Robot grinding machine fixing device with high flexibility

A fixed device and robot technology, applied in the direction of grinding drive device, grinding machine, grinding frame, etc., can solve the problem of inability to grind the workpiece to be ground, and achieve the requirements of grinding process, make up for insufficient stroke, and avoid rotation adjustment errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

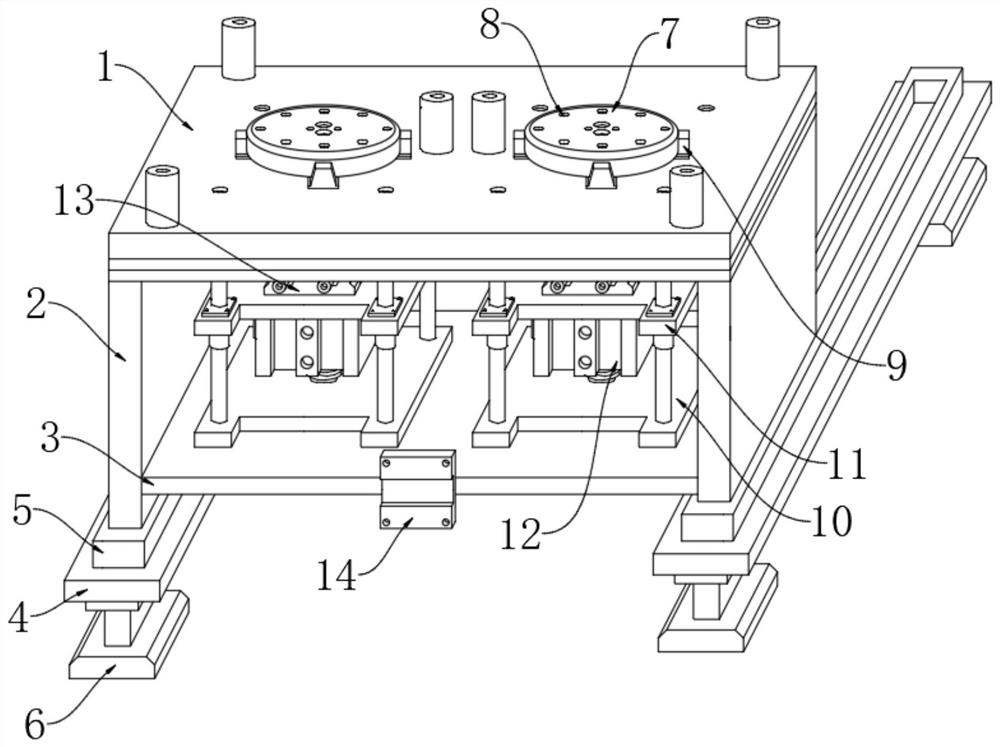

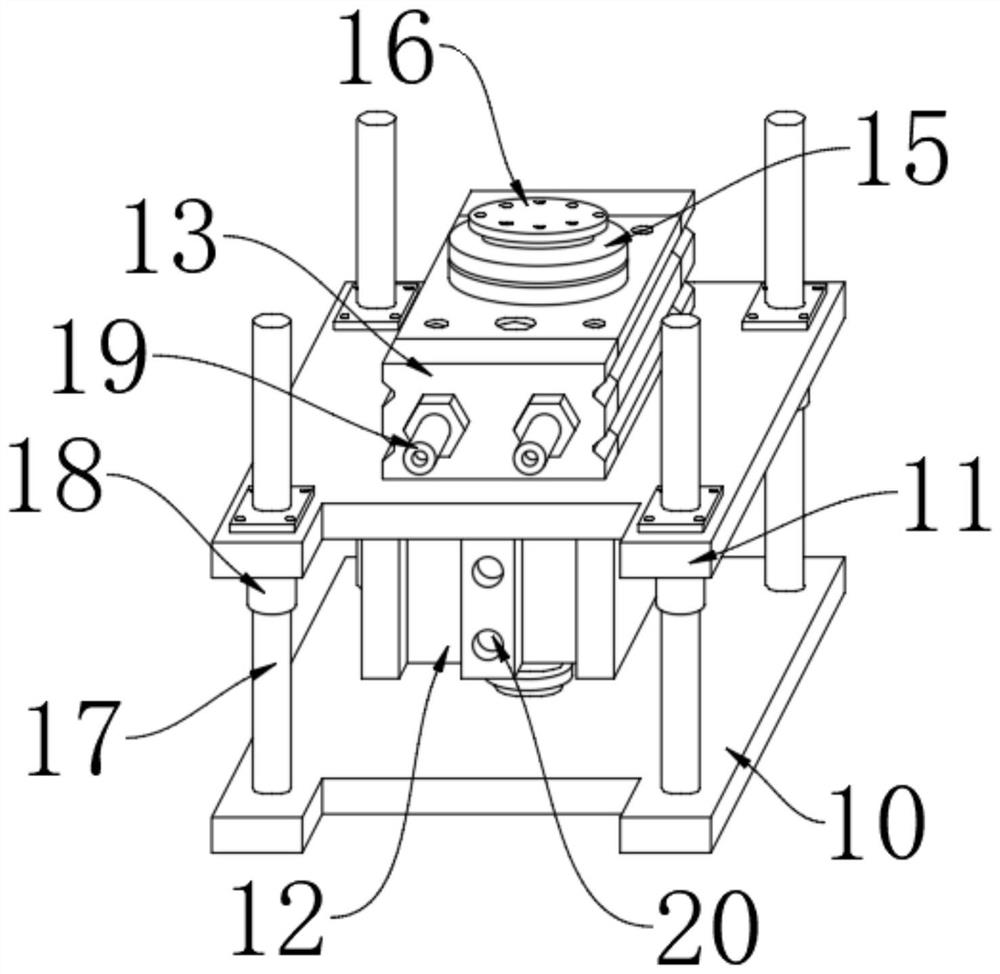

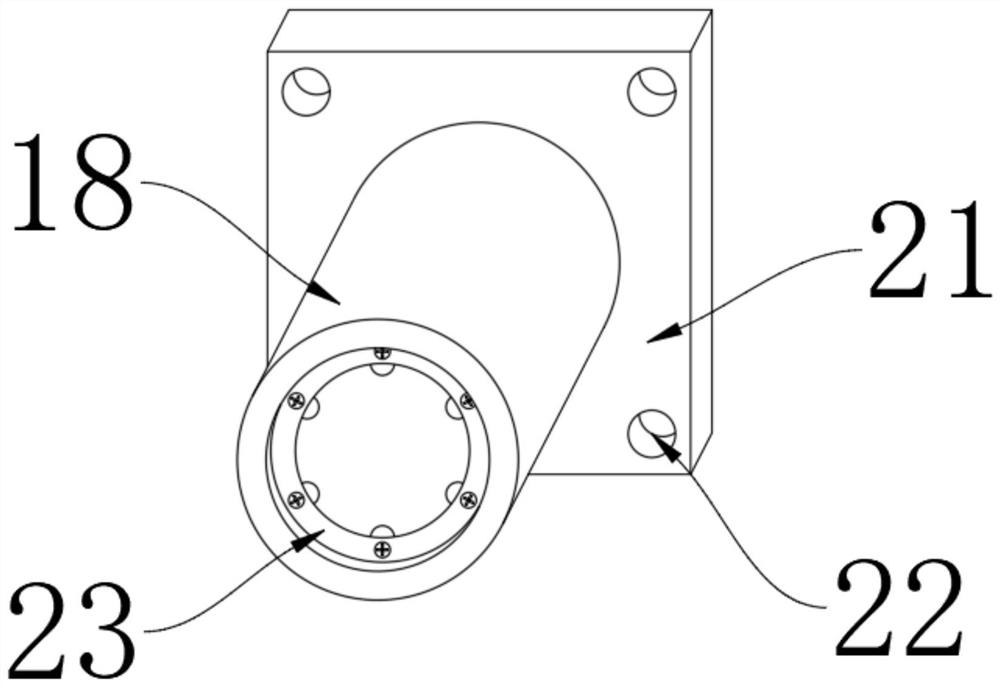

[0028] see Figure 1-6 , an embodiment provided by the present invention: a highly flexible robot grinding machine fixing device, including a robot grinding table 1, a grinding table bracket 2 is provided at the lower end of the robot grinding table 1, and an inner wall of the grinding table bracket 2 is provided with a Horizontal carrier plate 3, the upper end of the horizontal carrier plate 3 is provided with a static plate 10, the upper end of the static plate 10 is provided with a lifting cylinder 12, the output end of the lifting cylinder 12 is provided with a movable plate 11, and the upper end of the movable plate 11 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com