Additive manufacturing process for compositions comprising poly-aryl-ether-ketone(s)

A polyaryl ether ketone, additive manufacturing technology, applied in the direction of manufacturing tools, additive processing, additive manufacturing, etc., can solve the problem of not equipped with a system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0152] The filaments of Example 2 and Example 3 were successfully extruded. The tensile test data of Type IV specimens according to ASTM D638 are shown in Table 1 below:

[0153]

[0154] Table 1

[0155] The sample of Example 2 not according to the invention showed some visible signs of warping, as the surface of the sample did not appear to be perfectly flat. In contrast, the sample of Example 3 according to the invention did not show any signs of warping to the naked eye, since the surface of the sample appeared to be completely flat. From the tensile data in Table 1, it can be seen that the specimens from Example 3 have better tensile strength than Example 2 along the X / Y or Z directions, as indicated by higher values of maximum stress, yield strain, and break strain. mechanical properties.

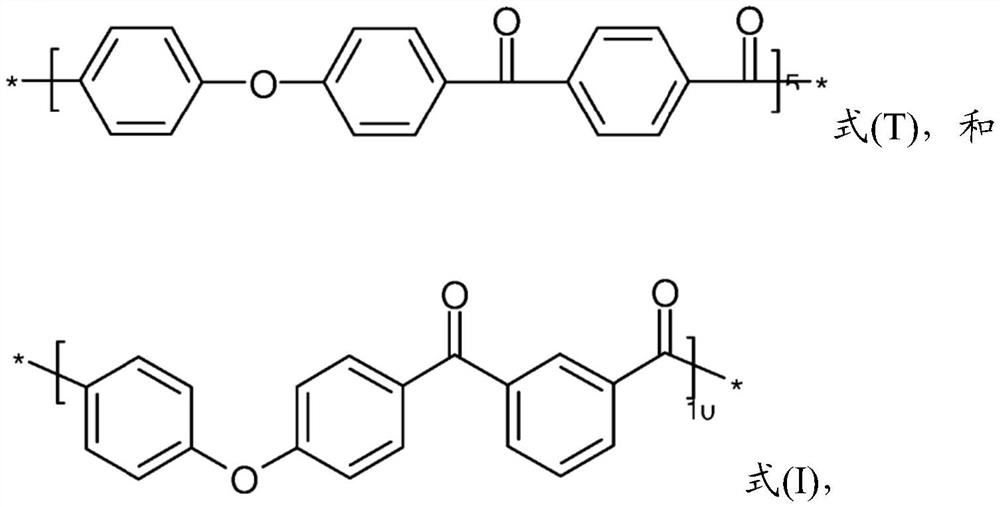

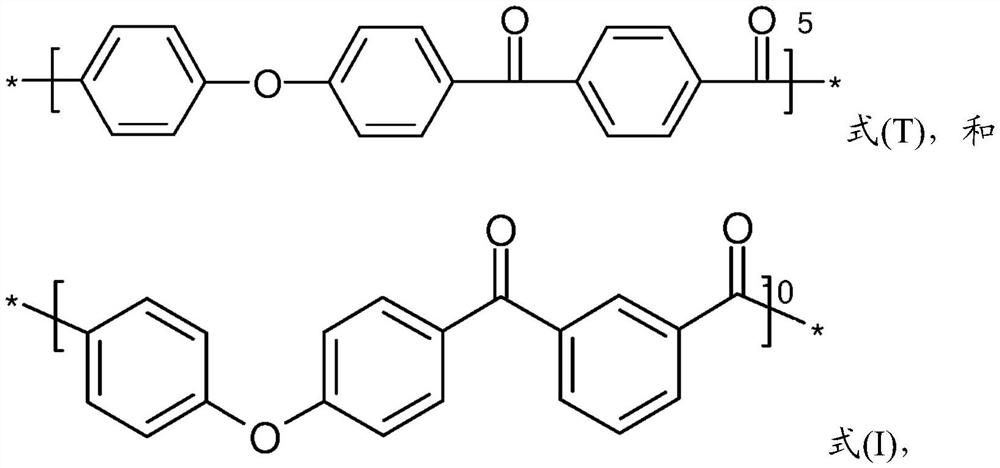

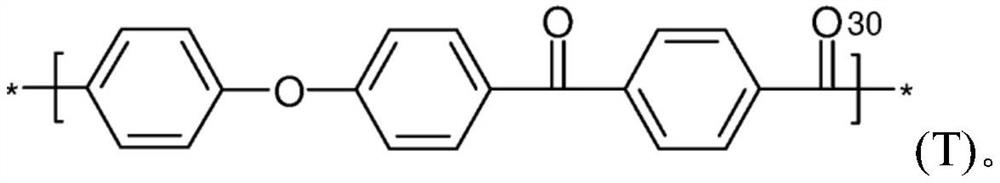

[0156] The currently used PEKK copolymer with a T:I ratio of 60:40 is particularly advantageous because it has a melt temperature of about 305°C, a half-time crystallization o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap