Anti-collision pipe fitting transfer device for building materials

A technology for transferring devices and building materials, applied in packaging, transportation and packaging, containers to prevent mechanical damage, etc., can solve problems such as increasing the surface paint film, staff discomfort, and falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

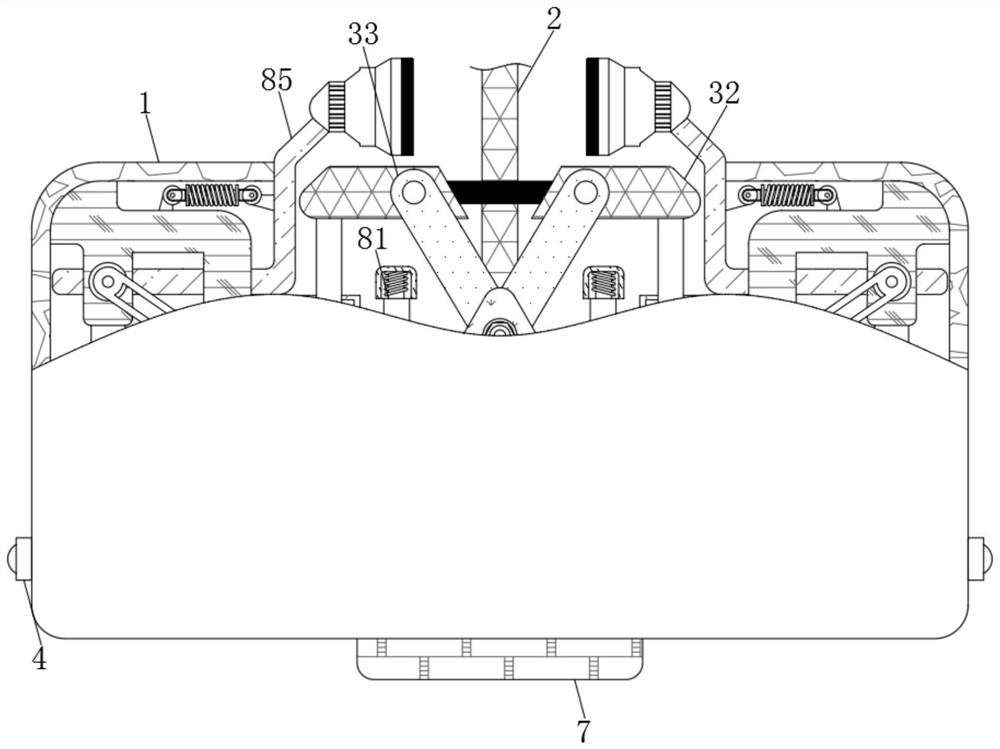

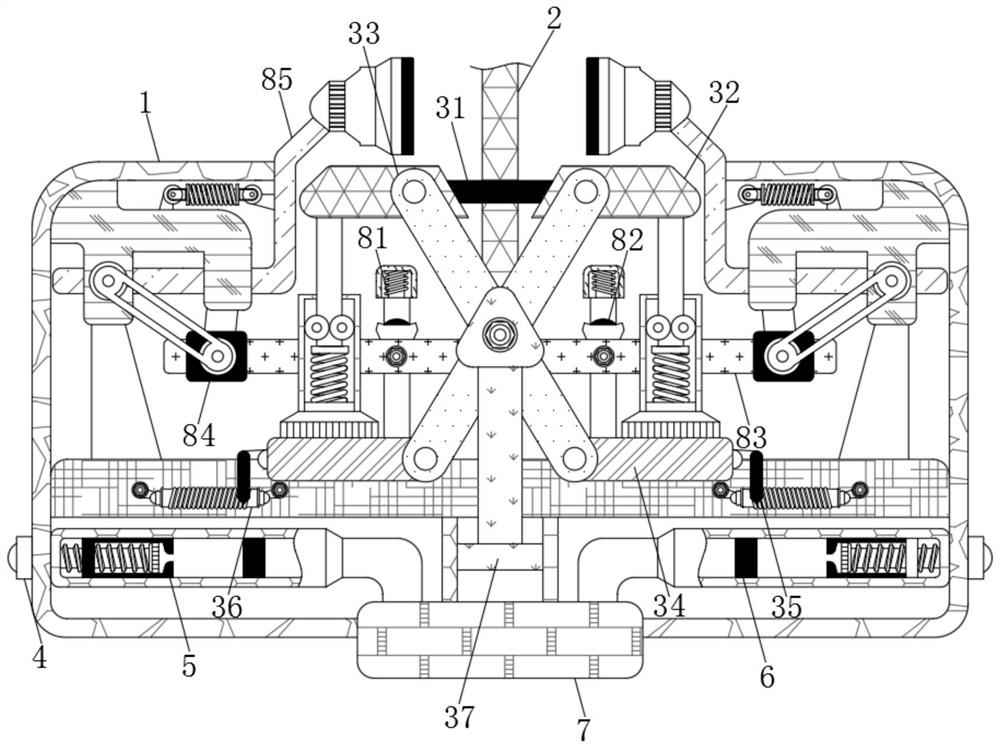

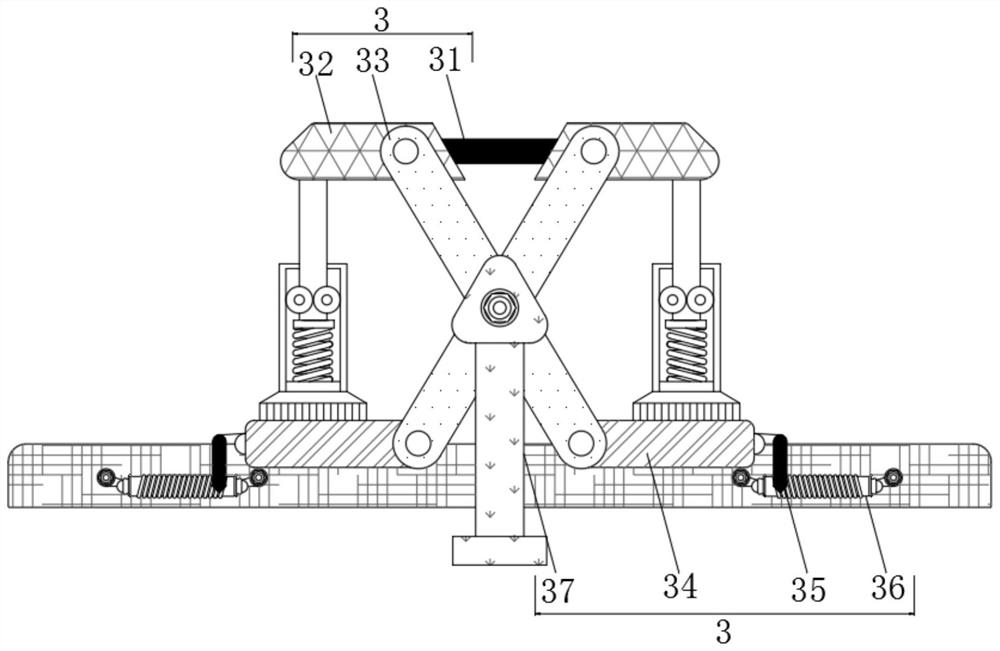

[0026] See figure 2 and image 3 A anti-collision type pipe transfer device for building materials, including the outer casing 1, and the inside of the outer casing 1 is provided with a strut 2, and the top portion of the strut 2 is fixedly connected, and the strut 2 is provided with a touch clutch mechanism 3, touch The clamp mechanism 3 includes a plate 31, and a through hole is opened inside the placed plate 31, and the size is fitted with the size of the strut 2, and the bottom portion of the placing plate 31 is fixedly connected with two specifications of the same strut, and the outer side of the struts. There is a sleeve, the strut is inserted inside the sleeve and is movable between the inner wall, and the sleeve is disposed at the top of the slider 34, and the struts are rotated and connected to two species of the same wheel, and the runner The inner wall of the sleeve is passed, and both sides of the placing plate 31 are inserted with a sheet 32, and the cartridge 32 has t...

Embodiment 2

[0029] See figure 2 and Figure 4 An anti-hit-type tubular transfer device for building materials, including the outer casing 1, and the inner portion of the outer casing 1 is provided, and the top portion of the strut 2 is fixedly connected, and the strut 2 is provided with a tie clip mechanism 3, housing. 1 The surface rotates to connect the buttons 4, the buttons 4 have two and the specifications are the same, the outer side of the buttons 4 is fixed, and the inside of the outer casing 1 is fixedly connected, the outer side of the screw is attached to the outer side of the button 4, the outer side of the button 4 And in the outer casing 1 is slidably connected to the block 5, the pressure plate 5 is composed of the card plate and the push rod, and the pressure plate 5 is located inside the outer side of the hydraulic tank 7, and the outer side of the pressure plate 5 is located in the inner wall of the pipe, and the push rod card is in the inner wall. In the card slot, the movem...

Embodiment 3

[0032] See Figure 1-4 A anti-collision type pipe transfer device for building materials, including the outer casing 1, and the inside of the outer casing 1 is provided with a strut 2, and the top portion of the strut 2 is fixedly connected, and the strut 2 is provided with a touch clutch mechanism 3, touch The clamp mechanism 3 includes a plate 31, and a through hole is opened inside the placed plate 31, and the size is fitted with the size of the strut 2, and the bottom portion of the placing plate 31 is fixedly connected with two specifications of the same strut, and the outer side of the struts. There is a sleeve, the strut is inserted inside the sleeve and is movable between the inner wall, and the sleeve is disposed at the top of the slider 34, and the struts are rotated and connected to two species of the same wheel, and the runner The inner wall of the sleeve is passed, and both sides of the placing plate 31 are inserted with a sheet 32, and the cartridge 32 has two and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com