Electroplating device based on lead frame and electroplating method thereof

A lead frame and electroplating device technology, applied in electrodes, electrolysis components, electrolysis process, etc., can solve the problems of troublesome reclaiming operation, single use structure, unfavorable use, etc., and achieve convenient reclaiming operation, easy control, and increased effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

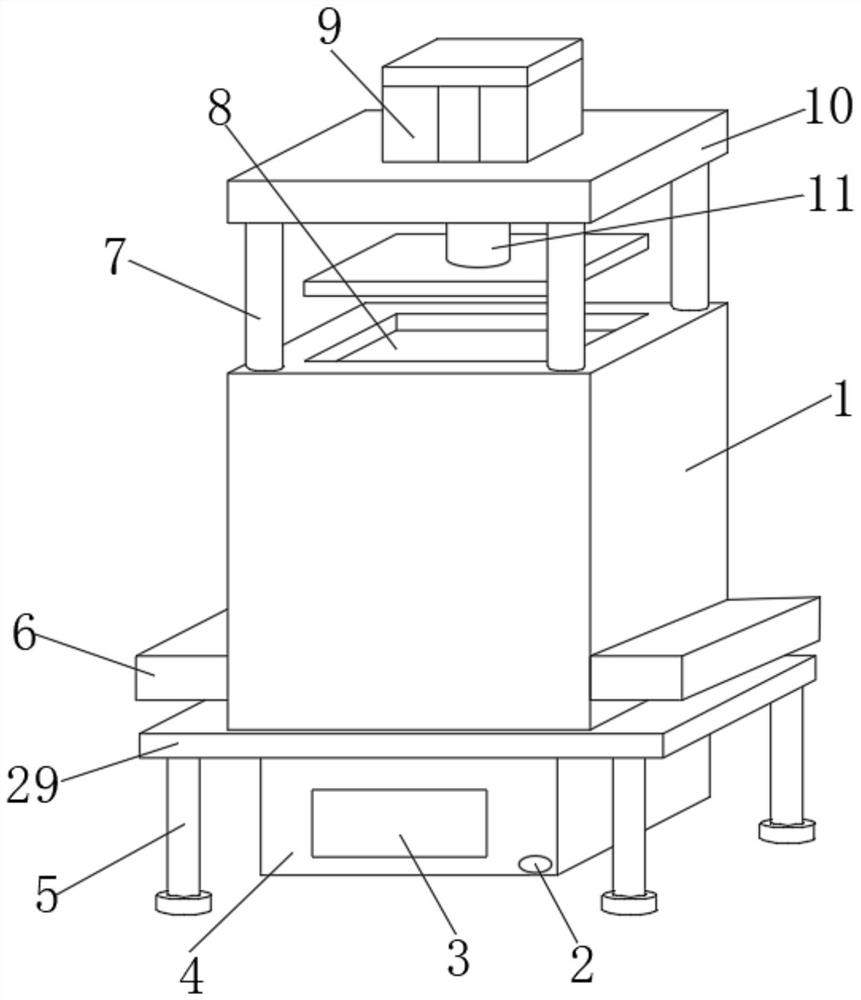

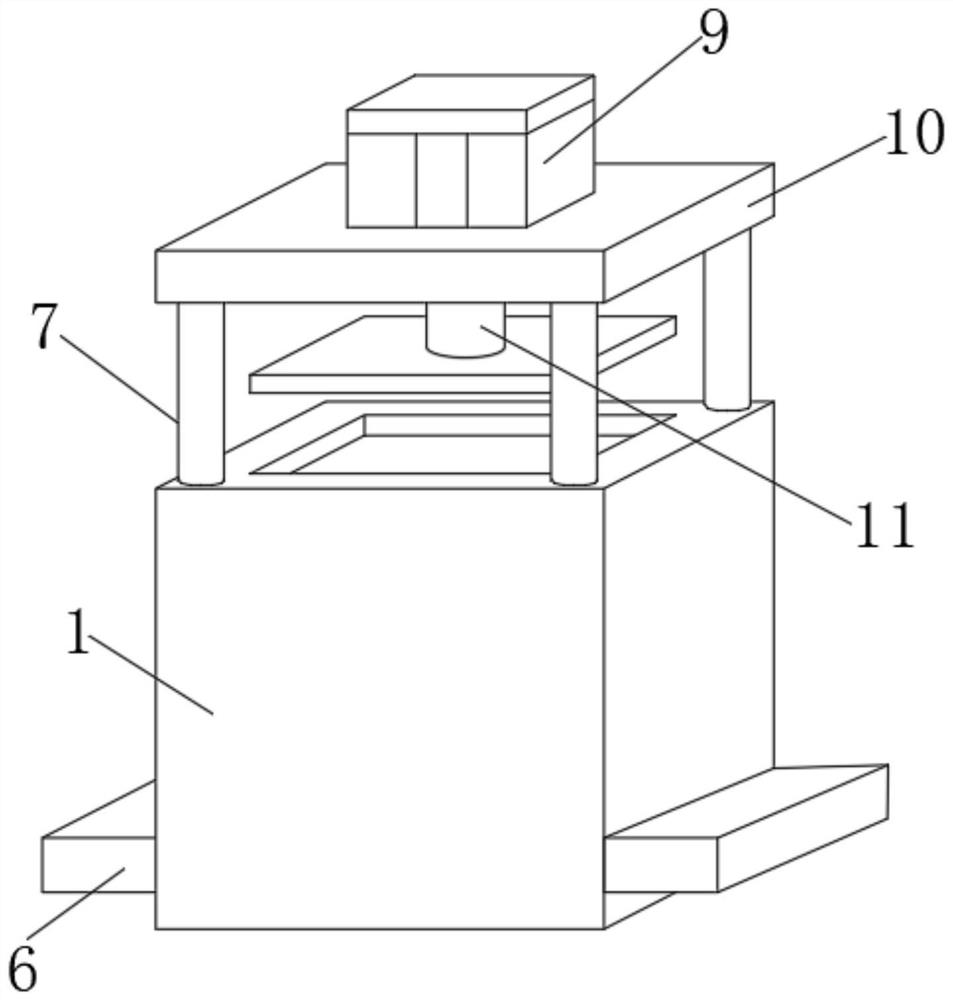

[0032] like Figure 1-6As shown, based on the electroplating device for lead frame, it includes a device main body 1, an installation support 29, a liquid outlet tank 4 and an electroplating function management platform. The front end of the liquid outlet box 4 is provided with an observation window 3 and a liquid outlet 2, the upper end of the device main body 1 is provided with a lifting column 7 at the four corners, the upper end of the lifting column 7 is equipped with a lifting plate 10, and the upper end of the device main body 1 is provided in the middle. There is an opening 8, and a foot 5 is mounted on the bottom of the mounting support 29.

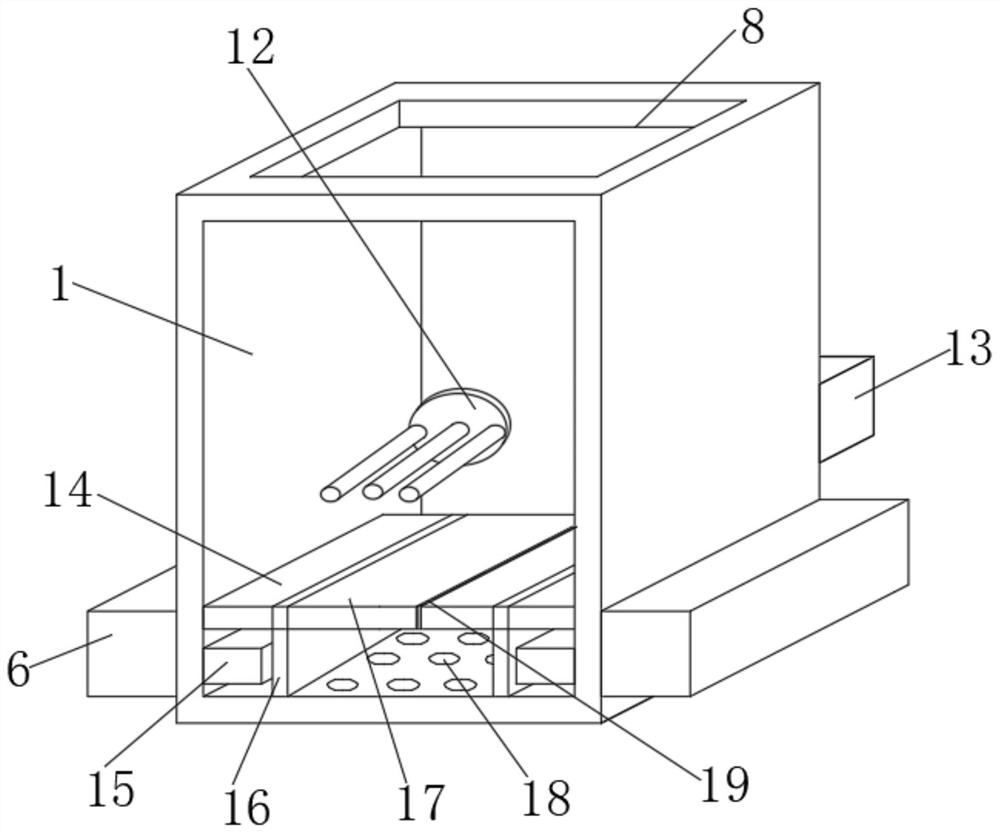

[0033] Further, a seat plate 14 is installed inside the device main body 1 , a telescopic plate 17 is arranged on the inner side of the seat plate 14 , a sealing gasket 19 is fixedly connected to the side of the telescopic plate 17 , and a sealing box is fixedly installed at the bottom of the seat plate 14 16. A heater 15 is ins...

Embodiment 2

[0037] On the basis of Example 1, as Figure 1-6 As shown, based on the electroplating device for lead frame, it includes a device main body 1, an installation support 29, a liquid outlet tank 4 and an electroplating function management platform. The front end of the liquid outlet box 4 is provided with an observation window 3 and a liquid outlet 2, the upper end of the device main body 1 is provided with a lifting column 7 at the four corners, the upper end of the lifting column 7 is equipped with a lifting plate 10, and the upper end of the device main body 1 is provided in the middle. There is an opening 8, and a foot 5 is mounted on the bottom of the mounting support 29.

[0038] Further, a cylinder 9 is installed on the upper end of the lifting plate 10, a lifting rod 11 is arranged at the bottom of the cylinder 9, a positioning connecting seat 23 is installed at the bottom position of the lifting rod 11, and a material reclaiming seat 27 is installed at the bottom positi...

Embodiment 3

[0041] On the basis of Embodiment 1 and Embodiment 2, as Figure 1-6 As shown, based on the electroplating device for lead frame, it includes a device main body 1, an installation support 29, a liquid outlet tank 4 and an electroplating function management platform. The front end of the liquid outlet box 4 is provided with an observation window 3 and a liquid outlet 2, the upper end of the device main body 1 is provided with a lifting column 7 at the four corners, the upper end of the lifting column 7 is equipped with a lifting plate 10, and the upper end of the device main body 1 is provided in the middle. There are 8 openings.

[0042] Further, the electroplating function management platform is connected with a state monitoring module, the state monitoring module is connected with a PLC control unit, the PLC control unit is connected with a display module and a state control module, and the state monitoring module includes a temperature monitoring module, an electroplating m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com