A model device for testing the leakage of geomembrane composite vertical barrier and its use method and application

A model device, geomembrane technology, used in measurement devices, surface/boundary effects, permeability/surface area analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

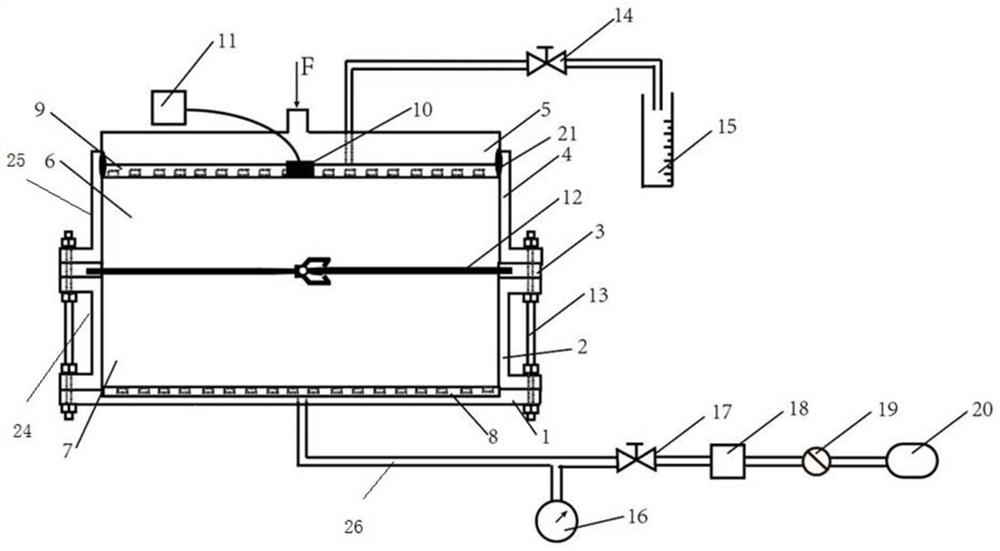

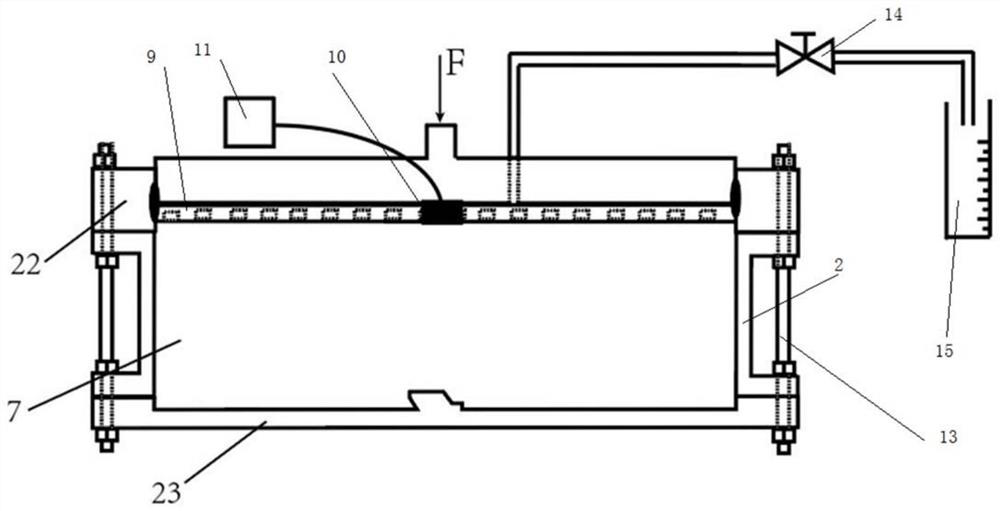

[0042] A model device for a vertical isolation engineering barrier based on a dry-wet cycle, comprising a bottom plate 1, a lower porous backing plate 8, a lower model box 2, a lower side wall 24, a geomembrane splint 3 with a geomembrane, an upper model box 4, Upper side wall 25, upper porous backing plate 9, cover plate 5; The bottom plate 1 is provided with a lower porous backing plate 8, and the bottom plate 5 is longer than the lower porous backing plate 8; The lower porous backing plate 8 is provided with a lower Model box 2, the periphery of described lower model box is provided with pad on the base plate 1, and the lower side wall 24 of equal height, the geomembrane splint 3 with geomembrane 12 is placed on the top of described lower side wall 24, and described geomembrane The membrane splint 3 is provided with an upper mold box 4, the periphery of the upper mold box 4 is provided with an upper side wall 25, and the upper part is successively arranged on the upper porou...

Embodiment 2

[0045] The above-mentioned method for using the model device for testing geomembrane composite vertical barrier leakage comprises the following steps:

[0046] Step 1, select a special-shaped plate 23, place the lower model box 2 on the special-shaped plate 23, enclose the lower model box 2 with the lower side wall 24, place a riser 22 above the lower side wall 24, and fix it with bolts 13 Connect the special-shaped plate 23, the lower side wall 24 and the riser 22; the height of the riser 22 is greater than 10 centimeters;

[0047] Step 2, the lower barrier material area 7 formed in the lower model box 2 is filled by controlling the slump, and the lower barrier material area 7 is filled with water after the filling is completed;

[0048] Step 3, place the force sensor 10 on the upper porous backing plate 9, place it on the filler in the lower barrier material area 7, then put the cover plate 5, and then connect the pipeline with the upper two-way valve 14 on the cover plate 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com