Hopper structure and spraying and smearing integrated robot

A hopper and main body technology, applied in the field of hopper structure and spraying integrated robot, can solve the problems of unfavorable cost control and large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

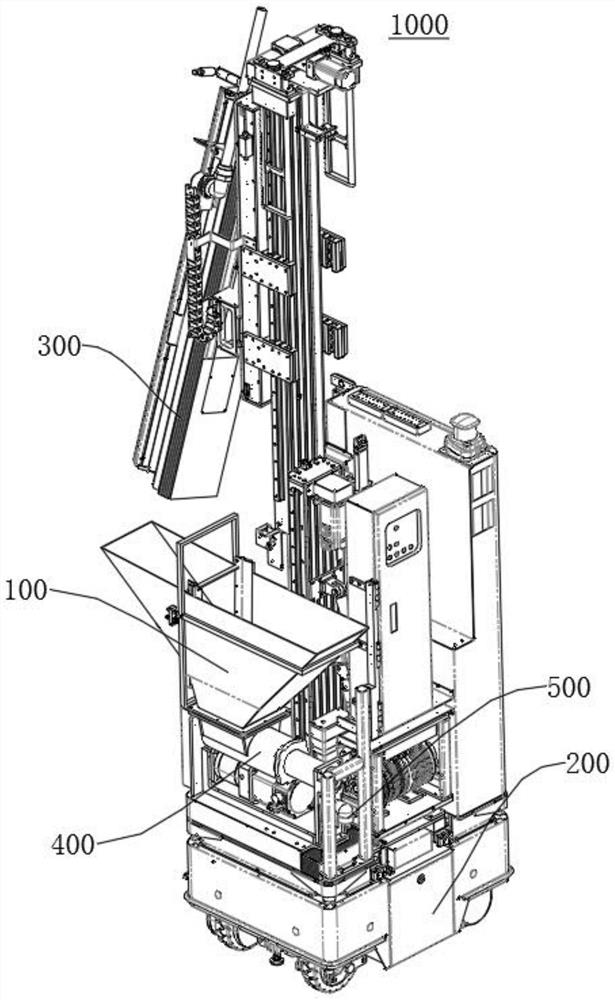

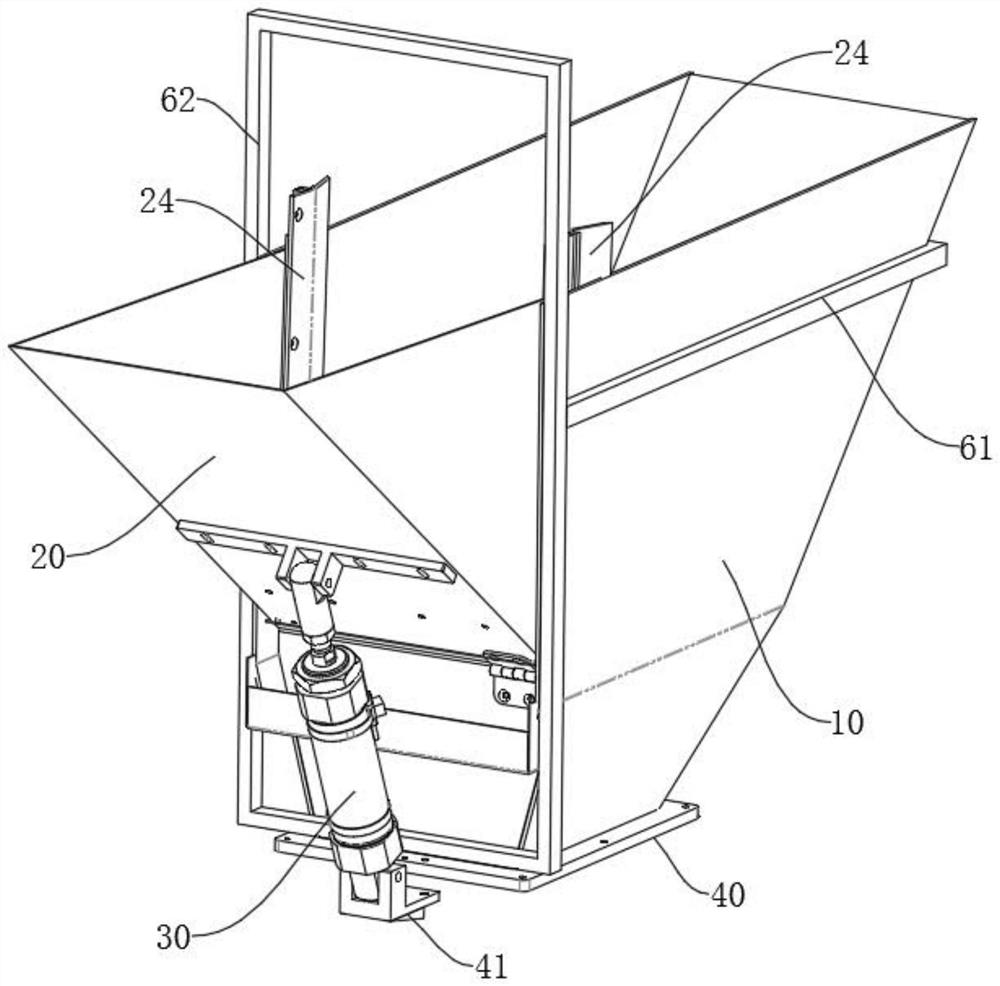

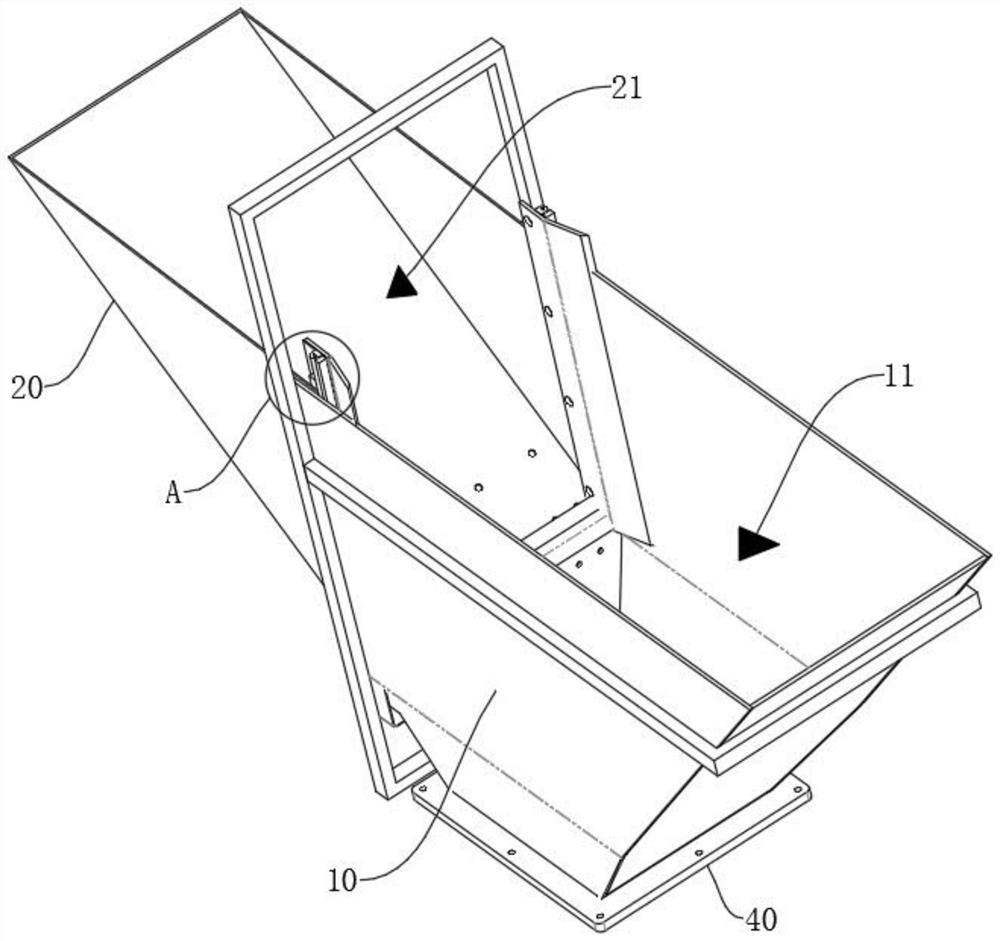

[0056] Please refer to figure 1 , figure 2 with image 3 , the embodiment of the present application provides a hopper structure 100, including:

[0057] The hopper main body 10, the hopper main body 10 has a first accommodating chamber 11;

[0058] The hopper turning part 20, the lower end of the hopper turning part 20 is hinged with the hopper main body 10, the hopper turning part 20 has a second accommodation chamber 21, and the second accommodation chamber 21 communicates with the first accommodation chamber 11; and

[0059] The driving mechanism 30 is used for turning the hopper turning part 20 relative to the hopper main body 10, so that the hopper turning part 20 switches between the first position and the second position;

[0060] When the hopper turning part 20 is in the first position, the hopper turning part 20 protrudes forward from the hopper main body 10 to receive overflow; when the hopper turning part 20 is in the second position, the hopper turning part 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com