A method for producing and forming an axial flow fan impeller

A technology for axial flow fans and impellers, which is applied in the field of production and molding of axial flow fan impellers, can solve problems such as inability to fully mix raw materials, take a long time for software calculations, and prone to dead angles in stirring, so as to improve the mixing effect of raw materials and the processing efficiency of raw materials. Improve the mixing effect and improve the overall processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A method for forming an axial flow fan impeller, comprising the following steps:

[0025] a. Raw material processing: put the raw materials required for the production of blades into the mixer for raw material mixing; b. Injection molding: put the mixed raw materials into the injection molding machine, and inject the blades; The blades are assembled on the impeller to obtain the finished product; d. Finished product cleaning: put the assembled finished impeller into a clear water tank for cleaning to remove dust and other impurities on the surface of the blades; the injection molding machine is a prior art.

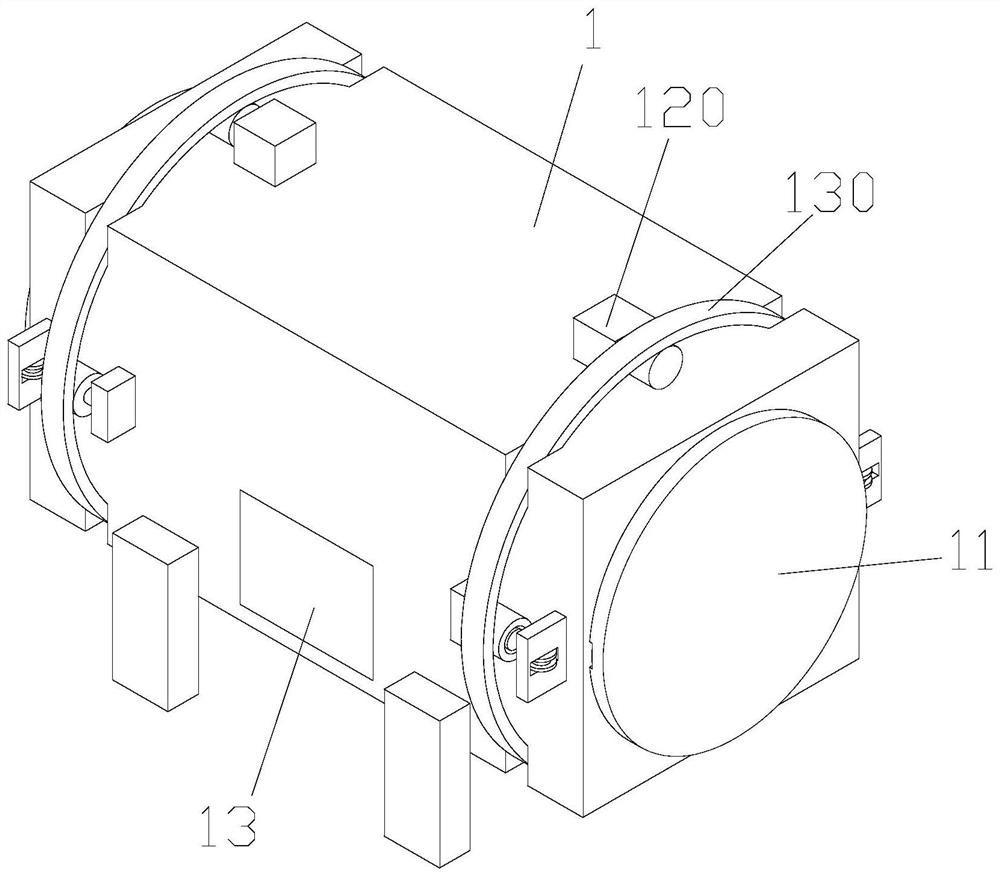

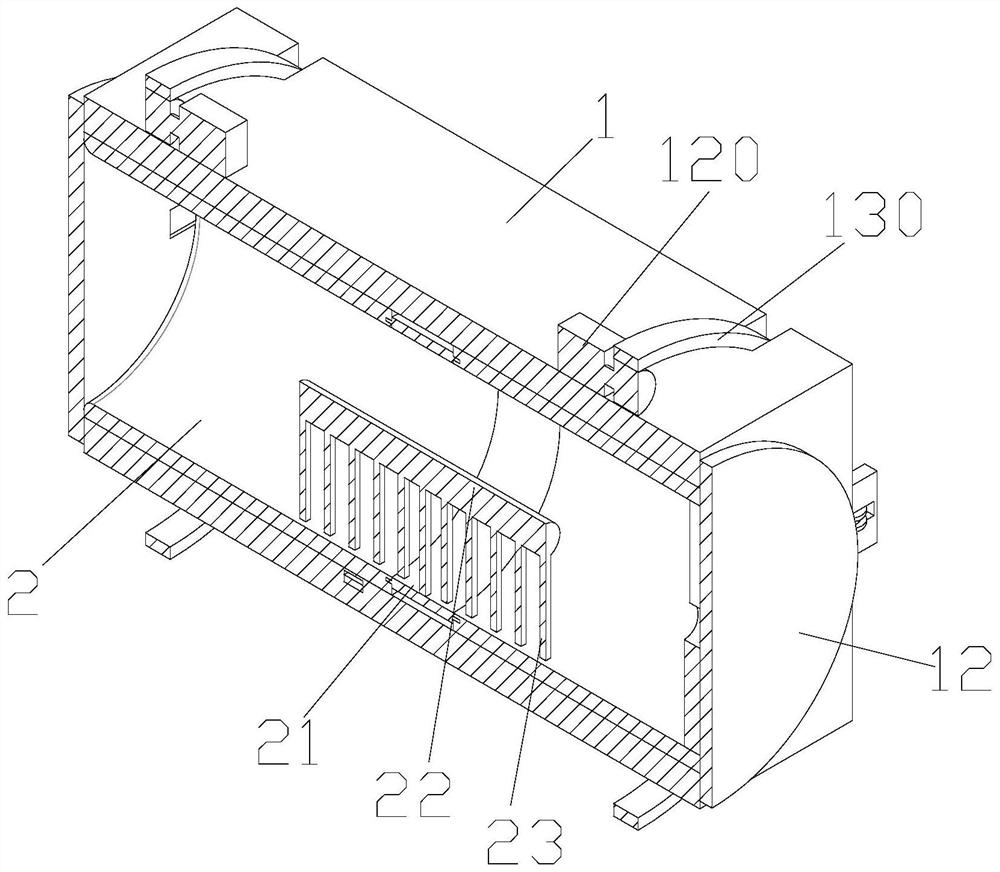

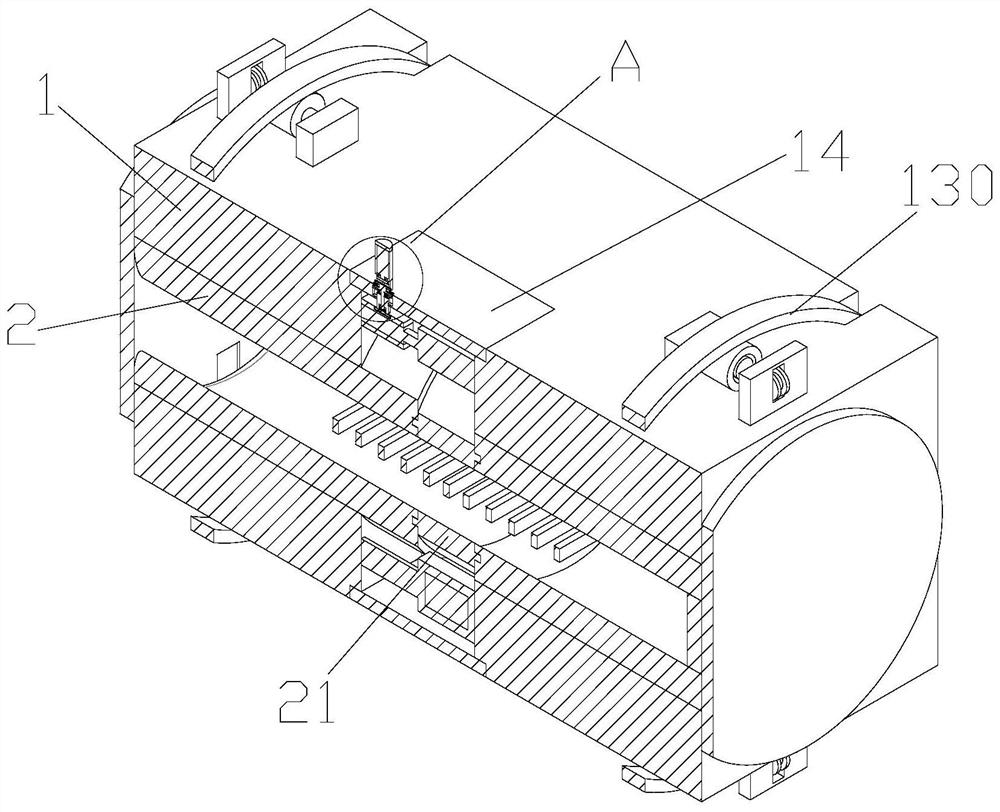

[0026] Such as Figure 1-9As shown, the mixer in the step a includes a mounting base 1 and a mixing bucket 2 rotatably arranged in the mounting base 1, the mixing bucket 2 is provided with a fracture, and a connecting ring 21 is provided in the fracture , the connecting ring 21 is provided with a connecting shaft 22, the connecting shaft 22 is fixedly connected in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com