Anti-disengaging bridge support and bridge adopting same

A bridge support and anti-detachment technology, which is applied to bridges, bridge parts, bridge materials, etc., can solve the problems of high cost of bearing replacement, damage to the upper structure, and large social impact, so as to ensure safety, prolong service life, and prevent Effect of disease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

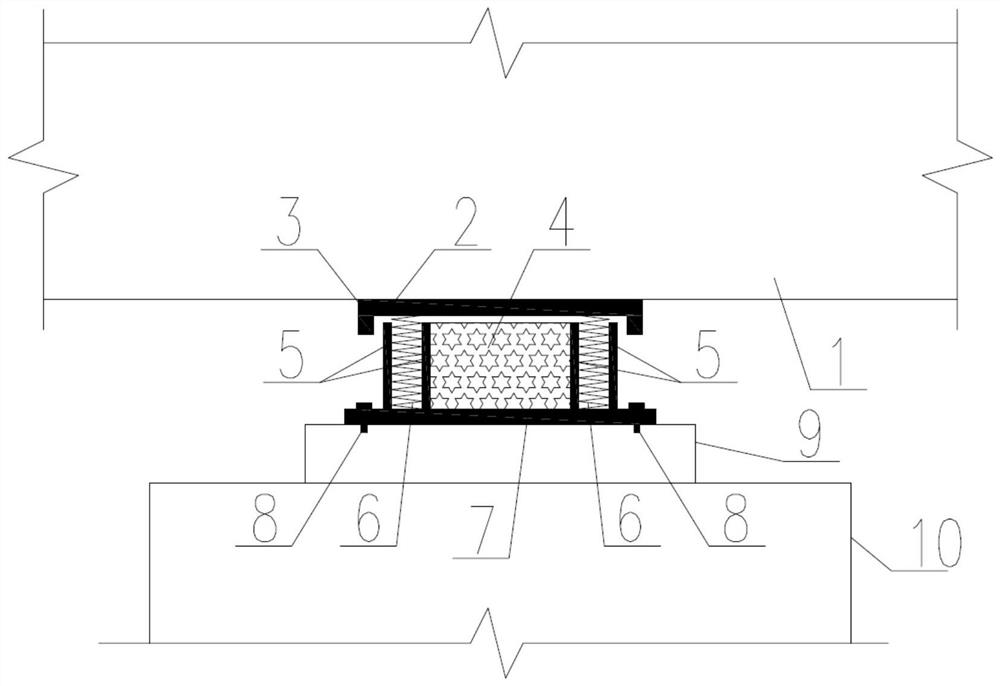

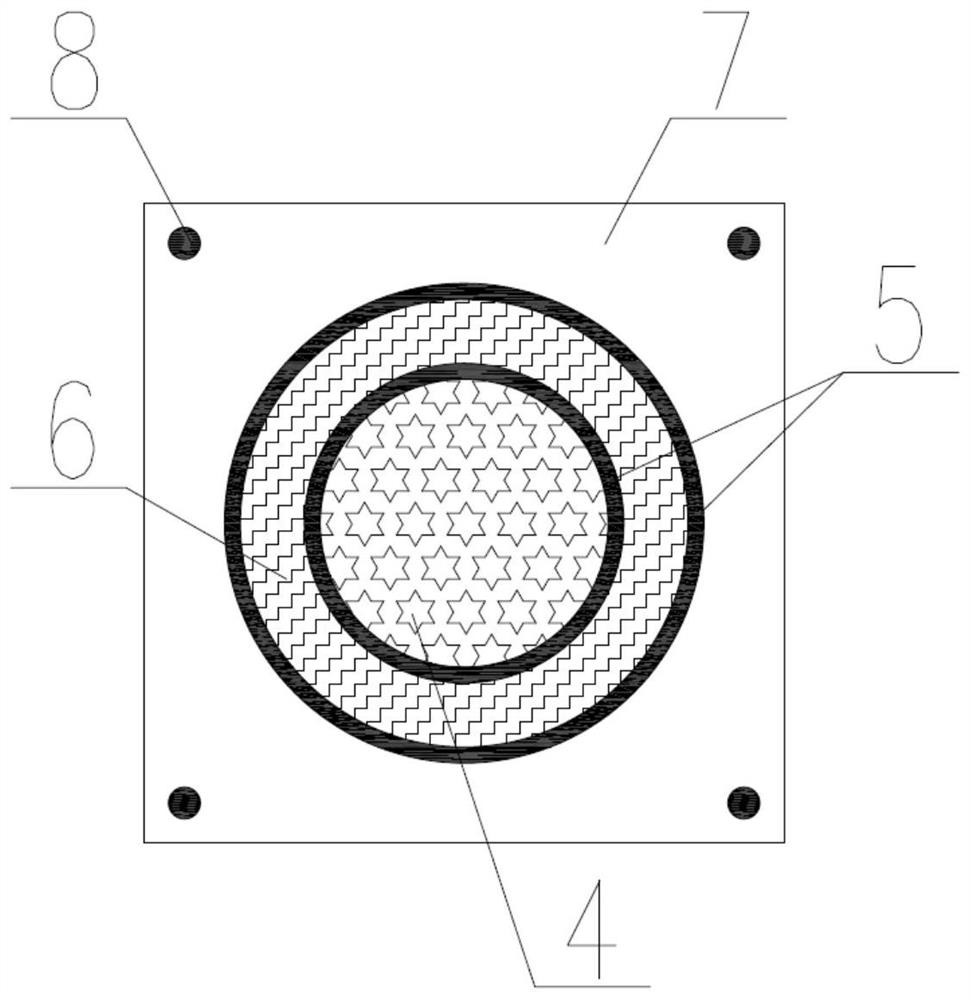

[0037] see figure 1 and figure 2 , a kind of anti-vacation bridge support, placed between the beam body 1 of the bridge superstructure and the bridge substructure 10, it includes the upper steel plate 2 of the support, the lower steel plate 7 of the support, the support stone 9, and the double-layer annular seal Steel plate 5, buffer component 4, elastic component 6. The steel plate 2 on the support is fixed on the beam body 1 of the bridge superstructure; anchor bolts 8 are arranged around the steel plate 7 under the support, and the anchor bolts 8 fix the steel plate 7 under the support on the support pad stone 9, and the support pad stone 9 is fixed on the bridge substructure 10. The double-layer annular sealing steel plate 5 is placed between the upper steel plate 2 of the support and the lower steel plate 7 of the support, its lower end is fixed on the lower steel plate 7 of the support, and there is a gap between the upper end and the upper steel plate 2 of the suppor...

Embodiment 2

[0040] The difference from Example 1 is that in order to better limit the vertical and horizontal displacement of the bridge, prevent excessive vertical and horizontal displacement, and prevent the occurrence of the anti-vacation phenomenon, according to the displacement requirements of the bridge, around the steel plate 2 on the support Set the limit plate 3.

[0041] In the present invention, the thickness of the steel plate 2 on the support and the steel plate 7 under the support is 20-40mm.

Embodiment 3

[0043] A kind of bridge, this bridge adopts embodiment 1 or embodiment 2 anti-vacation bridge support.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com