Sliding turnover mechanism, headrest adjusting device and headrest bracket

A technology of a flipping mechanism and an adjusting device, which is applied in the field of furniture, can solve the problems of complex structure, difficult manufacturing and installation, poor reliability, etc. of the sliding flipping mechanism, and achieves the effects of small occupied space, reduced manufacturing and installation steps, and smooth rotational movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

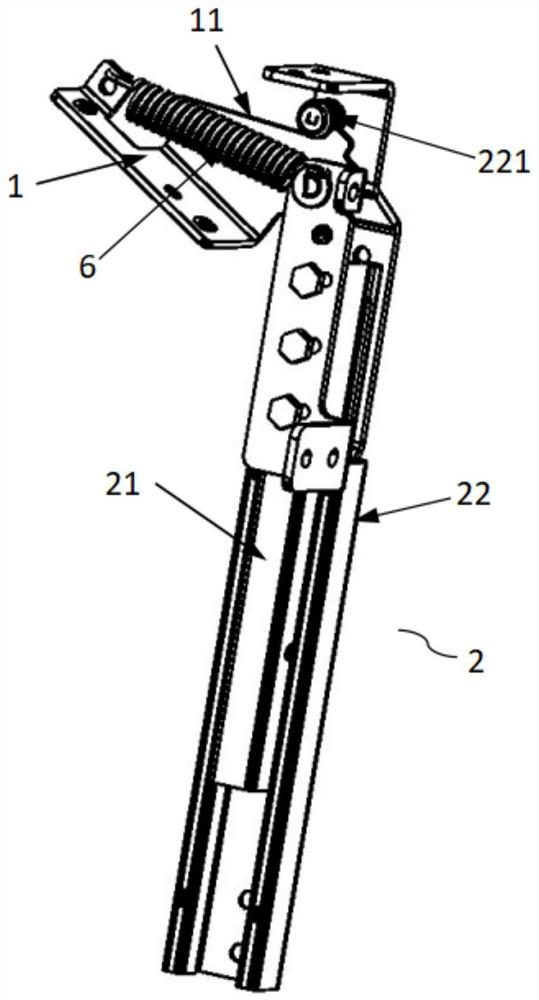

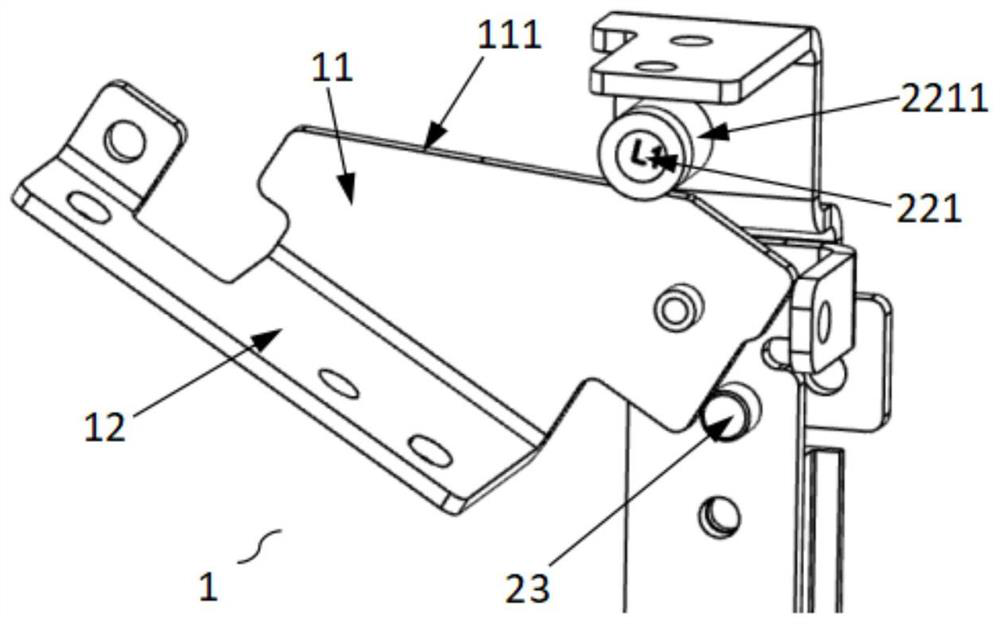

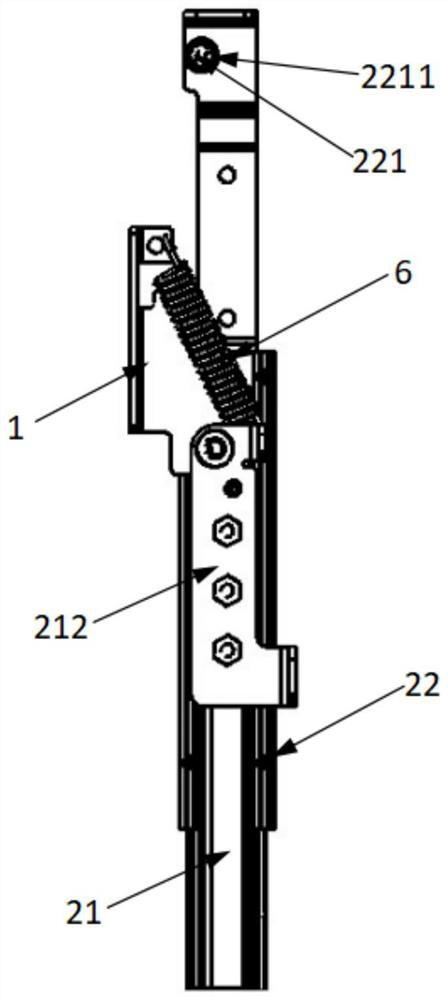

[0043] Such as Figure 1-5As shown, the present embodiment 1 provides a sliding and turning mechanism, including a turning connection part 1 and a lifting assembly 2, and the lifting assembly 2 includes a movable part 21 and a fixed part 22, the movable part 21 is used to move relative to the fixed part 22, and the turning part is connected Part 1 is used to rotate with the movable part 21; the fixed component 22 is provided with a limit deflection part 221, and the flip connector 1 is provided with a limit surface 11 matched with the limit deflection part 221, and the movable part 21 is used to drive the The turning connector 1 moves relative to the fixed assembly 22 , and when the limiting surface 11 contacts the limiting deflection member 221 , the movable member 21 continues to push to make the turning connecting member 1 rotate relative to the fixing assembly 22 .

[0044] Specifically, such as figure 2 As shown, the turning connector includes an integrally formed adjus...

Embodiment 2

[0058] Such as Figure 9 As shown, the lifting assembly 2 in the embodiment 2 is different from the embodiment 1. The difference between the lifting assembly 2 in the embodiment 2 and the embodiment 1 is that the movable part 21 is provided with a guide chute 213, and the fixed assembly 22 is provided with a guide chute. The slot 213 cooperates with the sliding part 224 , and the sliding part 224 is used for sliding connection with the guide chute 213 , and the guide chute 213 cooperates with the sliding part 224 to make the movable part 21 slide relative to the fixed assembly 22 . In Embodiment 2, the sliding member 224 is a sliding pin, at least two sliding pins are fixed on the fixed assembly 22, and the sliding pins are installed in the guide chute 213, and the guiding chute 213 is slidably connected with the sliding pin so that the movable member 21 can Sliding relative to the fixed assembly 22 .

[0059] Specifically, in this embodiment, the movable part 21 is hinged to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com