Micro-particle acceleration device based on MEMS technology

A technology of accelerating devices and microparticles, which is applied in the direction of measuring devices, improvement of process efficiency, testing of machine/structural components, etc., can solve problems that have not been quantitatively supported by physical theories and have not been directly observed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

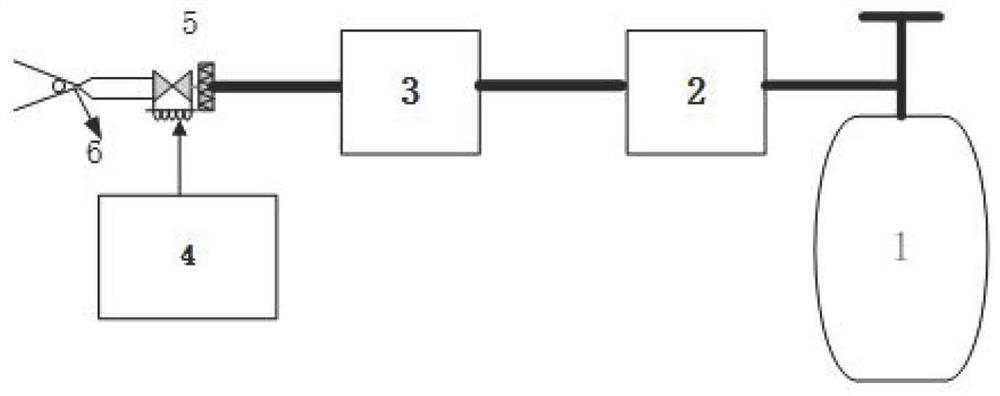

[0017] Such as figure 1 As shown, this embodiment relates to a microparticle accelerator based on MEMS technology, including: a high-pressure gas storage tank 1, a pressure reducing valve 2, a gas regulator 3, a solenoid valve drive control circuit 4, and a solenoid valve 5 connected in sequence . Miniature Lava micro-acceleration tube 6, wherein: after the gas regulator produces a stable air pressure, the electromagnetic valve is opened, and the microparticles are quickly ejected from the acceleration tube. The solenoid valve driving board is used to apply the driving voltage to the solenoid valve, shorten the time from the solenoid valve command to the actual time, and realize the millisecond pulse width injection.

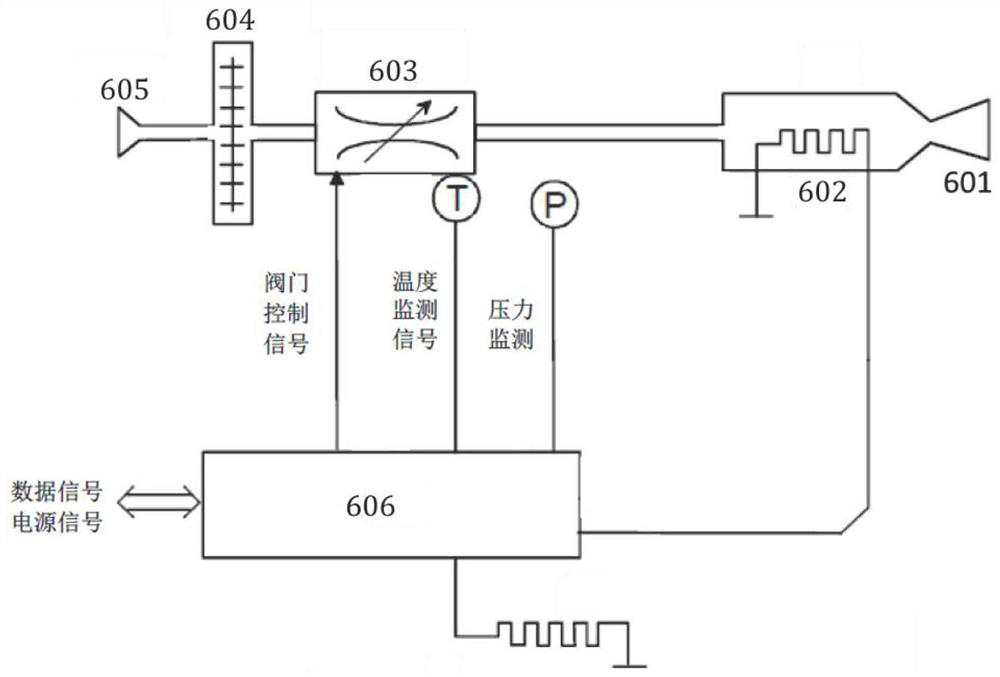

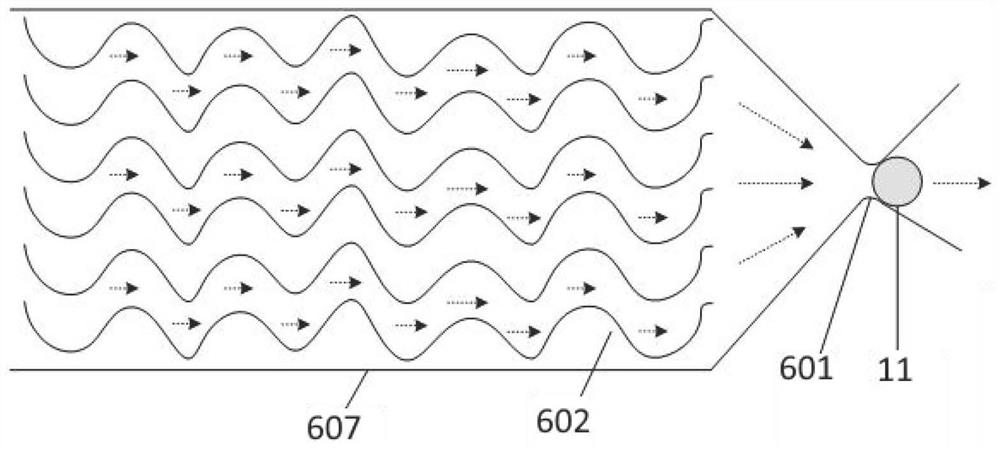

[0018] Such as figure 2 and image 3 As shown, the micro-Lava micro-accelerator tube 6 includes: a housing 607, a coiled heating chip array 602 disposed inside it, flow control valves 603 respectively disposed at the inlet and outlet ends of the housing, nozz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com