Material guiding device for wrapper composite calendering

A material guide device and dough skin technology, which is applied to dough forming machinery or equipment, dough sheeting machine/rolling machine/rolling pin, etc., and can solve problems such as waste of manpower, broken dough, and insufficient pulling power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

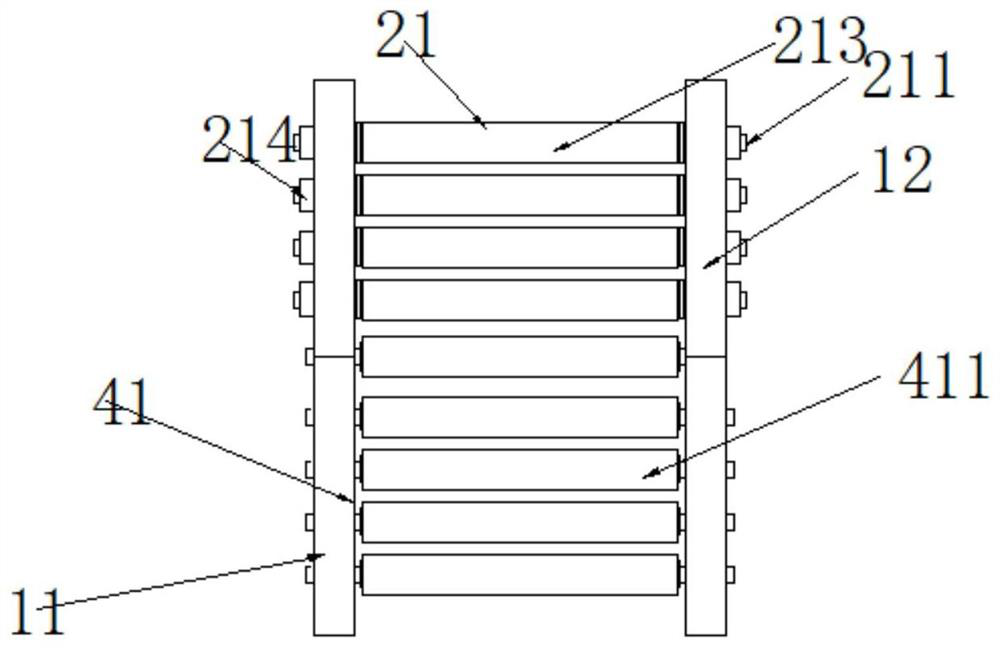

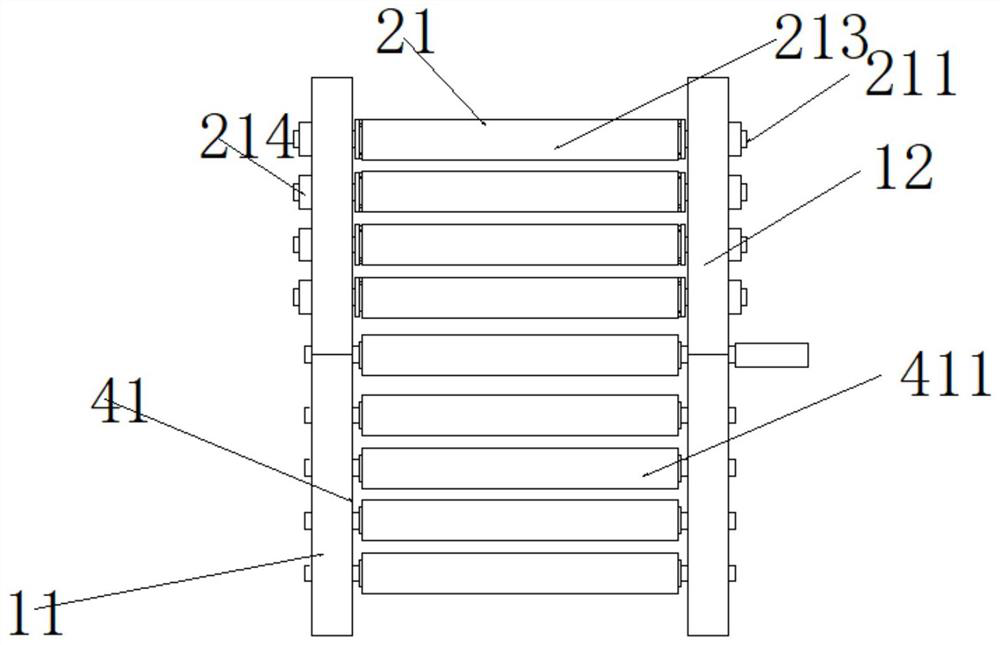

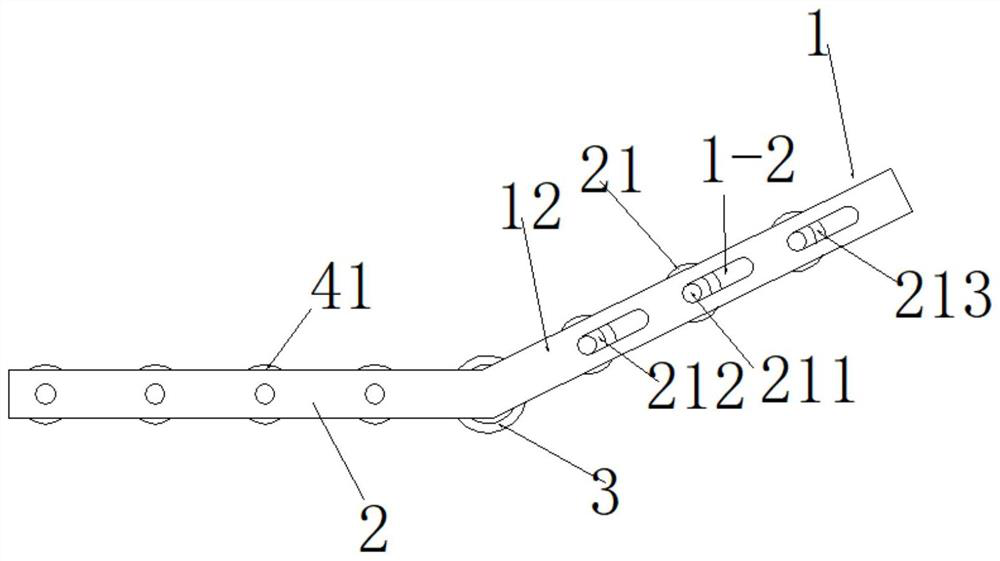

[0027] A material guide device for composite rolling of dough, comprising a material guide frame connected with a calender; the material guide frame includes a support frame 1 connected with the calender, and a material guide part 21 is provided on the support frame 1 The material guide shaft 212 connected to the material guide part 21, the material guide shaft 212 is provided with a material guide sleeve 213; the support frame 1 is arranged obliquely; the invention discloses a material guide for dough composite rolling device, the material guide device disclosed in the present invention mainly plays a guiding role, so that the dough can be conveniently entered into the composite calendering equipment for composite calendering operation; it mainly includes a material guide part 21, and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com