Combinable reinforced truss arm and triangular truss arm unit body thereof

A truss arm, triangle technology, applied in the field of truss arm structure, can solve the problems of weak structural stability, difficult disassembly and transportation, single combination form, etc., to achieve diversified combination methods, rich combination forms, and high stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

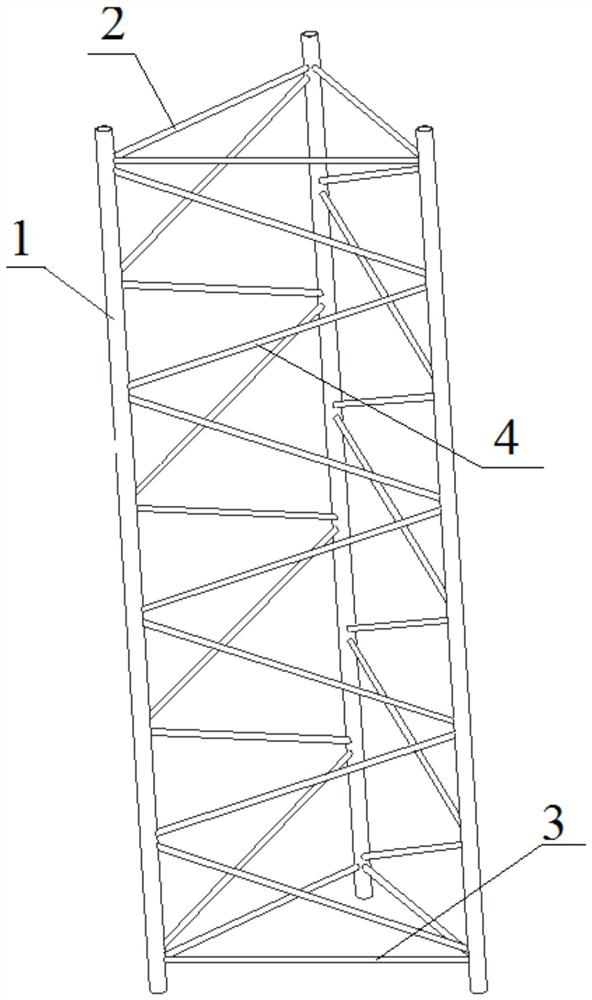

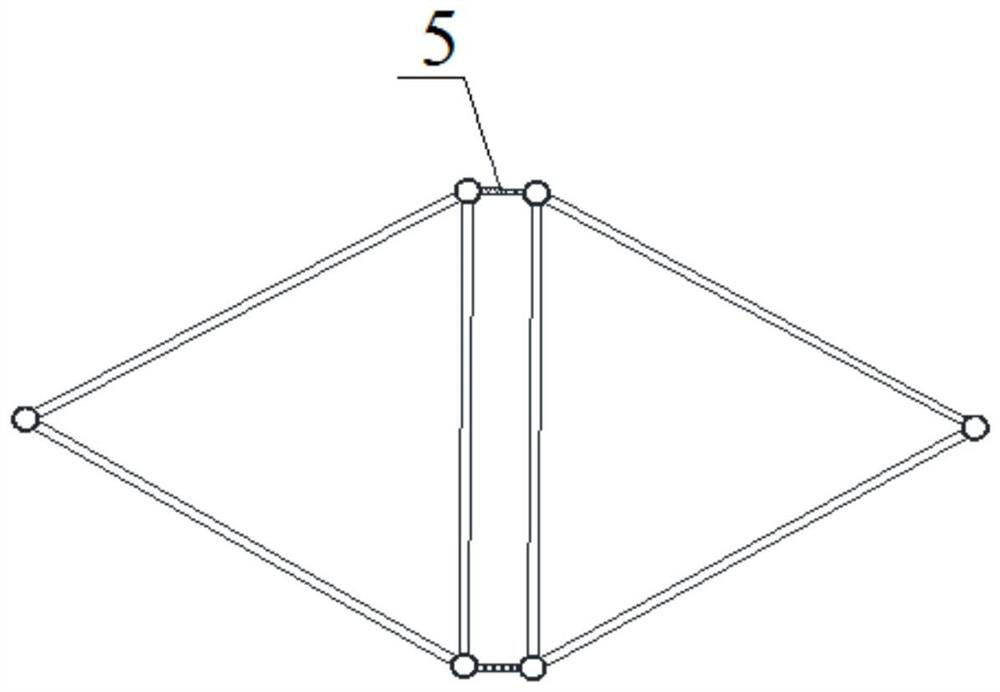

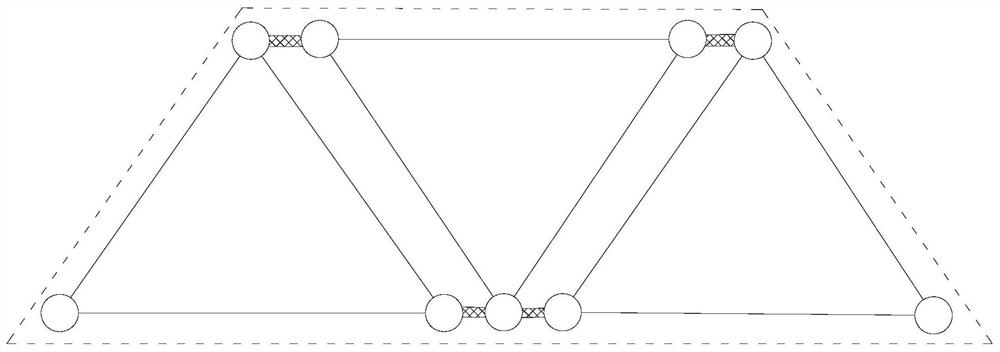

[0021] Such as figure 1 As shown, the present invention discloses a triangular truss arm unit body, which includes three main chords 1 arranged in pairs in parallel, the three main chords 1 form a triangular prism structure, and the upper part of the main chord 1 is connected with a top web bar between two pairs 2. The three top webs 2 form a triangular structure perpendicular to the main chord 1, and the bottom webs 3 are connected between two pairs of the lower part of the main chord 1, and the three bottom webs 3 form a triangular structure perpendicular to the main chord 1, Between two main chords 1 there are middle webs 4 repeatedly arranged in a zigzag shape, and the middle webs 4 are loca...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap