Error microphone having fault detection function and used for active noise control system and fault detection method

An active noise control and error microphone technology, which is applied in the directions of sound-producing instruments and instruments, can solve the problems of real-time detection of error microphone states, etc., and achieves the effect of simple method and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

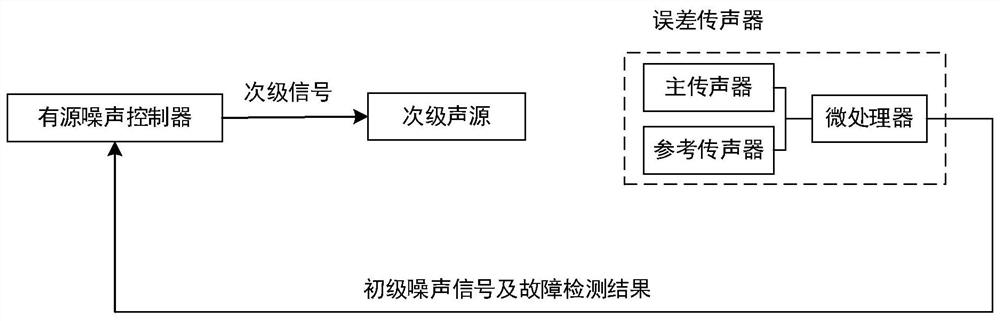

[0029] like figure 1 As shown, a principle module of an error microphone fault detection scheme for an active noise control system mainly includes an active noise controller, a secondary sound source, and an error microphone. The active noise controller is connected to the secondary sound source, The error microphone is connected to an active noise controller, and the error microphone module includes a main microphone, a reference microphone and a microprocessor. The main microphone and the reference microphone are connected to the microprocessor, and finally the signal of the main microphone and the fault detection result signal processed by the microprocessor are sent to the active noise controller. In engineering applications, the microprocessor can be a processor with signal processing functions such as DSP, FPGA or STM32 single-chip microcomputer.

Embodiment 2

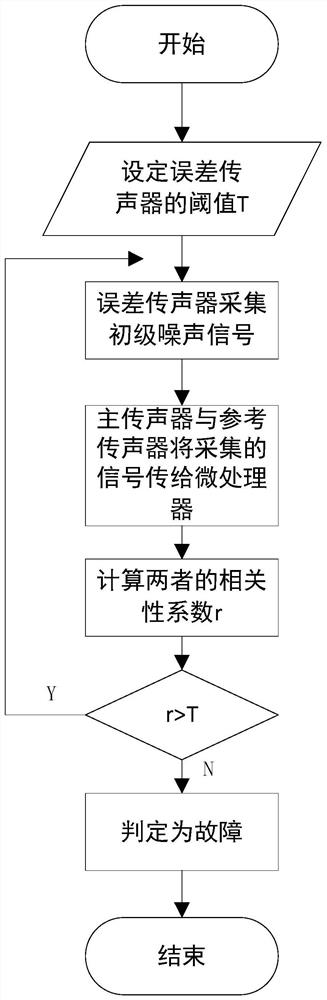

[0031] When the active noise controller is working, the error microphone collects the primary noise signal in the current environment in real time and feeds it back to the active noise controller. The secondary sound source is used to send out the secondary signal (the sound that cancels out the primary noise). In this process, the error microphone module uses two microphones with the same performance to collect, one of which is the main microphone, which is used to feed back the primary noise signal to the active noise controller, and the other is the reference microphone, which also has the same effect, but it is only used to provide the signal comparison between the microprocessor and the main microphone, and the microprocessor is used to calculate the correlation coefficient between the main microphone and the reference microphone signal, and compare it with the set threshold (if not set Within the threshold, it is judged that the error microphone is faulty), and the fault ...

Embodiment 3

[0044] Given that the sensitivity of a certain type of error microphone is 7.9mv / Pa, and the threshold T is set to 0.8, after the active noise reduction device is turned on, the secondary sound source and the error microphone start to work:

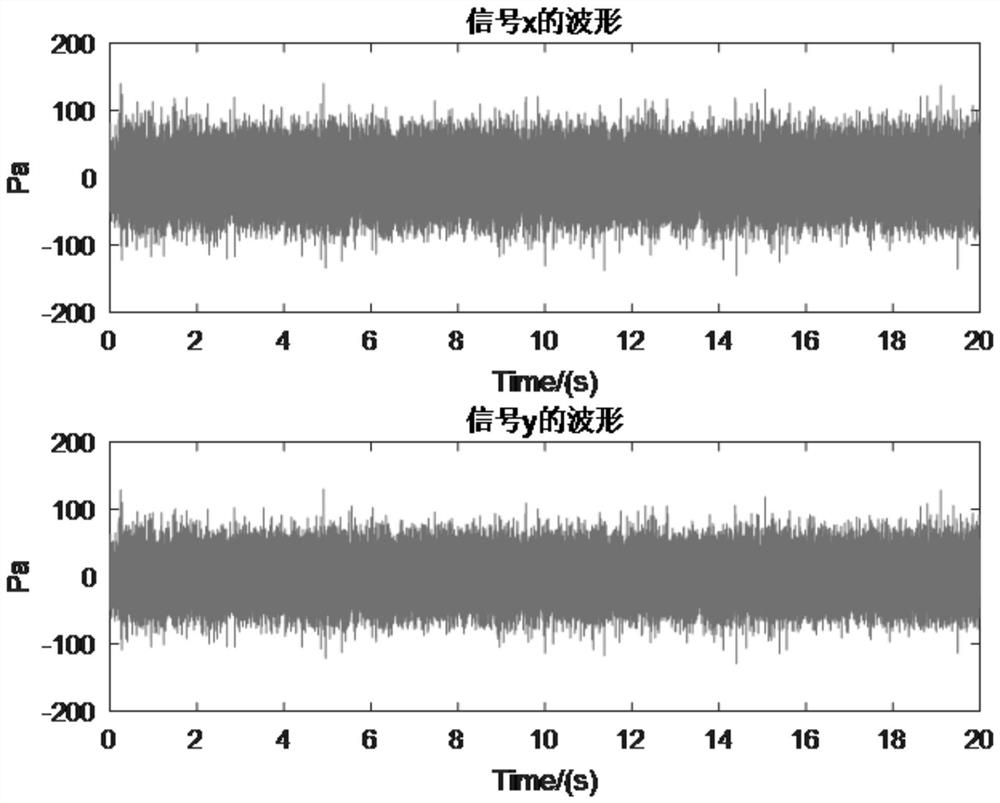

[0045] 1. The error microphone collects the primary noise, and the secondary sound source plays the secondary signal. The primary noise signals collected by the main error microphone and the reference error microphone for a certain period of time are x and y, such as image 3 shown;

[0046] 2. Calculate the correlation coefficient r between x and y through formula (1):

[0047] r=0.98;

[0048] 3. Whether the error microphone is faulty or not:

[0049] Comparing r=0.98>T=0.8, it is judged that the error microphone is normal;

[0050] 4. Feedback the fault detection result and the primary noise signal to the active noise controller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com