Chip resistor conductor layer drying equipment and using method thereof

A technology for chip resistors and drying equipment, which is used in the cleaning method of tools, resistors, resistors manufacturing, etc., to avoid dust blockage, reduce friction, and smooth moving operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

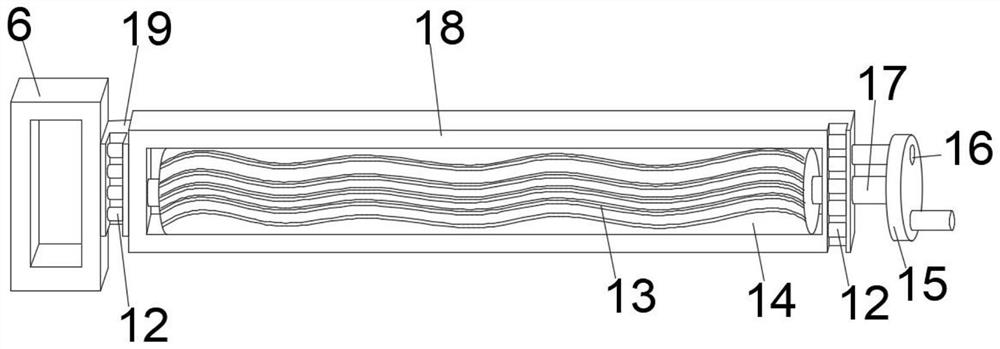

[0032]The cross-section of the fixed brush head 13 is a wave-shaped structure, and the outer surface of one end of the movable sliding frame 18 is fixedly equipped with a sliding card holder 19, and the inner side of the sliding card holder 19 and the other end of the moving sliding frame 18 are all movably installed with several groups of moving parts. The card wheel 12 utilizes the fixed brush head 13 of wave-shaped structure to clean up the accumulated dust in the exhaust hood 5 and the fixed side box 8 through the fixed brush head 13 when the movable slide frame 18 moves, and simultaneously utilizes the mobile card The setting of the wheel 12 can facilitate the movement of the sliding frame 18 for push-pull operation.

[0033] The moving slide frame 18 and the rolling brush rod 14 are movably connected by the docking rotating rod 17, and the outer surface of one end of the docking rotating rod 17 is fixedly equipped with a rotating disc 15, and the inner side of the rotatin...

Embodiment 2

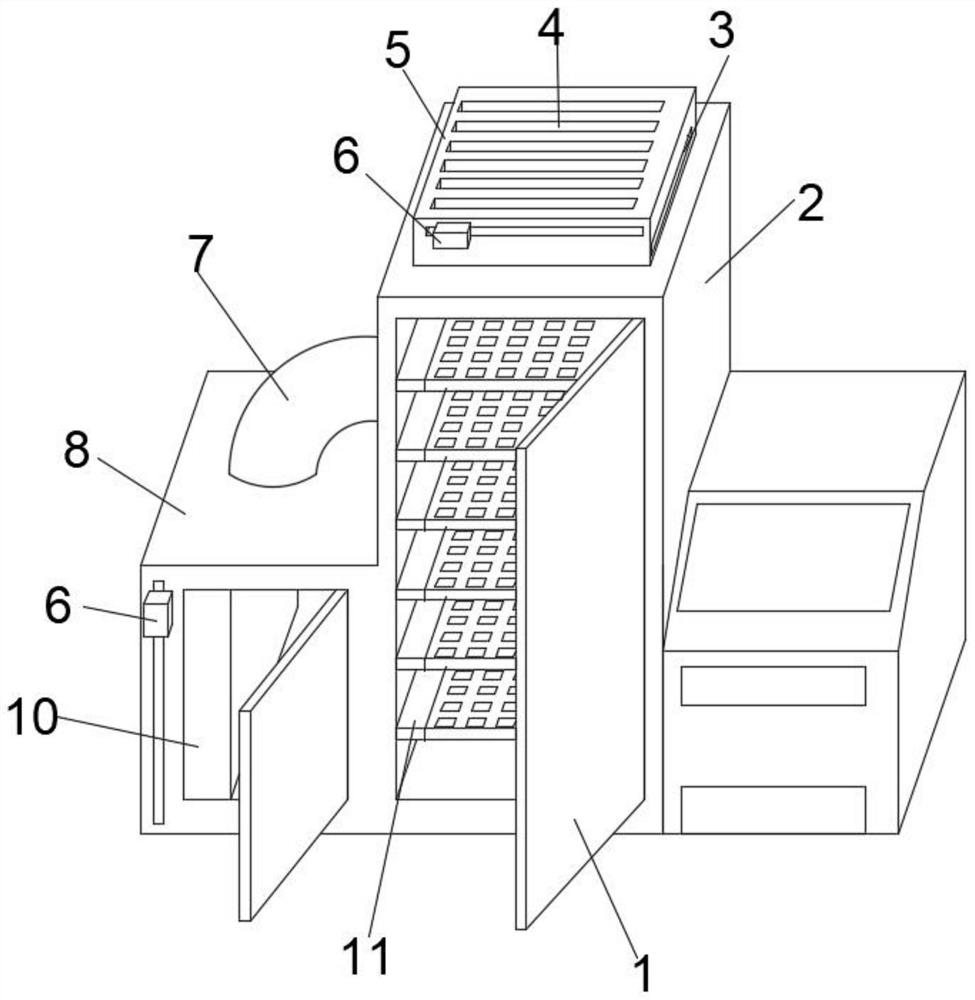

[0035] The inside of the fixed side box 8 is fixedly equipped with a dryer 10, and the inside of the fixed side box 8 and the exhaust hood 5 are provided with a dust discharge groove 3 and an air flow hole 4. Through the setting of the dust discharge groove 3, the fixed side box can 8 and the exhaust hood 5 complete the dust removal operation, the dust in the fixed side box 8 and the exhaust hood 5 is discharged, and the drying machine 10 cooperates with the connecting pipe 7 to perform drying and heating operations on the inside of the drying cabinet 2.

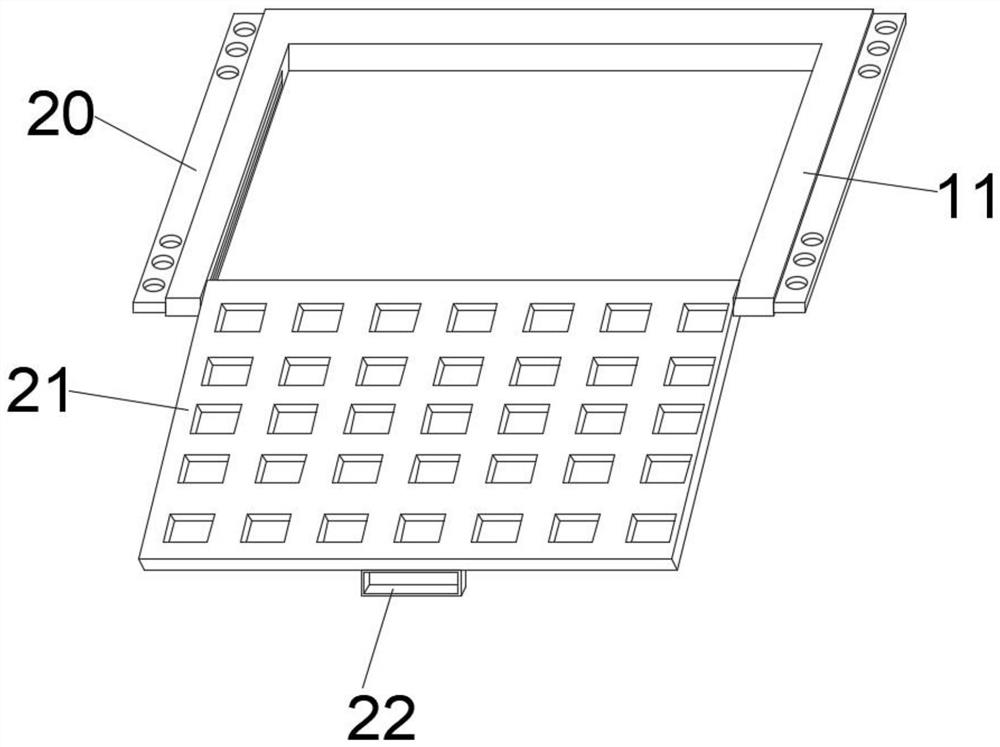

[0036] Two sets of push-pull grooves 9 are provided on the inner side of the fixed clamp 11, and two sets of positioning clamps 20 are fixedly installed on the outer surface of the side of the fixed clamp 11, and the positioning clamps 20 are passed between the fixed clamp 11 and the drying cabinet 2. Fixed connection, the upper part of the material setting plate 21 is provided with a rectangular notch, and the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com