Anti-loosening hexagonal flange nut machining equipment with anti-skid teeth

A flange nut and processing equipment technology, which is applied in the field of nut processing, can solve the problems that plate punching cannot be quickly inquired and positioned, and punching and nut cannot be accurately riveted and combined, so as to achieve accurate riveting and bonding position of the positioning center, punching The effect of precise hole query and positioning, and precise riveting position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

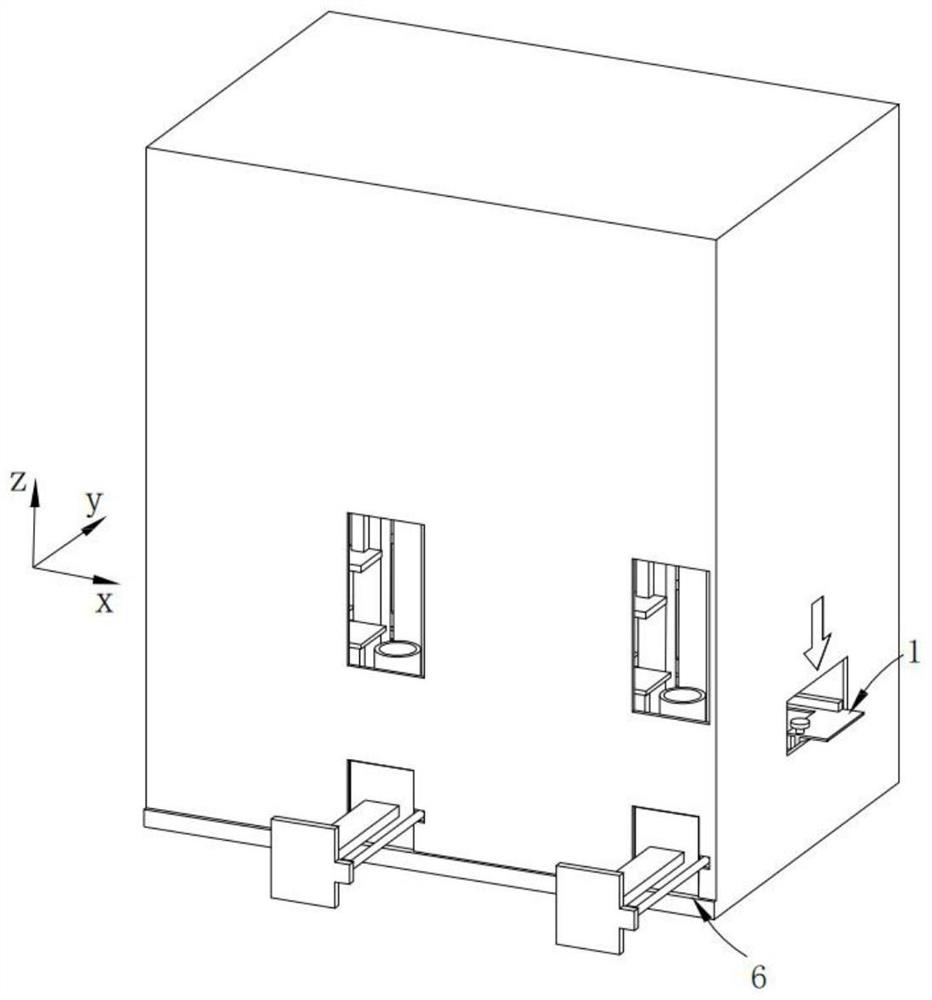

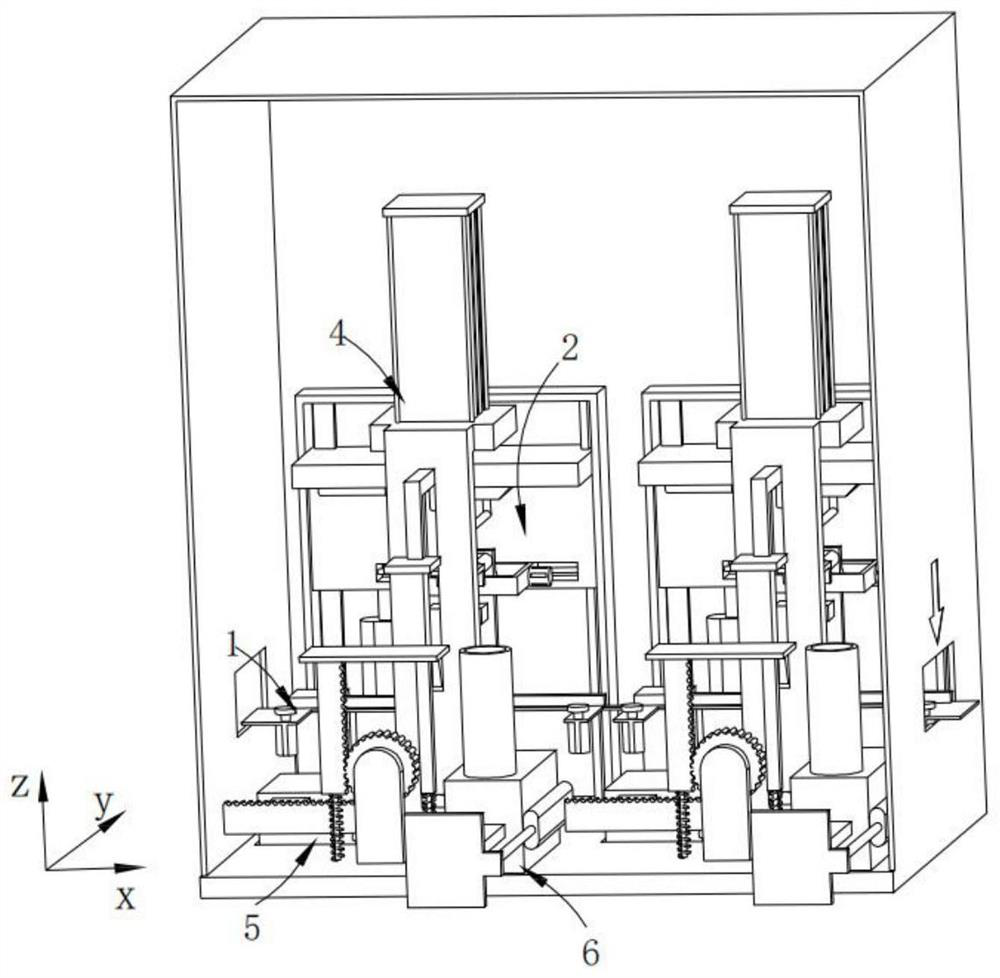

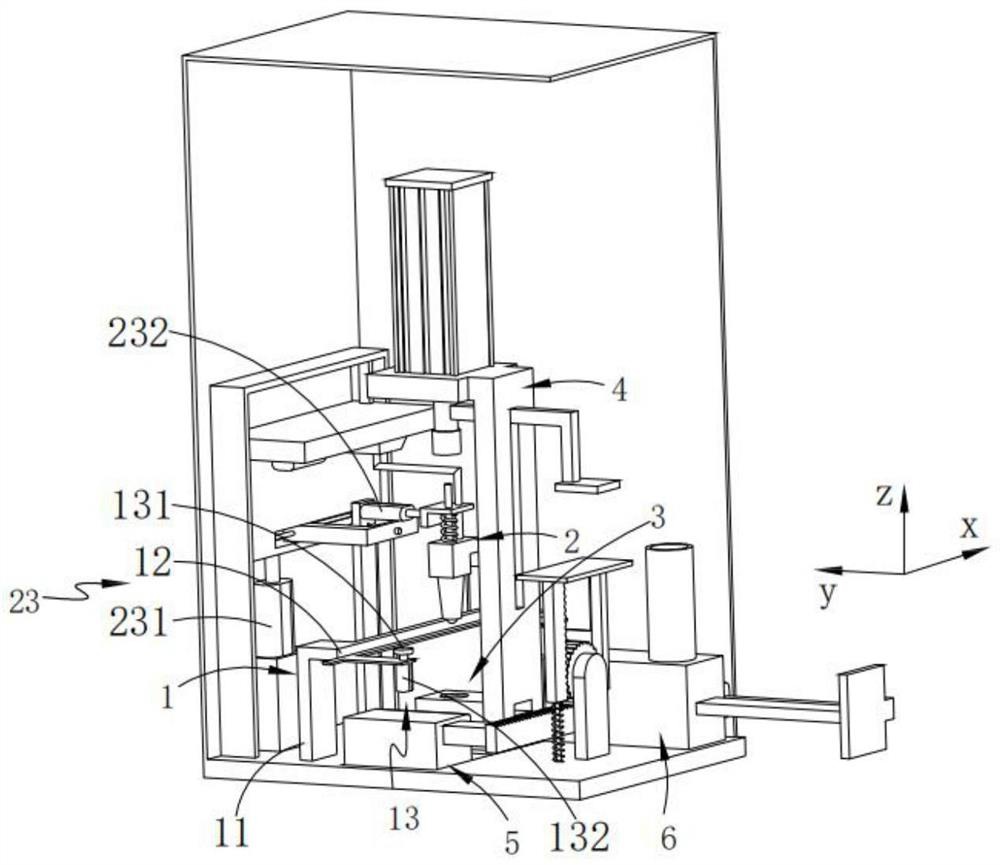

[0039] Such as Figure 1-3 As shown, a processing equipment for anti-loosening hexagonal flange nuts with anti-skid teeth, including:

[0040] Locking table 1 for keeping the plate punching position unchanged;

[0041] A positioning component 2 that is arranged above the plate and searches for and locates the punching hole of the plate;

[0042] Carry the nut and follow the positioning component 2 to the guide component 3 that is attached to the bottom of the center of the positioning punching hole;

[0043] Synchronously with the positioning assembly 2, reaching the riveting assembly 4 above the center of the positioning punching hole; and

[0044] A load-bearing component 5 provided on one side of the guide assembly 3 and supporting the bottom of the guide assembly 3 during riveting.

[0045] Through the above content, it is not difficult to find that in the process of riveting the nut and the plate, the punched plate is first placed on the locking table 1, and the punching...

Embodiment 2

[0100] Such as Image 6 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0101] The bearing assembly 5 includes:

[0102] Base 51;

[0103] sliding the support platform 52 arranged on the base 51;

[0104] Drive the supporting platform body 52 to move to the linkage part 53 at the bottom of the rising guide assembly 3; and

[0105] The power end of the riveting assembly 4 moves up and down and links the pressing part 54 of the linkage part 53 .

[0106] In this embodiment, when the riveting assembly 4 performs the riveting action downward, it will move synchronously with the pressing part 54, and when the pressing part 54 reaches the linkage part 53, it will drive the linkage part 53, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com