Horizontal parting core shooter

A horizontal parting and core-shooting machine technology, which is applied to molding machines, casting molding equipment, metal processing equipment, etc., can solve the problems of low safety factor for workers, inconvenient material retrieving, small operating space, etc., and achieve material retrieving operation Convenience, improve production efficiency and safety, and increase the effect of reclaiming space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

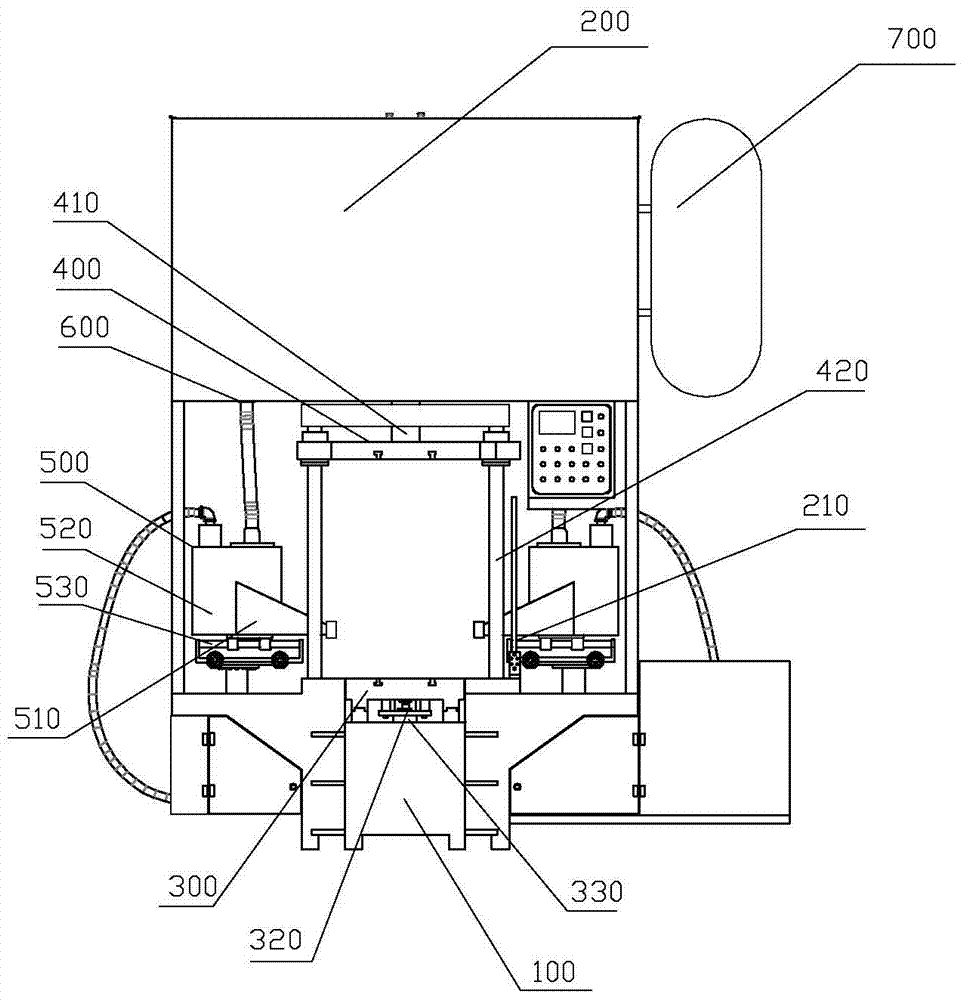

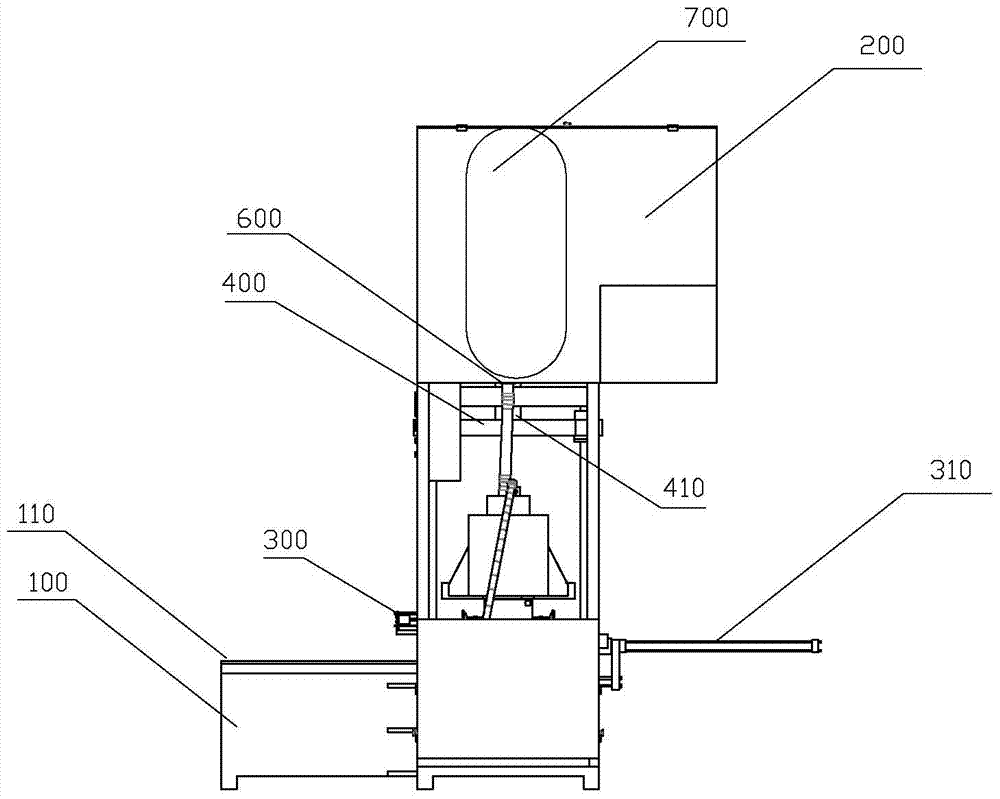

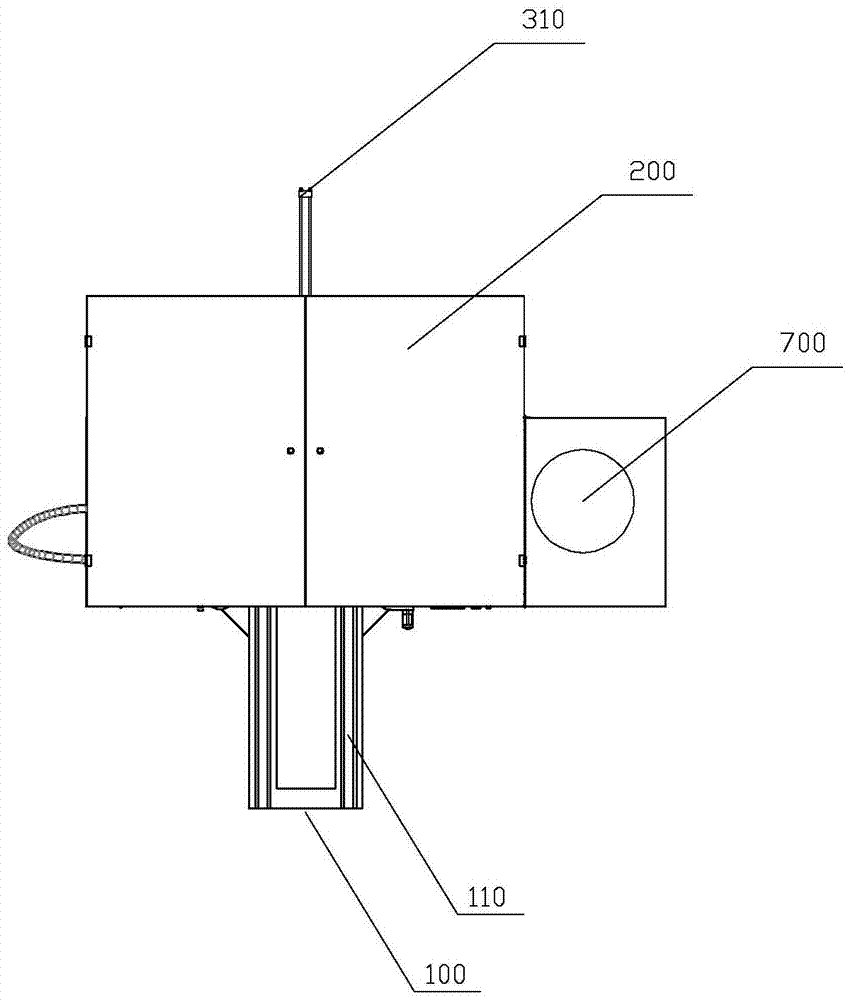

[0014] like Figure 1 to Figure 4 As shown, a horizontal type core shooting machine includes a frame 200, and sand funnels 600 are arranged on both sides of the frame 200, and a sand shooting valve mechanism is arranged under the frame 200 corresponding to the sand funnel 600 500, the sand shooting valve mechanism 500 includes a shooting head 510 and a sand cylinder 520, the direction of the shooting head 510 is in the horizontal direction, and the sand shooting valve mechanism 500 is connected to the frame 200 with a transmission device 530;

[0015] The middle part of the frame 200 is provided with a base 100, and a horizontally movable workbench 300 is arranged above the base 100. The workbench 300 is provided with a workbench positioning device corresponding to the position of the frame 200 in the horizontal direction. The workbench 300 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com