Feeding device for stirring station for putty powder production building machinery

A technology for construction machinery and mixing stations, applied in the field of putty powder processing, which can solve the problems of the feeding device's stuck conveying efficiency, interference, and affecting feeding efficiency, etc., achieve good absorption and attenuation effects, facilitate the discharge of raw materials, and suppress horizontal shaking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

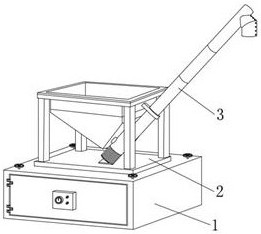

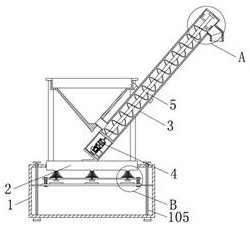

[0038] A feeding device for a mixing station for construction machinery for producing putty powder, comprising a bottom box 1, a support seat 2 is embedded in the center of the top of the bottom box 1, and a feeding member is fixedly installed on the top of the support seat 2;

[0039] The feeding components include: feeding pipe 3, servo motor 4, and conveying shaft 5;

[0040] The feeding pipe 3 is fixedly connected to the center of the top of the support base 2. There are two cavities inside the feeding pipe 3. The two cavities are arranged up and down and separated by a baffle. The servo motor 4 is fixedly connected to the feeding pipe. The internal bottom cavity of 3, the conveying shaft 5 is connected to the internal top cavity of the feeding tube 3 through bearing rotation;

[0041] Wherein, a feeding hopper is installed at the outer lower position of the discharge pipe 3, and the feeding hopper is fixed on the top of the support seat 2 through four pillars, and the wei...

Embodiment 2

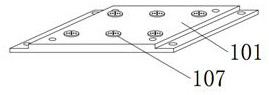

[0044] The difference between this embodiment and Embodiment 1 is that a support plate 101 is horizontally installed in the middle of the bottom box 1, and four springs 102 for shock absorption are equidistantly installed on the top of the support plate 101, and the springs 102 are installed on the top. There are horizontally arranged horizontal plates 103;

[0045] The top of the horizontal plate 103 is provided with a groove, and the inside of the top groove of the horizontal plate 103 is fixedly connected with equidistantly distributed springs 104, and the support seat 2 is horizontally installed on the top of the springs 104;

[0046] The first-level shock absorption is realized through the spring 102 between the support plate 101 and the support base 2, absorbing and attenuating the vibration transmitted from the discharge pipe 3 and the servo motor 4 to the up and down direction of the support base 2;

[0047] Wherein: the top edge place of support plate 101 is equipped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com