Goods shelf facilitating taking and placing steel

A technology for steel and racks, applied in the field of racks that facilitate the taking and placing of steel, can solve problems such as the inability to effectively control the amount of steel transferred, the inability to take and transfer the steel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

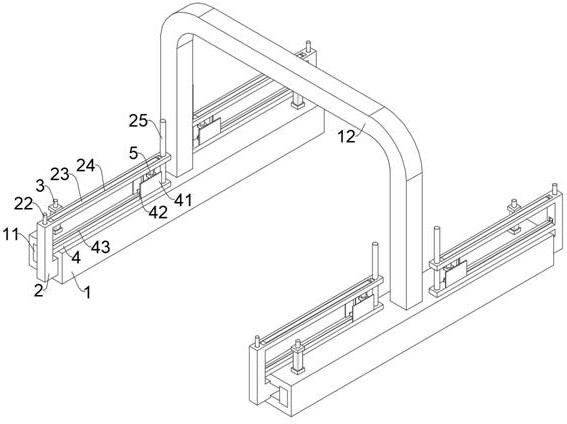

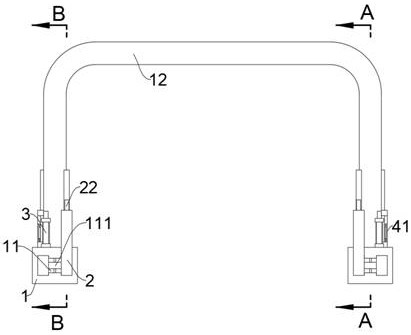

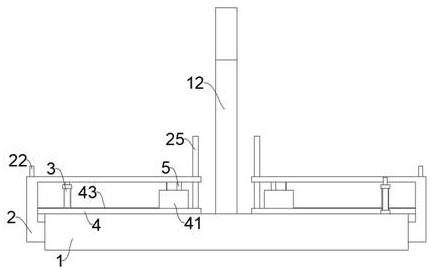

[0029] This embodiment provides a shelf that is convenient for picking and placing steel materials, and is mainly used to solve the problems that the existing steel material storage shelves cannot effectively take and transfer steel materials and cannot effectively control the transferred quantity of steel materials.

[0030] refer to figure 1 with Figure 4 As shown, since the steel of the pipe type is tubular, when the steel is placed on the ground, the outer peripheral surface of the steel will form a contact surface with the ground when it is placed in contact. It is extremely inconvenient for steel materials, and then it is necessary to place the steel materials through a suspended shelf. In order to solve this kind of problem, in this embodiment, a shelf that is convenient for picking and placing steel materials includes two fixed bases 1 and for Connect the connecting frame 12 of the fixed base 1. The fixed base 1 is provided with two counter-sliding placement parts 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com