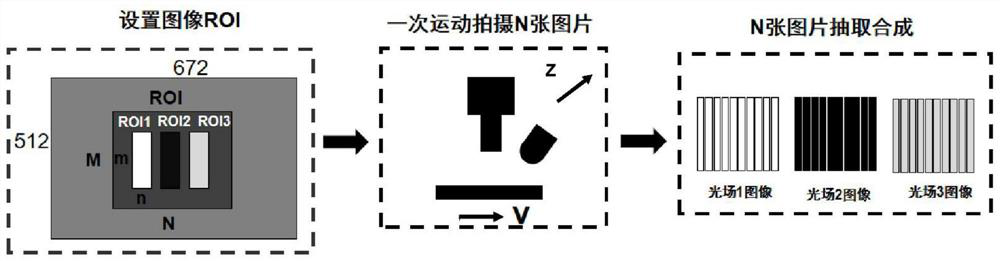

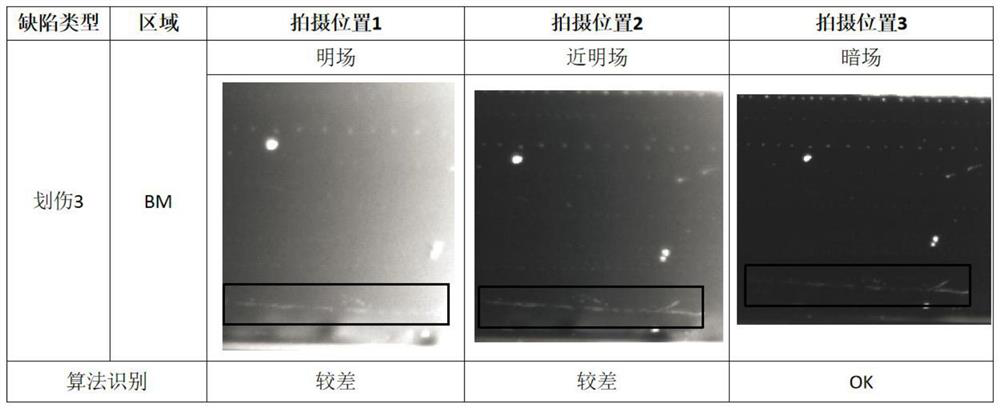

[0058] Such as image 3 , Figure 4 and Figure 5 As shown, camera No. 1, camera No. 2, and camera No. 3 are located at shooting position 1, shooting position 2, and shooting position 3 respectively. The images acquired by each camera under different light fields are synthesized and extracted, and identified by algorithms After the comprehensive inspection, it was found that different defects appeared on the 3D arc edge of the glass cover of the mobile phone, such as scratches, indentations, bumps, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com