Patents

Literature

32results about How to "Easy to take out the material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stirring device with good stirring effect

InactiveCN112058143AStir wellAvoid stickingRotary stirring mixersTransportation and packagingSlurryMechanical engineering

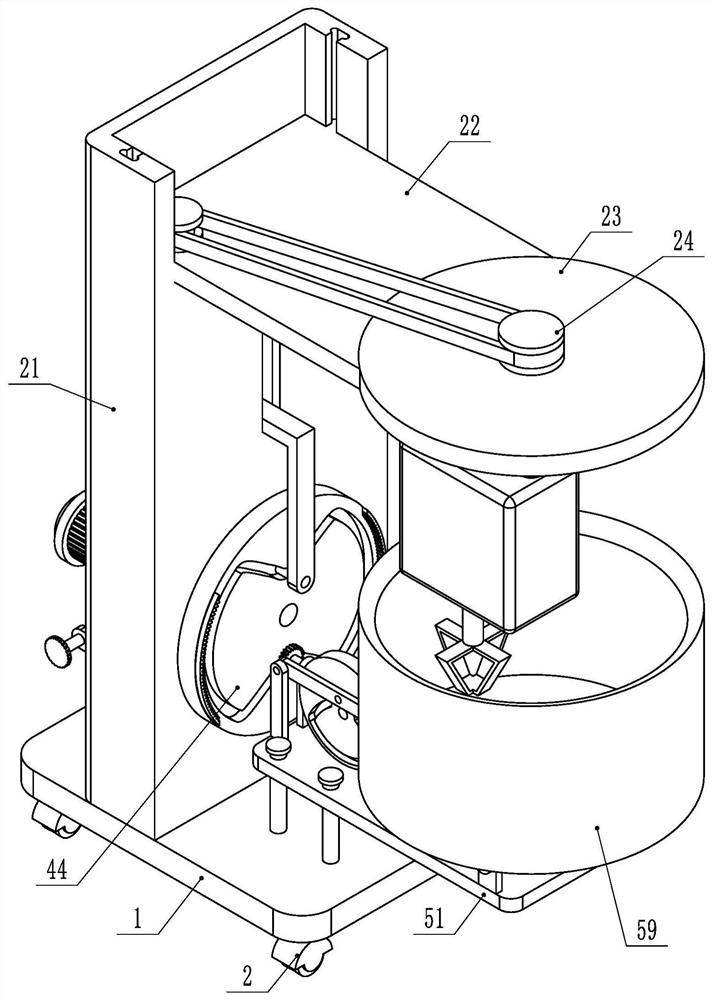

A stirring device with a good stirring effect comprises a bottom plate, a supporting box is fixedly connected to the surface of the upper end of the bottom plate, a concave square plate is slidably connected to the inner wall of the upper end of the supporting box, a rotatable first grooved wheel is mounted on the lower side of the surface of the front end of the supporting box, and a square supporting plate is mounted on the front side of the upper end of the bottom plate; a stirring barrel is hinged to the front side of the upper end of the square supporting plate, and when the square supporting plate moves downwards to the bottom, a front-back overturning structure of the stirring barrel can be formed; a first circular plate is fixedly connected to the surface of the front end of the concave square plate, a mounting box capable of moving up and down while rotating is mounted at the lower end of the first circular plate, and a stirring frame capable of moving front and back while rotating is mounted at the lower end of the mounting box; through the stirring frame capable of circumferentially rotating while moving back and forth and auto-rotating while moving up and down, raw materials in the stirring barrel can be fully stirred, and a large amount of slurry can be prevented from adhering to the inner wall of the stirring barrel.

Owner:秦国现

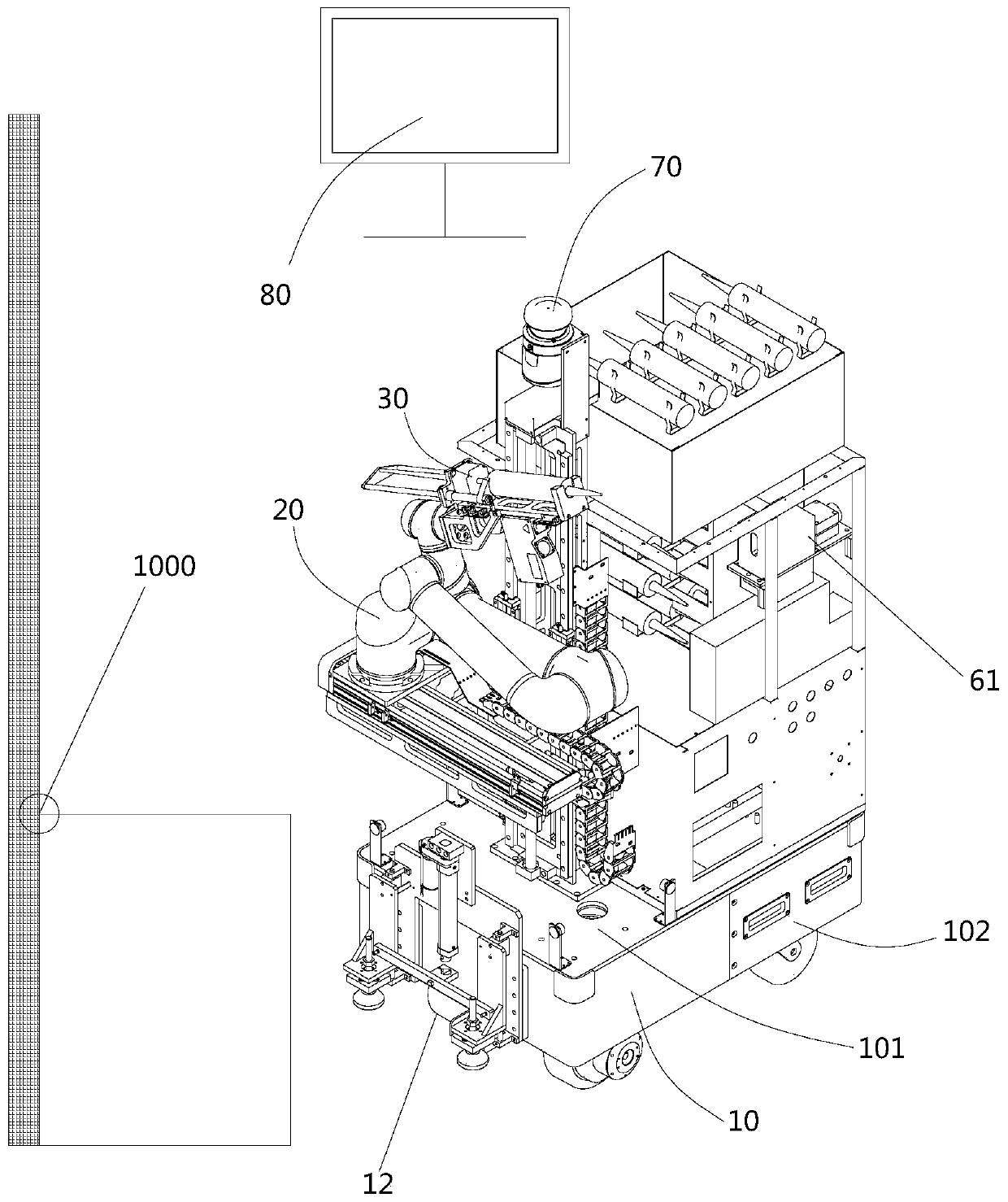

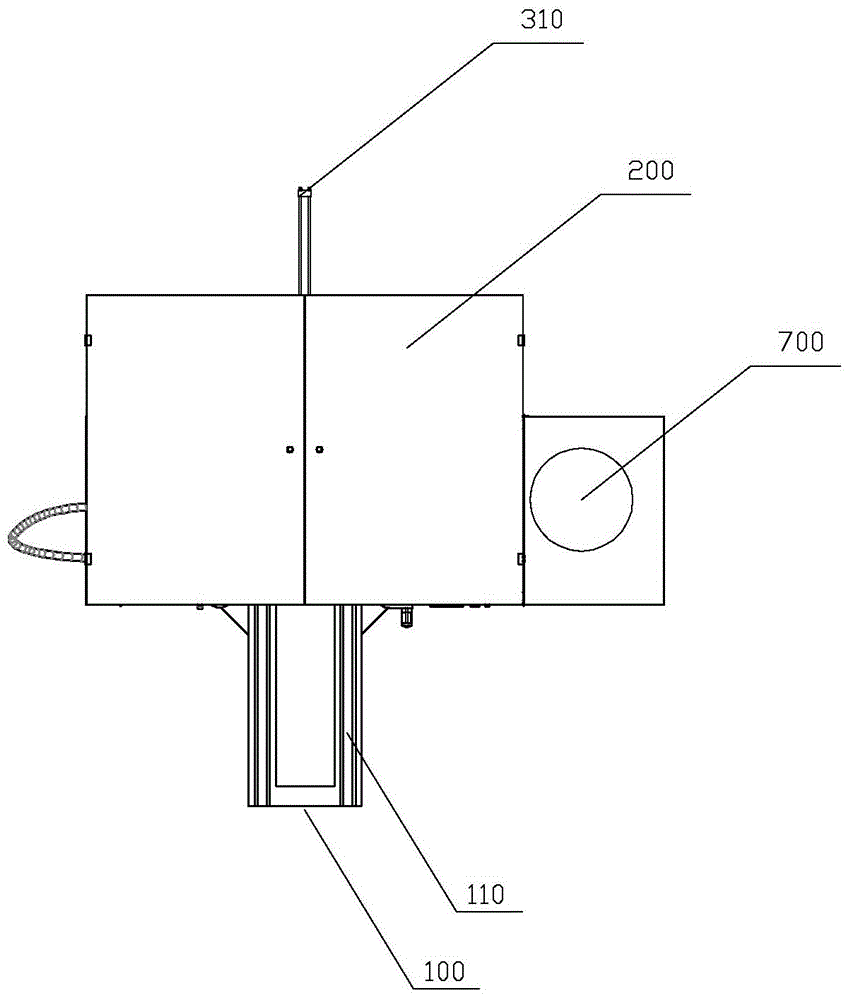

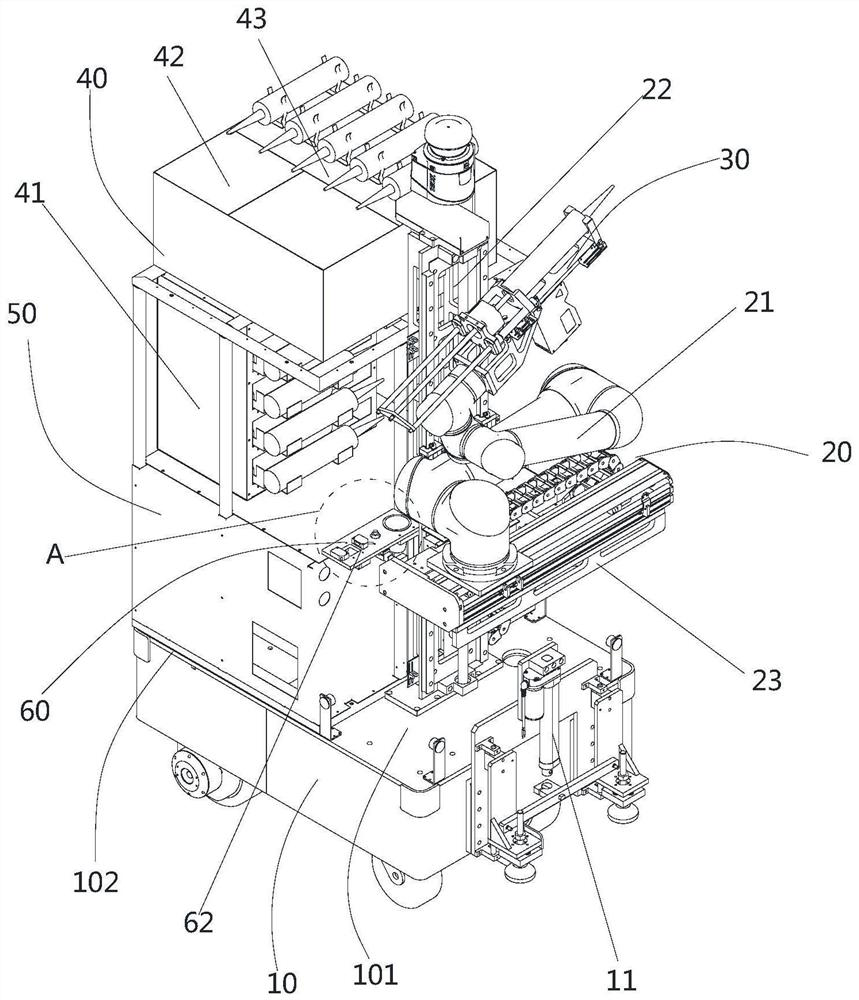

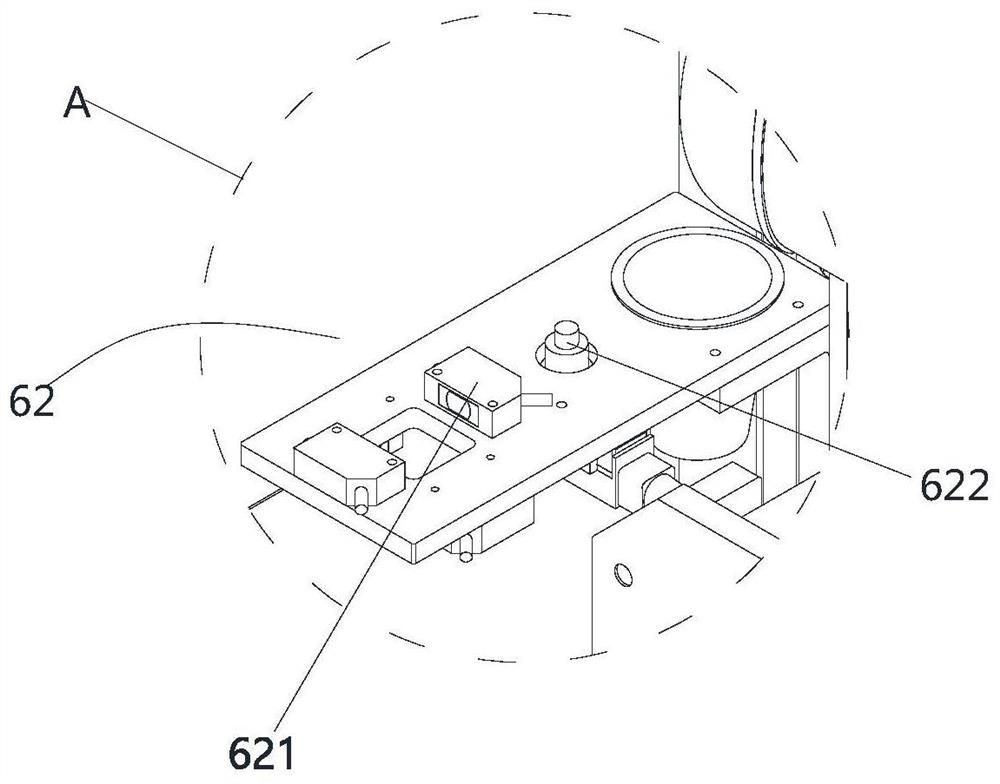

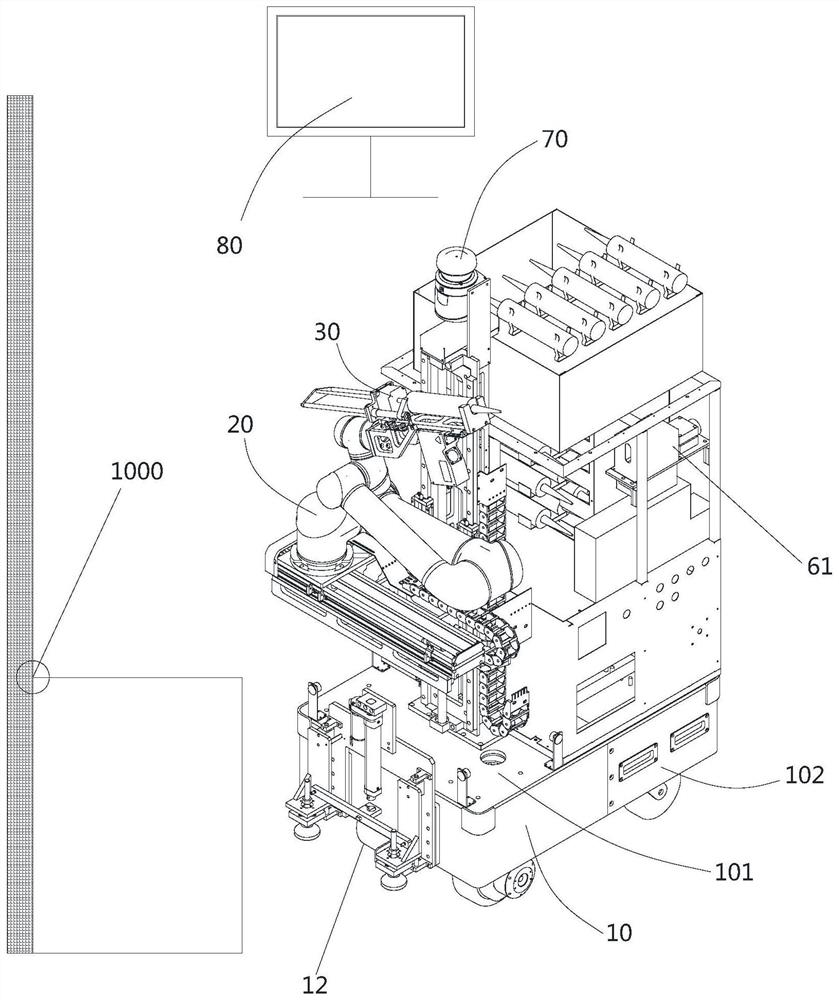

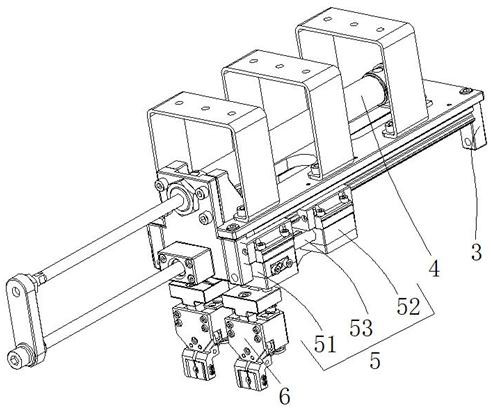

Gluing robot

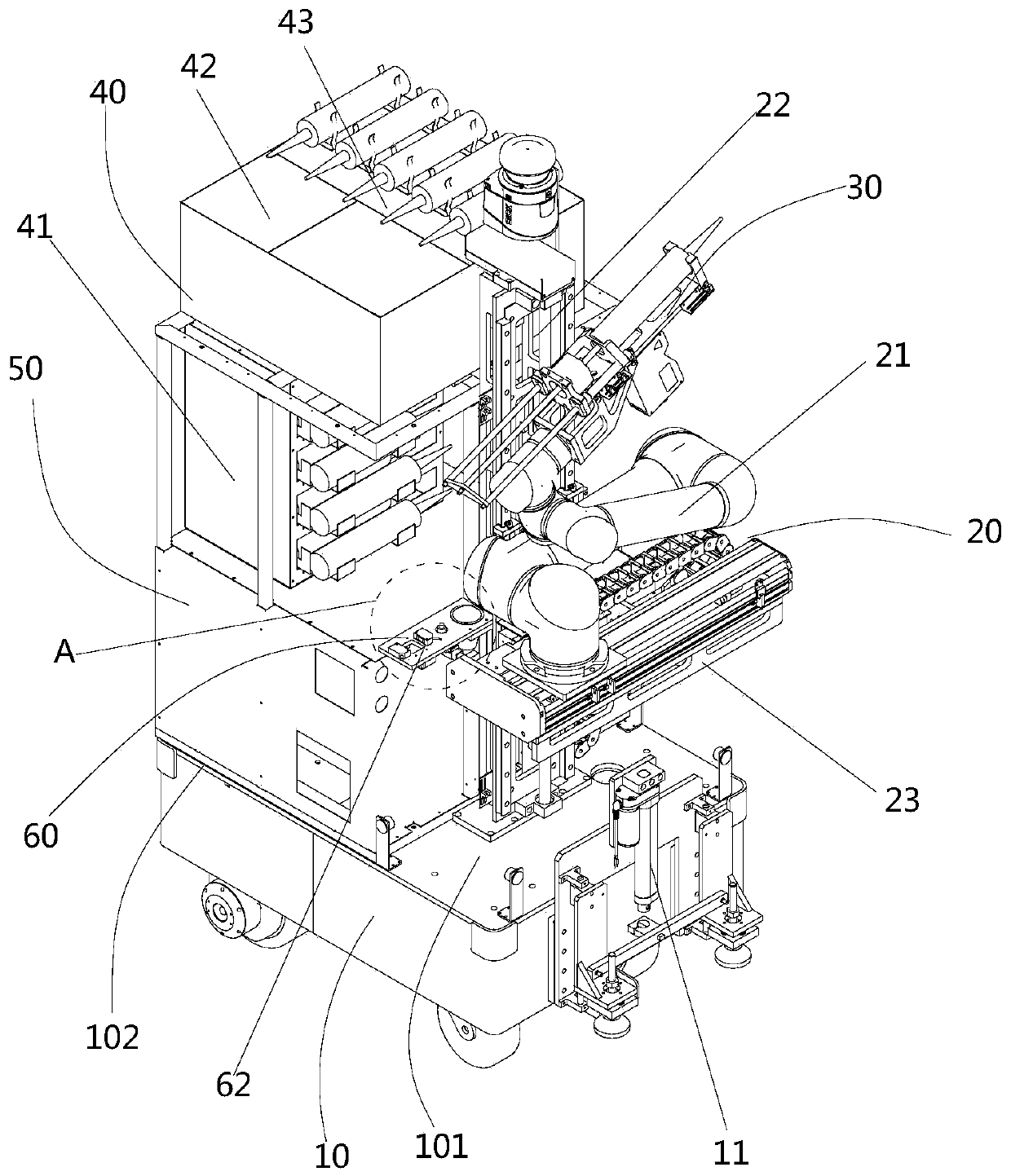

ActiveCN110962144AImprove stabilityConvenient glue workLiquid surface applicatorsCoatingsLarge rangeRolling chassis

The invention provides a gluing robot. The gluing robot comprises a movable chassis, a gluing moving device, a gluing device and a stock bin; the movable chassis is used for providing walking power, and is provided with a gluing implementation area and a glue barrel supply area in the front end and the rear end respectively; the gluing device and the gluing moving device are both arranged in the gluing implementation area, the gluing moving device is connected to the movable chassis, and the gluing device is arranged on the gluing moving device and used for automatically clamping a glue barrelto conduct gluing or loosening the glue barrel to replace the glue barrel; and the stock bin is arranged in the rubber barrel supply area. The movable chassis, the gluing device, the gluing moving device and the stock bin are arranged, the stock bin is arranged at the rear end of the movable chassis, and the gluing device and the gluing moving device are arranged at the front end of the movable chassis, so that the space above the chassis is reasonably utilized, gluing in a larger range is conveniently completed, the weight of the gluing implementation area is matched with that of the glue barrel supply area, and the stability of the gluing robot is improved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

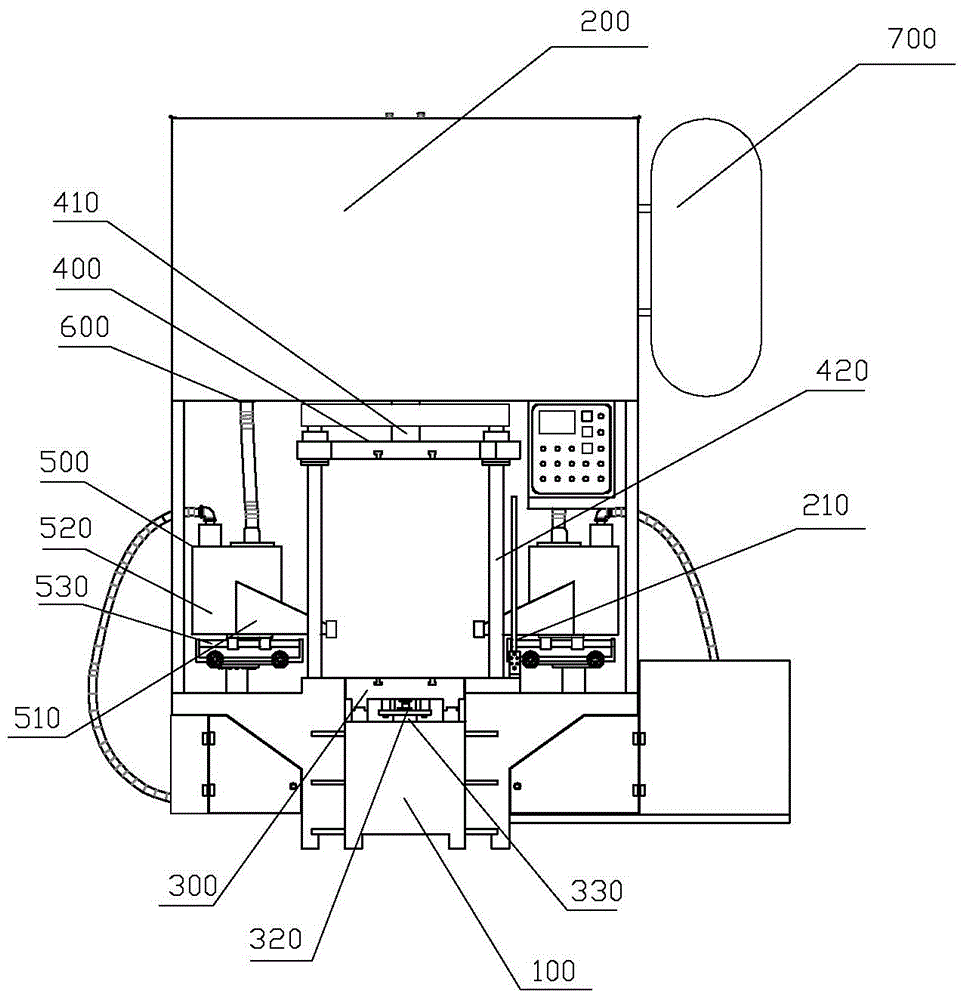

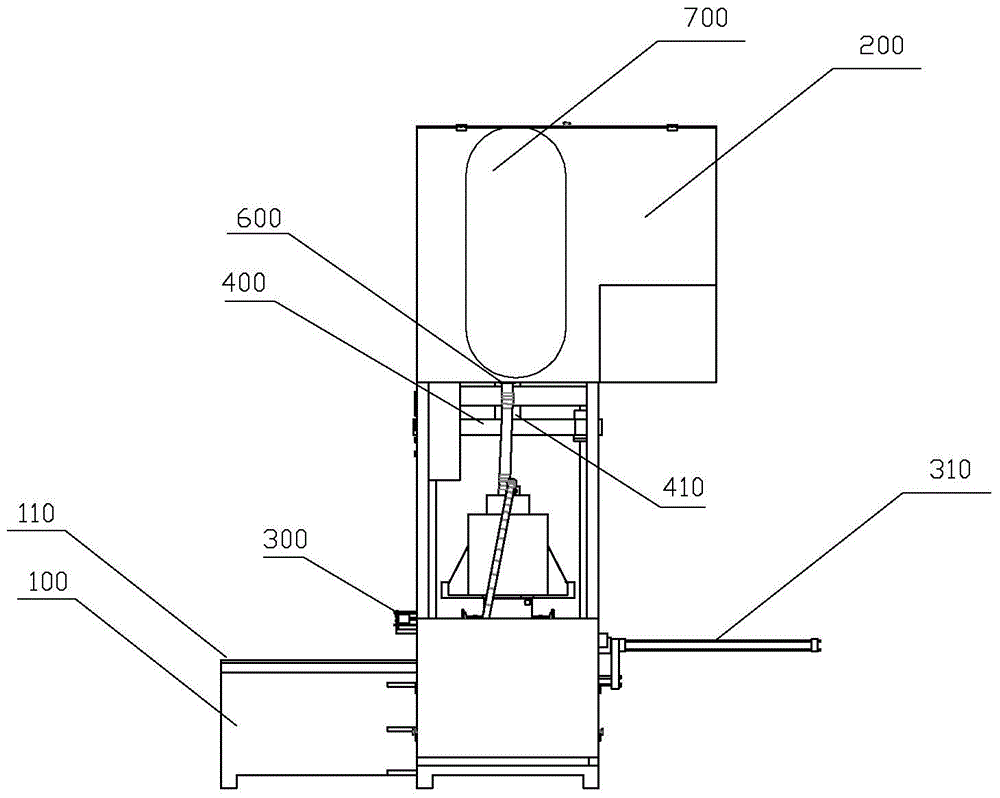

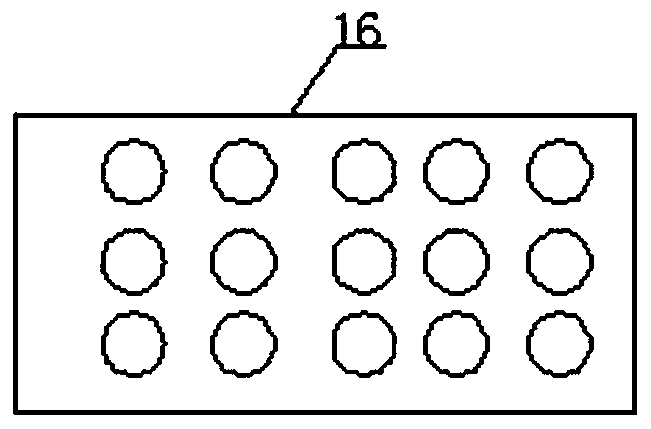

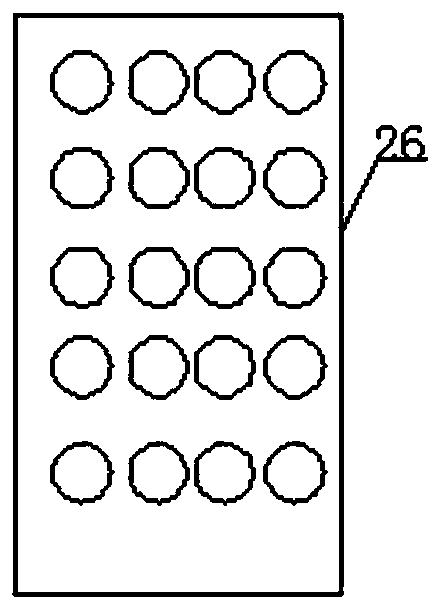

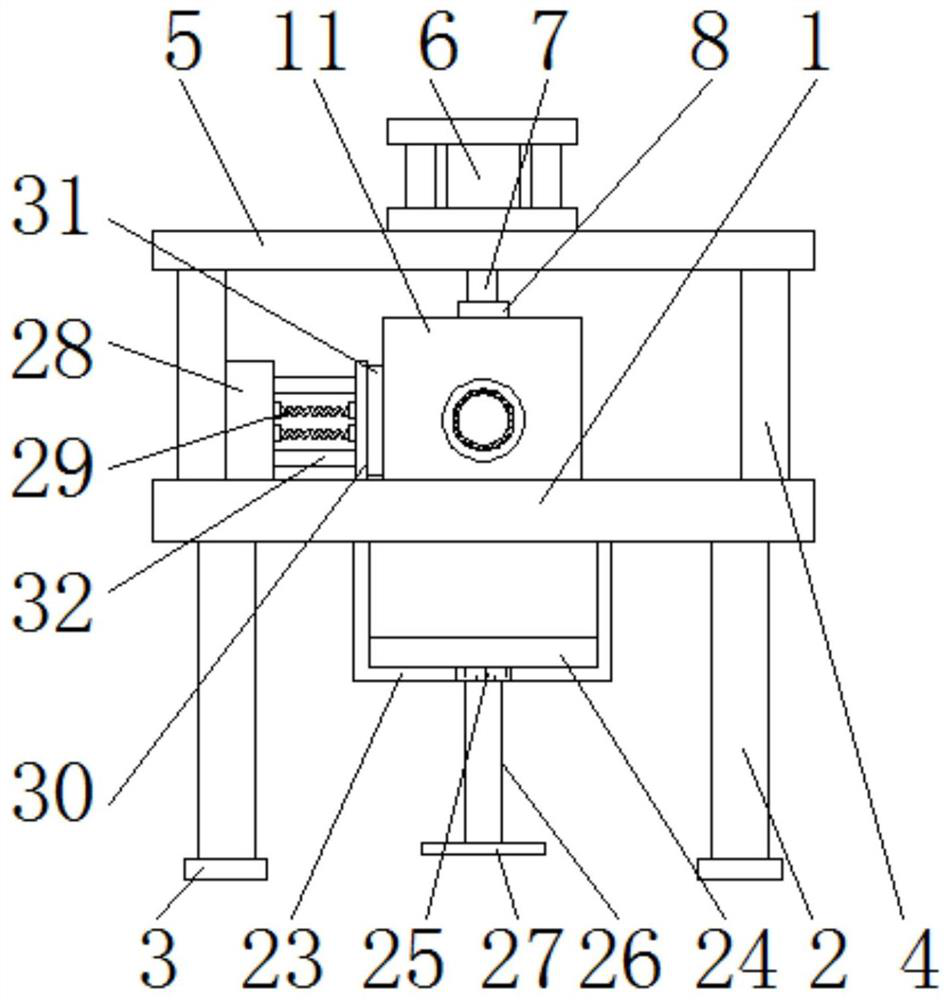

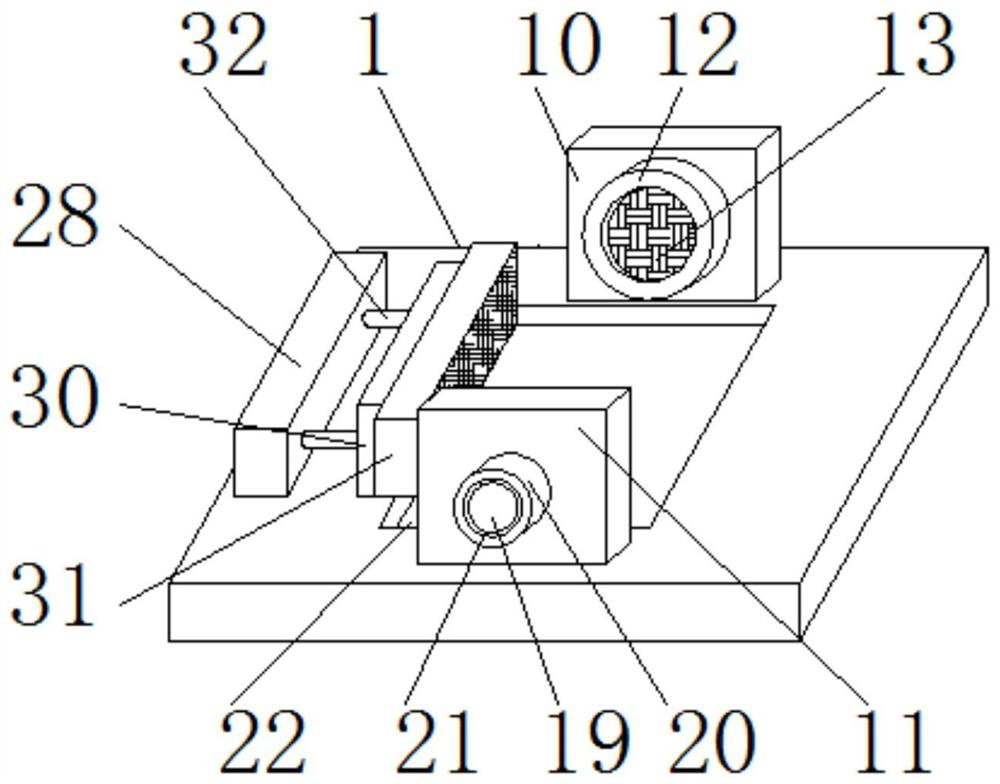

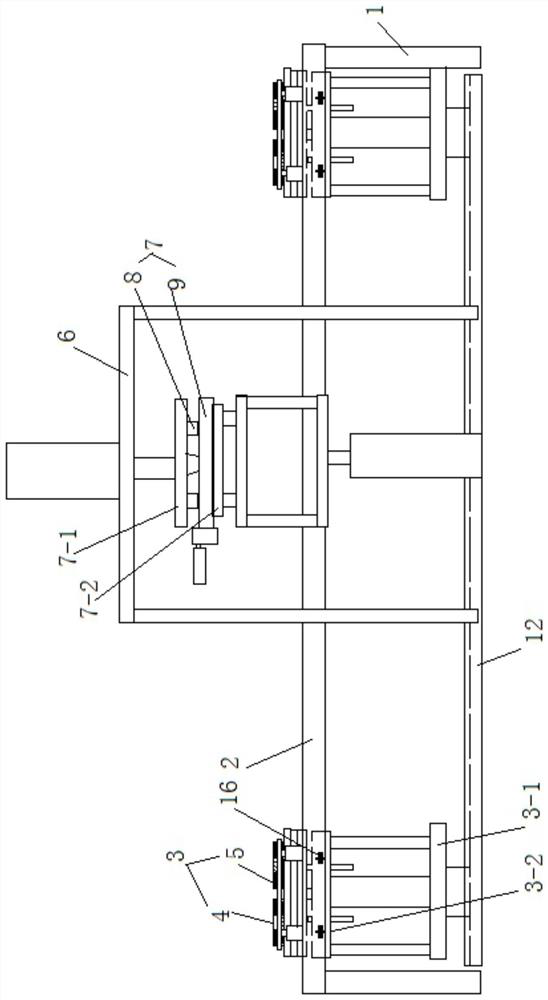

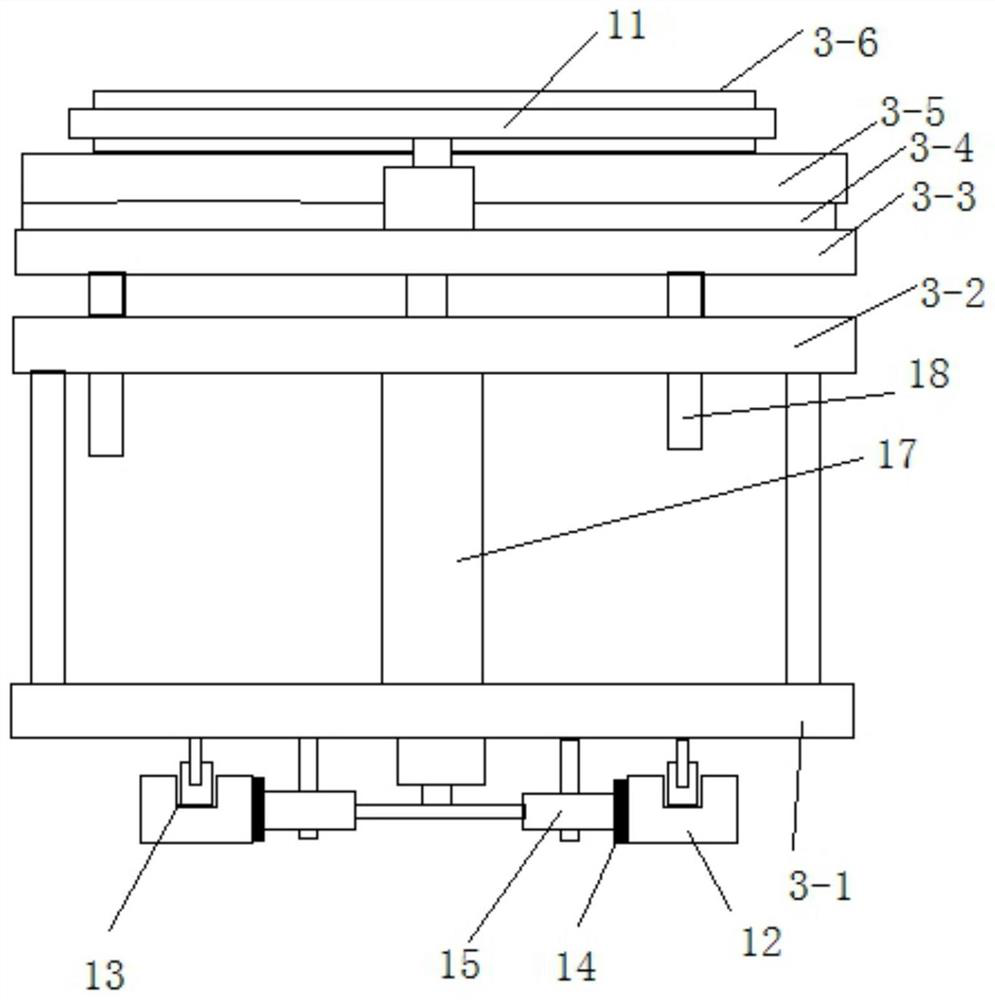

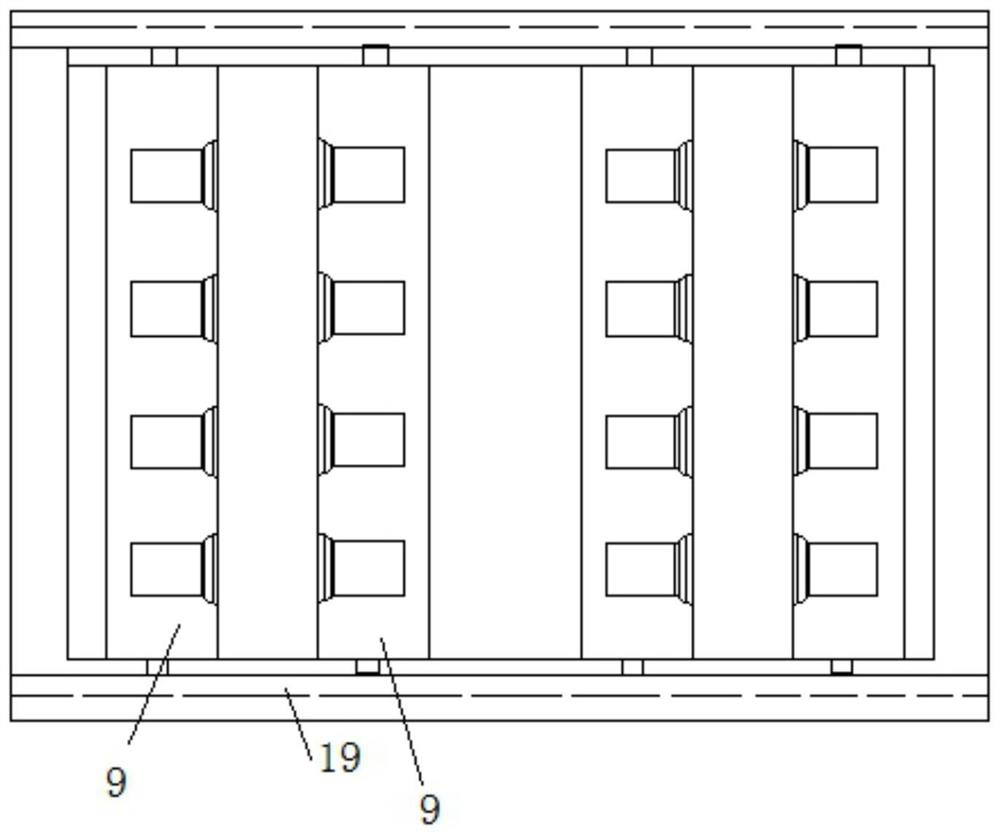

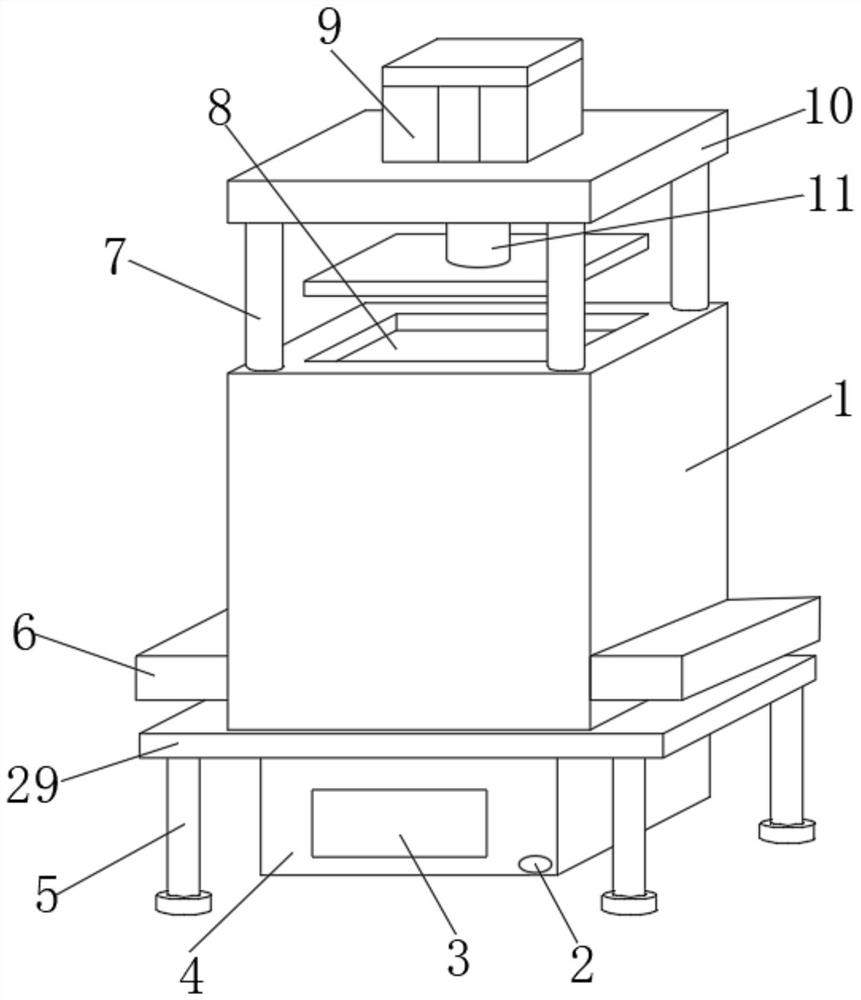

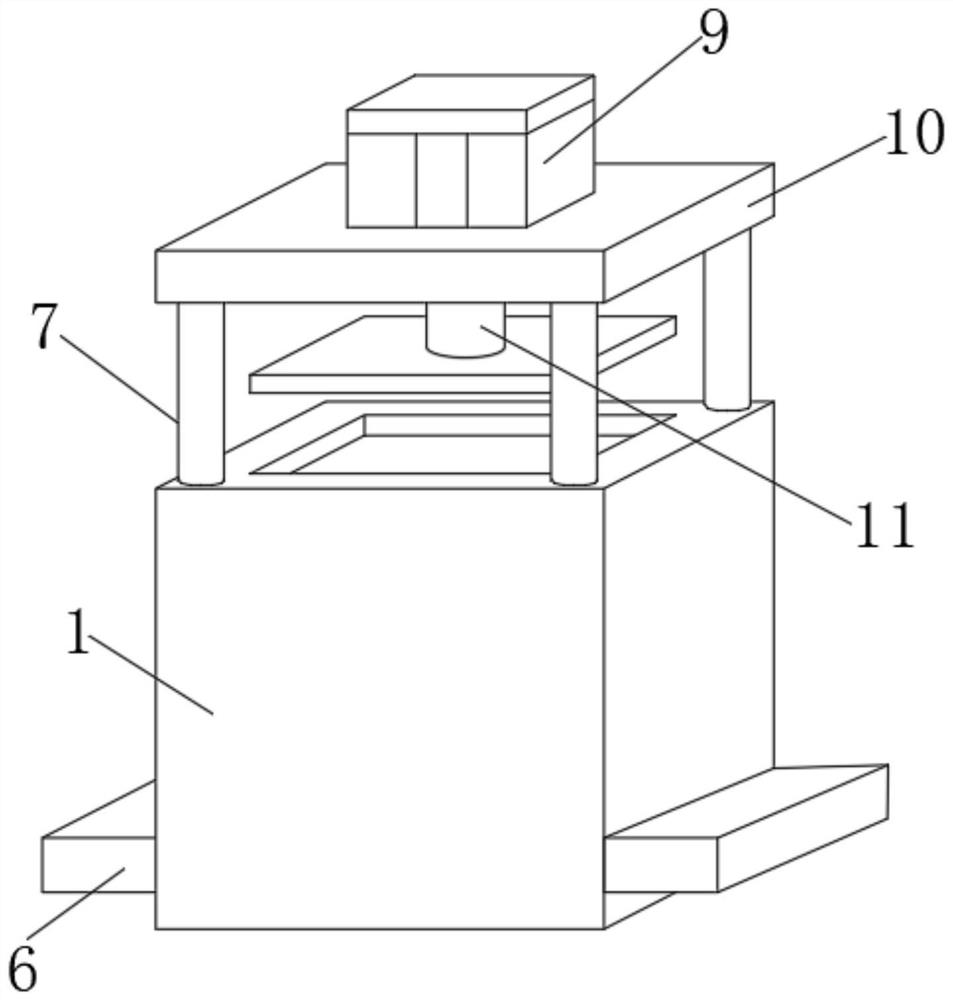

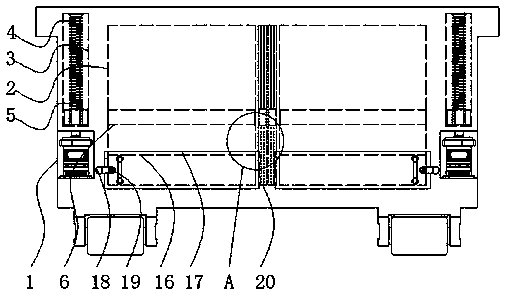

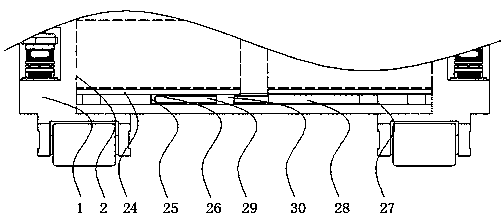

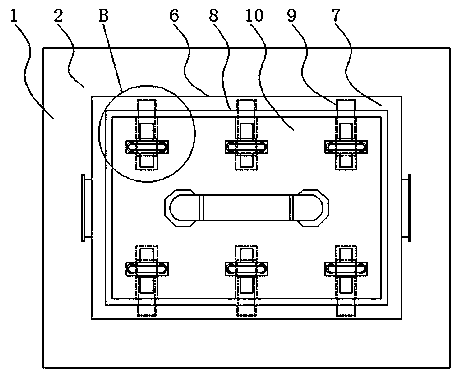

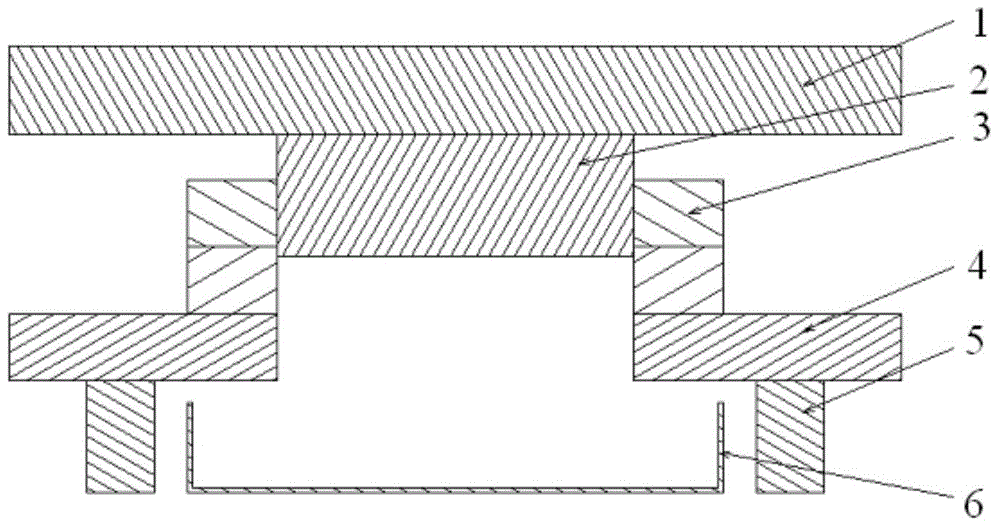

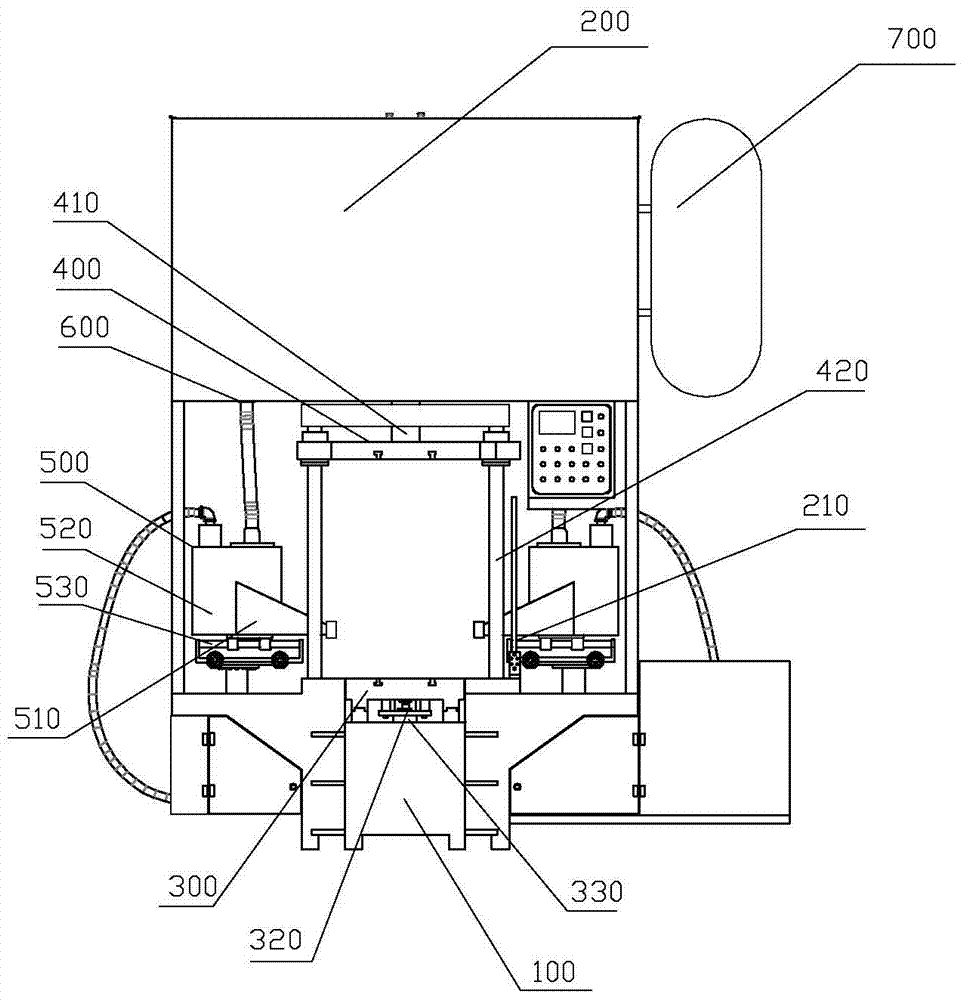

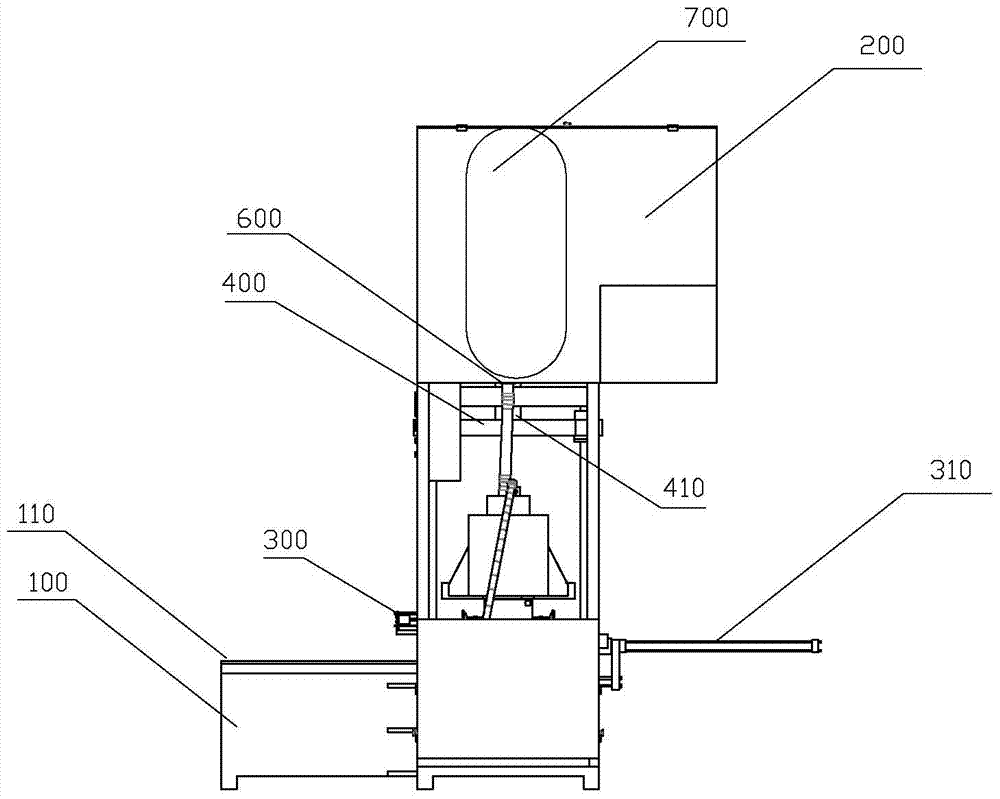

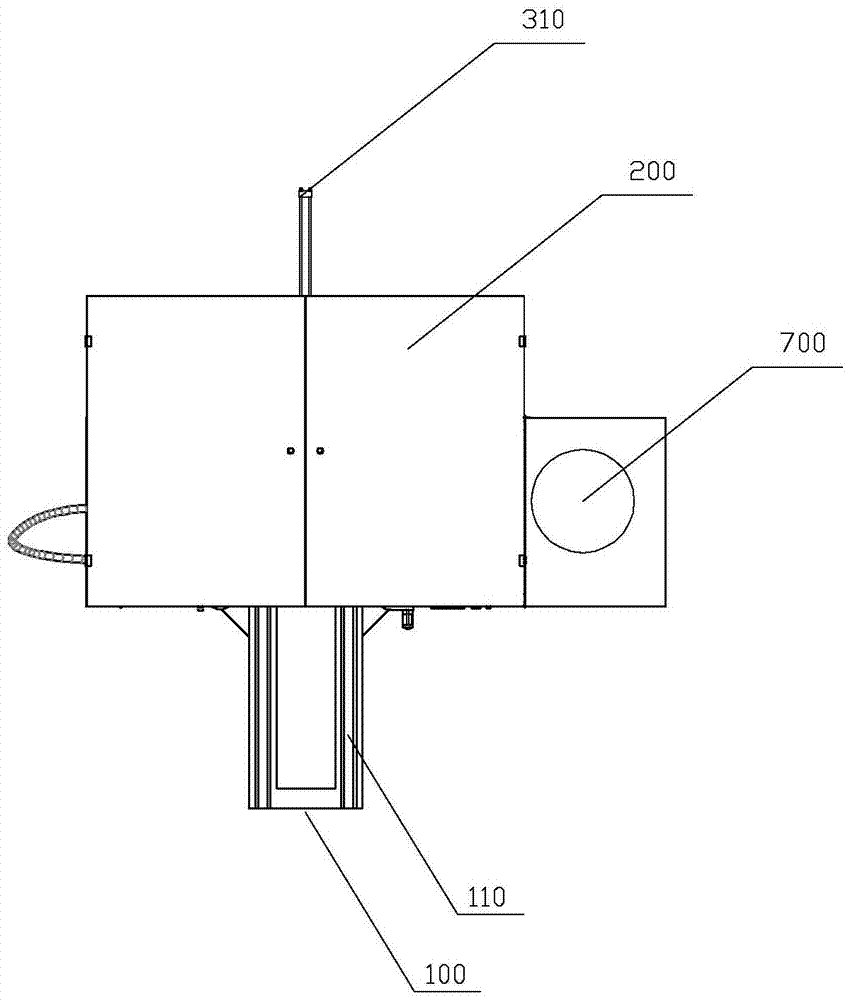

Horizontal parting type core shooter

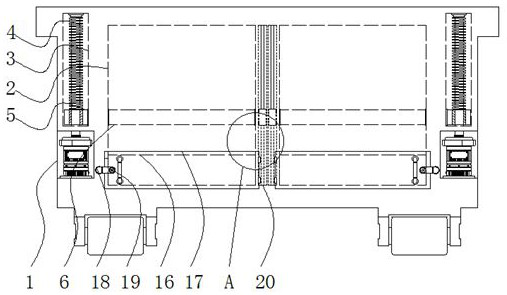

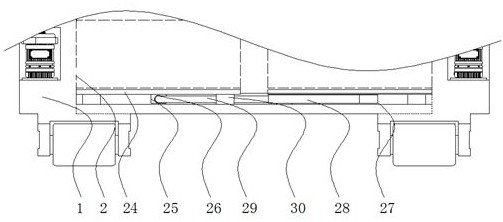

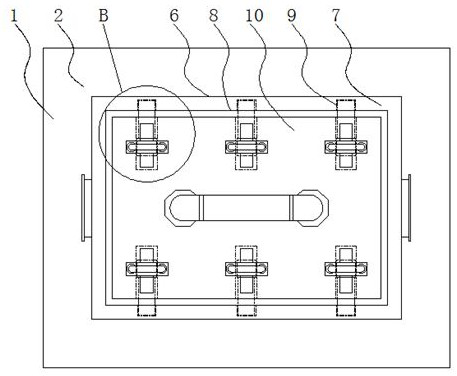

ActiveCN104588596ACompact structureThe operation of sand shooting is simple and convenientMoulding machinesStructural engineeringWorkbench

The invention relates to a horizontal parting type core shooter which is mainly used for solving the problems that an existing horizontal parting type core shooter is small in mould operation space and inconvenient to take out materials after sand mould processing. The horizontal parting type core shooter is characterized by comprising a rack, wherein a sand adding funnel is arranged on the rack; a sand shooting valve mechanism is arranged at a position, corresponding to the sand adding funnel, of the rack; the sand shooting valve mechanism comprises a shooting head and a sand barrel; a base is arranged in the middle part of the rack; a horizontal movable workbench is arranged above the base; matched linear guide rails are arranged between the workbench and the base; a lifting table is arranged above the workbench; a lifting base is arranged in the middle of the workbench; mounting slots for fixing the mould are formed in the upper surface of the workbench and the lower surface of the workbench. The horizontal parting type core shooter is compact in structure, and realizes sand shooting operation simply and conveniently; the workbench horizontally moves, so that the space for operating the mould and taking out material from the sand mould is increased, the material-taking operation is convenient, and the production efficiency and the safety are improved.

Owner:温州威众机械科技有限公司

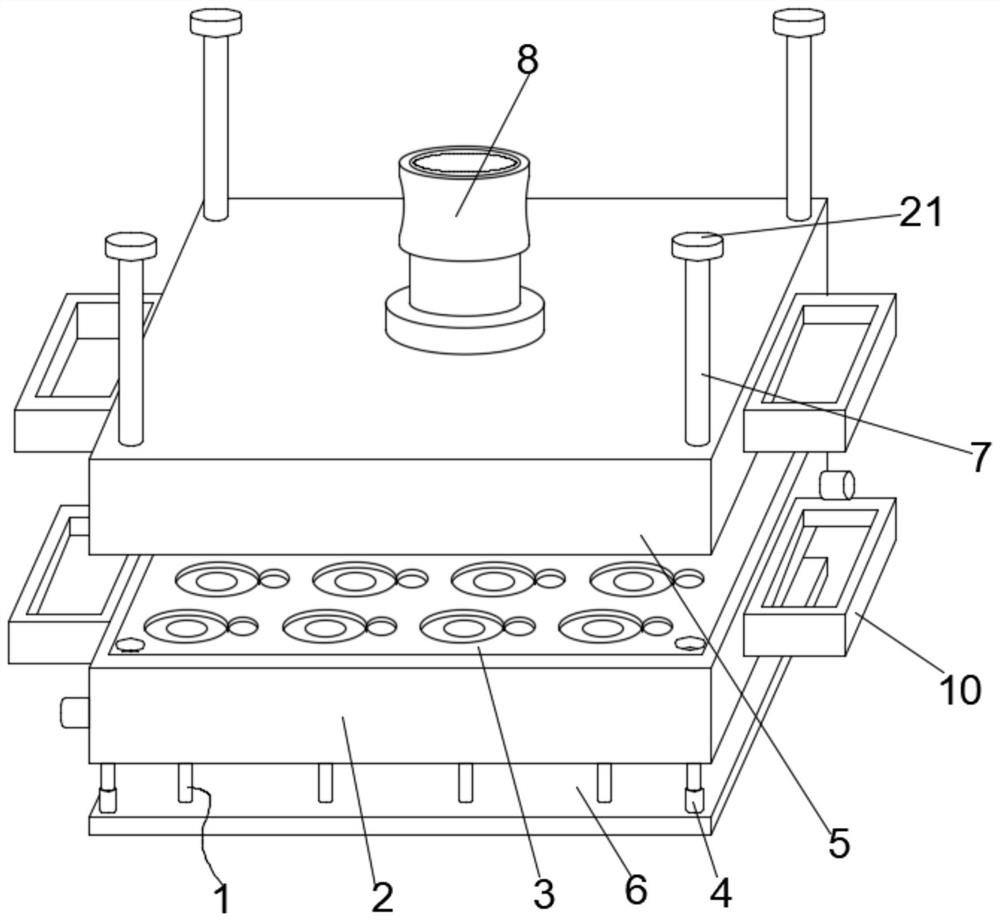

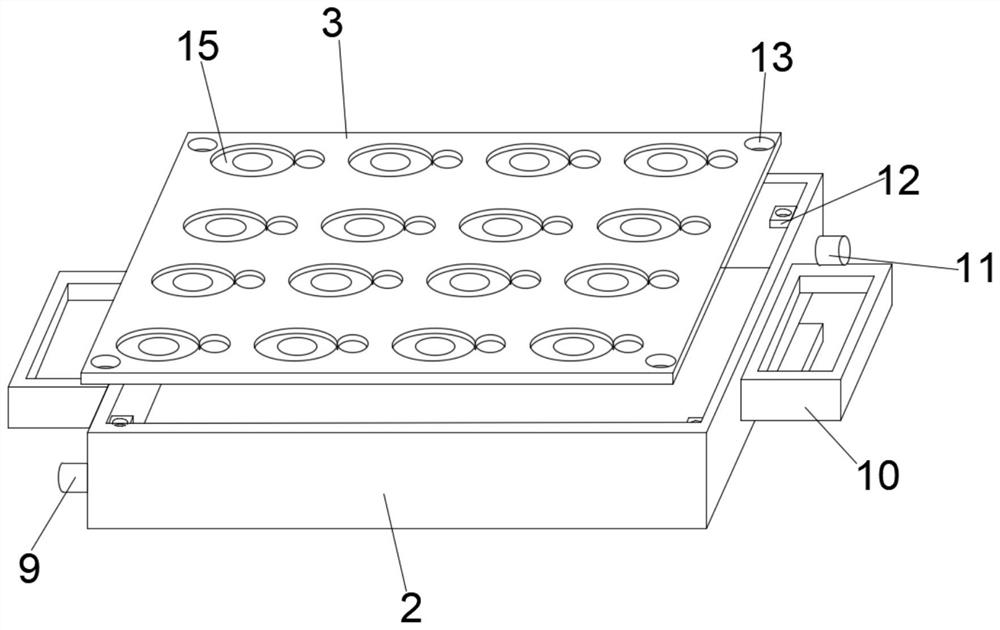

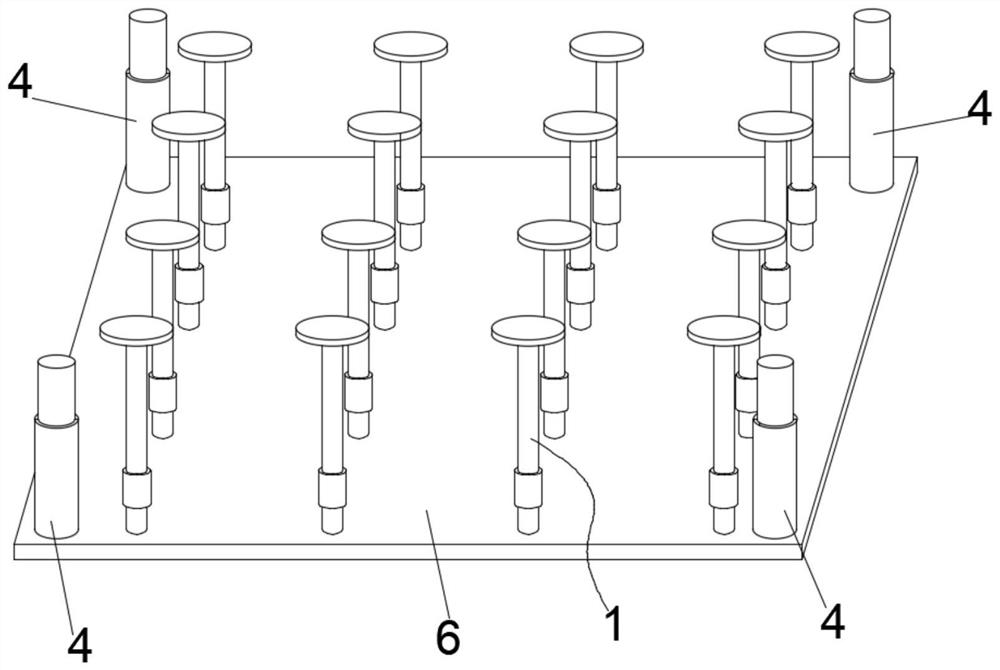

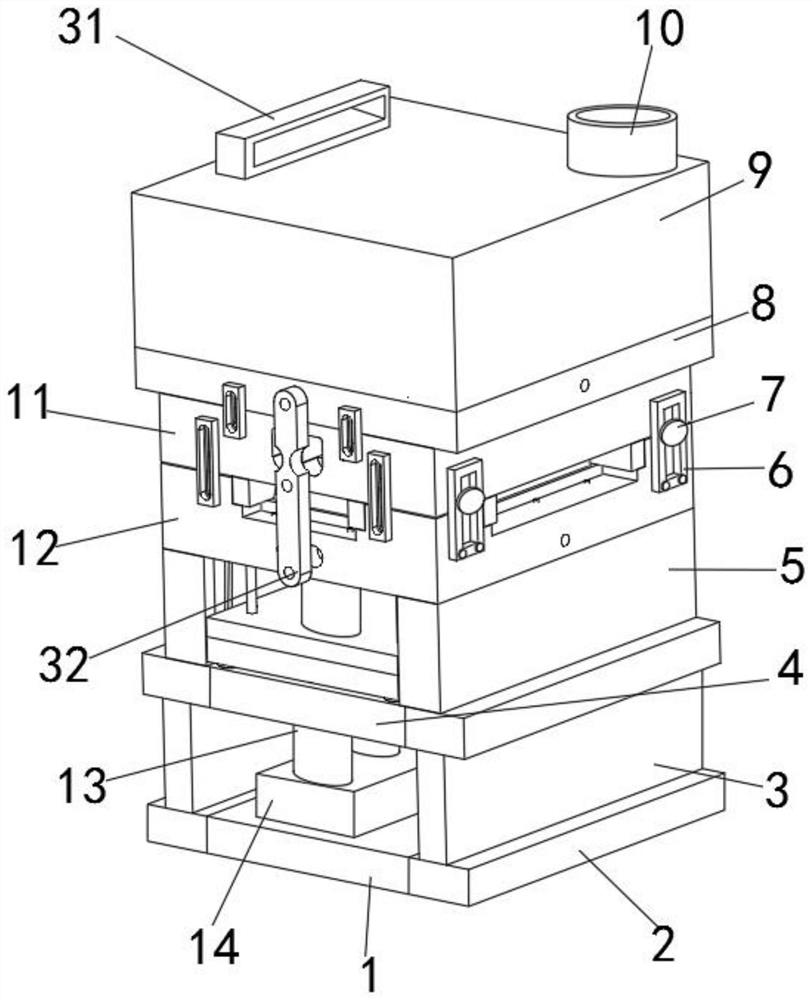

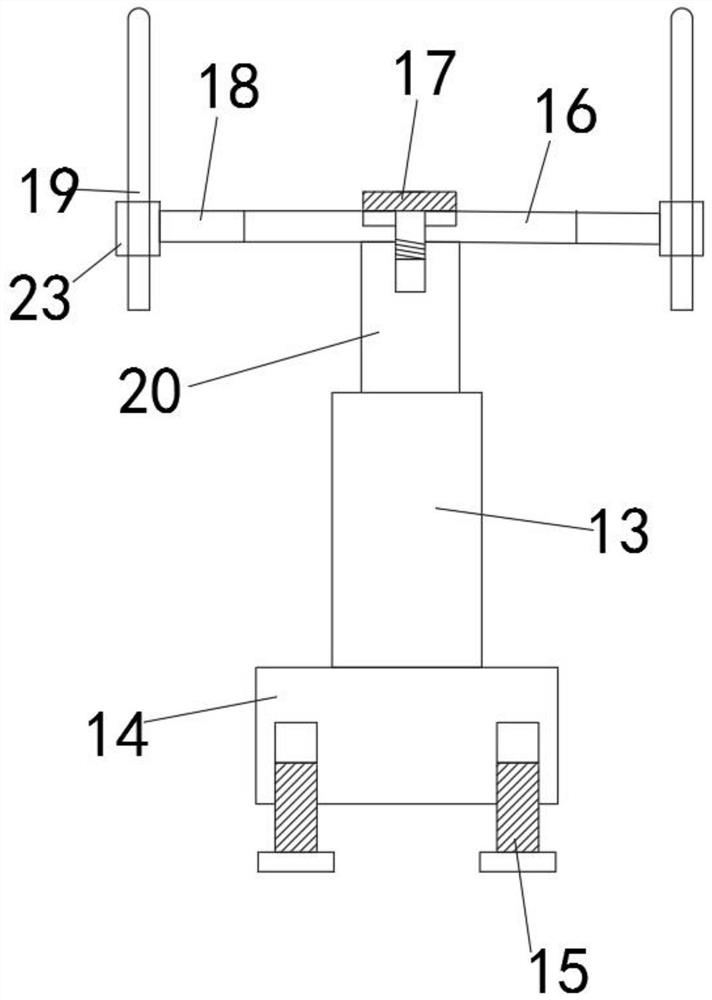

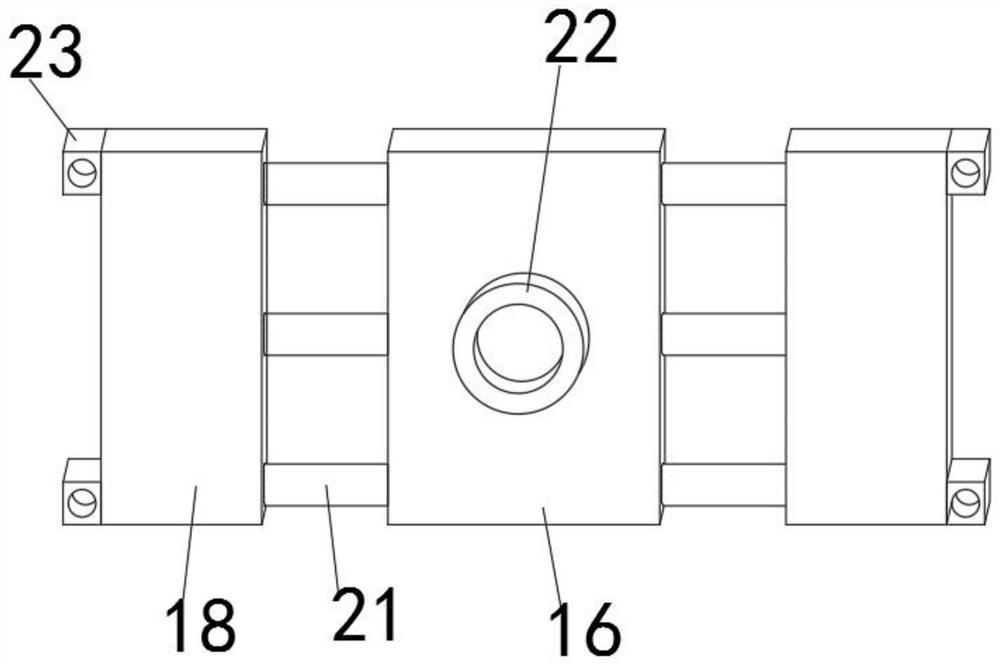

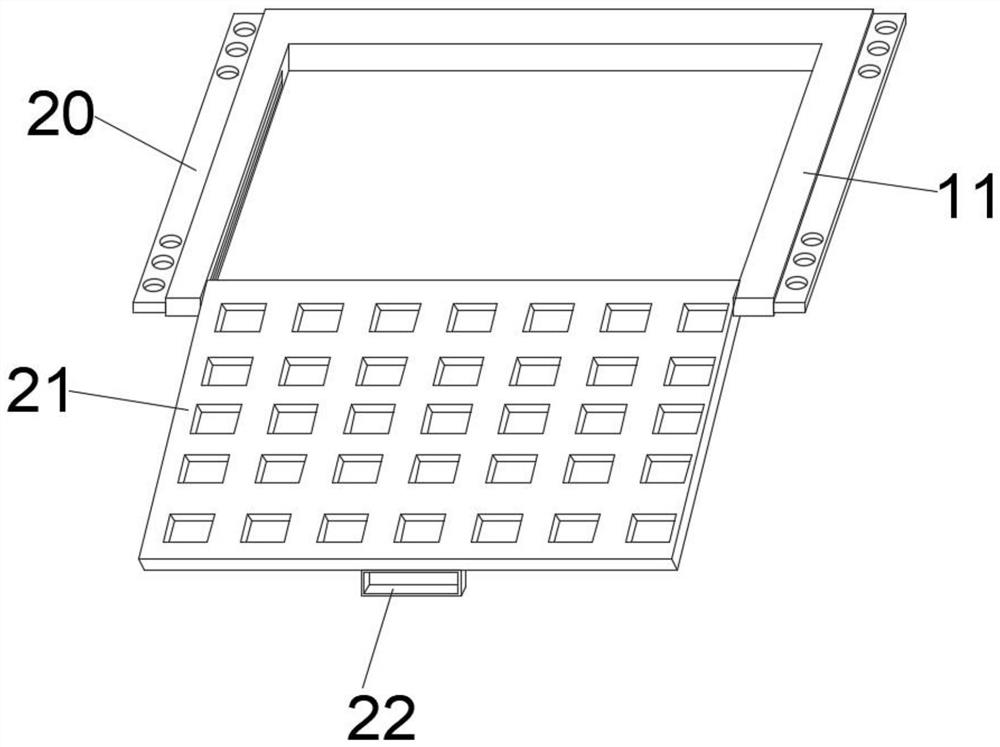

Mold structure for forming and processing bionic bait

PendingCN113997504AHigh forming precisionAuxiliary fixationStructural engineeringMechanical engineering

The invention discloses a mold structure for forming and processing bionic bait. The mold structure comprises a lower mold body and an upper mold body, the upper mold body is mounted on the outer surface of the upper end of the lower mold body in a spliced mode, four sets of positioning guide rods used for positioning are connected between the lower mold body and the upper mold body in a sleeved mode, and a supporting bottom plate is arranged at the bottom of the lower mold body; a plurality of sets of ejector rods used for ejecting materials are arranged between the lower mold body and the supporting bottom plate, and the lower mold body and the supporting bottom plate are elastically connected through four sets of spring ejector rods. By means of the arrangement of the supporting bottom plate, multiple sets of ejector rods can be installed at the same time, discharging operation of multiple sets of shaping grooves can be conveniently carried out, meanwhile, by means of the arrangement of spring ejector rods, elastic reset operation can be carried out between the lower mold body and the supporting bottom plate after the lower mold body is pressed downwards, the lower mold body can be conveniently and repeatedly used, by means of the ejector rods and the supporting bottom plate, the mold for bionic bait forming and processing can carry out lifting type material jacking operation, and material taking operation is more convenient and faster.

Owner:安徽宏飞钓具有限公司

Energy-saving and environmental-friendly aluminum alloy wheel forming process

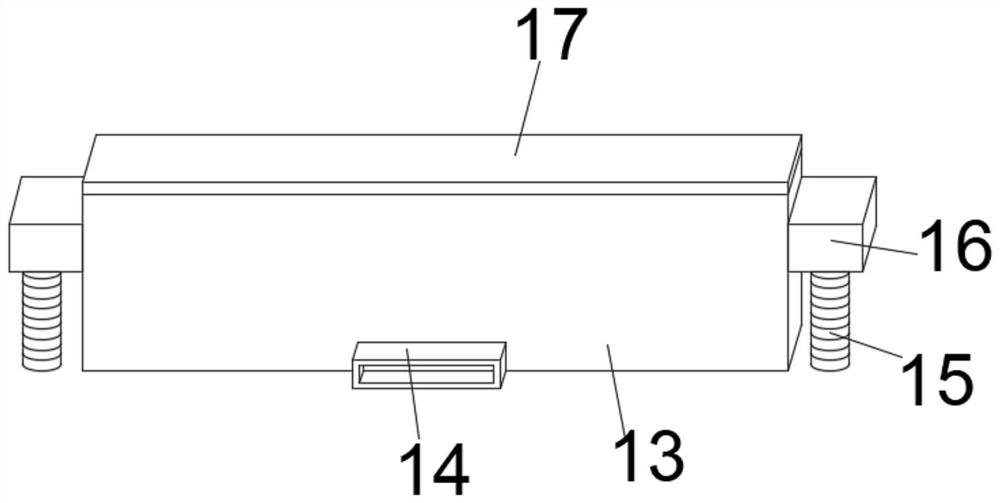

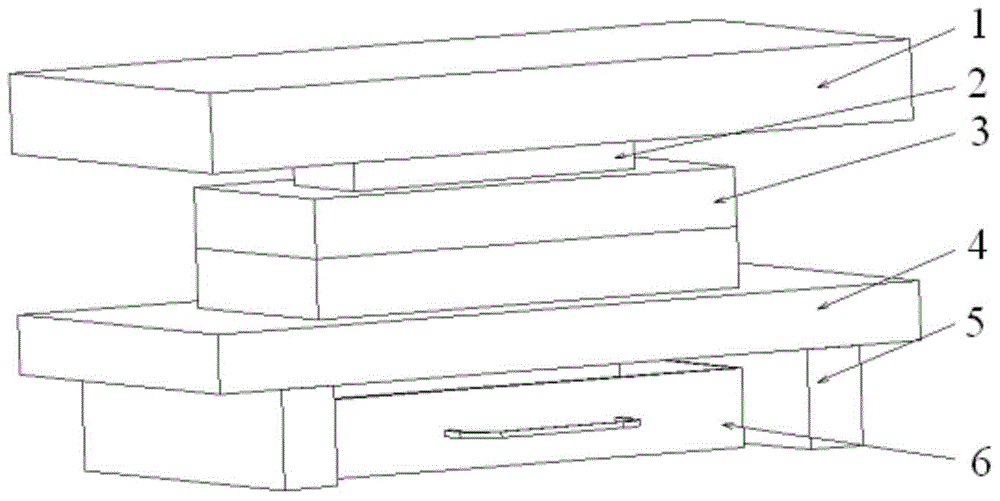

ActiveCN112139458AEasy to take out the materialImprove work efficiencyFoundry mouldsFoundry coresEngineeringAlloy wheel

The invention discloses an energy-saving and environmental-friendly aluminum alloy wheel forming process which comprises the following steps of: heating an aluminum alloy material to a liquid state; injecting the aluminum alloy material into a material holding box of a forming device by using a feeding pipe; extracting an inner sleeving plate from a first bottom plate and a second bottom plate bypulling a first pull plate and a second pull plate at two ends of the first bottom plate and the second bottom plate according to sizes of an upper die body and a lower die body; adjusting the using sizes of the first and second bottom plates as the extracted inner sleeving plate is matched with the first and second bottom plates, wherein the lower die body is fixed to a second side plate of the second bottom plate; meanwhile, clamping the upper die body to the lower die body, fixing the upper and lower die bodies by using fixing clamping strips; and meanwhile, inserting a fixing clamping capinto a lifting clamp and fixing the upper die body by the fixing clamping cap. According to the forming process, lifting type discharging operation can be conducted on the aluminum alloy wheel, so that the operation steps of a user are reduced, and meanwhile, fixed adjusting operation can be conducted in the forming process, so that the application range of the forming process is widened, and theworking efficiency is improved.

Owner:常州市恒成新材料有限公司

Air pollution treatment device for agricultural land

InactiveCN110918589ARealize up and down movementEasy to take out the materialDirt cleaningRural landAgricultural land

The invention aims to solve the problem that air treatment on rural land is difficult to perform at present, and discloses an air pollution treatment device for agricultural land. The air pollution treatment device comprises a push rod, a rotating disk, a first motor, a mounting rod, water injection holes, water tanks, water guiding pipes, a connecting plate, second motors, end covers, material passing pipes, discharging pipes, spiral blades, first rotating shafts, positioning plates, discharging plates, positioning rods, sliding pipes, spiral springs, guiding frames, a mounting box, supporting legs, universal wheels, bulge blocks, a handle, material passing plates and a second rotating shaft. By the aid of the air pollution treatment device, loosened soil form soil blocks reasonably, thesoil blocks are spread on the surface of the land, then dust on the land is covered, and flying dust is reduced; and the air pollution treatment device is reasonable in design, convenient to operate,safe and reliable.

Owner:张燕

Deburring equipment for aluminum alloy castings

The invention discloses deburring equipment for aluminum alloy castings, and belongs to the technical field of deburring. The deburring equipment includes a platform body, supporting rods are vertically welded to peripheral edge positions of the upper surface of the platform body, a same set of load-bearing plates are fixedly installed among the upper end positions of the four groups of the supporting rods, a motor is fixedly installed at the middle position of the upper surface of each load-bearing plate, rotating shafts are vertically and movably connected to the bottom middle positions of the motors, the lower ends of the rotating shafts are fixedly sleeved with mounting sleeves, and a first base plate and a second base plate are vertically welded to the middle position of the upper surface of the platform body. A clamping structure of the deburring equipment can be subjected to front-back position adjustment to apply backward squeezing force to the aluminum alloy castings, the stability of the clamping installation of objects is improved, adjusting can be flexibly carried out according to the size of the objects, the feeding and discharging operations of the aluminum alloy castings are facilitated, the operations are far away from a polishing area, the safety is high, and meanwhile, a cleaning structure is arranged to clean a polishing surface, so that the cleanliness of finished products is improved.

Owner:马鞍山思哲知识产权服务有限公司

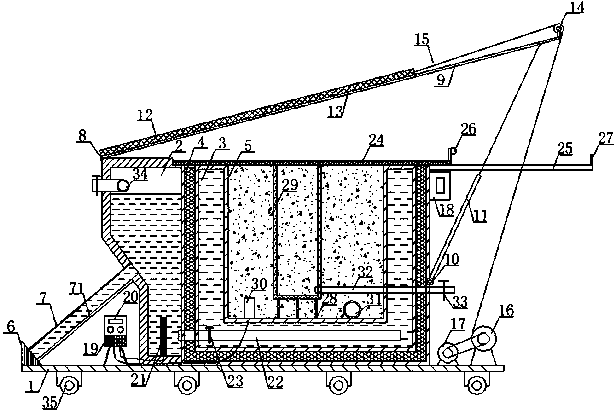

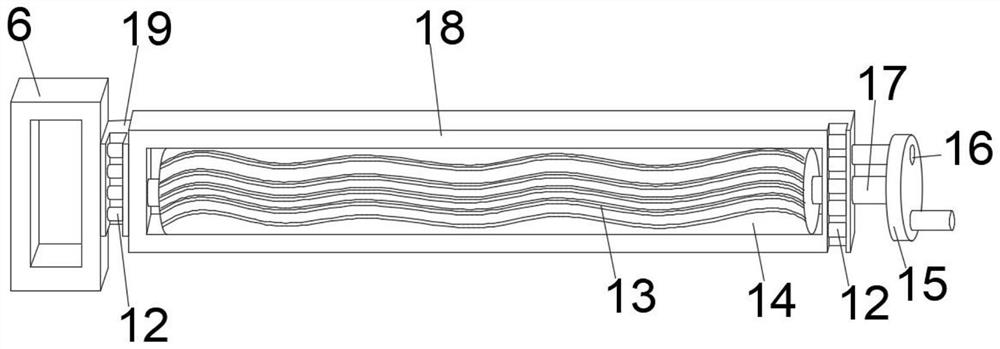

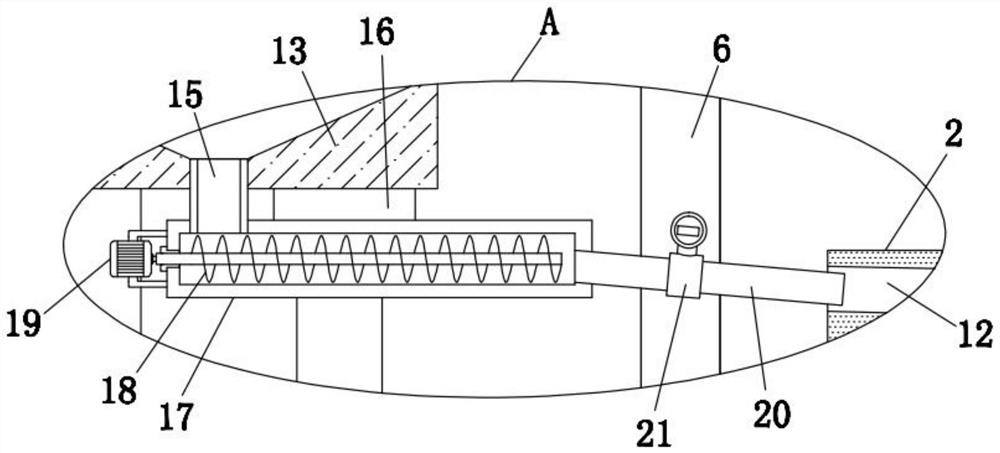

Full-automatic multifunctional solar photovoltaic brewing machine

PendingCN108130257ACompact structureSafe and stable over temperatureBioreactor/fermenter combinationsBiological substance pretreatmentsThermal insulationHeater Rod

The invention relates to a full-automatic multifunctional solar photovoltaic brewing machine. A high temperature water tank and a constant temperature water tank are arranged on the upper surface of achassis; a thermal insulation layer is arranged between wallboards of the high temperature water tank and the constant temperature water tank; a fermentation tank is arranged in the constant temperature water tank; a solar evacuated tube is erected between an inclined plane of a delta gasket and the side wall of the high temperature water tank; a photovoltaic module bypasses a steering pulley anda winding machine on the upper surface of the chassis by virtue of a pulling rope; the photovoltaic module passes an inverter by virtue of a wire and then is connected with a storage battery; a heating rod is also arranged at the bottom of the high temperature water tank; a cover plate sliding rail is fixed in the lateral direction of the upper edge of the right side wall of the thermal insulation layer; a permeation filter screen is erected on an inner base plate of the fermentation tank by virtue of a supporting frame; and a discharging pipe is arranged on the inner wall of the lower part of the permeation filter screen. The invention can provide a full-automatic multifunctional solar photovoltaic brewing machine which is compact in structure, greatly shortened in fermentation period, high in production efficiency, clean and sanitary and fully utilizes clean energy.

Owner:江苏辉强新能源科技有限公司

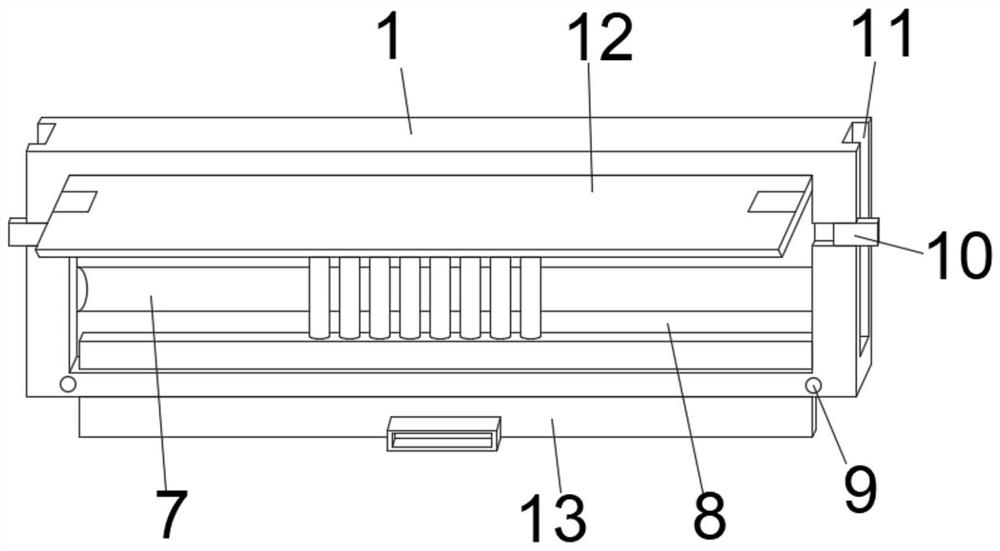

Stamping type shaping equipment for fishhook processing

InactiveCN114515807APlay the role of splicing and fixingEasy to take out the materialWire articlesStructural engineeringMechanical engineering

The stamping type shaping equipment for fishhook processing comprises a fixed base and a fixed frame, the fixed frame is fixedly installed on the outer surface of the upper end of the fixed base, a stamping block is movably installed on the inner side of the fixed frame, and the inner side of the fixed base is movably sleeved with a movable supporting plate used for containing fishhook materials. A telescopic top plate used for fixing one end of a fishhook material is movably installed on the inner side of the movable supporting plate, and a rotary clamping plate used for fixing the other end of the fishhook material is movably installed on the upper portion of the movable supporting plate. According to the stamping type shaping equipment for fishhook processing, bent fishhook materials can be moved out by pulling the movable supporting plate, a user can take the fishhook materials conveniently, by means of the arrangement of the movable supporting plate and the stamping block, the stamping type shaping equipment for fishhook processing can complete bending and shaping operation on the whole row of fishhook materials at a time, and therefore the working efficiency of the stamping type shaping equipment is effectively improved.

Owner:JIESHOU XINGLONG FISHING TACKLE

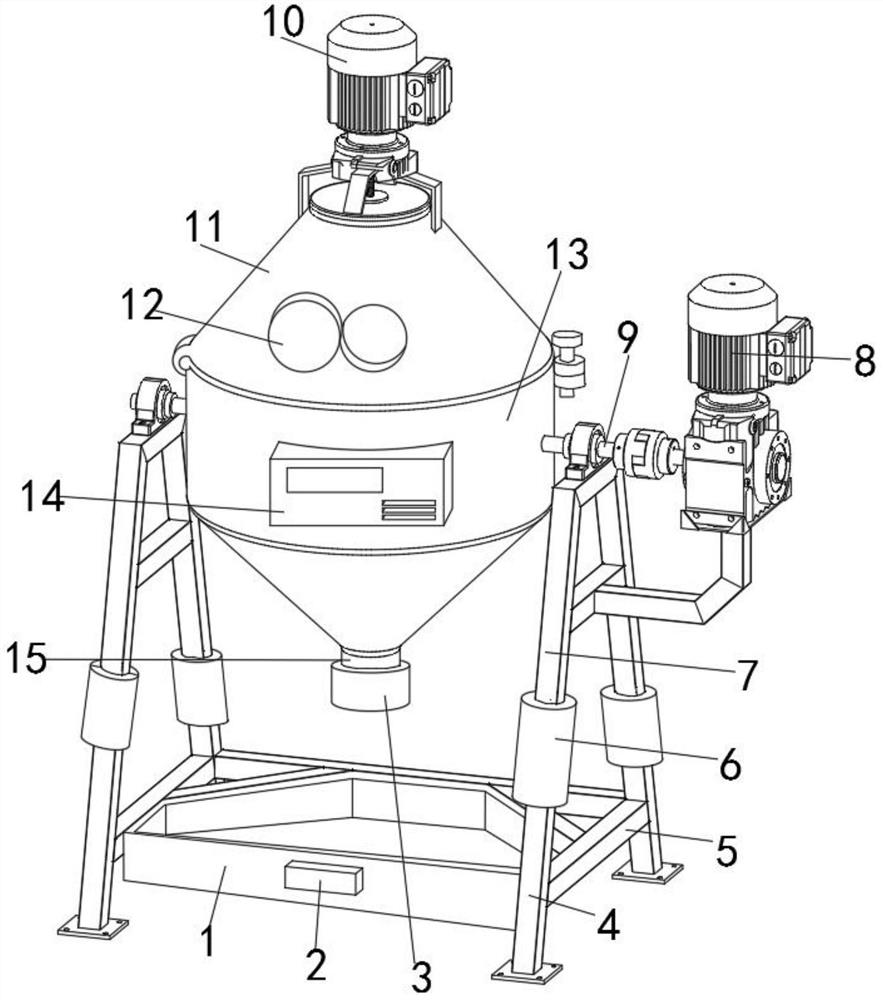

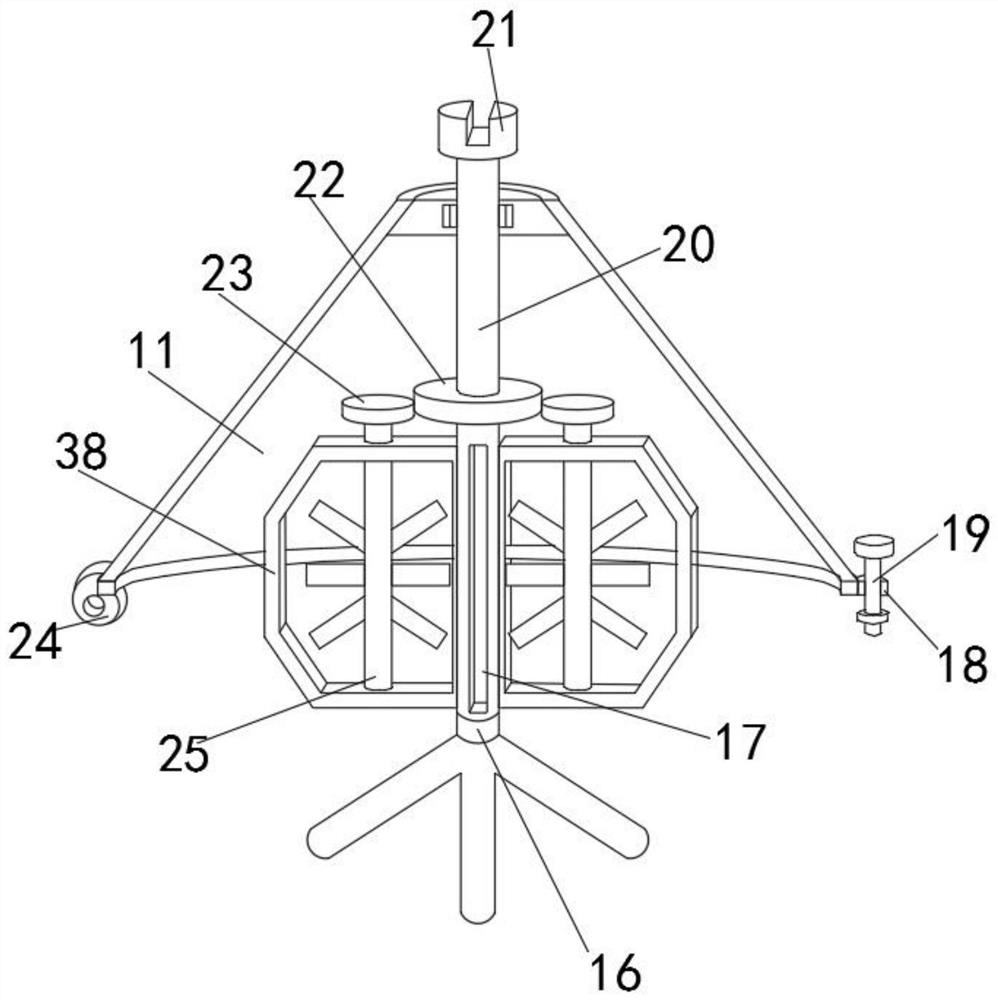

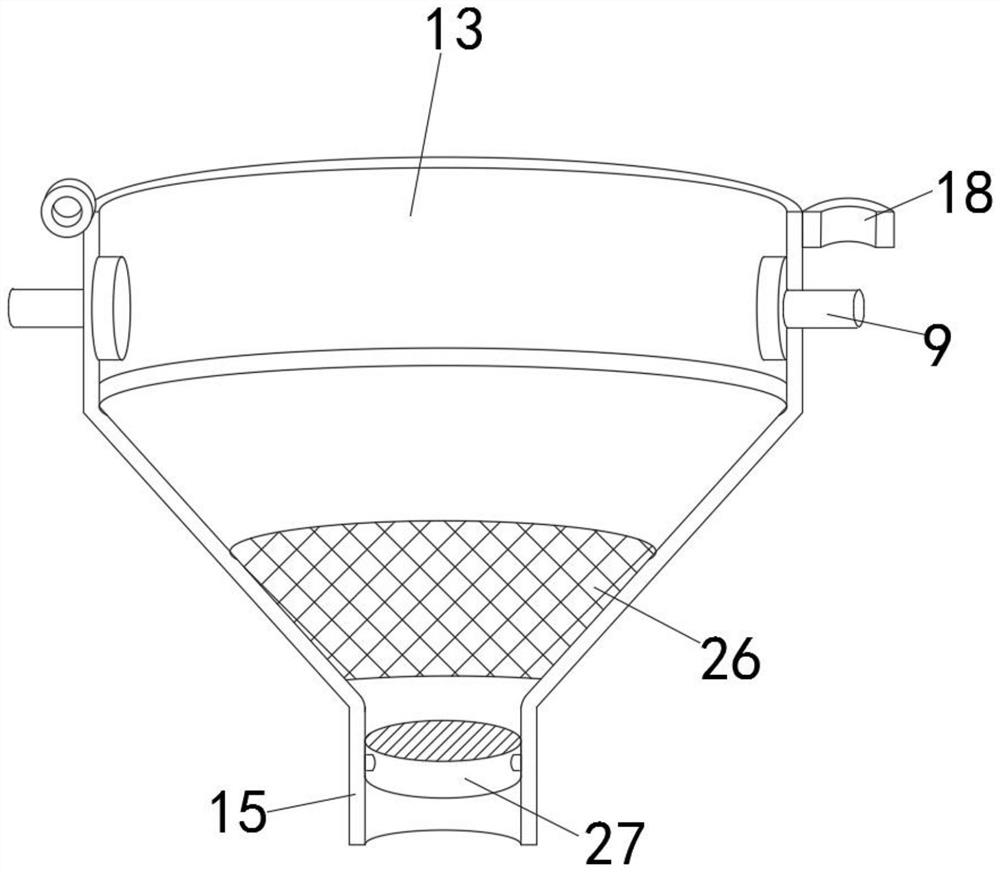

Saponification treatment device for lubricating grease production

InactiveCN112387243AEasy to take out the materialEasy to operateChemical/physical/physico-chemical moving reactorsEngineeringMechanical engineering

A disclosed saponification treatment device for lubricating grease production comprises a mixing barrel, a side-rotating top cover and a second rotating rod, the side-rotating top cover is movably installed on the outer surface of the upper end of the mixing barrel, the second rotating rod is movably installed in the middle of the inner side of the side-rotating top cover, and a stirring rod is fixedly installed on the outer surface of the lower end of the second rotating rod; a butt joint clamping rod is arranged in the middle of the upper end of the stirring rod, the stirring rod and the second rotating rod are fixed in a butt joint mode through the butt joint clamping rod, three sets of splicing foot rods are fixedly installed on the outer surface of the lower portion of the stirring rod, a threaded clamping groove is formed in the inner side of the lower portion of the stirring rod, and a threaded rod head is fixedly mounted on the outer surface of one end of each splicing foot rod. According to the saponification treatment device for lubricating grease production, the saponification treatment device is provided with an auxiliary discharging structure, use and operation of thesaponification treatment device are more convenient, meanwhile, the saponification treatment device is provided with a triple mixing structure, and the working efficiency of the saponification treatment device is improved.

Owner:安徽中天石化股份有限公司

Glue robot

ActiveCN110962144BImprove stabilityConvenient glue workLiquid surface applicatorsCoatingsSpinningGelatin

The invention provides a gluing robot, which includes a movable chassis, a gluing mobile device, a gluing device and a silo; Cylinder supply area; the gluing device and the gluing moving device are both arranged in the gluing implementation area, and the gluing moving device is connected to the movable chassis, and the gluing device is arranged in the gluing implementation area. The glue moving device is used to automatically clamp the rubber cartridge for glue application or loosen the glue cartridge for replacement of the glue cartridge; the silo is located in the glue cartridge supply area. By setting the movable chassis, gluing device, gluing mobile device and silo, and setting the silo at the rear end of the movable chassis, the gluing device and the gluing mobile device at the front end of the movable chassis, it can be used reasonably The space above the chassis facilitates the completion of a larger range of gluing work, and makes the weights of the gluing implementation area and the rubber cartridge supply area match each other, improving the stability of the gluing robot.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

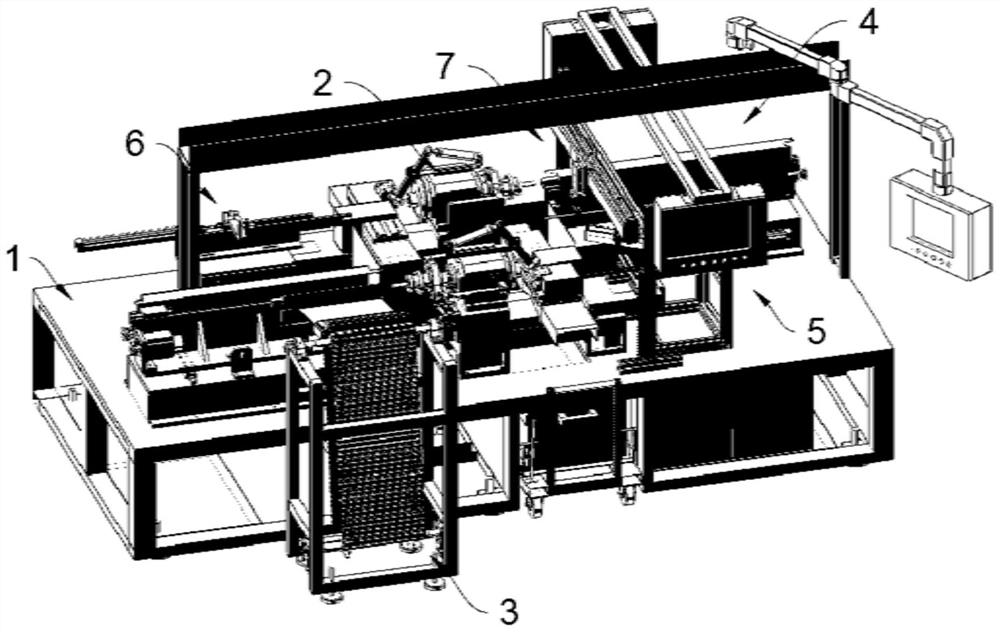

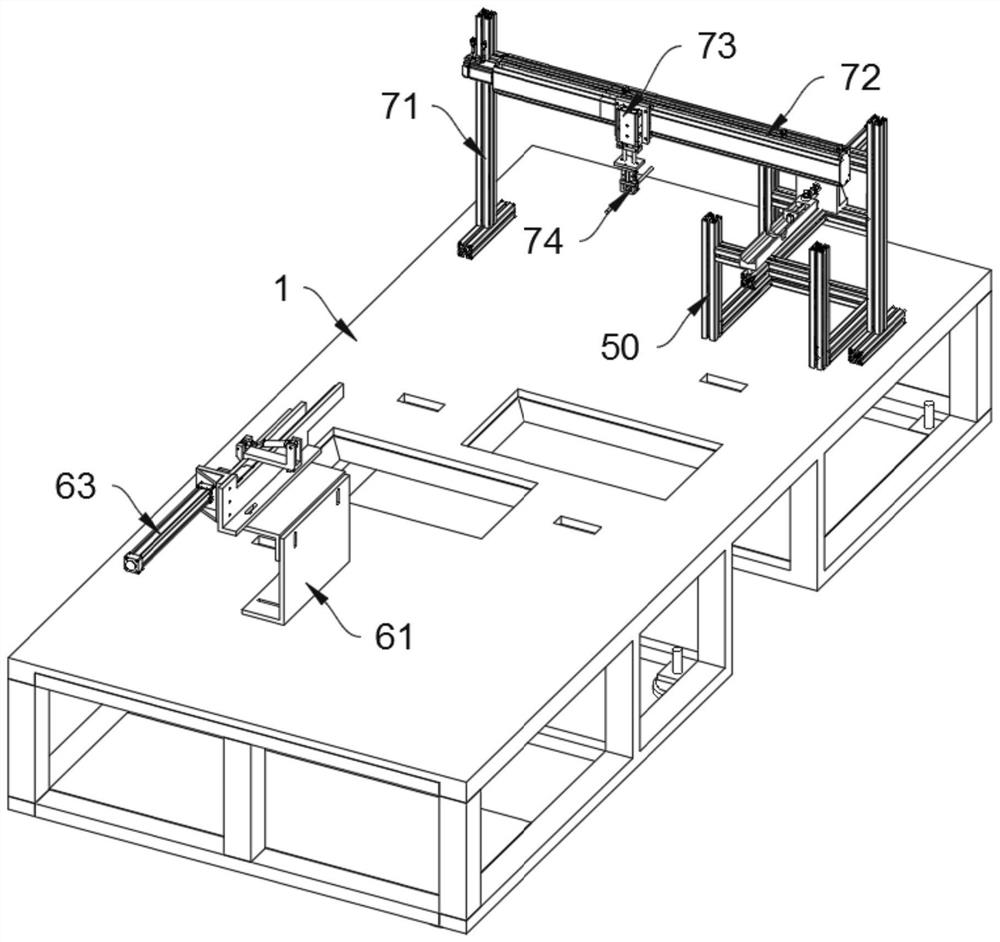

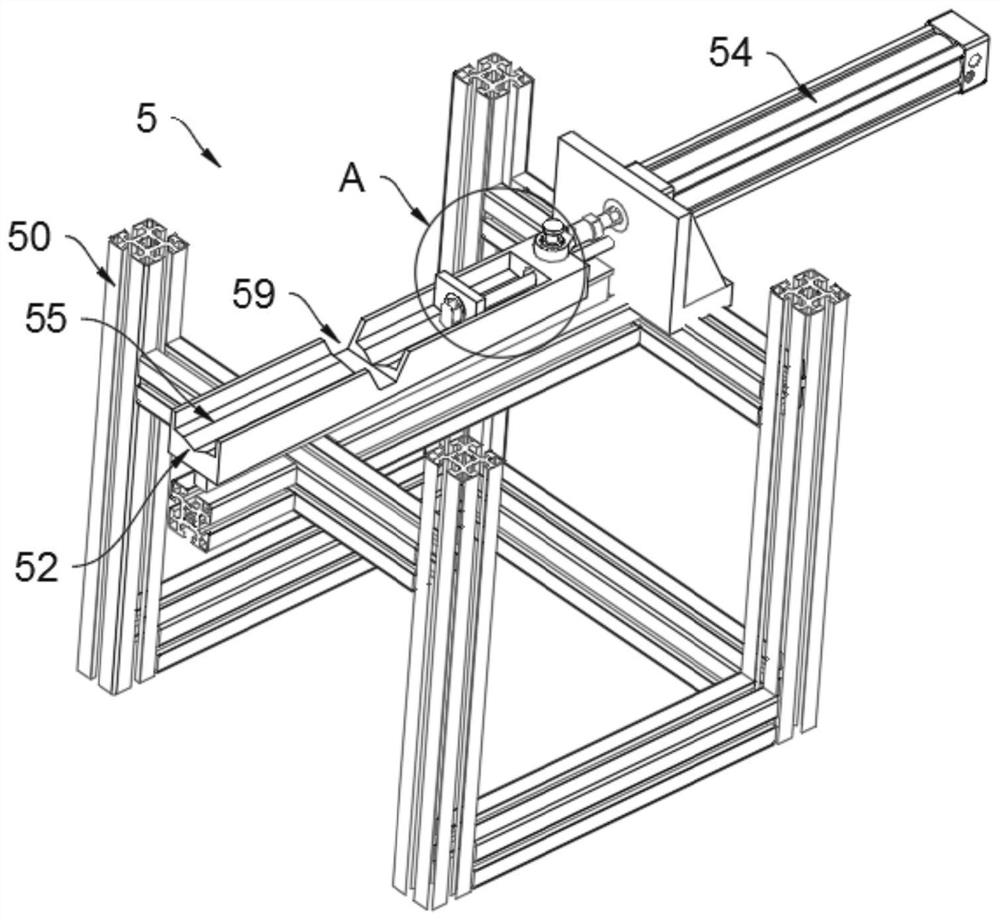

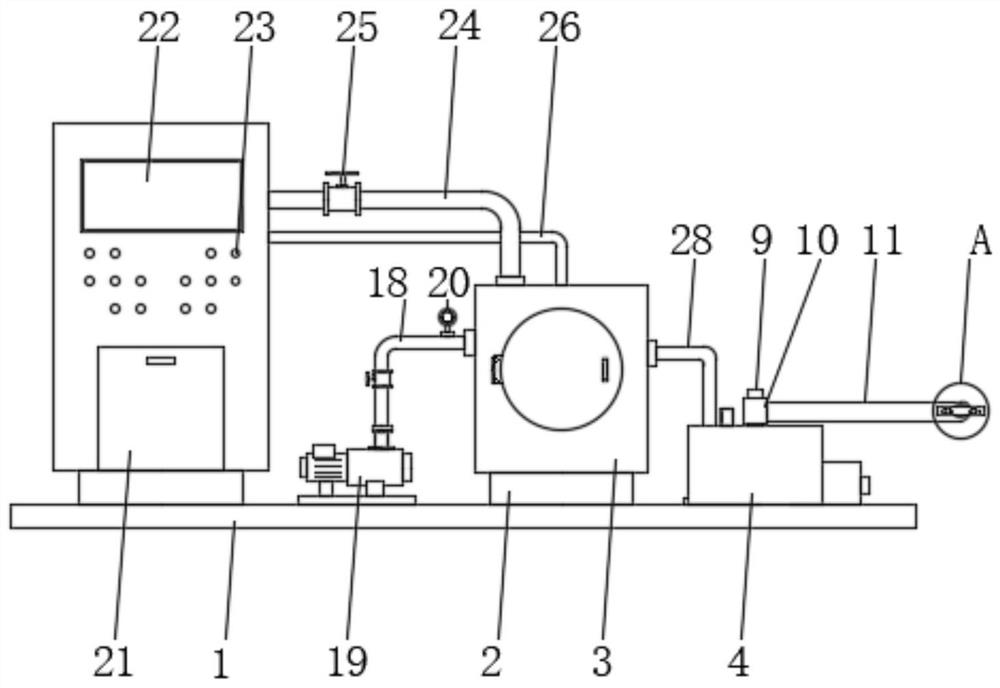

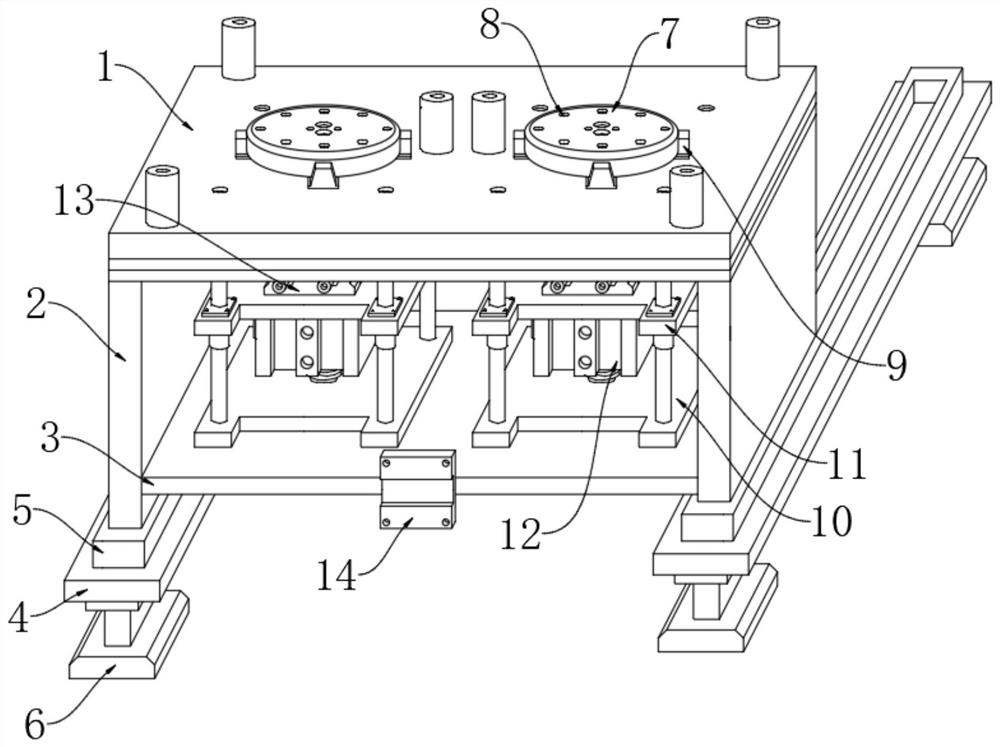

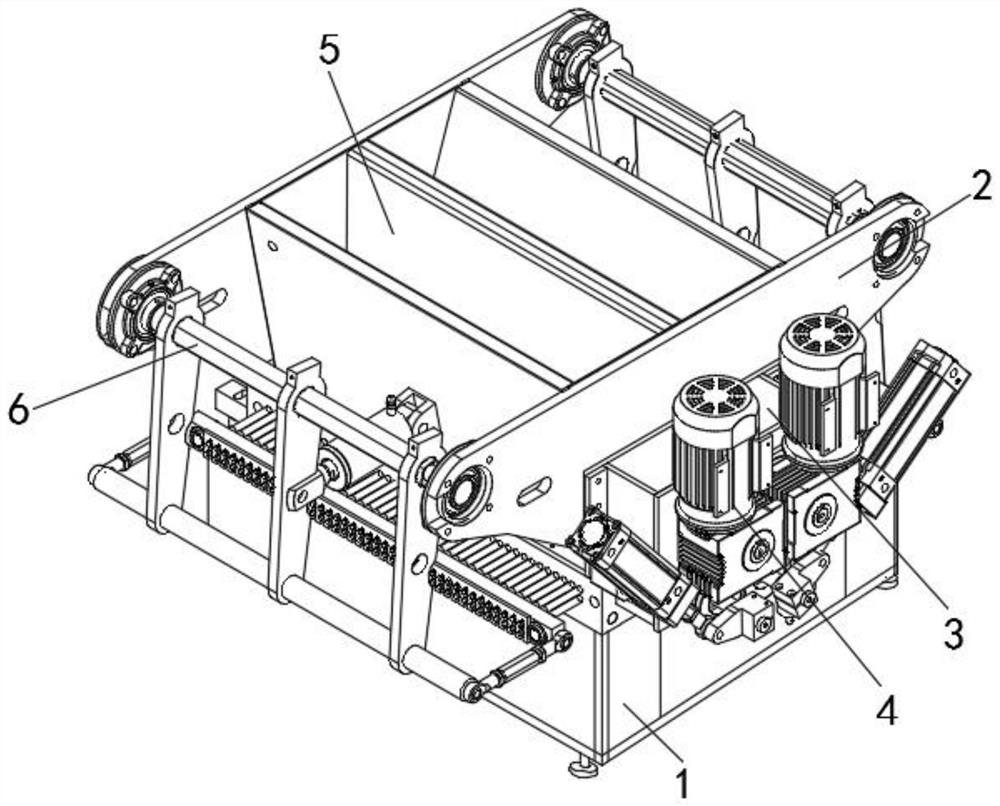

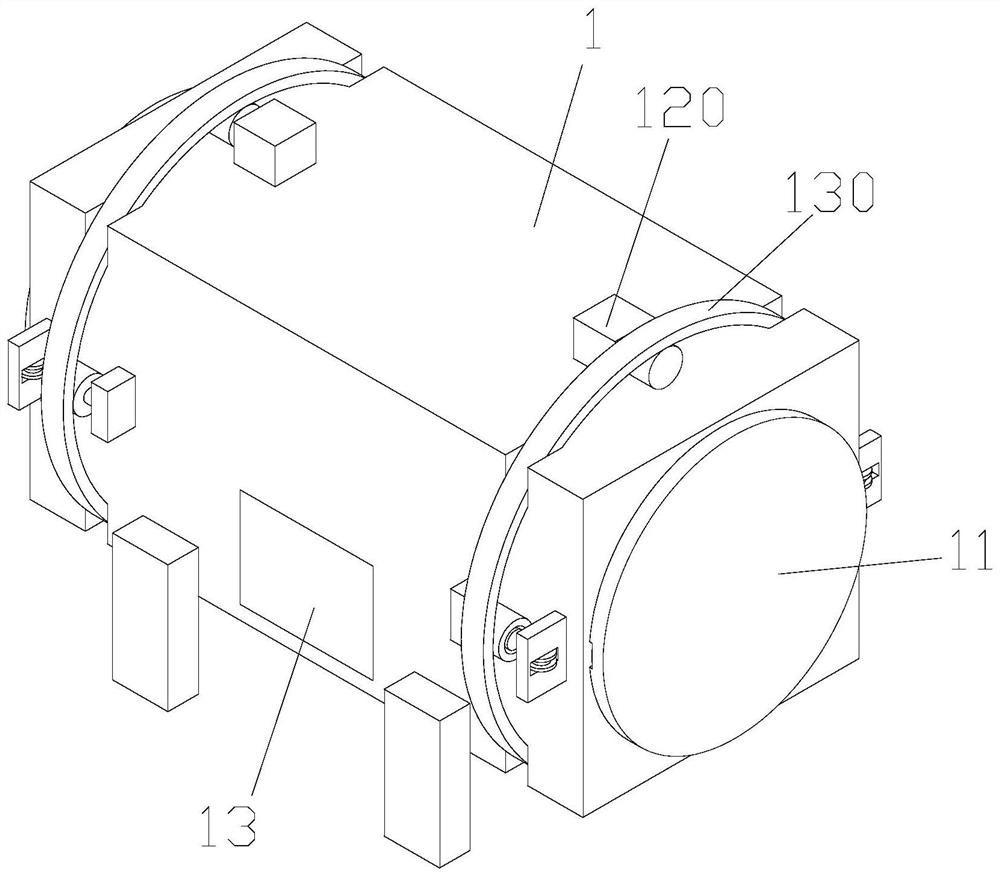

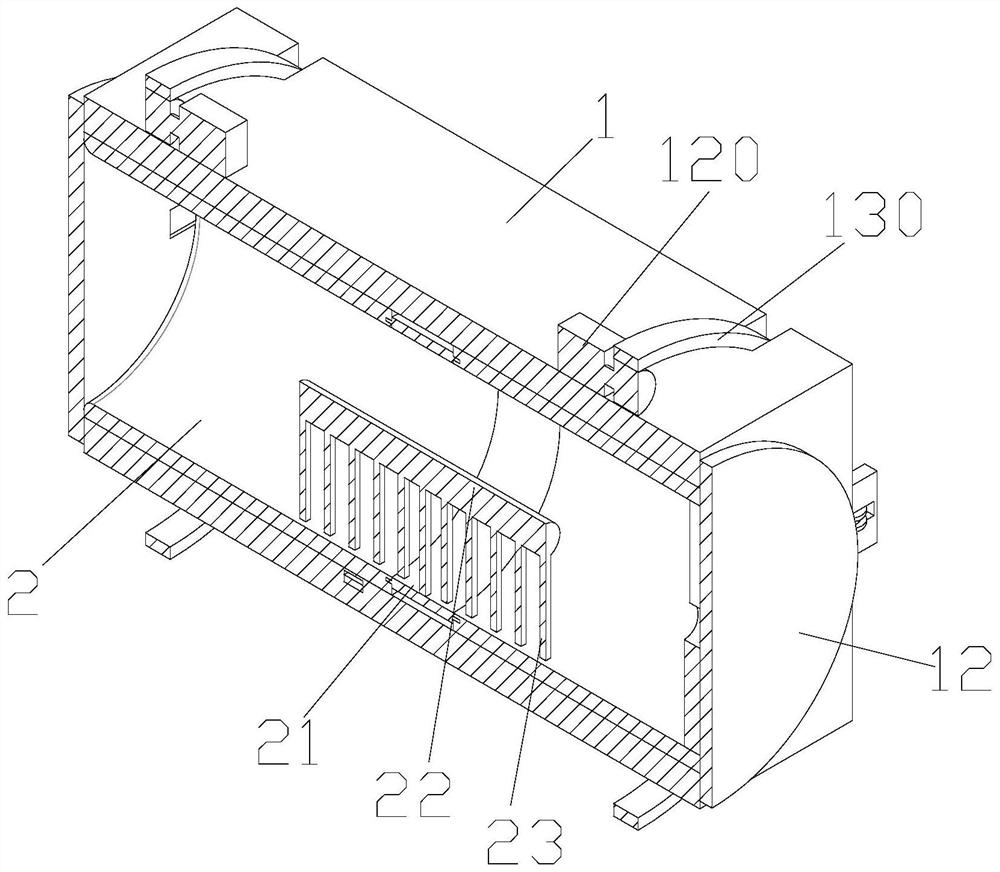

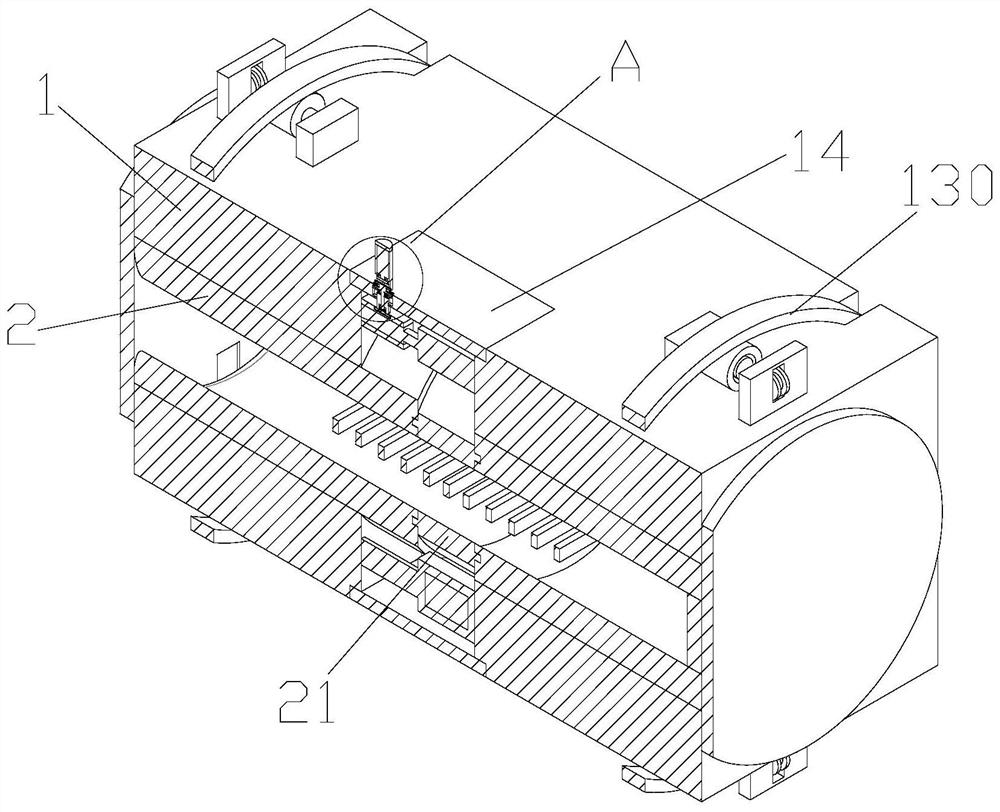

Intelligent feeding and taking mechanism for piston rod machining

ActiveCN114273960ARealize automatic changeoverImprove processing efficiencyMetal working apparatusNumerical controlElectric machinery

The invention belongs to the technical field of piston rod machining equipment, and particularly relates to an intelligent feeding and taking mechanism for piston rod machining. The intelligent feeding and taking mechanism for piston rod machining comprises an equipment base, permanent magnet motor numerical control machining machines are installed at the positions, close to the front side and the rear side, of the top of the equipment base correspondingly, and a feeding machine and a receiving machine are arranged at the feeding ends of the two permanent magnet motor numerical control machining machines correspondingly; a first material taking mechanism and a second material taking mechanism are arranged at the machining ends of the two permanent magnet motor numerical control machining machines correspondingly. According to the piston rod machining device, equipment of two piston rod machining procedures is optimized and integrated, compared with a traditional machining mode, the procedure inventory is reduced, the product turnover rate is increased, meanwhile, through mutual cooperation of the first material taking mechanism, the second material taking mechanism and the material moving mechanism, manual adjustment of the position of the piston rod is avoided, and the machining efficiency is improved. Automatic remodeling of two machining procedures of the piston rod is achieved, and the machining efficiency of the piston rod is improved.

Owner:QINGDAO ZHANGSHI MACHINERY

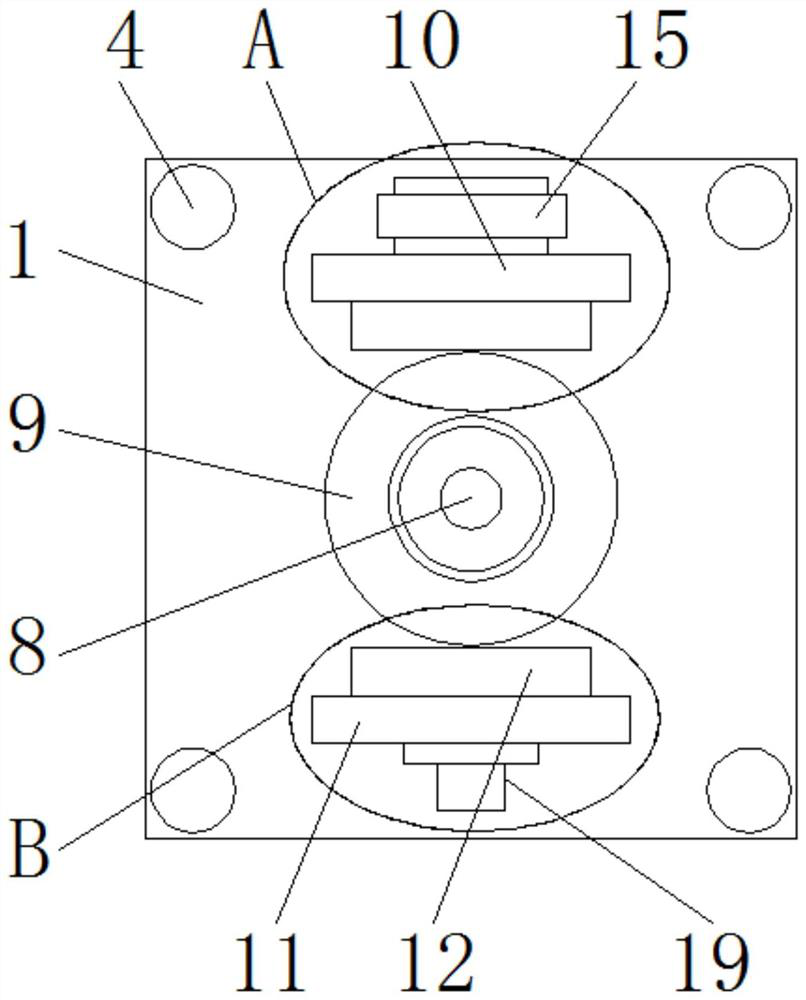

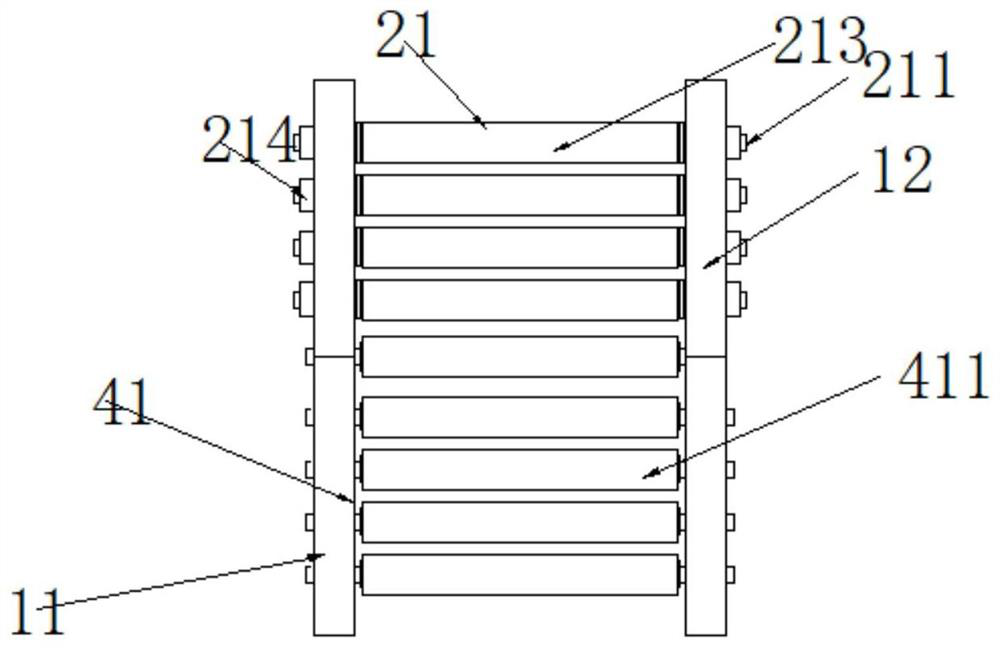

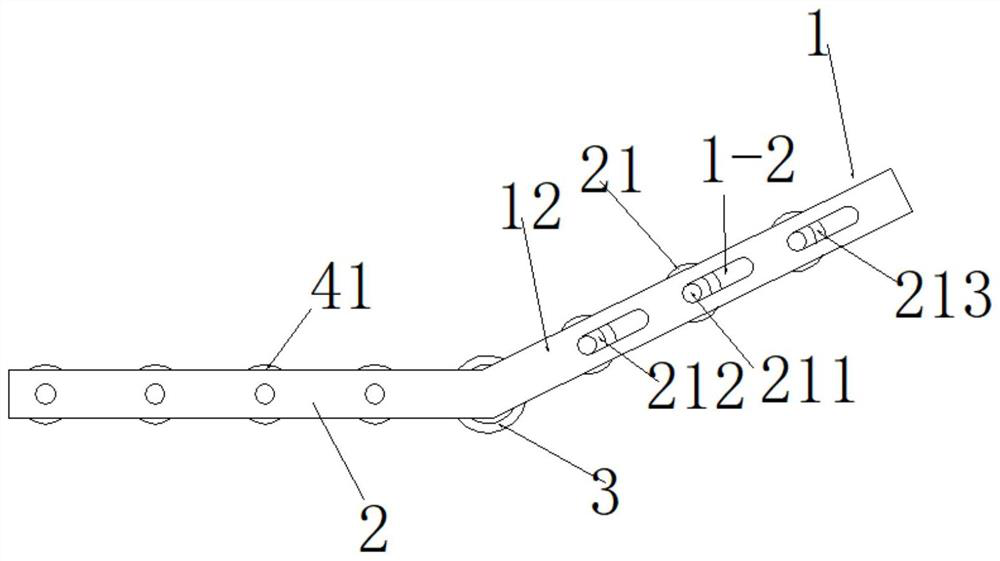

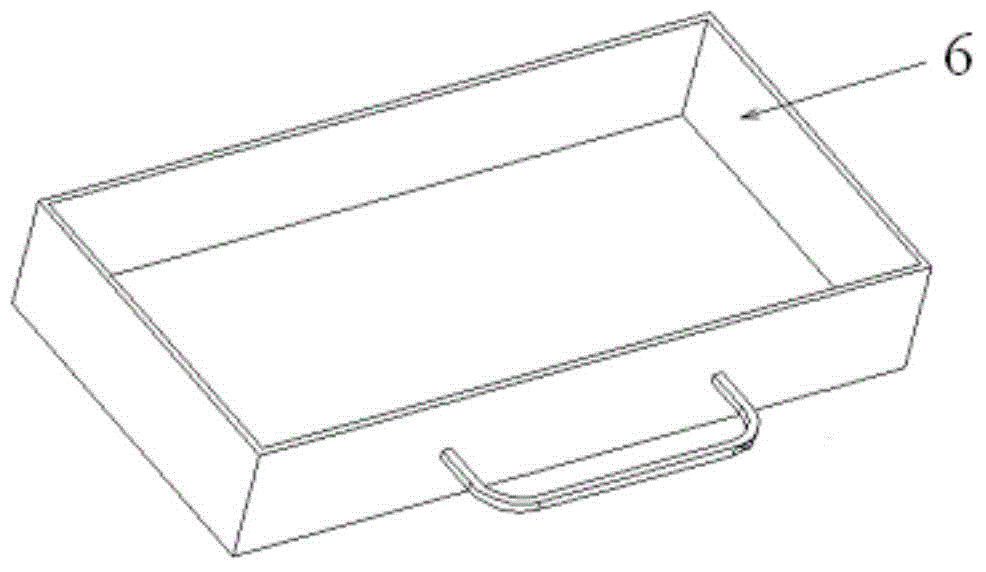

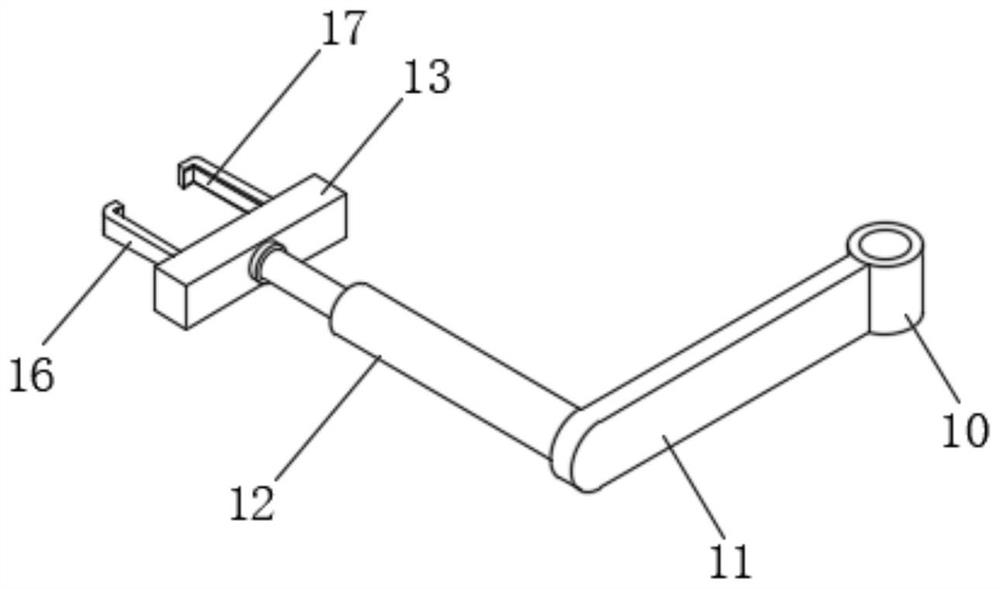

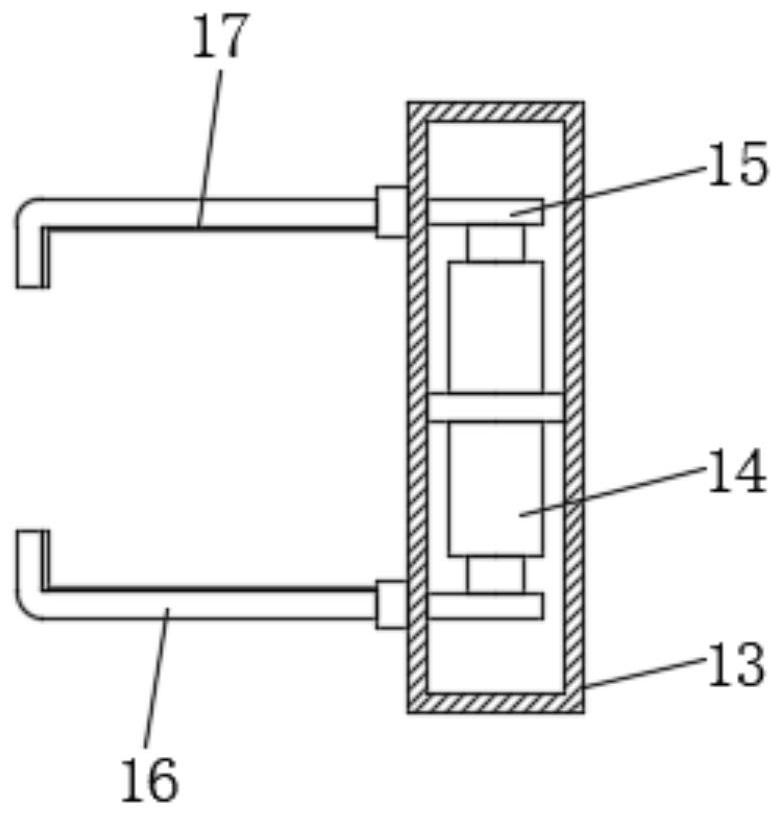

Receiving device for stamping equipment and stamping steel plate mold

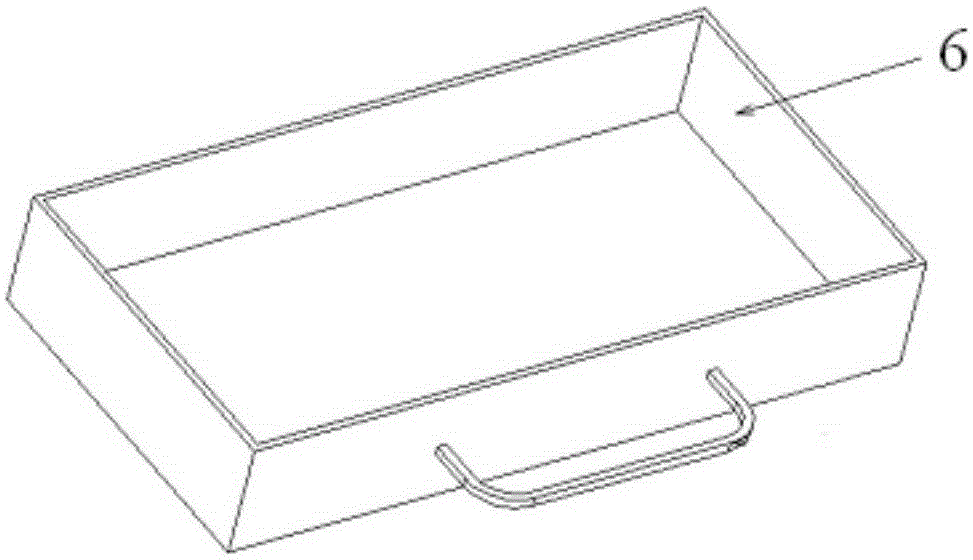

ActiveCN104148526BEasy to take out the materialSave materialShaping toolsMetal-working feeding devicesEngineeringMechanical engineering

The invention discloses a material receiving device for stamping equipment and a steel plate stamping die. The material receiving device comprises a base plate, a supporting piece, a material extraction piece and a material blocking piece. The supporting piece is arranged on the base plate, and is used for supporting a stamped piece. The material extraction piece is in sliding connection with the base plate, and the material extraction piece has a material waiting position and a material taking position on the sliding stroke. The material blocking piece is arranged at one end of the material extraction piece, and in the process that the material extraction piece moves to the material taking position from the material waiting position, the material blocking piece is used for driving the stamped piece to move along with the material extraction piece. According to the material taking operation of the material receiving device, part but not all of the material receiving device needs to be pulled out and pushed back, and compared with the prior art, the device is more convenient and faster to use.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

A conveying device with compression function for biomass fuel

The invention relates to a conveying device with a compression function for biomass fuel, comprising a body and a top block. A storage compression chamber is opened inside the body, and side through grooves are opened in the left and right walls of the body. , the inner end of the side penetration groove is connected with a transmission screw, and the outer wall of the transmission screw is connected with a transmission seat, the inner end of the storage compression chamber is installed with a compressor, and the outer side of the compressor is fixed with a locator, A bottom discharge port is arranged at the bottom end of the storage compression chamber, and a sealing plate is installed on the outer side of the bottom discharge port. The beneficial effects of the present invention are: the biomass fuel conveying equipment with compression function is provided with a bottom rod, a top rod and a top block, and through the rotation between the bottom rod and the top rod, the bottom rod can be adjusted through the action of the thread. The distance between the rod and the ejector rod can then achieve the effect of extending the positioner, which is convenient for extending the use or shortening the storage positioner, and improving the convenience and simplicity of its operation.

Owner:兴隆县一通新能源科技有限公司

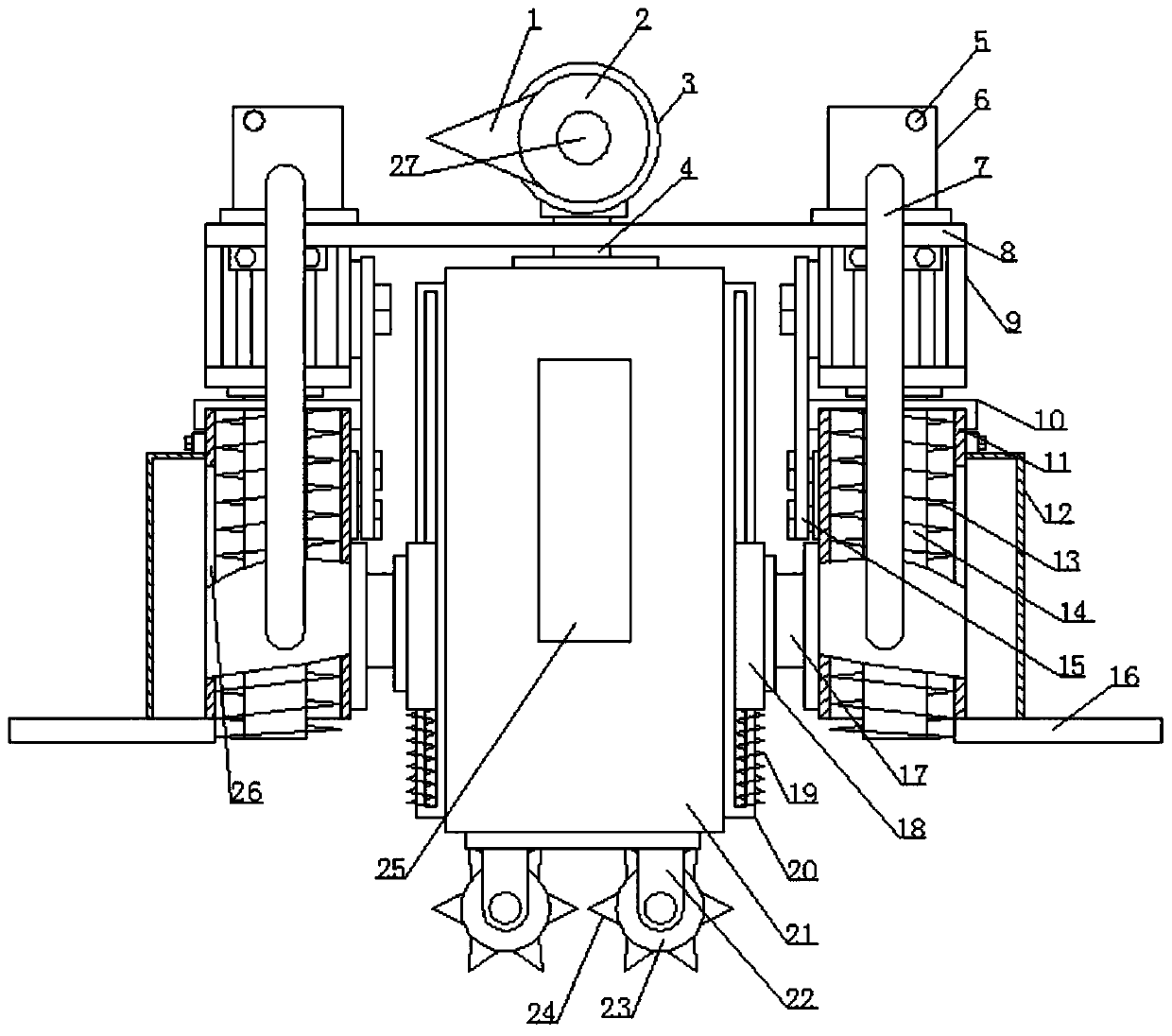

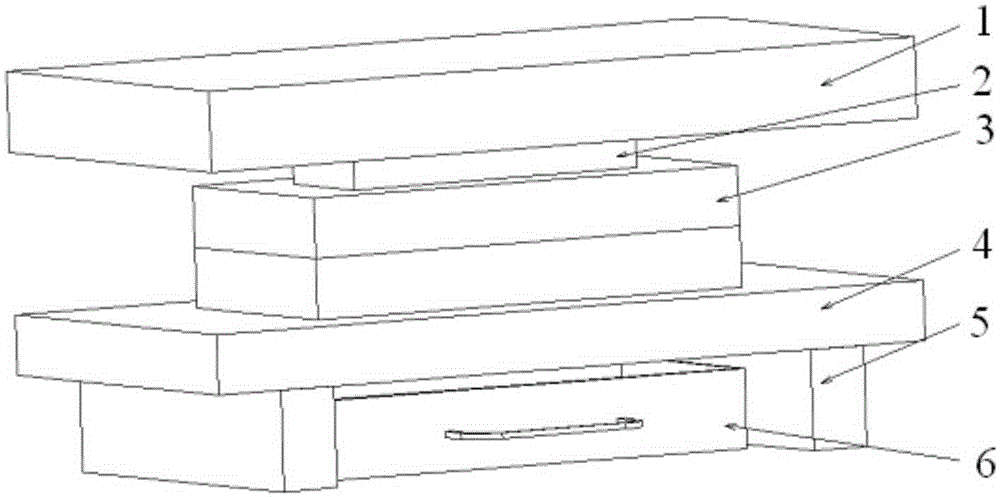

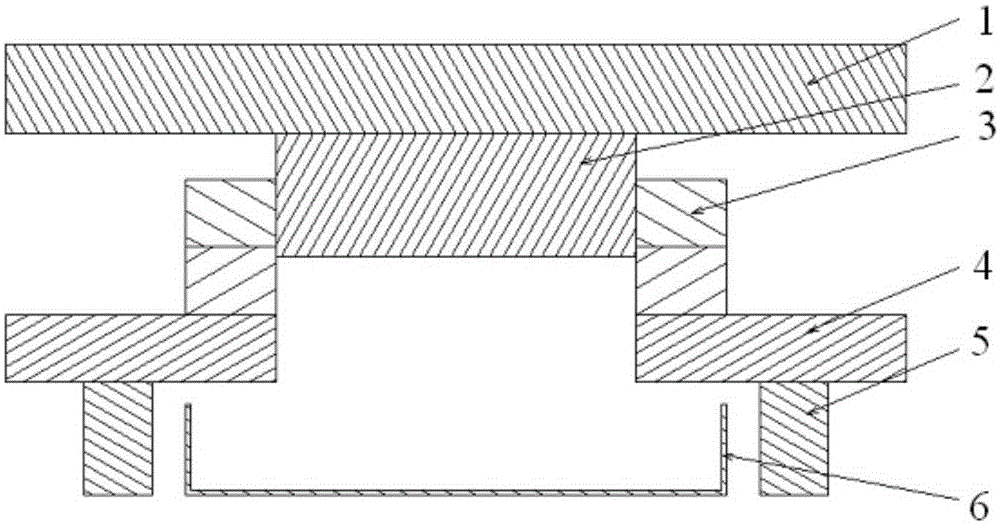

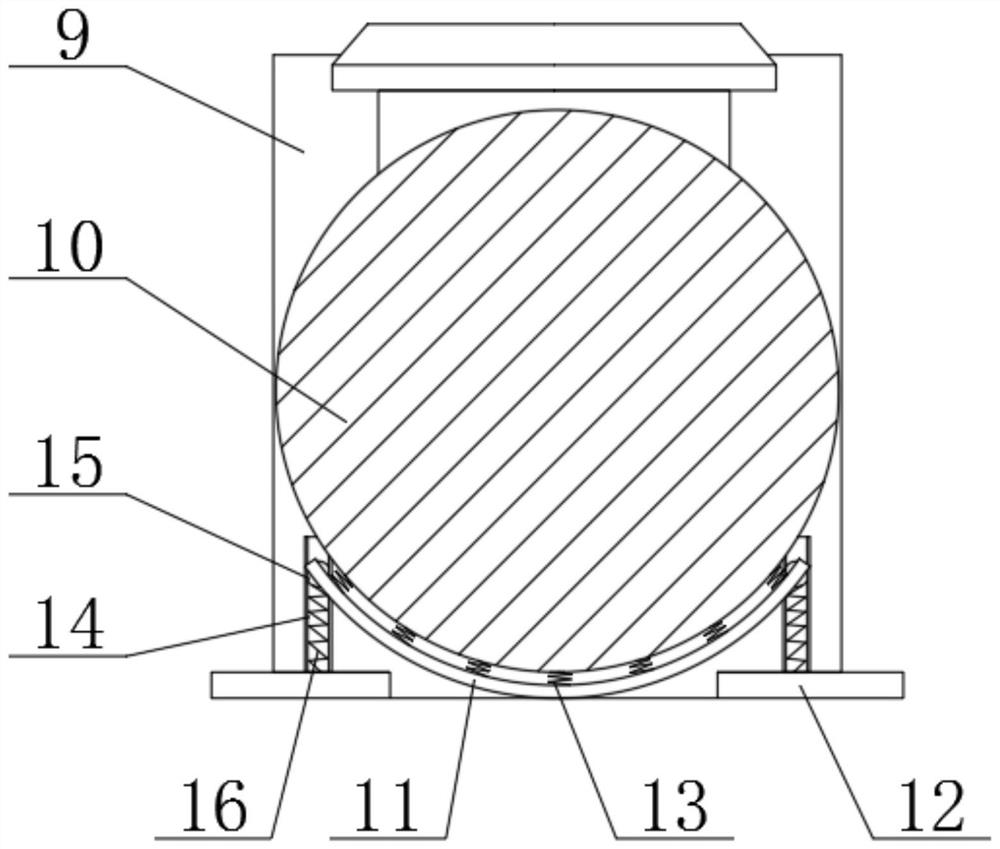

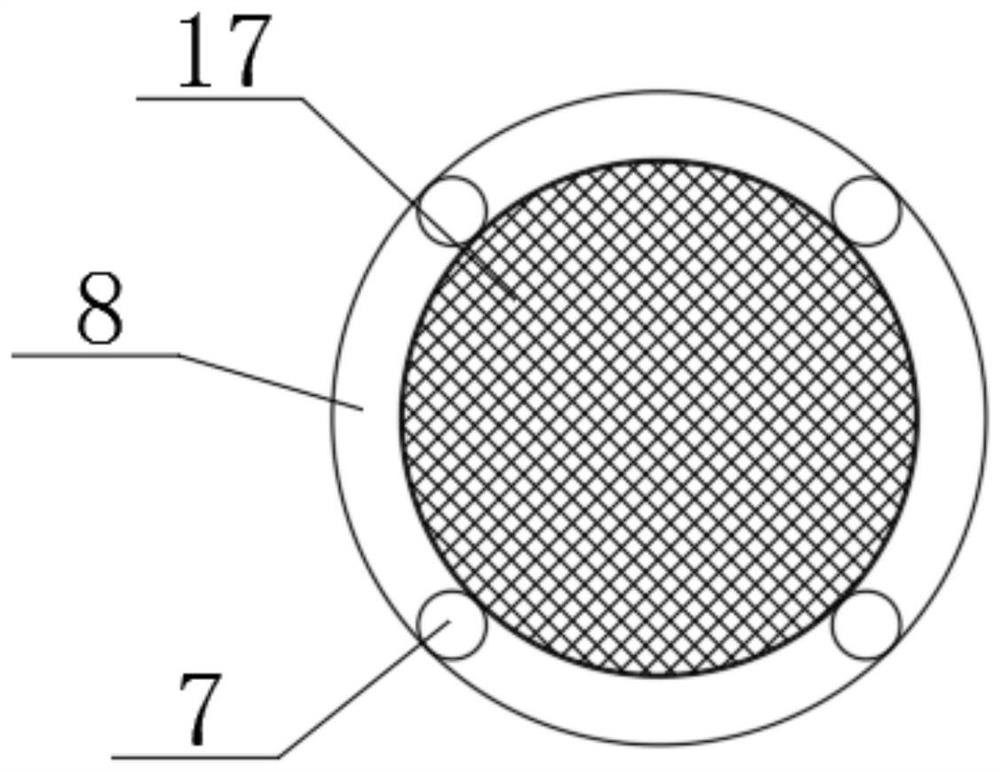

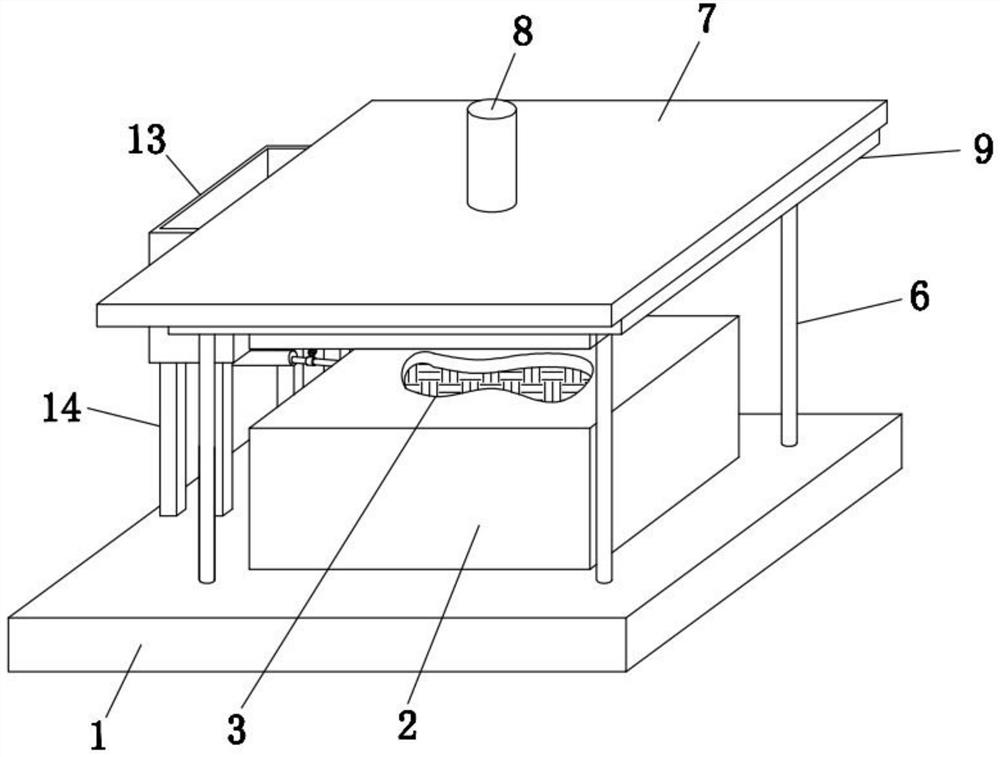

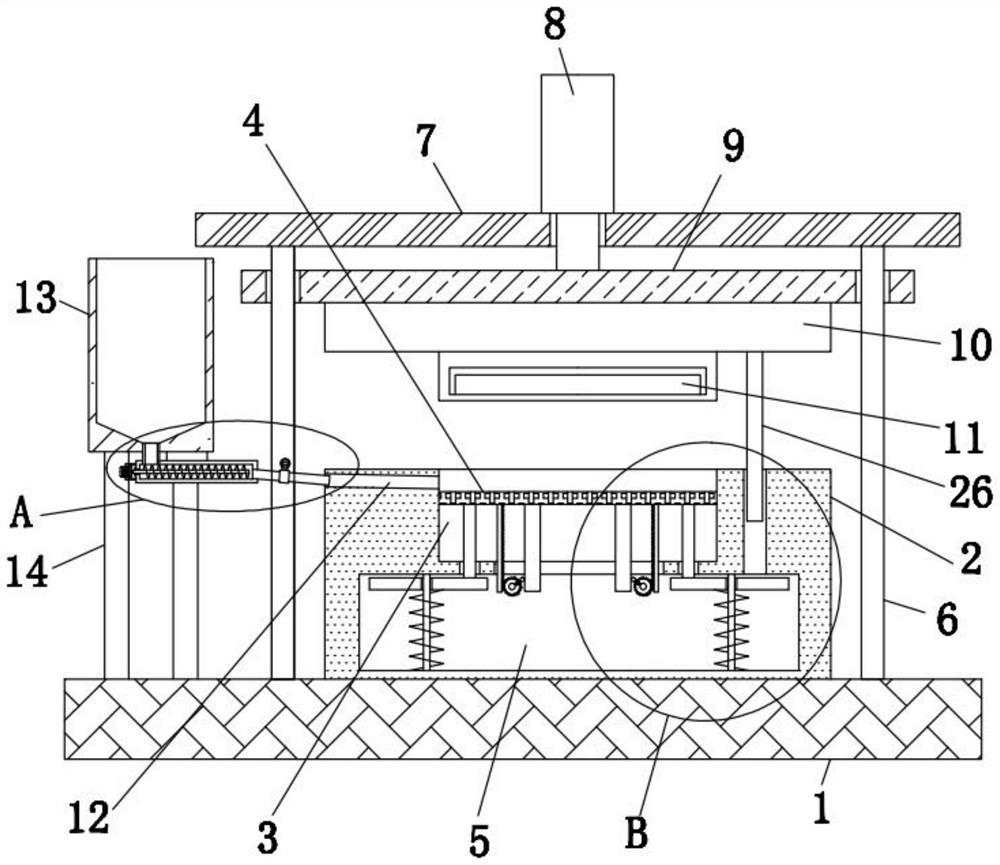

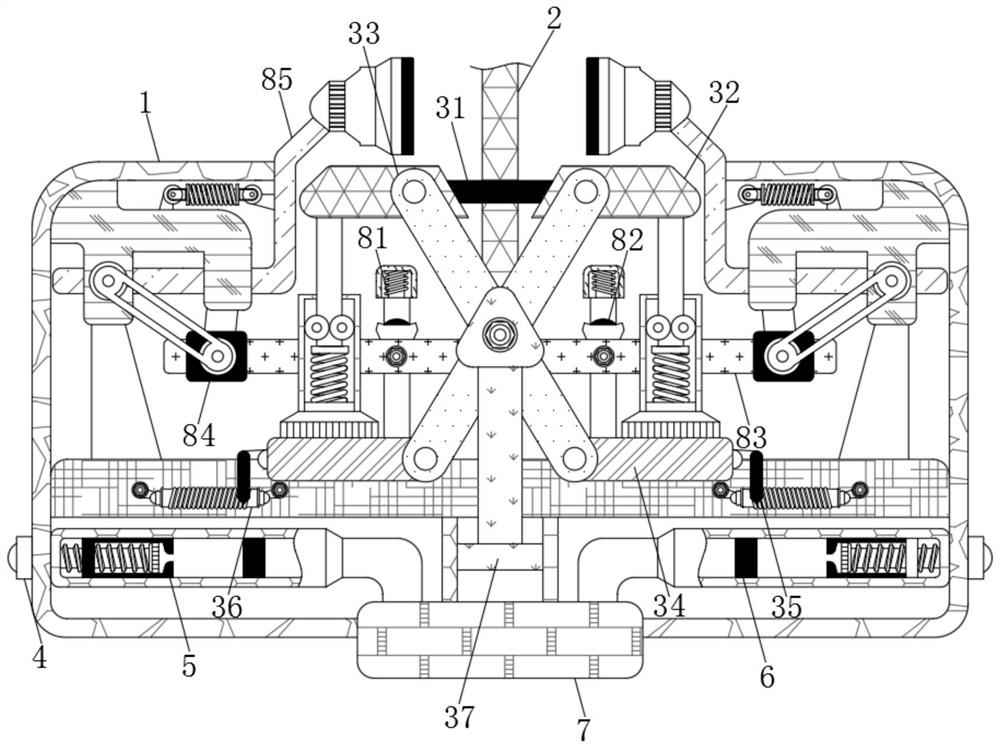

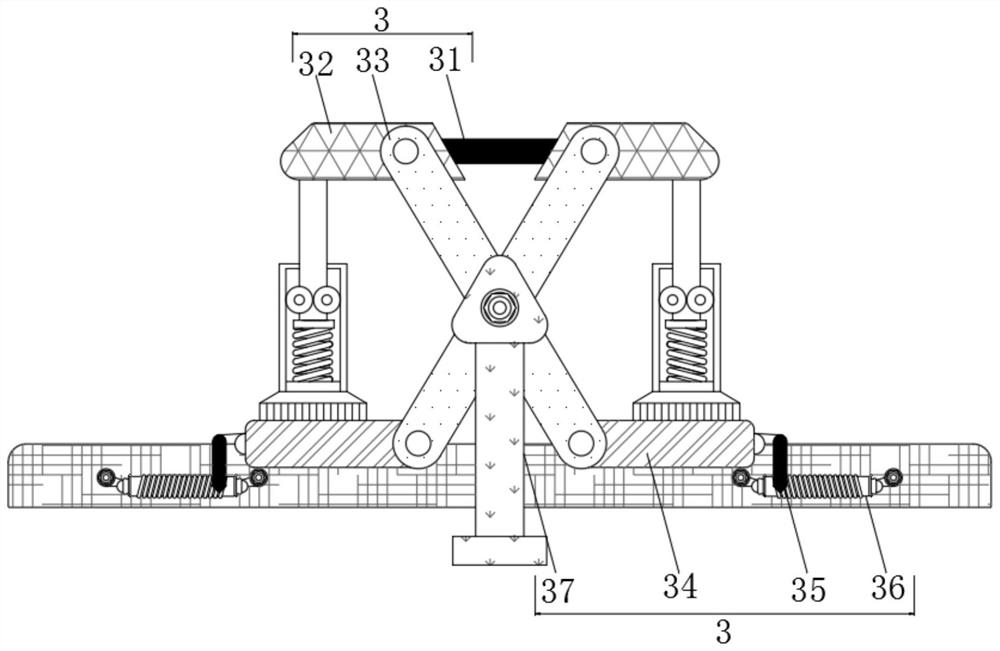

Forming device of novel rubber spherical hinge mold opening mode and opening method of novel rubber spherical hinge mold opening mode

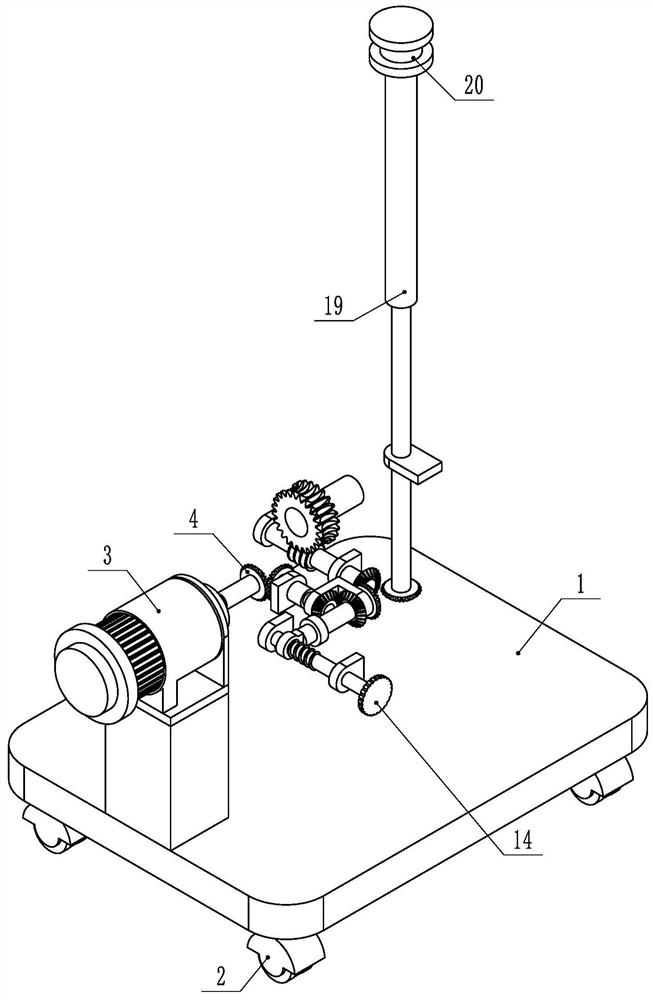

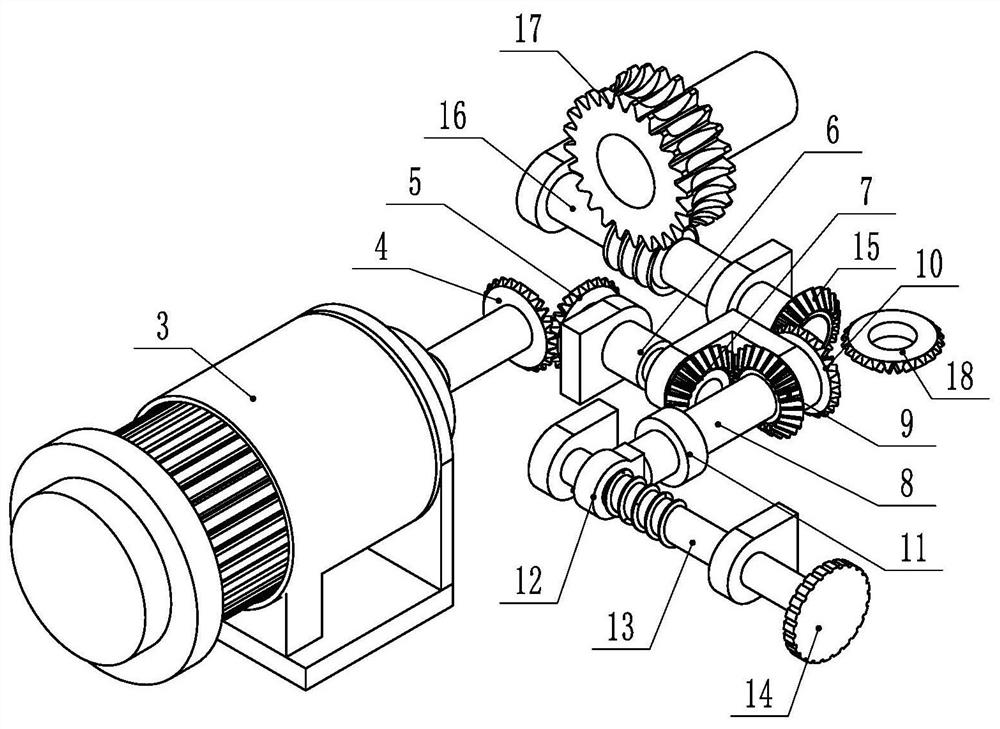

ActiveCN113071054AEasy to take out the materialImprove processing efficiencyDomestic articlesGear wheelMachining

The invention discloses a forming device of a novel rubber spherical hinge mold opening mode and an opening method of the novel rubber spherical hinge mold opening mode. The forming device comprises a rack, wherein two fixing beams arranged side by side are erected on the rack, the middle area between the two fixing beams is a forming station, the areas at the two ends are feeding and discharging stations, and two movable lower mold assemblies are installed between the fixing beams in a guiding mode; the lower mold assembly comprises a fixed lower mold body and a movable lower mold body; a top plate is erected above the forming station, an upper mold assembly is installed below the top plate and comprises a fixed upper mold body and a movable upper mold body, and the movable upper mold body is driven by gear pull rod mechanisms at the two ends of the movable upper mold body to move; and the upper end surfaces of the fixed lower mold body and the movable lower mold body and the lower end surfaces of the fixed upper mold body and the movable upper mold body are respectively provided with cavities which are mutually folded and are used for forming spherical hinge rubber. The machining efficiency is improved, the opening mode of the gear pull rod mechanism is good, stability is good, long-term use can be achieved, operation is simplified, and the requirements for batch machining and production are met.

Owner:ANQING HUITONG AUTOMOTIVE PARTS

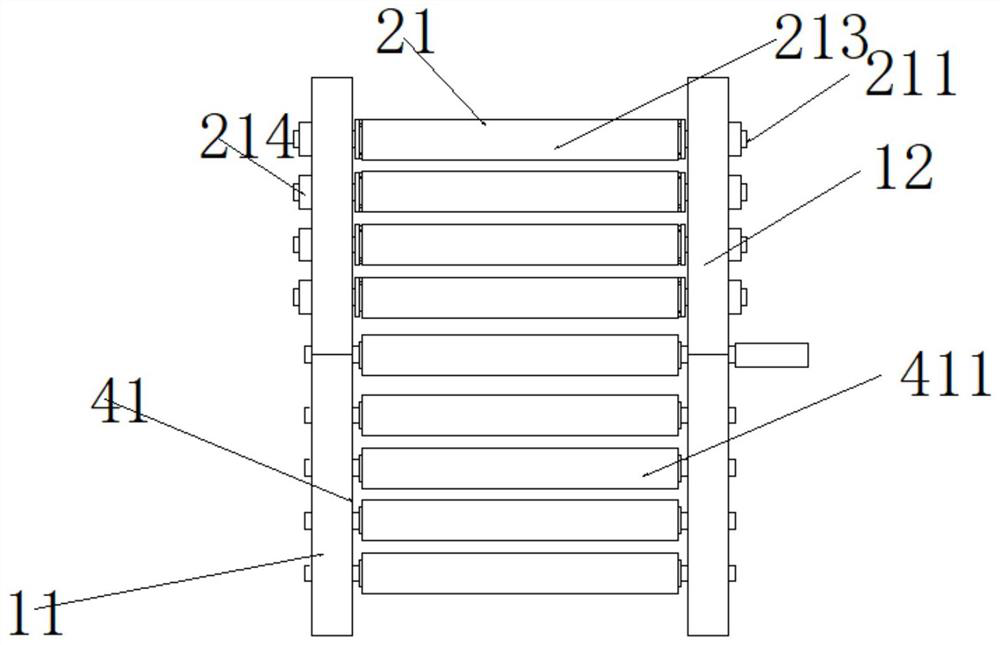

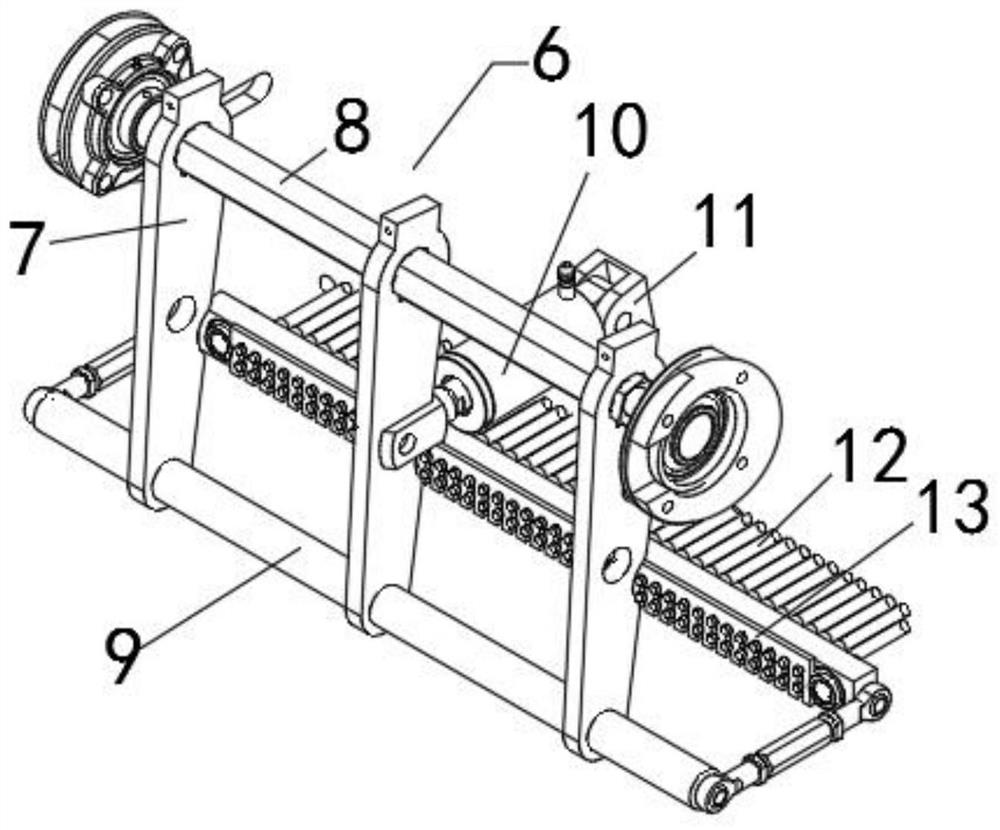

Material guiding device for wrapper composite calendering

InactiveCN114052055AConvenient composite calendering operationReduce the impact of movementDough-sheeters/rolling-machines/rolling-pinsDough processingEngineeringInstant noodle

The invention relates to the field of calendering equipment, in particular to a material guiding device for wrapper composite calendering. The device comprises a material guide frame connected with a calender, the material guide frame comprises a support frame connected with the calender, a material guide part is arranged on the support frame, a material guide shaft is connected with the material guide part, a material guide sleeve is arranged on the material guide shaft, and the support frame is obliquely arranged. The invention discloses the material guiding device for wrapper composite calendering, the material guiding device disclosed by the invention mainly plays a guiding role, and instant noodles enter composite calendering equipment to be subjected to composite calendering operation. The material guiding device mainly comprises the material guide part, the influence of the material guide part on movement of the wrappers can be reduced in a calendering mode while the wrappers are supported by the material guide part, and the instant noodle wrappers are taken out in the meshing state of calendering rollers.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

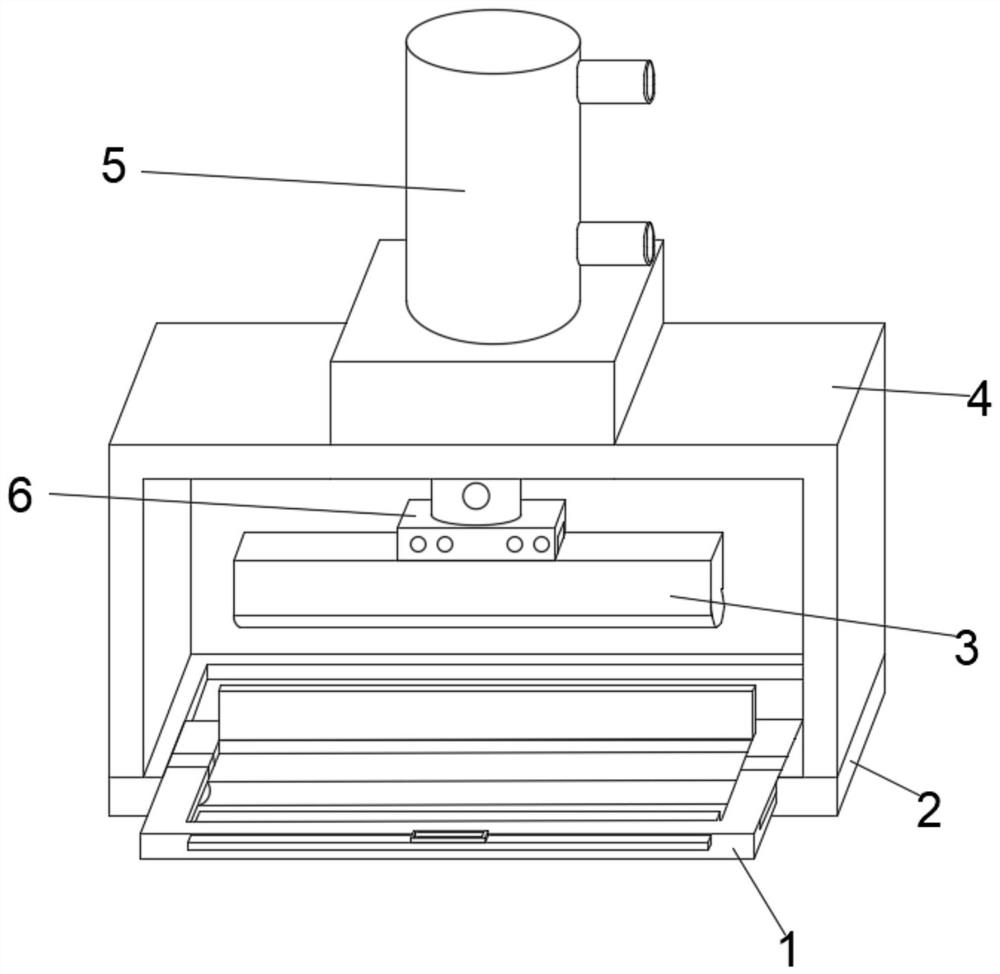

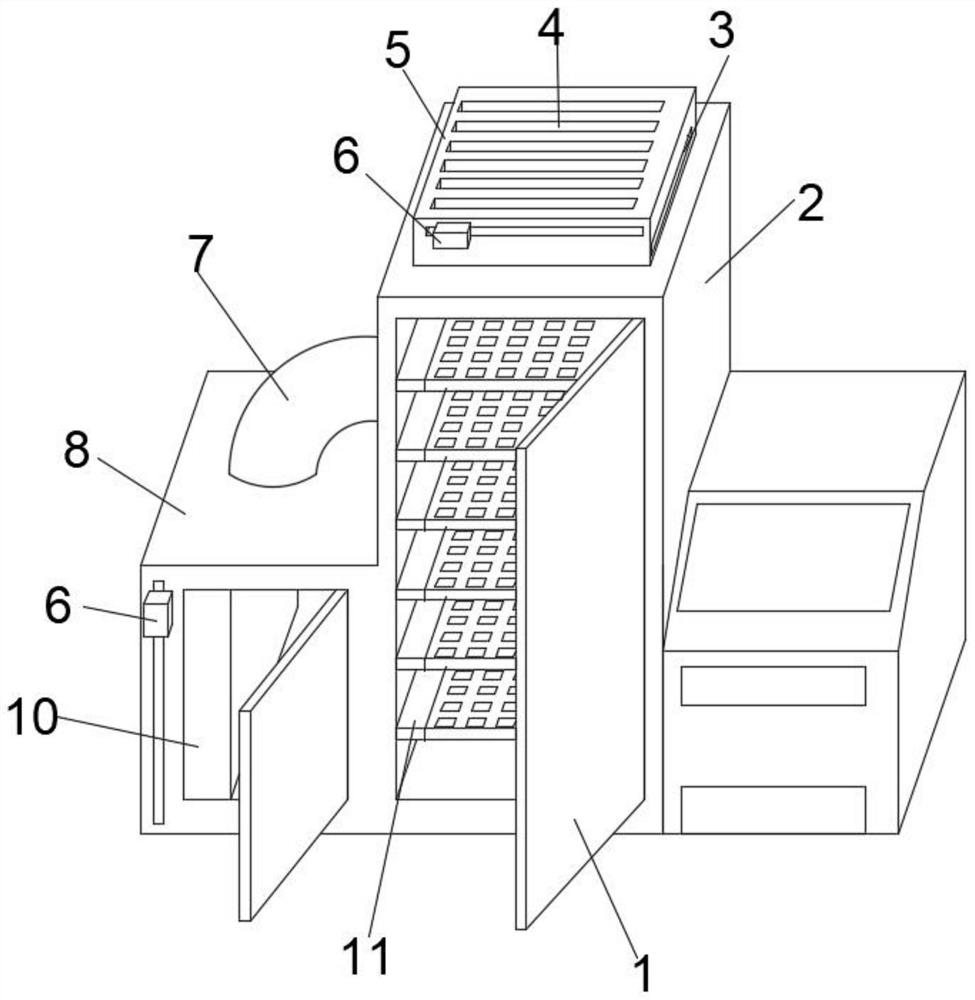

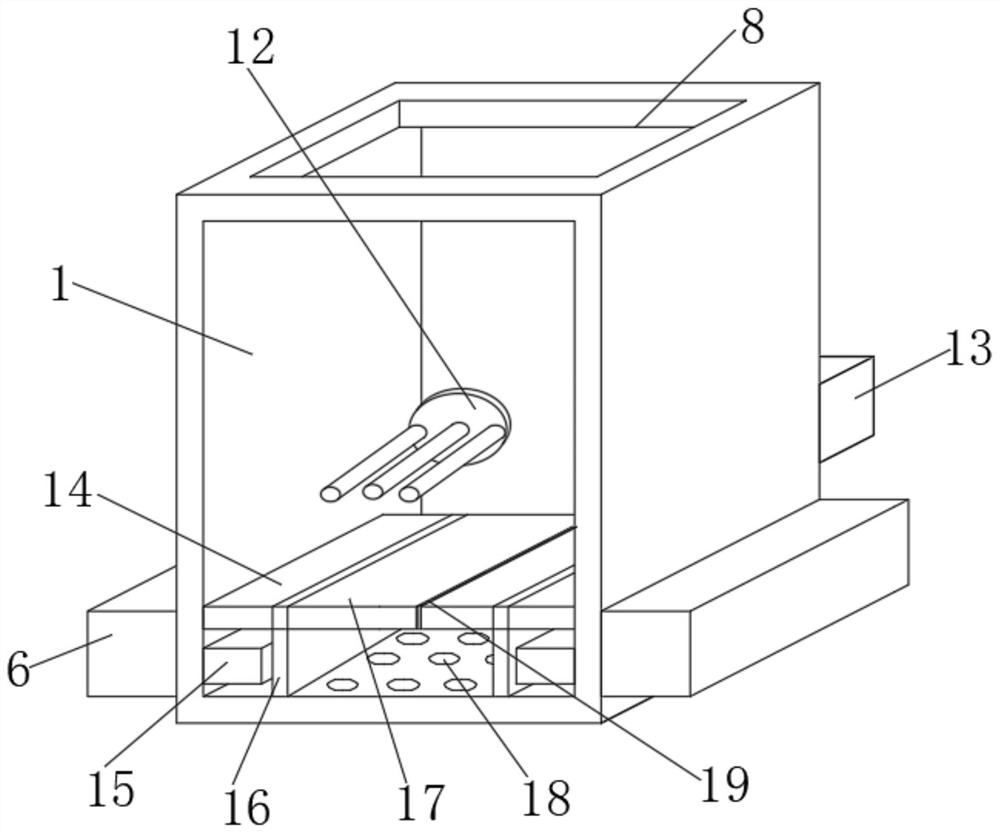

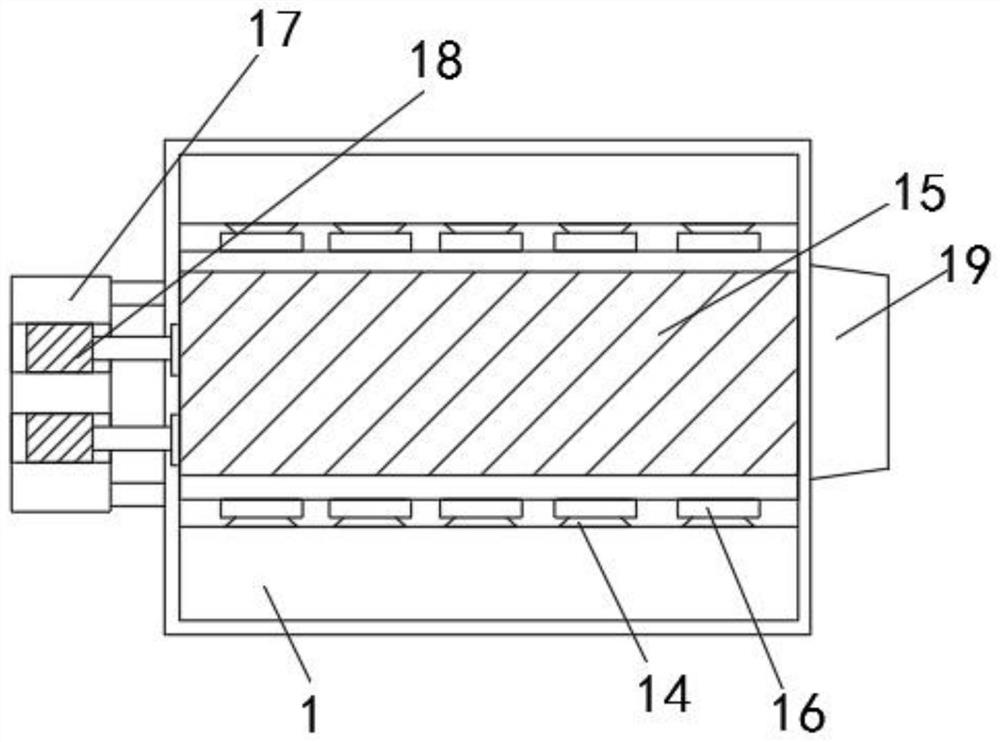

Chip resistor conductor layer drying equipment and using method thereof

InactiveCN113539593APrevent rotationReduce frictionResistor chip manufactureCleaning using toolsElectrical conductorDust control

The invention discloses chip resistor conductor layer drying equipment and a using method thereof. The chip resistor conductor layer drying equipment comprises a drying cabinet and a fixed side box. The fixed side box is fixedly installed on the outer surface of one side of the drying cabinet, a communicating pipe is arranged between the fixed side box and the drying cabinet, and an exhaust hood is fixedly installed on the outer surface of the upper end of the drying cabinet. Push-pull buckles are movably installed on the outer surfaces of the side edges of the exhaust hood and the fixed side box, a movable sliding frame is fixedly installed at one end of each push-pull buckle, the movable sliding frames are movably installed on the inner sides of the exhaust hood and the fixed side box, and a rolling brush rod is movably installed in the middle of the inner side of each movable sliding frame. The movement of the movable sliding frames is matched with the rolling brush rods in a fixed state to conduct dust removal operation on the interior of the equipment, and meanwhile the movement of the movable sliding frames is matched with the rolling brush rods in a rotating state to discharge cleaned dust from a dust discharging groove, so that dust removal operation on the interior of the equipment is completed under the condition that the equipment is not disassembled, and the phenomenon that the equipment is blocked due to accumulated dust is avoided.

Owner:安徽省富捷电子科技有限公司

Electroplating device based on lead frame and electroplating method thereof

PendingCN114645308AEasy to controlEase of plating operationCellsElectrodesTemperature controlEngineering

The electroplating device comprises a device body, a mounting support, a liquid outlet box and an electroplating function management platform, the device body is located at the upper end of the mounting support, the liquid outlet box is located at the bottom of the mounting support, and an observation window and a liquid outlet are formed in the front end of the liquid outlet box; lifting columns are arranged at the four corners of the upper end of the device body, a lifting plate is installed at the upper ends of the lifting columns, and an opening is formed in the middle of the upper end of the device body. According to the electroplating device based on the lead frame and the electroplating method of the electroplating device, the temperature control type electroplating mechanism, the lifting material taking mechanism and the electroplating function management platform are arranged, electroplating operation can be conveniently and better carried out, the temperature control effect is achieved, the cathode part can move and stir, the electroplating effect is improved, efficiency is higher, and the electroplating effect is better. And material taking operation can be conveniently carried out, rapidness is achieved, function modules of the whole device can be conveniently controlled, and the device is simple and practical.

Owner:泰兴市龙腾电子有限公司

Conveying equipment with compression function for biomass fuel

The invention relates to conveying equipment with a compression function for biomass fuel. The conveying equipment comprises an equipment body and a top block, wherein a storage compression chamber isformed inside the equipment body; side penetrating grooves are formed in the left wall and the right wall of the equipment body separately; the inner end of each side penetrating groove is connectedwith a transmission lead screw; the outer wall of each transmission lead screw is connected with a transmission seat; a compressor is mounted at the inner end of the storage compression chamber; a positioning device is fixed on the outer wall of the storage compression chamber; a bottom discharging opening is formed in the bottom end of the storage compression chamber; a sealing plate is mounted on the outer side of the bottom discharging opening; and positioning bearings are separately connected to the outer sides of the left end and the right end of the equipment body. The conveying equipment with the compression function for the biomass fuel has the beneficial effect that the conveying equipment with the compression function for the biomass fuel is provided with a bottom rod, a top rodand the top block, the distance between the bottom rod and the top rod can be adjusted through rotation between the bottom rod and the top rod by the effect of threads, then an effect of extending a position adjuster is achieved, the position adjuster can extend to be used or retract to be stored conveniently, and convenience and simplicity of operation of the position adjuster are improved.

Owner:兴隆县一通新能源科技有限公司

Material receiving device for stamping equipment and steel plate stamping die

ActiveCN104148526ASave materialEasy to take out the materialShaping toolsMetal-working feeding devicesSteel platesMechanical engineering

The invention discloses a material receiving device for stamping equipment and a steel plate stamping die. The material receiving device comprises a base plate, a supporting piece, a material extraction piece and a material blocking piece. The supporting piece is arranged on the base plate, and is used for supporting a stamped piece. The material extraction piece is in sliding connection with the base plate, and the material extraction piece has a material waiting position and a material taking position on the sliding stroke. The material blocking piece is arranged at one end of the material extraction piece, and in the process that the material extraction piece moves to the material taking position from the material waiting position, the material blocking piece is used for driving the stamped piece to move along with the material extraction piece. According to the material taking operation of the material receiving device, part but not all of the material receiving device needs to be pulled out and pushed back, and compared with the prior art, the device is more convenient and faster to use.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Low-energy-consumption industrial microwave sintering equipment

InactiveCN112229203AAvoid direct contactAvoid burnsMuffle furnacesMaintainance of heating chambersElectric machineGear wheel

The invention discloses low-energy-consumption industrial microwave sintering equipment and belongs to the field of microwave sintering. The equipment comprises a bottom plate, the upper surface of the bottom plate is fixedly connected with a sintering furnace base, a sintering furnace is fixedly connected with the top of the sintering furnace base, a driving box is fixedly connected with the upper surface of the bottom plate, a driving motor is fixedly connected with the inner bottom wall of the driving box, the output end of the driving motor is sleeved with a first gear, one side of the first gear is engaged with a second gear, a rotating shaft is inserted into the inner wall of the second gear, a rotating column is fixedly connected to the top of the rotating shaft, and the outer wallof the rotating column is sleeved with a fixed cylinder. Through the arrangement of the driving motor, the first gear, the second gear, the rotating shaft, the rotating column, a supporting arm, an extensible air cylinder, a limiting barrel, an electric push rod and a clamping plate, the design is high in automation degree and operation is easy; the trouble of manually taking out a crucible is avoided, workers are prevented from making direct contact with the crucible, and the workers are prevented from being scalded; and therefore, the effects that the device is convenient in material takingand high in safety are achieved.

Owner:娄底光华机械设备制造有限公司

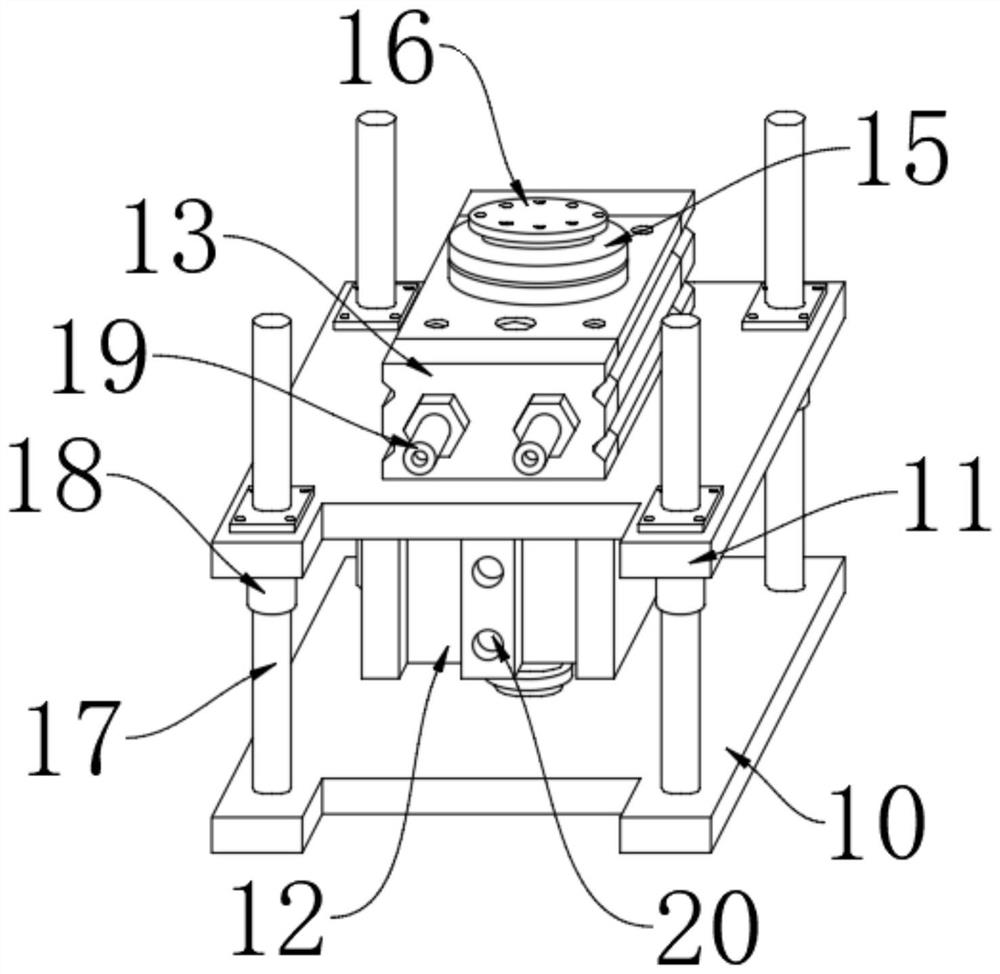

Robot grinding machine fixing device with high flexibility

ActiveCN113681401AMeet the grinding requirementsRealize repeated precise positioningGrinding carriagesGrinding drivesRobot handMachine

The invention discloses a robot grinding machine fixing device with high flexibility, relates to the technical field of robot grinding machines, and aims to solve the problem that a tool of a robot manipulator cannot grind all positions of a ground workpiece due to stroke limitation due to the requirements of a grinding process in the using process of an existing robot grinding machine. A grinding table support is arranged at the lower end of a robot grinding table; a horizontal carrying plate is arranged on the inner wall of the grinding table support; a static plate is arranged at the upper end of the horizontal carrying plate; a jacking air cylinder is arranged at the upper end of the static plate; and a movable plate is arranged at the output end of the jacking air cylinder; a rotating air cylinder is arranged at the upper end of the movable plate; a rotating end is arranged at the output end of the rotating air cylinder; a circular truncated cone carrying groove is formed in the robot grinding table, the circular truncated cone carrying groove and the robot grinding table are integrally formed; and an inner communicating groove is formed in the lower end of the circular truncated cone carrying groove.

Owner:艾蒂盟斯(苏州)工业科技有限公司

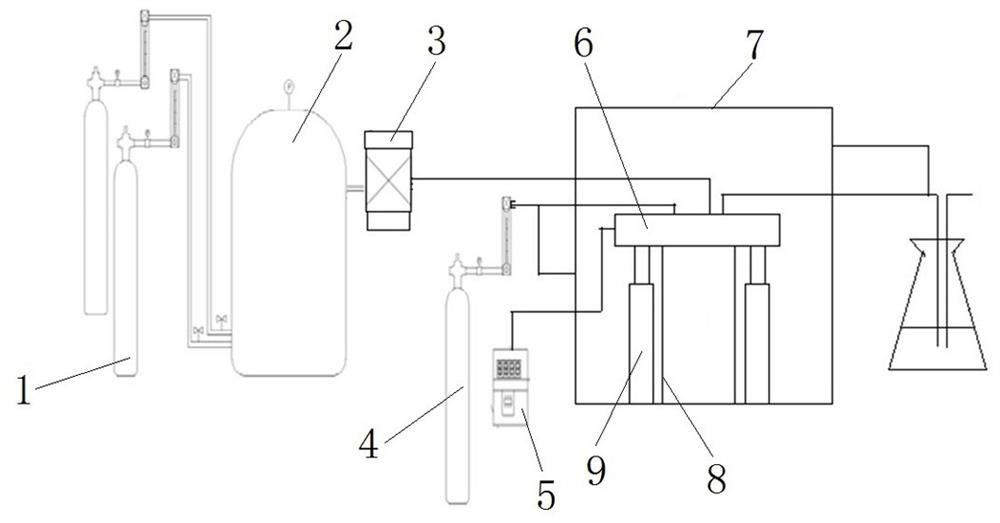

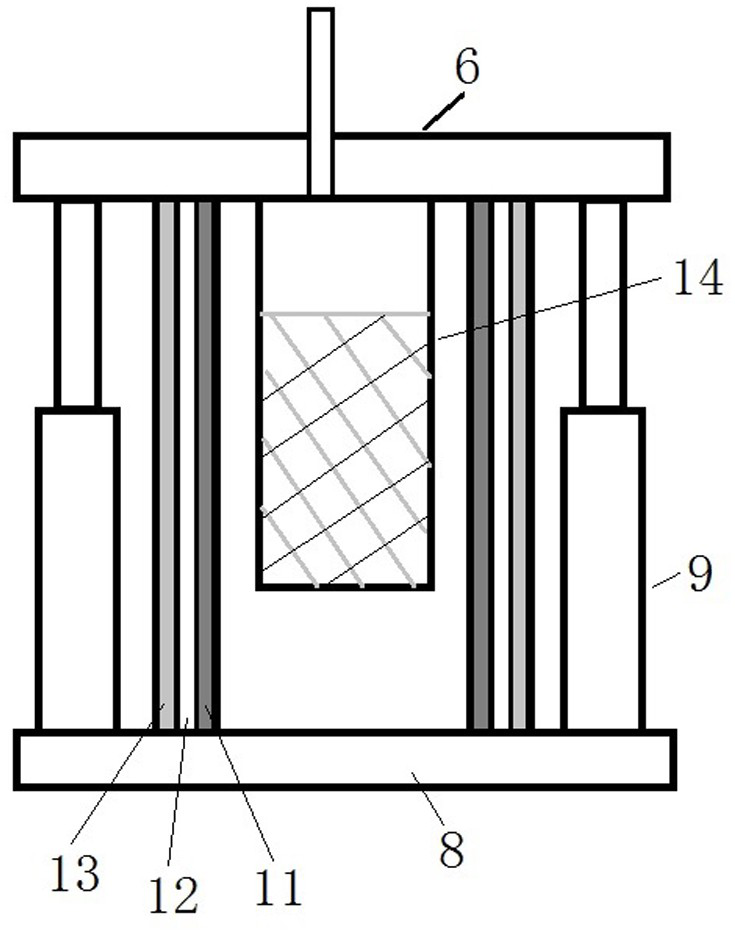

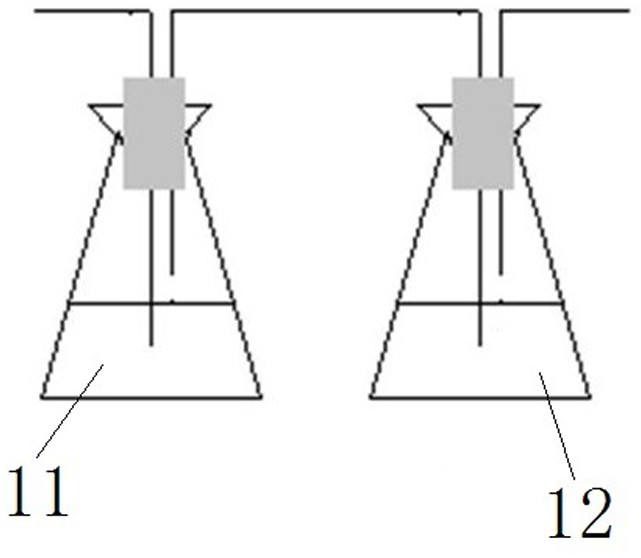

A filter material corrosion performance testing device

ActiveCN109752309BReduce concentrationReduce harmWeather/light/corrosion resistanceFlue gasProcess engineering

The invention provides a device for testing the corrosion performance of filter material, which can reduce the harm caused by corrosion smoke to operators when the material is taken out after the test. The filter material corrosion performance test device includes a test box for placing the filter material. The test box has a corrosion smoke inlet and a filter material pick-and-place door for taking and placing the filter material. The test device also includes a purification chamber for containing the test box. box, the test device also includes a driving mechanism for opening the filter material access door to communicate with the purification box and the test box, and the test device also includes an air filling device for filling the purification box with purified gas after the purification box and the test box are connected. Pipes and discharge pipes for the corrosive fumes and purge gases in the purge box to discharge. The invention can reduce the corrosion smoke concentration at the test box and the filter material after the test is completed, facilitates the operator to perform the material retrieving operation, and reduces the injury to the operator.

Owner:河南合众电力技术有限公司

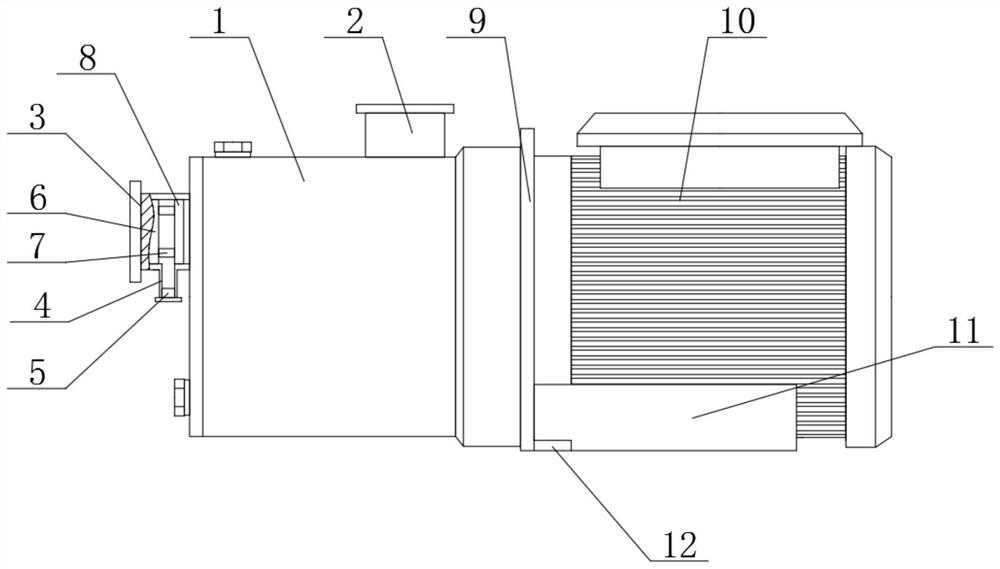

Water-cooling energy-saving water pump

PendingCN112727780AAvoid interferenceEasy to take out the materialPump componentsPump installationsThermodynamicsCooling energy

The invention relates to the technical field of water pumps, in particular to a water-cooling energy-saving water pump. The water-cooling energy-saving water pump comprises a pump body, a water outlet end is connected to one side of the top of the pump body in a sealed mode, a water inlet end is connected to one side of the pump body in a sealed mode, a discharging connecting pipe is arranged at the bottom of the water inlet end, a sealing plug is installed at the bottom end of the discharging connecting pipe in a sealed mode, and a threaded connecting pipe is installed on the inner side of the water inlet end. According to the device, through the arrangement of a sieve plate, the water inlet end, the threaded connecting pipe, a short column and an outer frame body, when liquid needing to be conveyed flows into the water inlet end, through the connection and cooperation of the threaded connecting pipe, the short column and the outer frame body, the sieve plate can filter impurities doped in the liquid through the arrangement that the surface of the sieve plate is of a latticed structure, material taking operation through the discharging connecting pipe in a later period is more convenient, and meanwhile the situation that due to impurity accumulation, the screening effect of the whole screening structure is interfered is avoided.

Owner:南京沃鸿宇智能物联有限公司

Efficient shoe sole compression molding equipment for shoe processing

PendingCN114474539AConvenient and accurate judgmentRealize automatic feedingDomestic articlesCompression moldingMechanical engineering

The efficient shoe sole compression molding equipment for shoe processing comprises a platform, a lower mold base is fixedly mounted at the top of the platform, a cavity is formed in the top of the lower mold base, a base is slidably mounted in the cavity, and a mounting cavity located below the cavity is formed in the lower mold base; four stand columns which are symmetrically arranged in pairs are fixedly installed on the top of the platform, and the same top plate is fixedly installed at the top ends of the four stand columns. The device is reasonable in design and good in practicability, materials can be automatically conveyed into the cavity, the conveying amount can be metered, in the mold closing process, particle raw materials can be automatically controlled to be spread on the base, the particle raw materials can be conveniently and better heated and melted in the follow-up process, formed shoe soles can be automatically ejected out of the cavity, and the production efficiency is improved. A worker can quickly take out the formed shoe sole, so that the material taking operation is convenient, the labor amount of the worker can be effectively reduced, and the working efficiency is improved.

Owner:张强

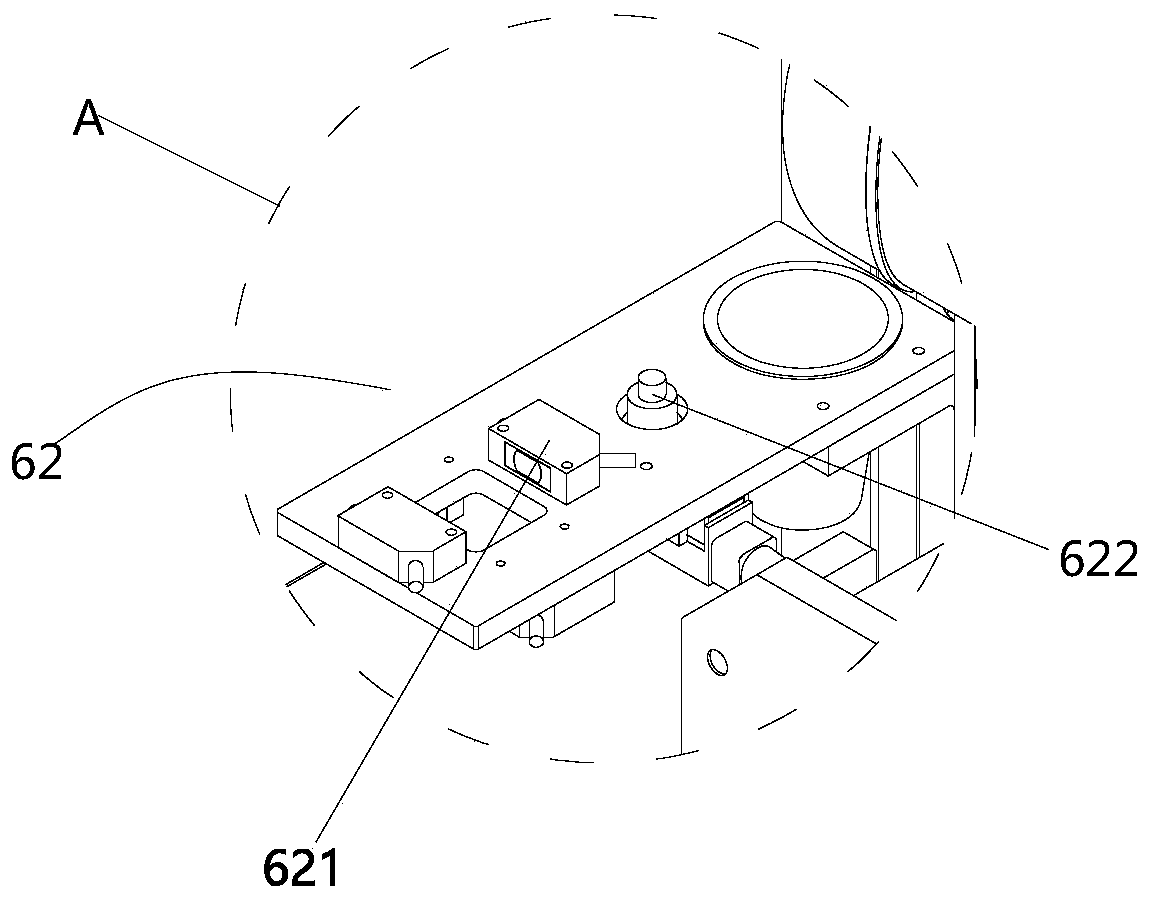

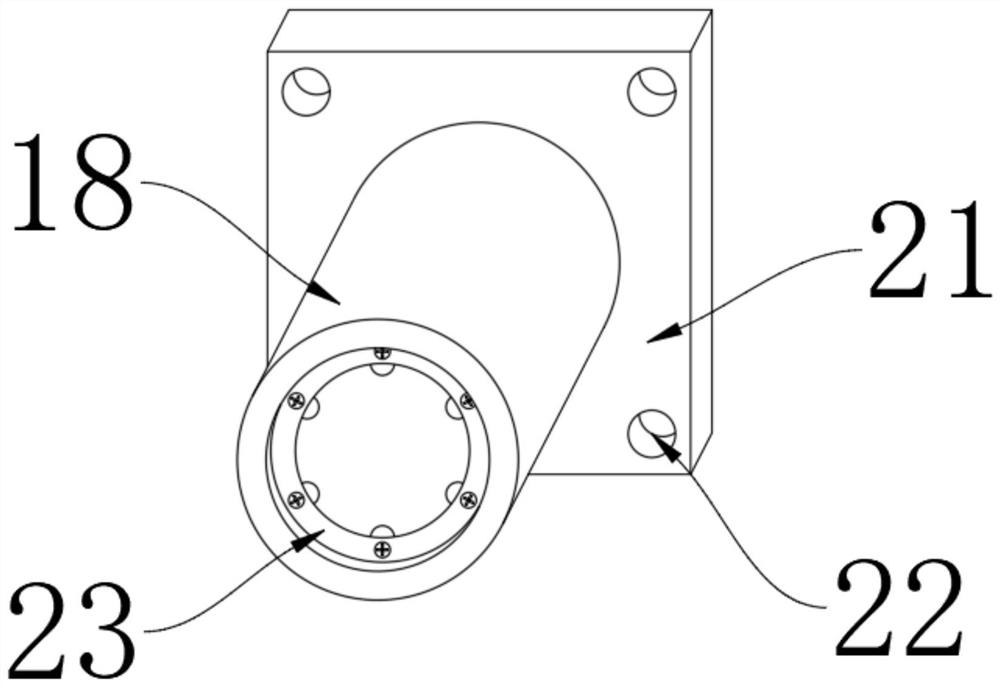

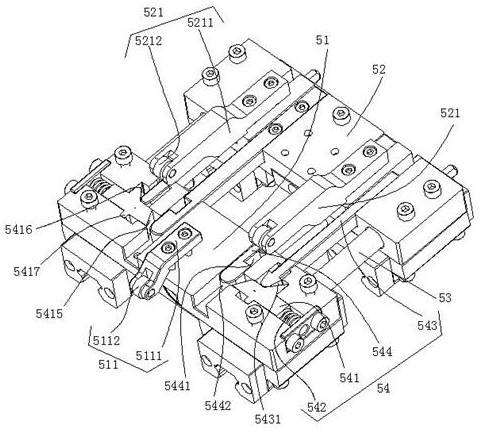

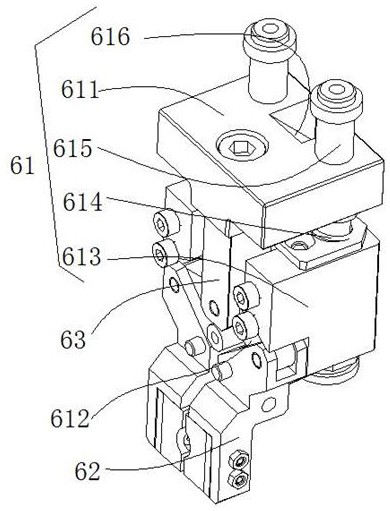

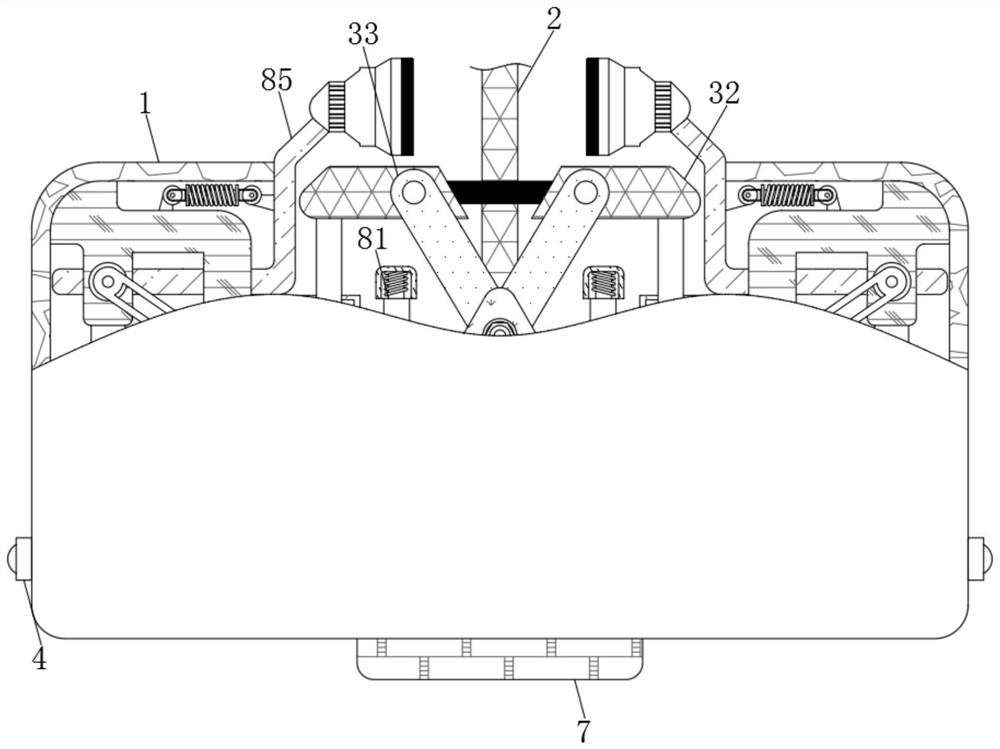

Discharging mechanism for wire harness detection machine and detection equipment applying same

PendingCN113787020AImprove crawling efficiencyReduce manufacturing costSortingControl systemControl engineering

The invention discloses a discharging mechanism for a wire harness detection machine. The discharging mechanism comprises a base, a first driving source, an under-actuated mechanism and a clamping jaw mechanism, wherein the first driving source is arranged on the base and used for providing power, the under-actuated mechanism is arranged on the base in a sliding mode, the first driving source can drive the under-actuated mechanism to move back and forth in a reciprocating mode and conduct leading positioning on the wire harness at the same time, the clamping jaw mechanism is movably arranged on the under-actuated mechanism, and the under-actuated mechanism can drive the clamping jaw mechanism to be opened and closed. The under-actuated mechanism is driven only by one power source, compared with other multi-power driving mechanisms, multi-power mutual cooperation is not needed, the debugging time is shortened, the response time of a control system is shortened, and mechanical action is higher in speed, smoother and more accurate.

Owner:厦门工学院

Horizontal parting core shooter

ActiveCN104588596BCompact structureThe operation of sand shooting is simple and convenientMoulding machinesEngineeringStructural engineering

The invention relates to a horizontal parting type core shooter which is mainly used for solving the problems that an existing horizontal parting type core shooter is small in mould operation space and inconvenient to take out materials after sand mould processing. The horizontal parting type core shooter is characterized by comprising a rack, wherein a sand adding funnel is arranged on the rack; a sand shooting valve mechanism is arranged at a position, corresponding to the sand adding funnel, of the rack; the sand shooting valve mechanism comprises a shooting head and a sand barrel; a base is arranged in the middle part of the rack; a horizontal movable workbench is arranged above the base; matched linear guide rails are arranged between the workbench and the base; a lifting table is arranged above the workbench; a lifting base is arranged in the middle of the workbench; mounting slots for fixing the mould are formed in the upper surface of the workbench and the lower surface of the workbench. The horizontal parting type core shooter is compact in structure, and realizes sand shooting operation simply and conveniently; the workbench horizontally moves, so that the space for operating the mould and taking out material from the sand mould is increased, the material-taking operation is convenient, and the production efficiency and the safety are improved.

Owner:温州威众机械科技有限公司

Anti-collision pipe fitting transfer device for building materials

InactiveCN113184382AIncrease linkageHigh degree of automationContainers to prevent mechanical damageElectrical resistance and conductancePipe fitting

The invention relates to the technical field of building materials, and discloses an anti-collision pipe fitting transfer device for building materials. The anti-collision pipe fitting transfer device comprises a shell, and a supporting column is arranged in the shell; a pipe fitting is inserted on the outer side of the supporting column and presses a placing plate to move downwards, a sliding block drives a metal sliding piece to move on the surface of a resistance coil of an insulation pipe, an electromagnet electrically connected with the metal sliding piece is electrified to generate magnetism, follow-up fixing operation is automatically triggered, the electromagnet attracts a metal block to move upwards, a movable rod synchronously moves upwards, and two clamping rods are close to each other. The clamping rods are close to the pipe fitting on the outer side of the supporting column to clamp the pipe fitting, the effect of automatic fixing is achieved, a rotating button is rotated, a screw rod on the outer side of the rotating button moves synchronously, the screw rod drives a pressing plate to move so as to push a movable block to move in a branch pipe at the top of a hydraulic box, a piston is pushed to move upwards under the action of generated pressure, the electromagnet loses magnetism and cannot attract the metal block at the top of the moving rod, the two clamping rods are far away from each other under the elastic action of the spring, the pipe fitting is not fixed any more, and the pipe fitting is convenient to detach.

Owner:佛山嘉绣微建材有限公司

A method for producing and forming an axial flow fan impeller

The invention discloses a method for producing and molding an axial flow fan impeller, comprising the following steps: a. Raw material processing: putting the raw materials required for producing blades into a mixer for raw material mixing; b. Injection molding: mixing the raw materials Put it into the injection molding machine and get the blades by injection molding; c. Component assembly: assemble the produced blades on the impeller to obtain the finished product; d. Finished product cleaning: put the assembled finished impeller into the clean water tank for cleaning, and remove the blades Dust and other impurities on the surface. The invention improves the raw material mixing effect and raw material processing efficiency under the action of the mixer, improves the entire blade processing technology, and improves the overall processing efficiency of the blade, so as to quickly complete the production of the blade after modeling, increase the output of the blade, and complete the amount of the blade Produce.

Owner:无锡佳谊林电气有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com