Sealing performance inspection device and method for fuel gas inlet valve

A technology of gas intake and inspection device, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement, fluid tightness test, measuring device, etc., to reduce maintenance costs, reduce inspection cycles and costs, and improve maintenance efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The invention replaces the traditional method of checking air tightness with soap bubbles, and adopts an air tightness checking device capable of measuring leakage to realize quantitative judgment on the air tightness of gas inlet valves.

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it should not be used to limit the protection scope of the present invention.

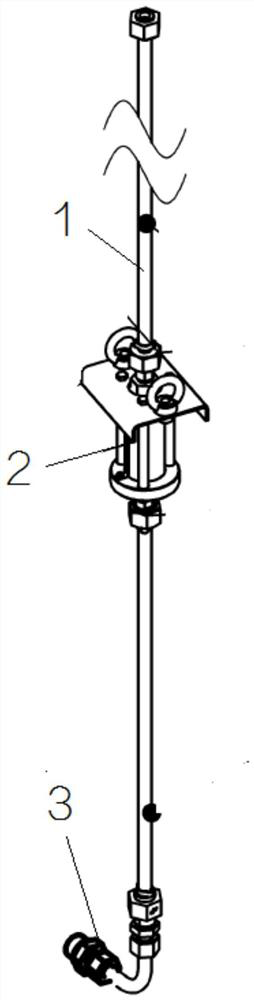

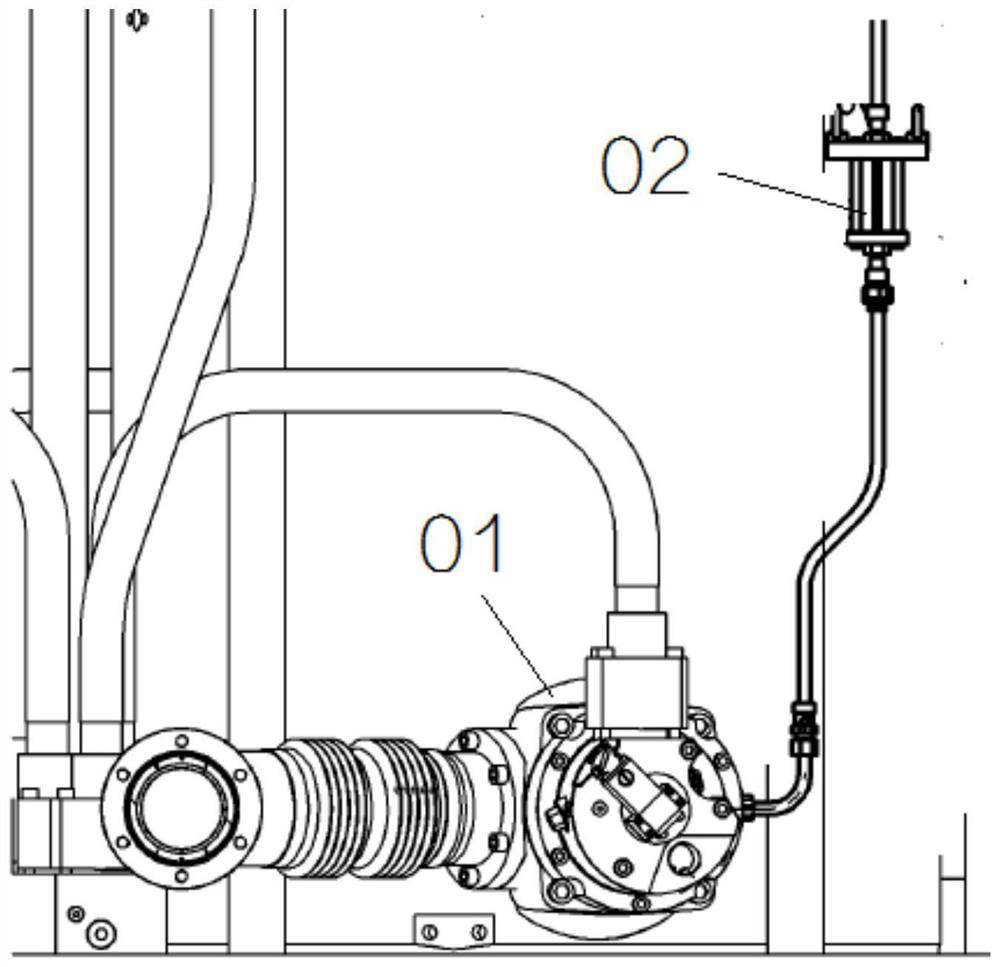

[0021] Please see first figure 1 , which shows the tightness inspection device for the gas intake valve, including the compressed air connecting pipe 1 , the oil storage unit 2 and the intake valve connecting pipe 3 .

[0022] The oil storage unit 2 is a sealed container for containing lubricating oil; the inlet of the oil storage unit 2 is connected to the compressed air source through the compressed air connecting pipe 1, and the outlet is connected to the compressed air source through the inlet valve connecting pipe 3. The gas inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com