Forming device of novel rubber spherical hinge mold opening mode and opening method of novel rubber spherical hinge mold opening mode

A technology of rubber ball hinges and opening methods, which is applied to household appliances, other household appliances, household components, etc., and can solve problems such as inability to meet batch processing and production, unstable product quality, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

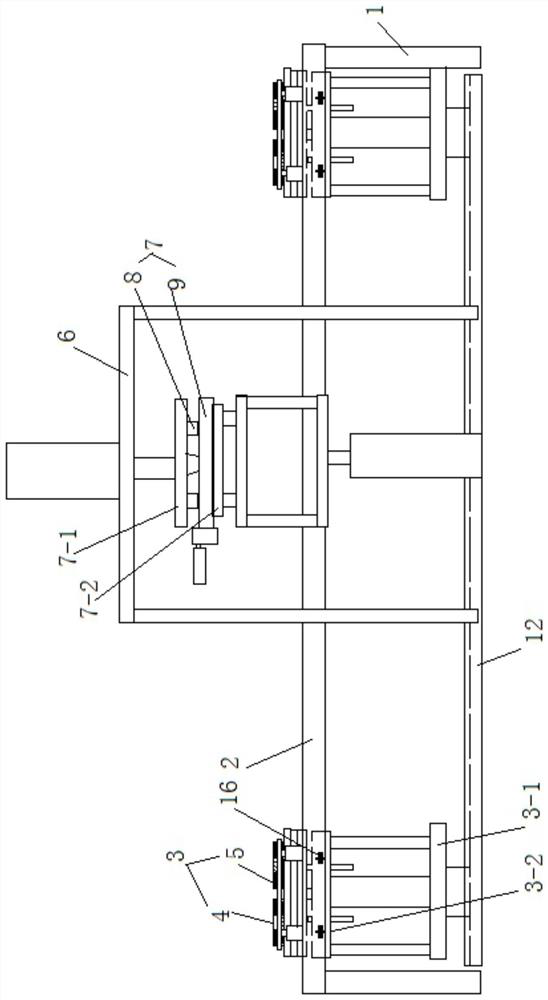

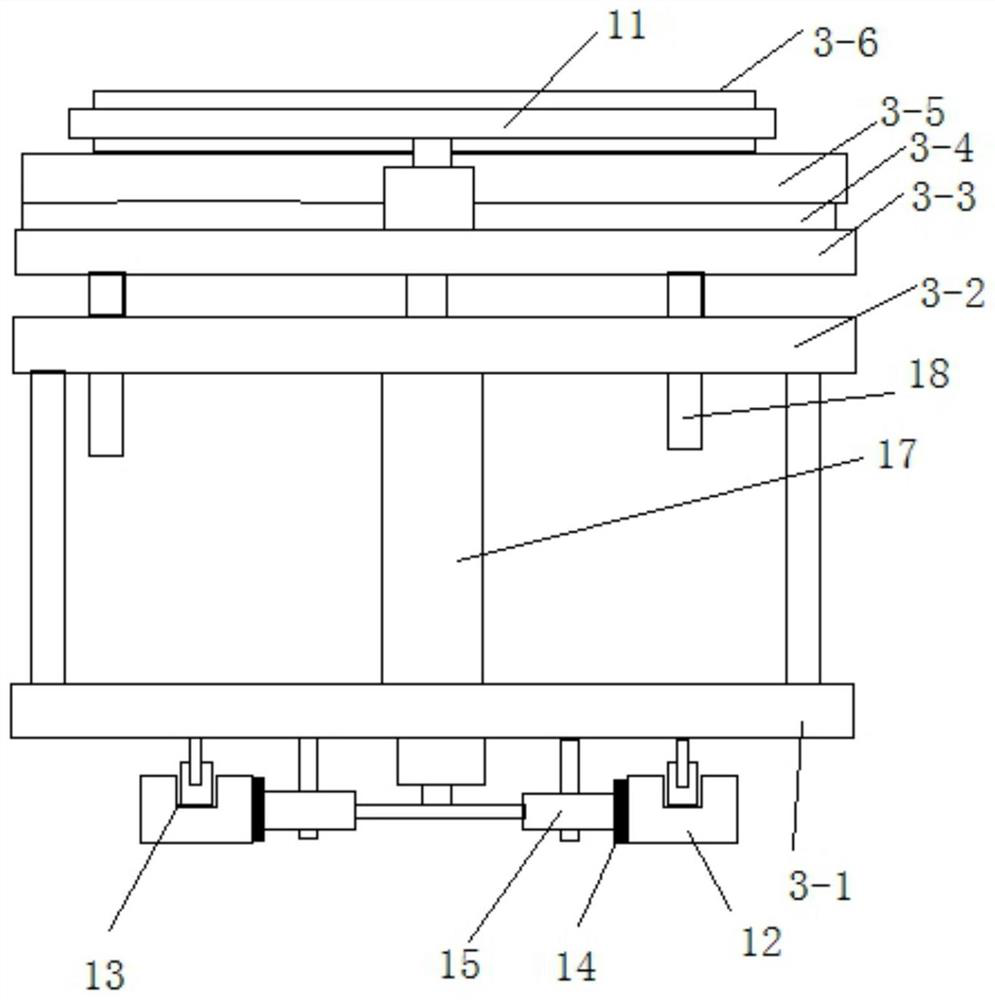

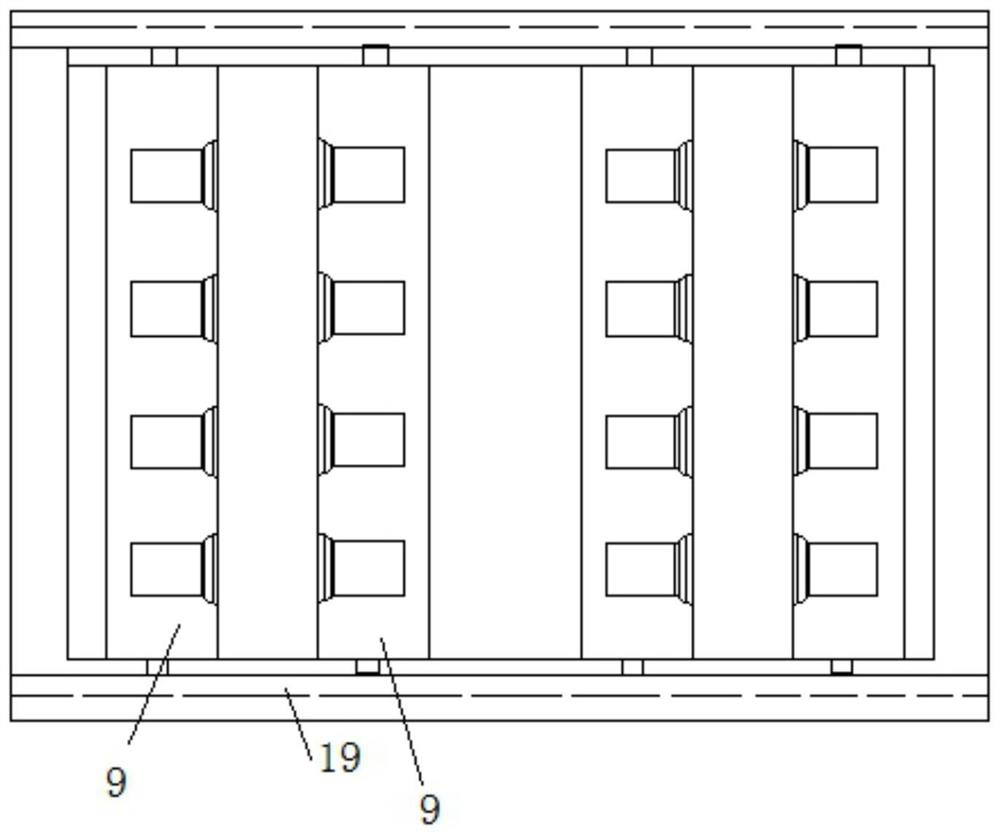

[0031] See attached picture.

[0032] A molding device of a new type of rubber ball hinge mold opening method, including a frame 1, on which two fixed beams 2 arranged side by side are mounted, the middle area between the two fixed beams 2 is a molding station, and the two end areas Both are loading and unloading stations, and two movable lower mold assemblies 3 are guided and installed between the fixed beams 2. The lower mold assembly 3 includes a fixed lower mold body 4 and a movable lower mold body 5; Top plate 6, upper mold assembly 7 is installed below the top plate 6, upper mold assembly 7 includes fixed upper mold body 8 and movable upper mold body 9, the movement of movable upper mold body 9 is through the gear pull mechanism at its two ends 10 drive, the upper end surfaces of the fixed lower mold body 4 and the movable lower mold body 5 and the lower end surfaces of the fixed upper mold body 8 and the movable upper mold body 9 are respectively provided with cavities ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com