Discharging mechanism for wire harness detection machine and detection equipment applying same

A technology of unloading mechanism and wire harness detection, which is applied in the field of detection equipment and wire harness detection equipment, can solve problems such as slow production speed, low production efficiency, and easy fatigue of workers, achieve accurate detection results, reduce manual errors, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to enable those skilled in the art to better understand the present invention, the following will clearly and completely describe the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are only a part of the present invention, rather than Full examples.

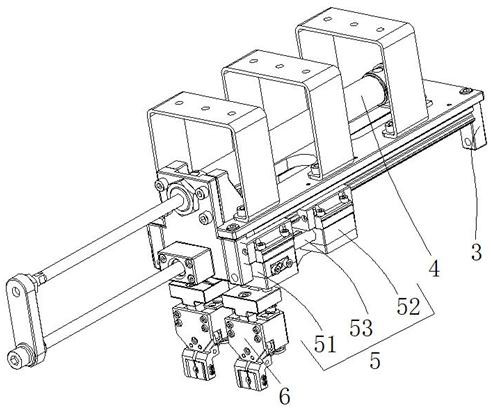

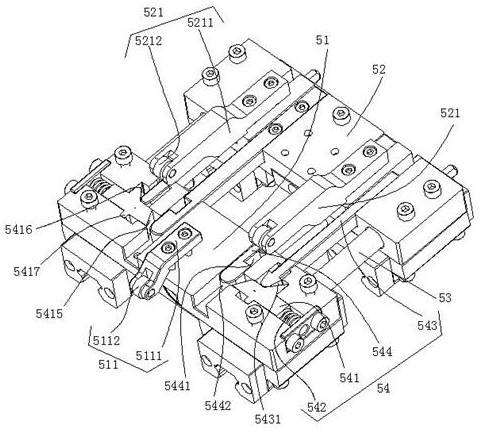

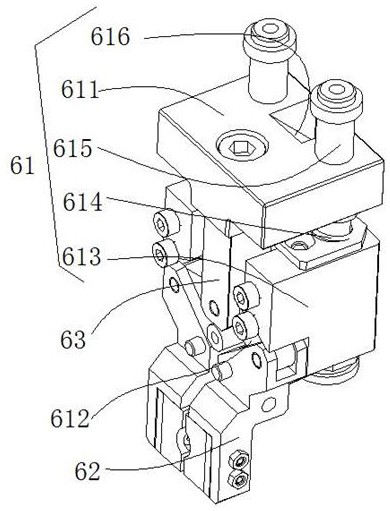

[0041] Please refer to the attached figure 1 ~ attached Figure 9 As shown: a wire harness testing machine provided by the present invention includes a frame 1 , a discharge mechanism, a conduction test mechanism 2 , a correction mechanism 8 , a drop and visual detection mechanism 9 and a conveying mechanism 10 . Wherein, the frame 1 can usually be made of metal materials such as steel, aluminum, etc., and is used for its supporting operation. They are all arranged inside the frame 1. The correction mechanism 8 is arranged on the frame 1, and is used to limit the feeding direction and the feeding position of the terminals at both ends of the wire harness to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com