Patents

Literature

36results about How to "Easy to add ingredients" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

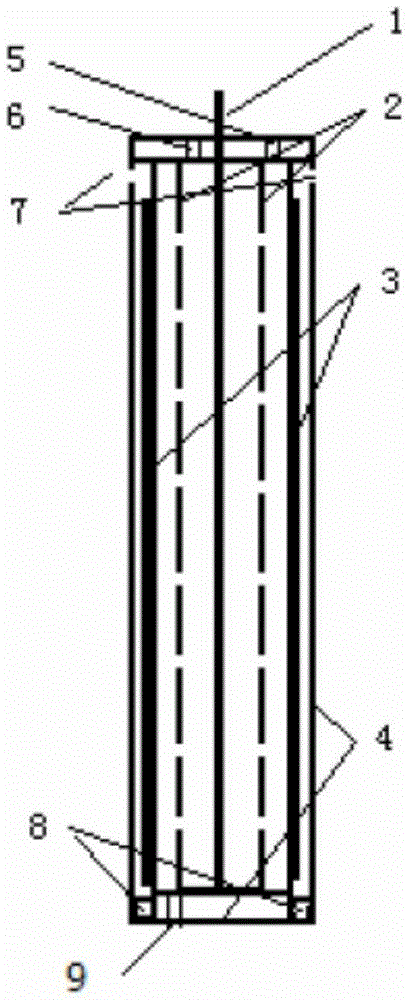

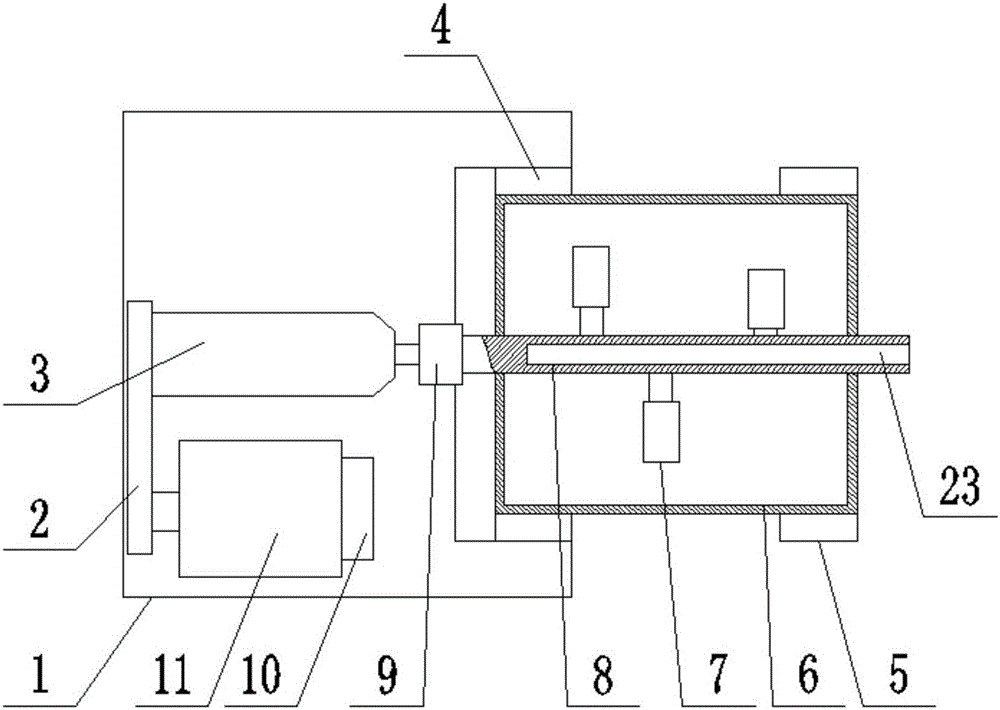

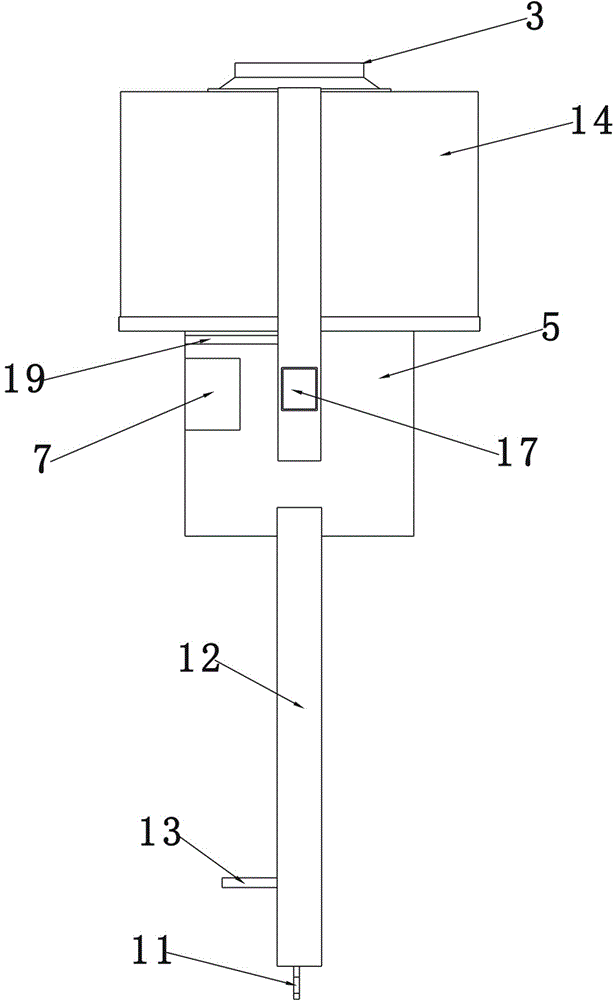

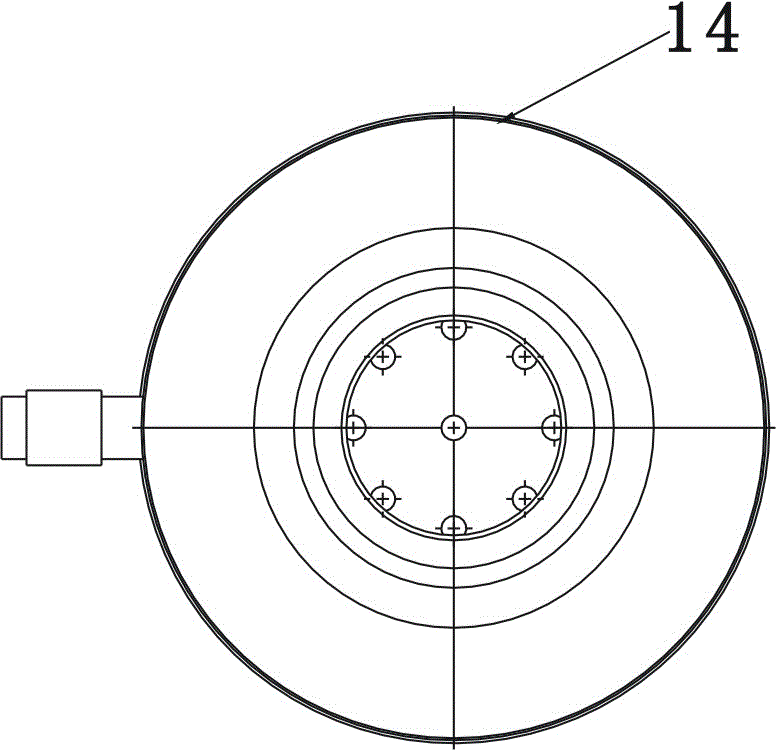

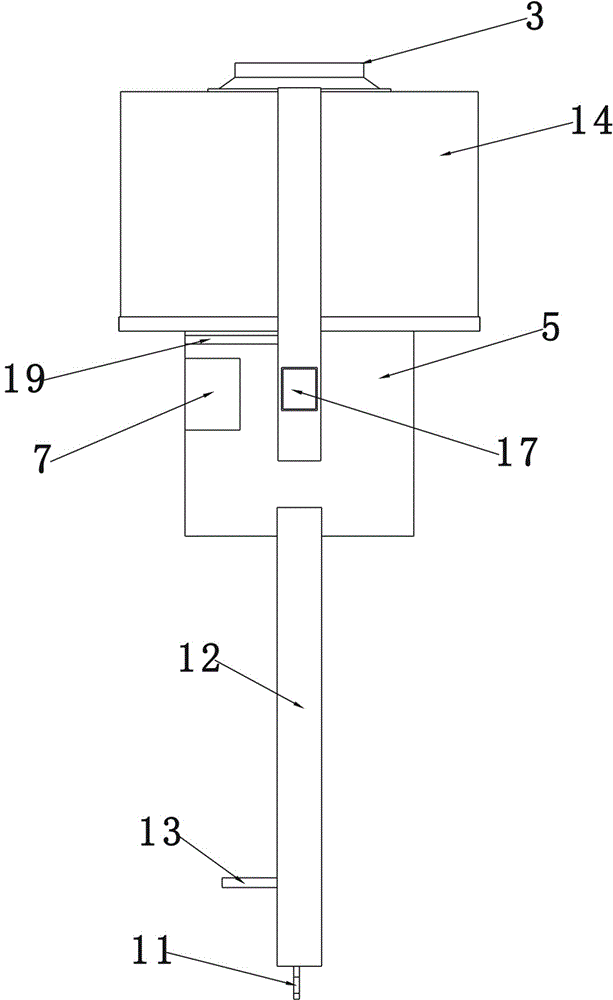

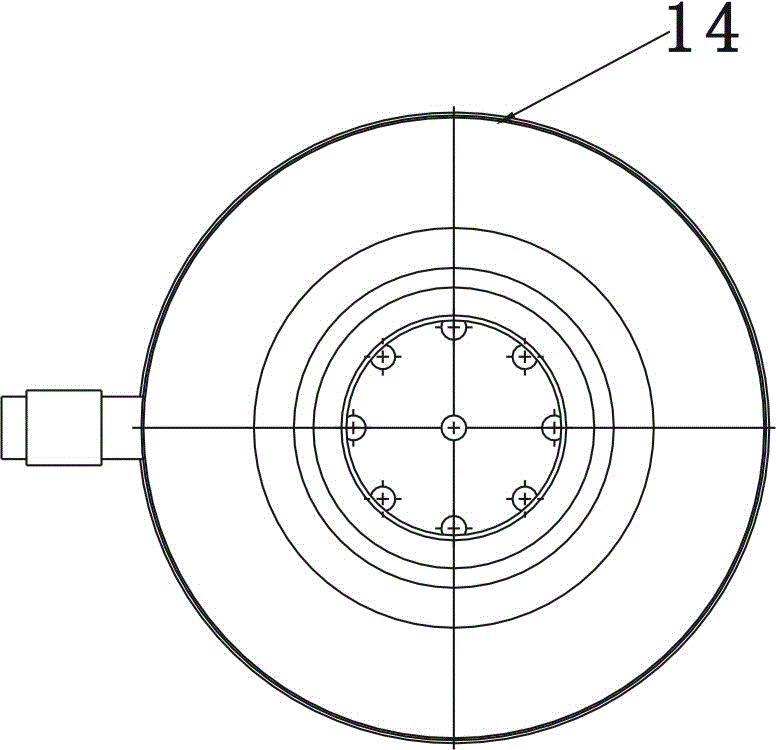

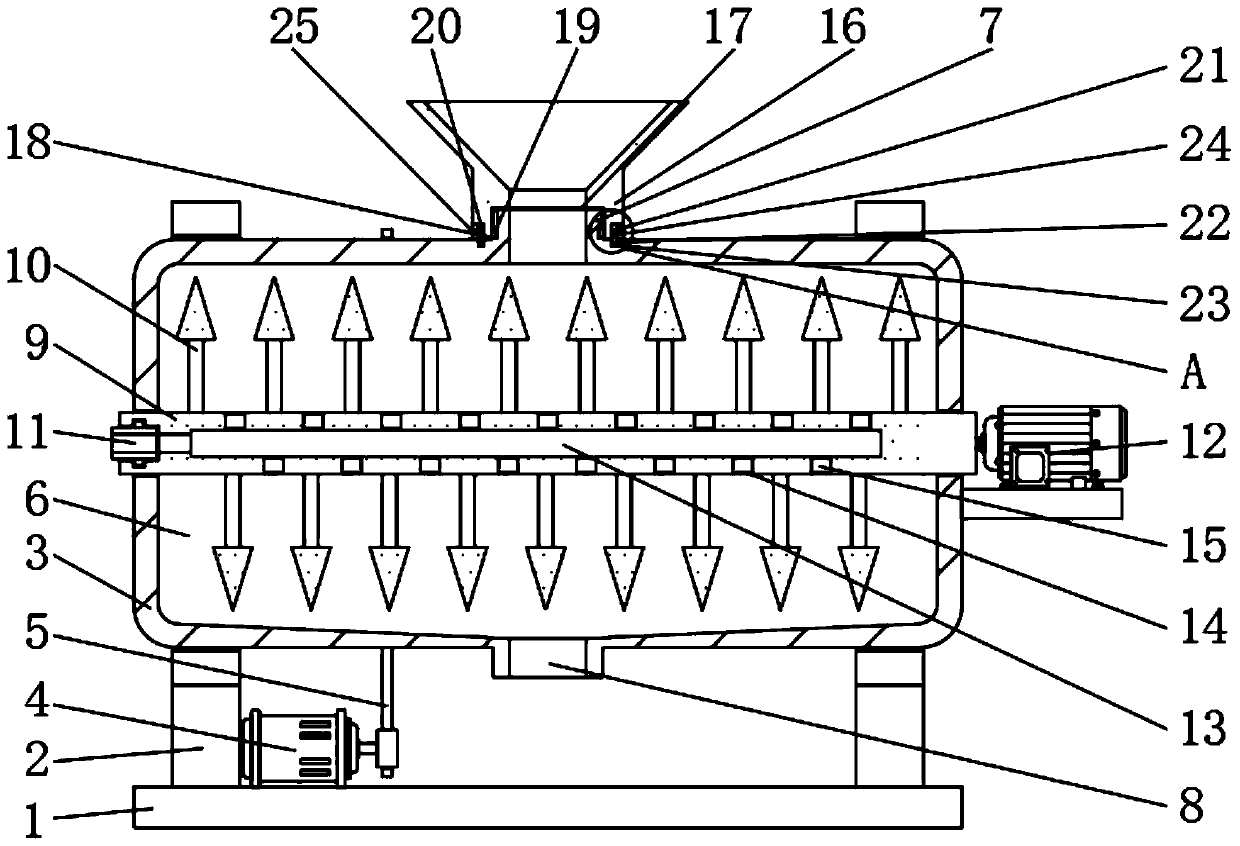

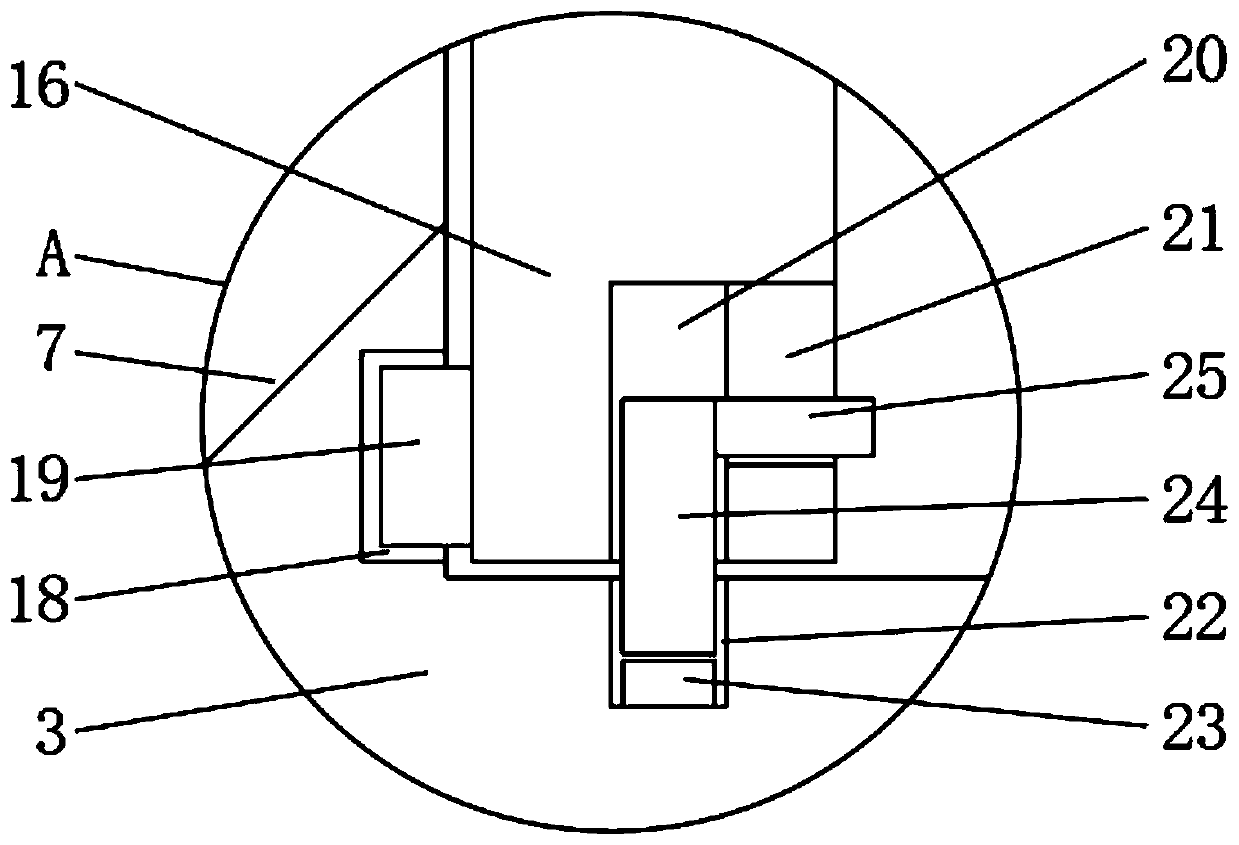

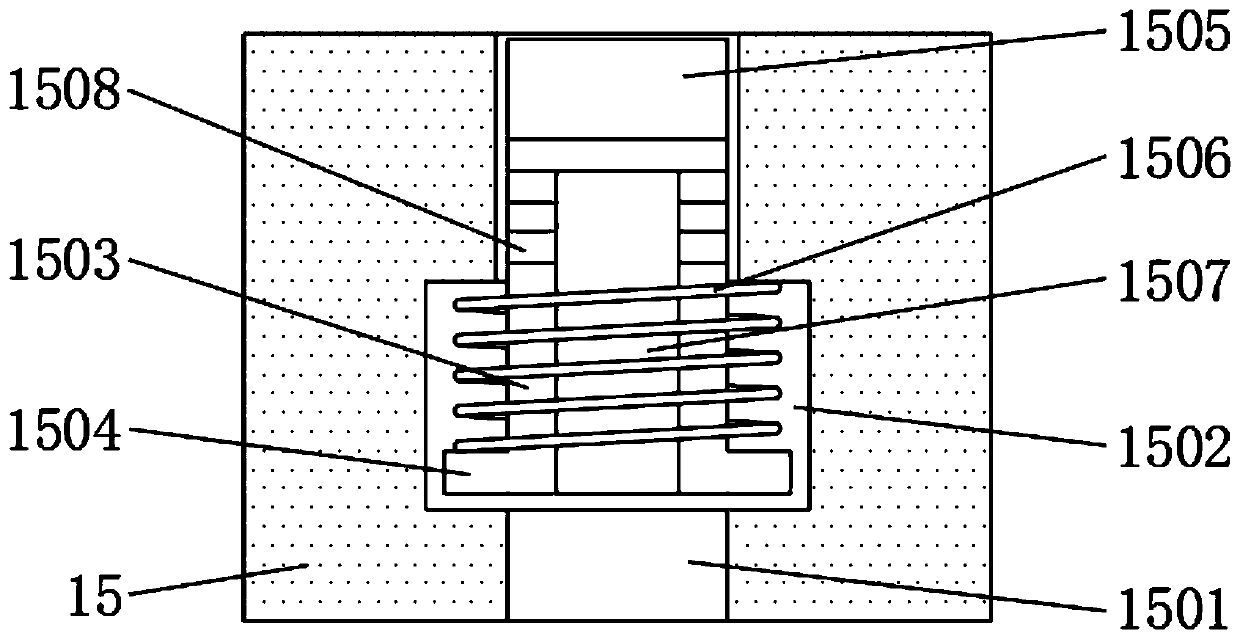

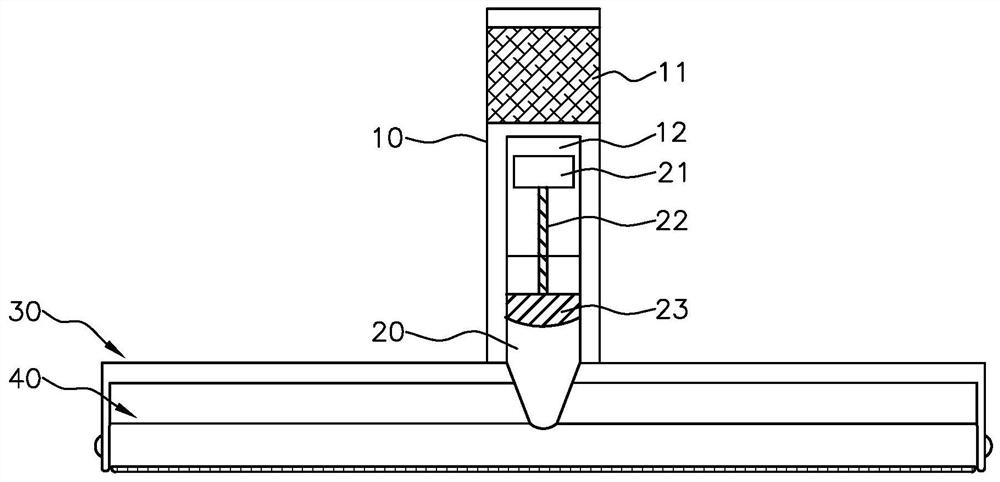

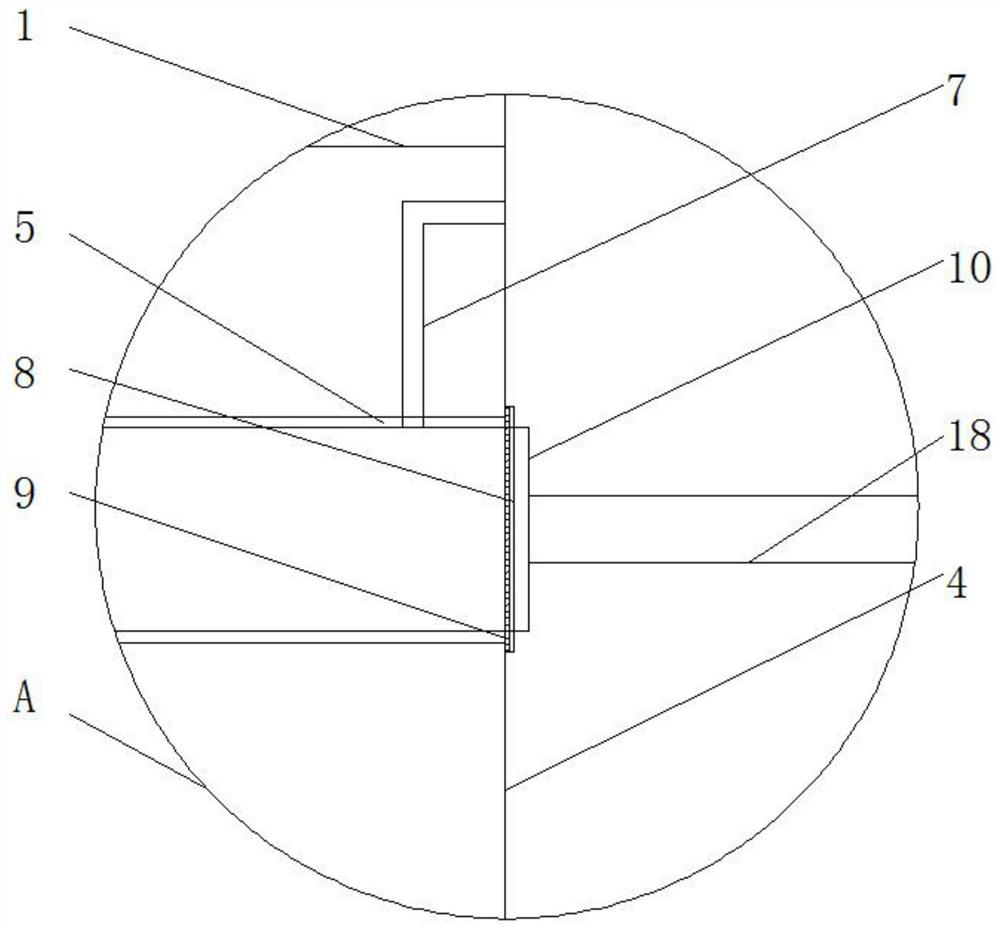

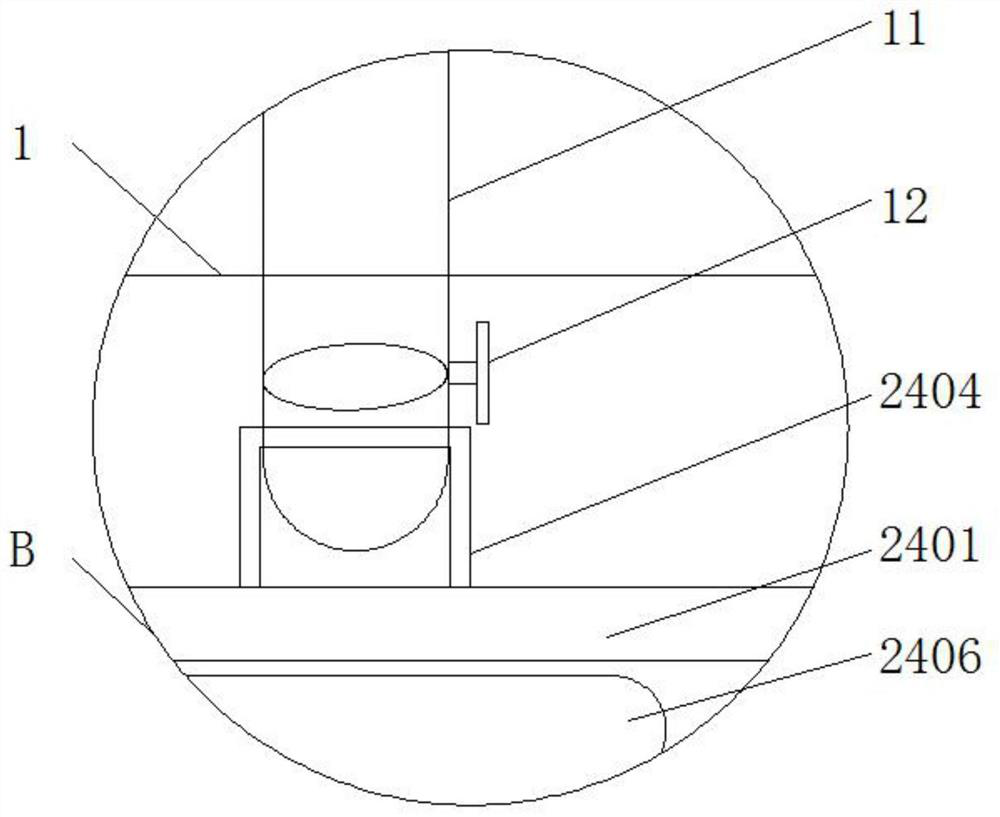

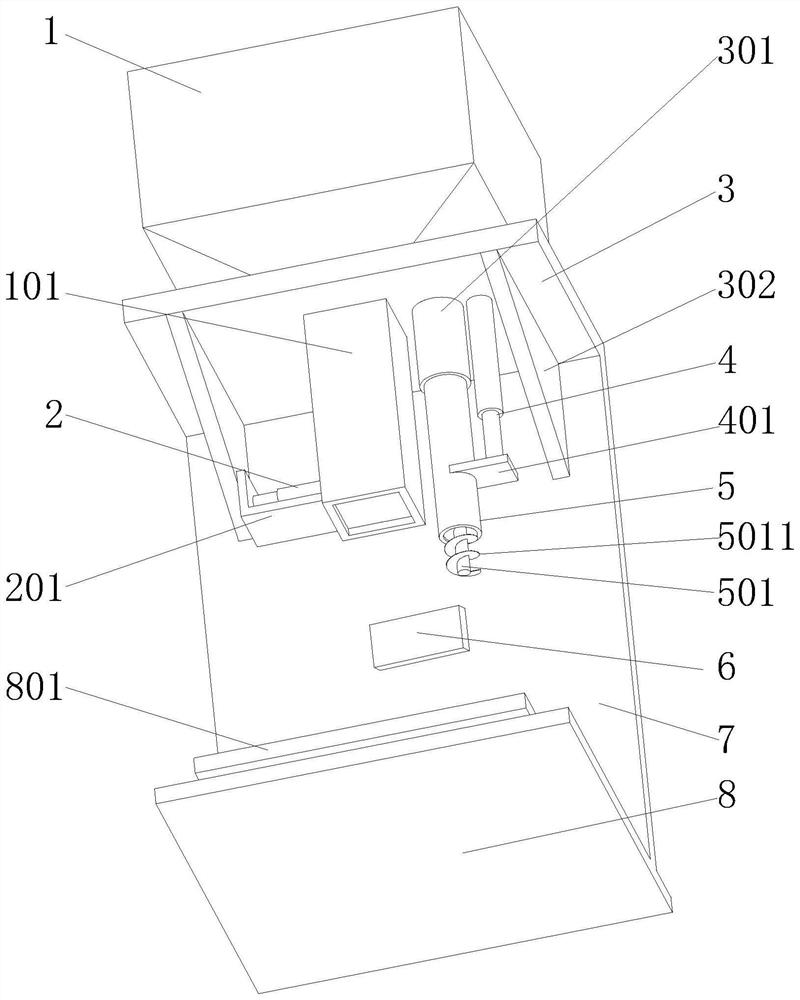

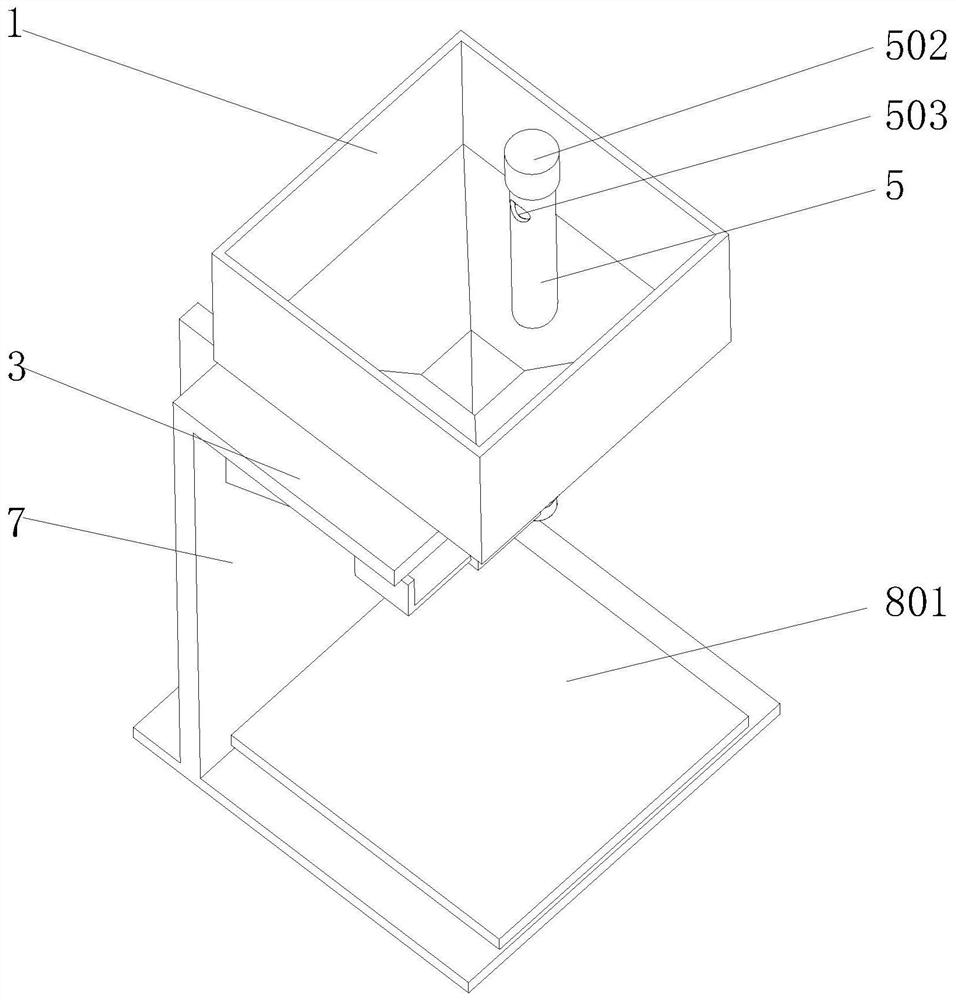

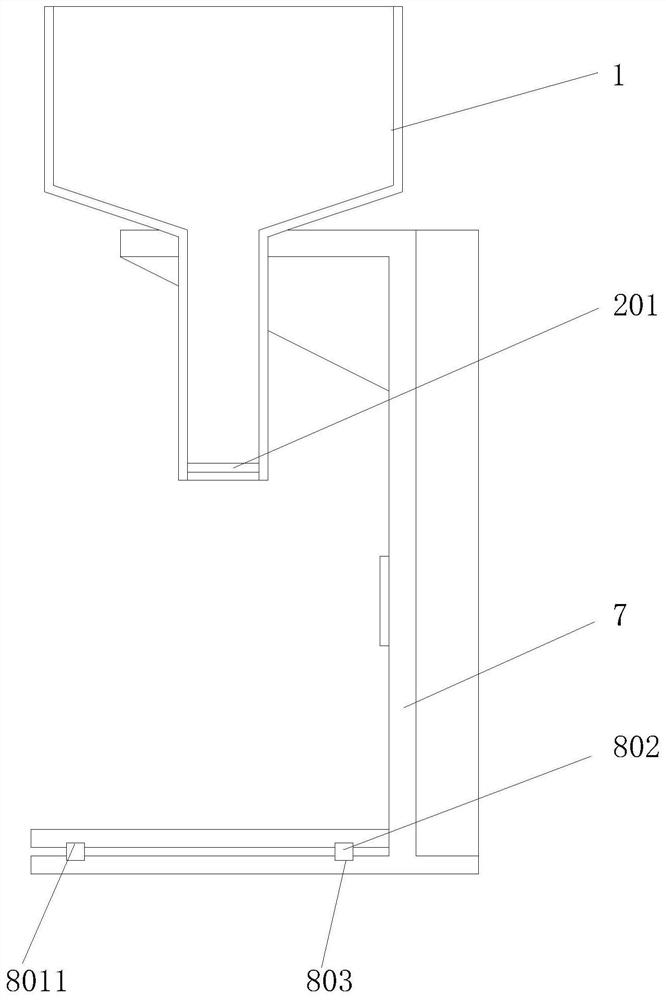

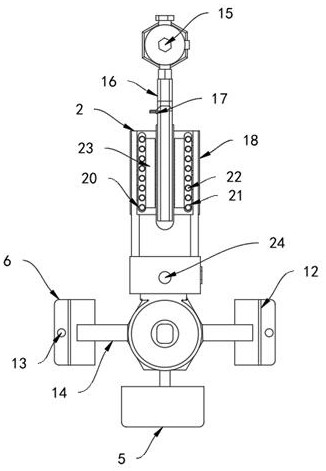

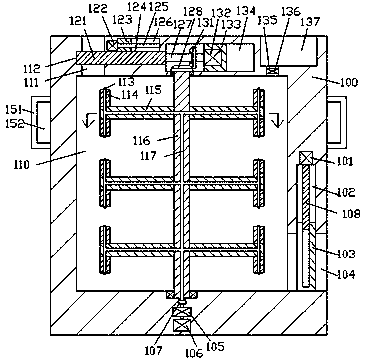

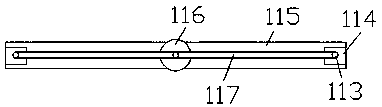

Dry pressing molding equipment and method for silicon carbide composite ceramic processing

InactiveCN111531683AFine grainAvoid accumulationCeramic shaping apparatusGrain treatmentsCarbide siliconComposite ceramic

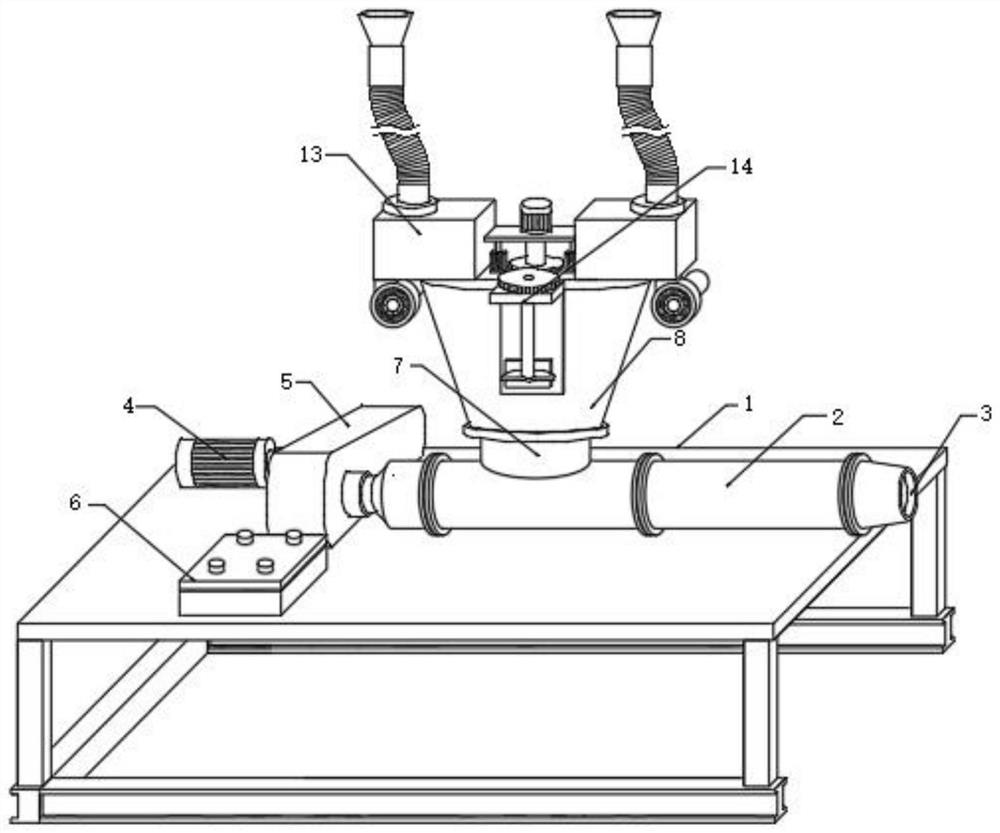

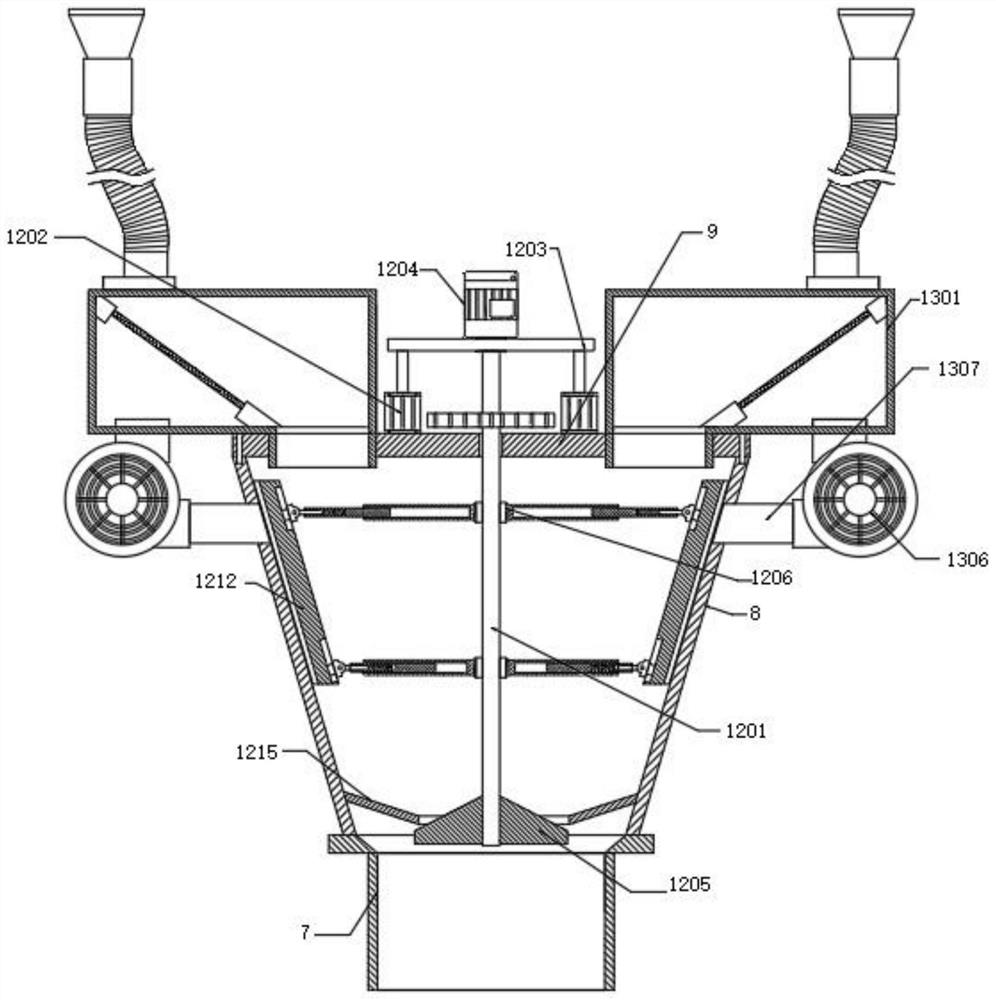

The invention discloses dry pressing molding equipment and method for silicon carbide composite ceramic processing, and belongs to the technical field of ceramic processing. The dry pressing molding equipment for silicon carbide composite ceramic processing comprises a crushing box, a granulation box, a rotating table and a base. A crushing cavity, a discharging cavity and a communication openingare formed in the crushing box, a crushing assembly is arranged in the crushing cavity, a storage cylinder, a second sealing assembly and a molding plate are arranged at the bottom of the granulationbox, and a molding groove is formed in the rotating table. The crushing assembly moves in a reciprocating mode to further crush and refine ceramic materials, the communication opening is opened through a first sealing assembly, and powder enters the discharging cavity through a scraper blade and enters the granulation box for granulation; the rotating table rotates intermittently through a drivingassembly, and the second sealing assembly moves to open a feeding pipe intermittently, so that the movement of the rotating table and the second sealing assembly are matched, feeding is carried out during the stop of the rotating table, and the feeding, molding and discharging can be carried out at the same time, and the molding processing efficiency is improved.

Owner:SHENZHEN SHINDY TECH

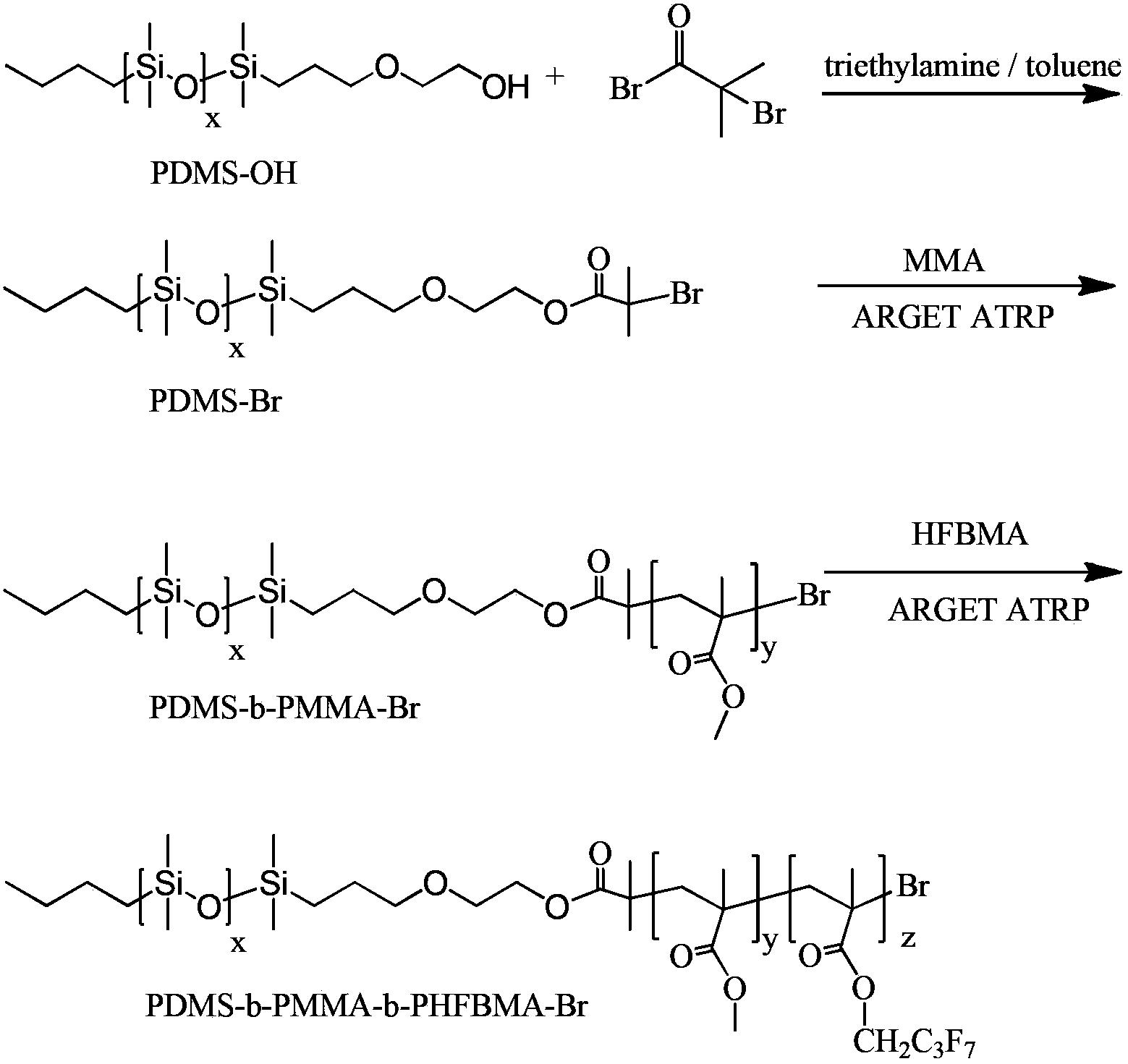

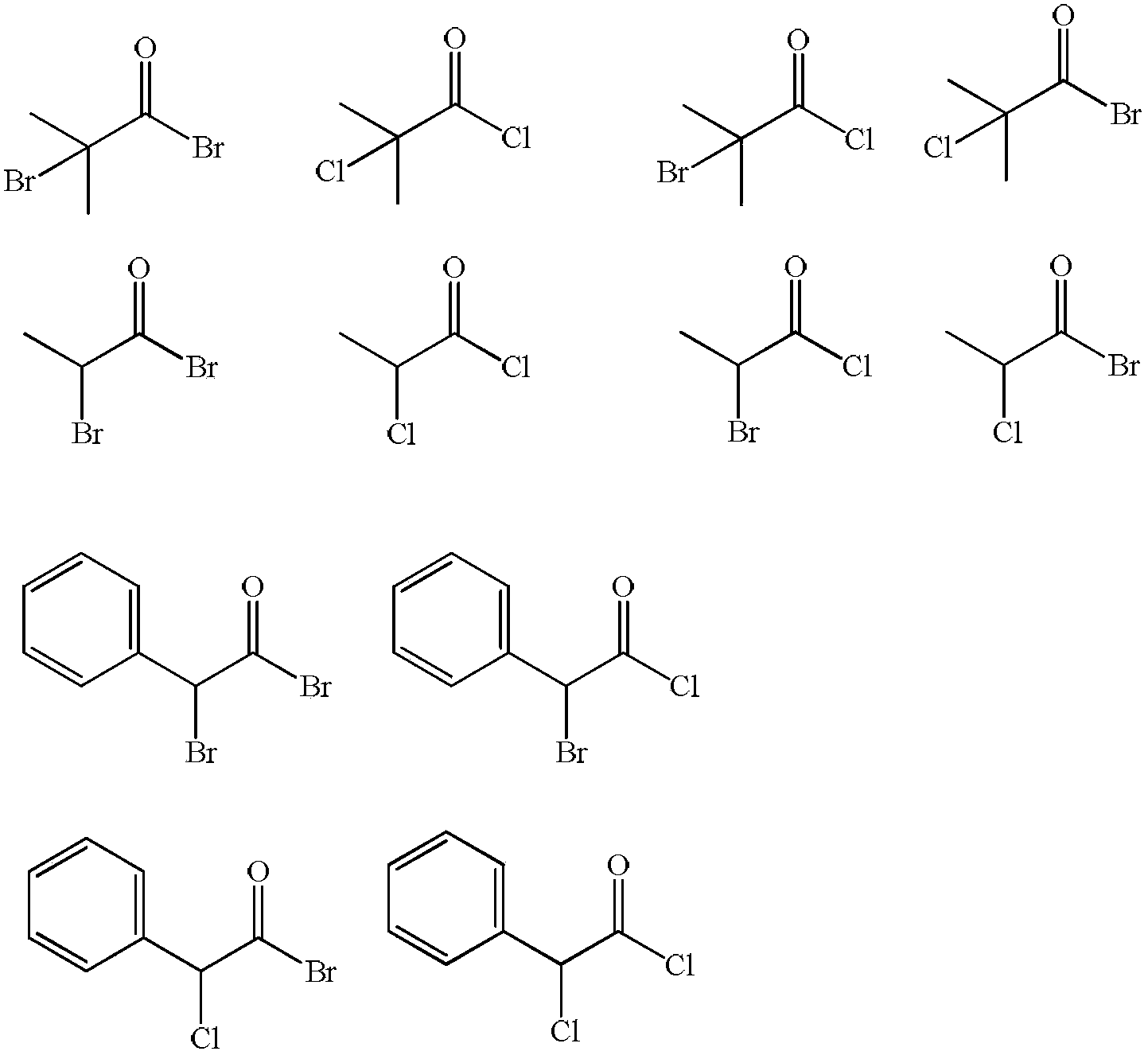

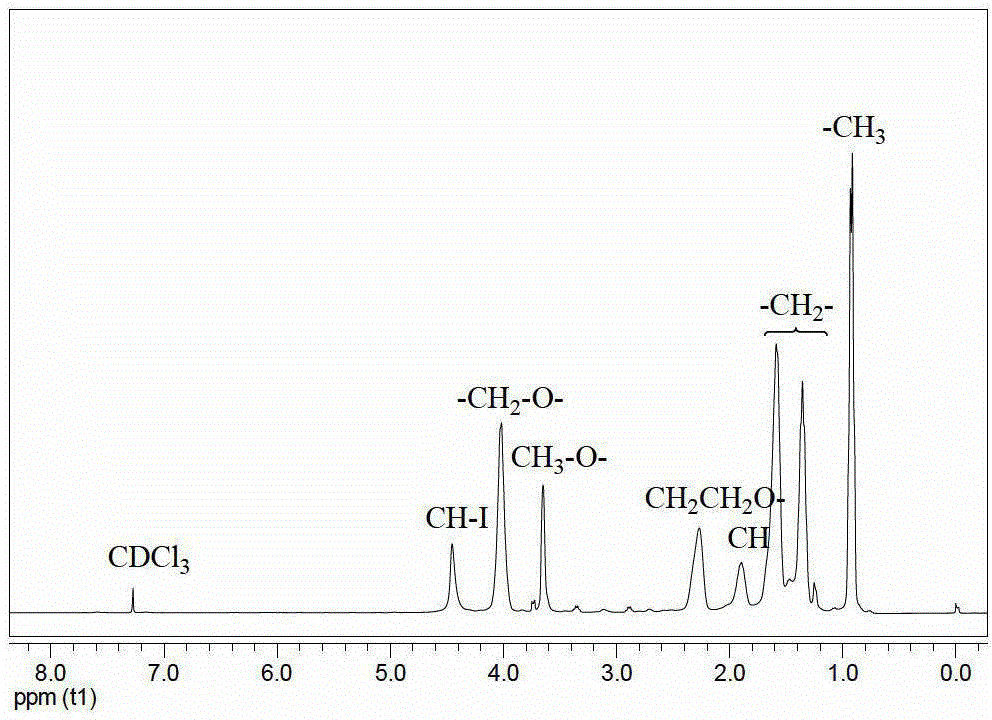

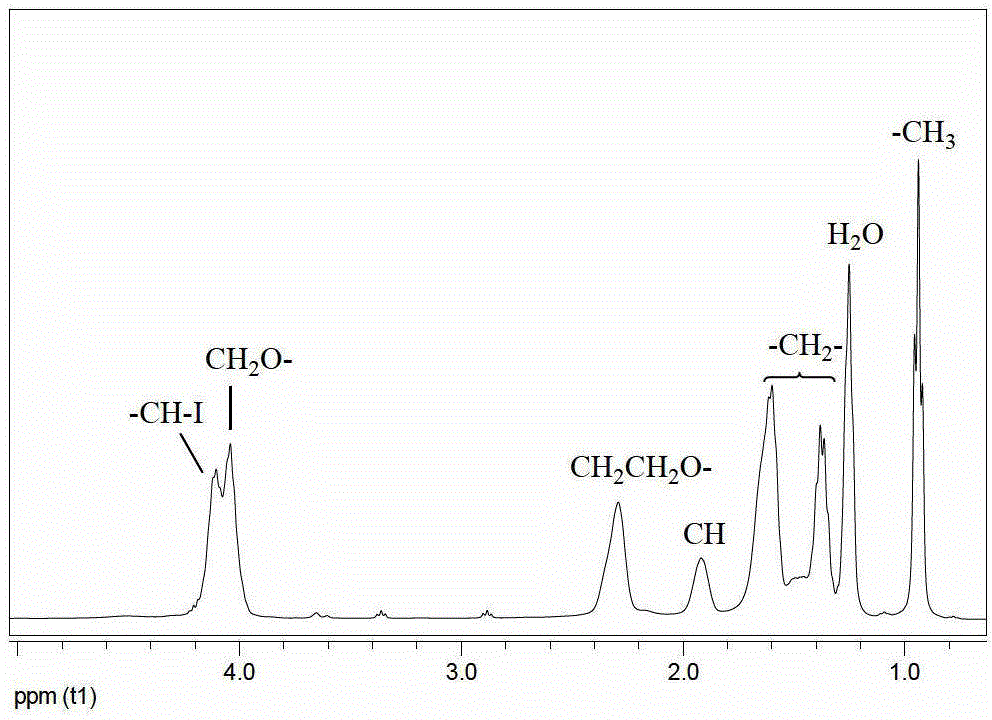

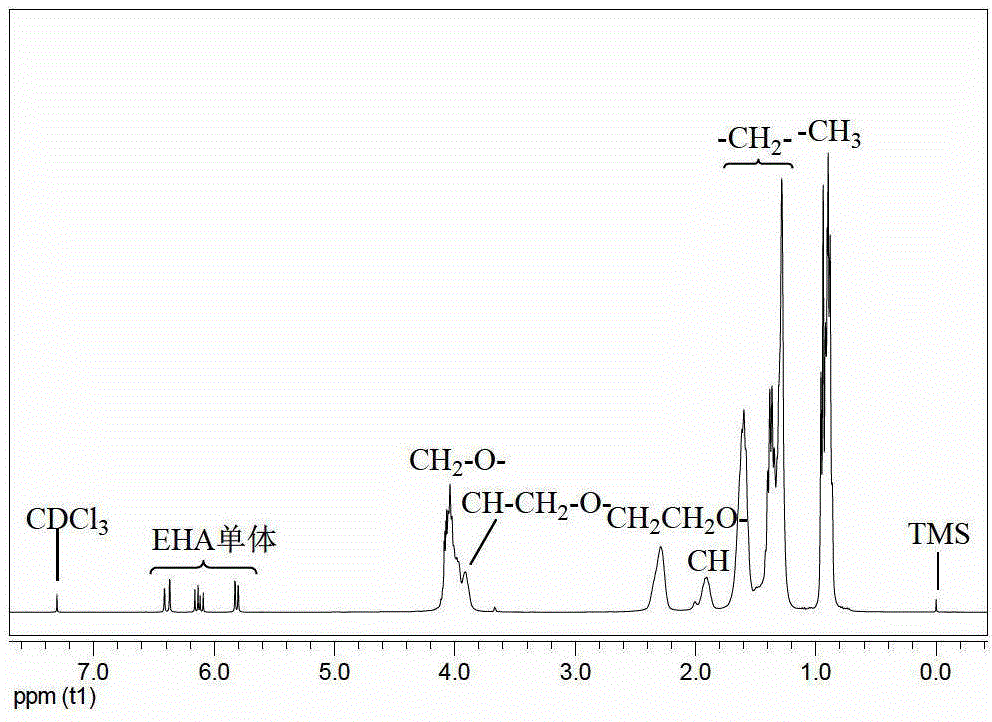

Fluorine-silicon tri-block copolymer and preparation method thereof

The invention specifically relates to a method for preparing a fluorine-silicon tri-block copolymer through activators regenerated by electron transfer-atom transfer radical polymerization (ARGET ATRP) under the condition of a low catalyst concentration, belonging to the field of technical materials. According to the invention, an excess weak reducing agent is used to continuously reduce a passivating agent in a system, and an activator prepared through in-situ reaction catalyzes atom transfer radical polymerization of a monomer; in such a process, a small amount of oxygen hard to thoroughly remove in the system can be consumed in situ; the amount of a catalyst used in a polymerization system is substantially reduced at the same time; and the step of removal of copper in subsequent operation can be avoided. The preparation method for the fluorine-silicon tri-block copolymer has the advantages of a low catalyst concentration, mild reaction conditions and suitability for industrial production.

Owner:SKSHU PAINT

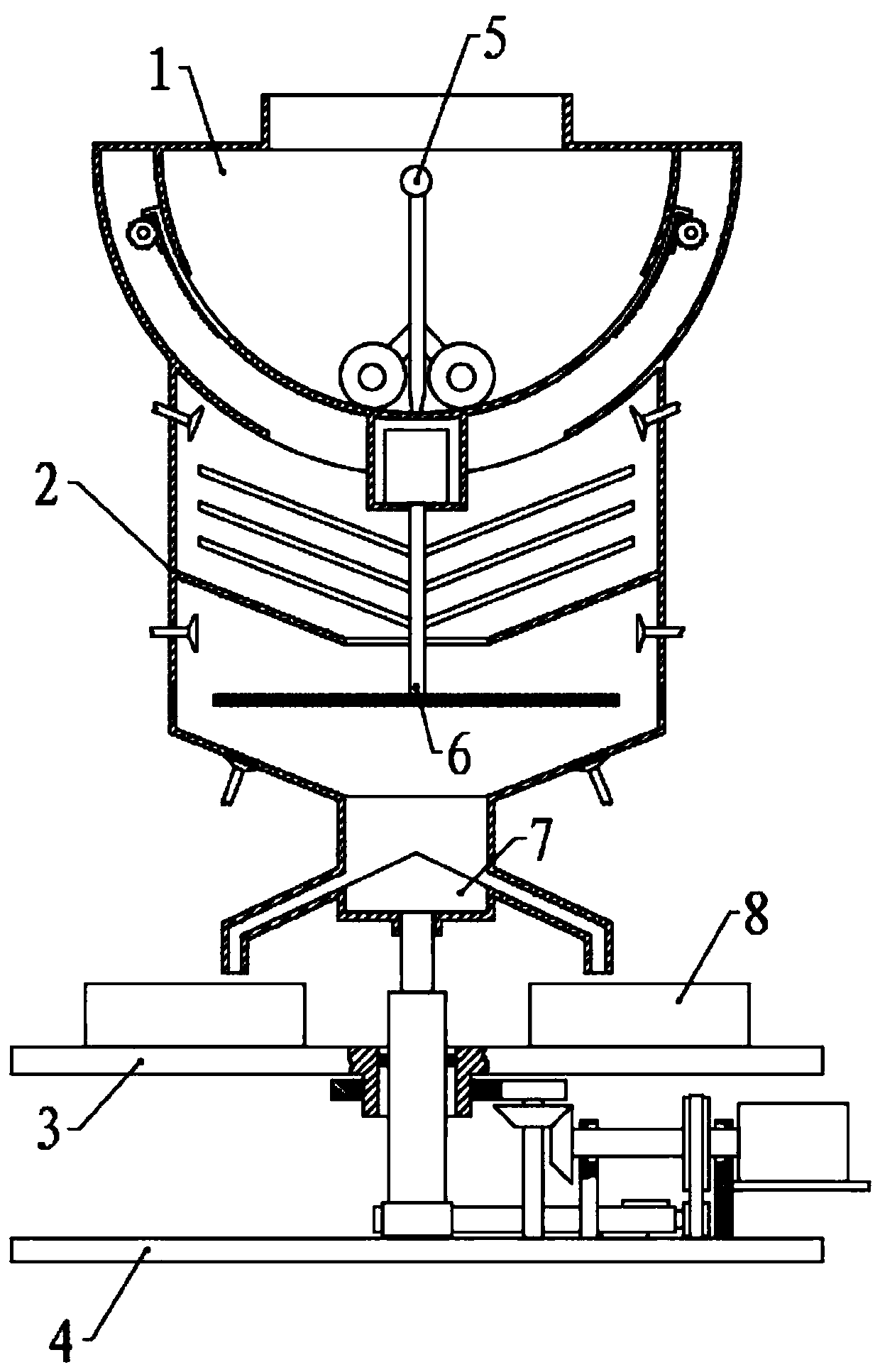

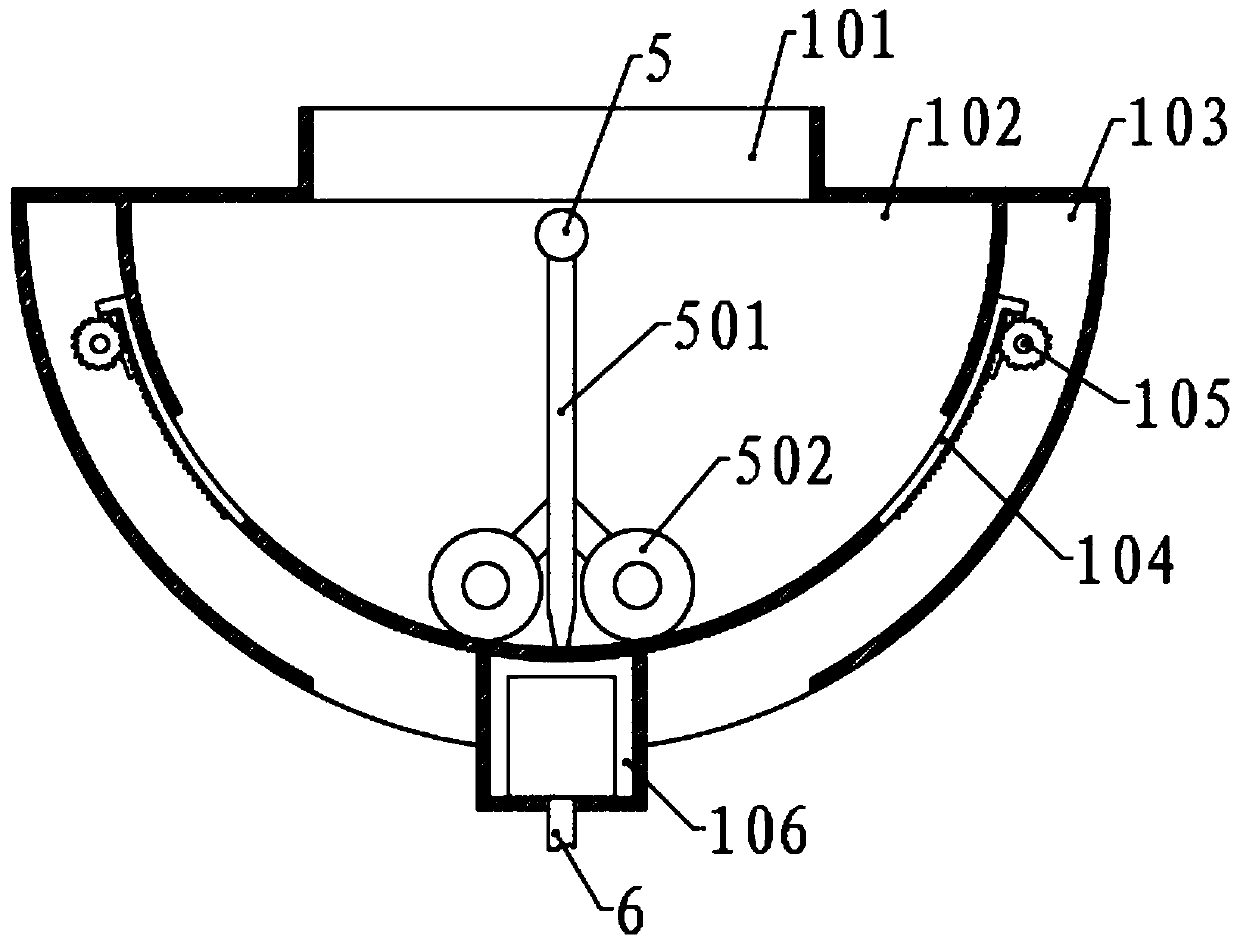

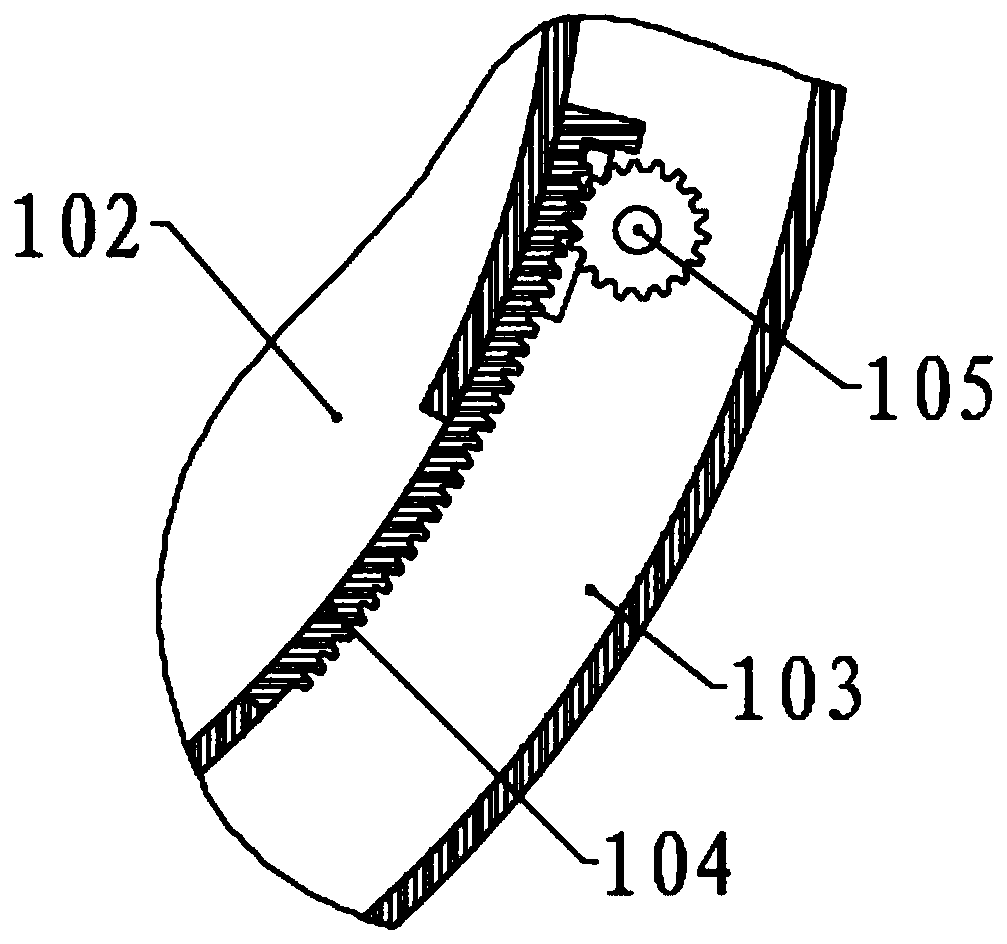

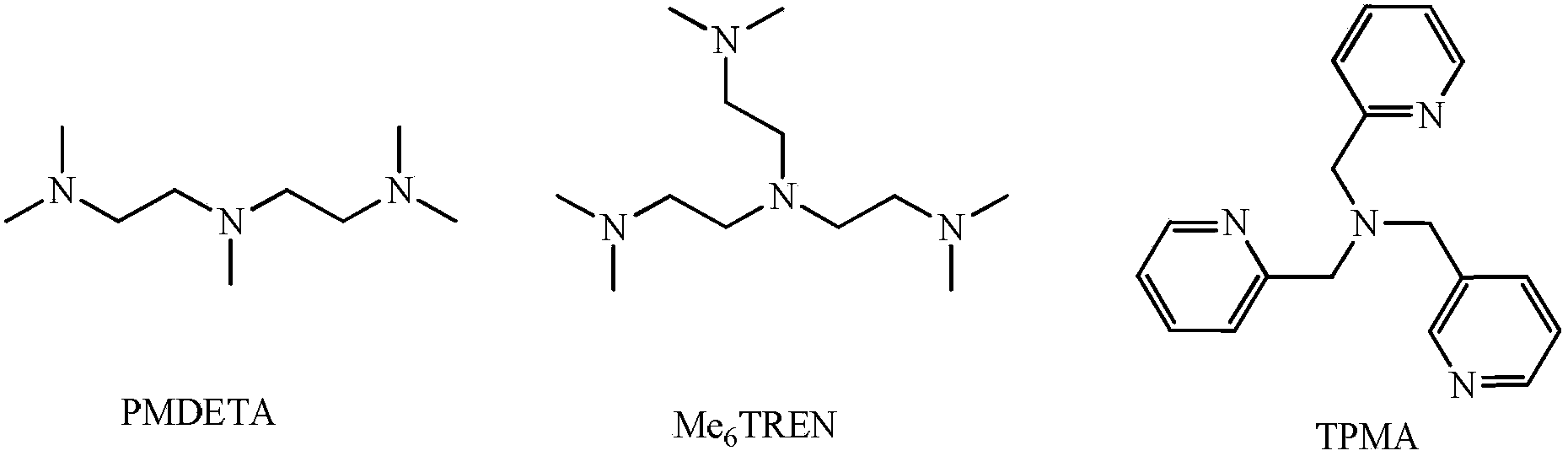

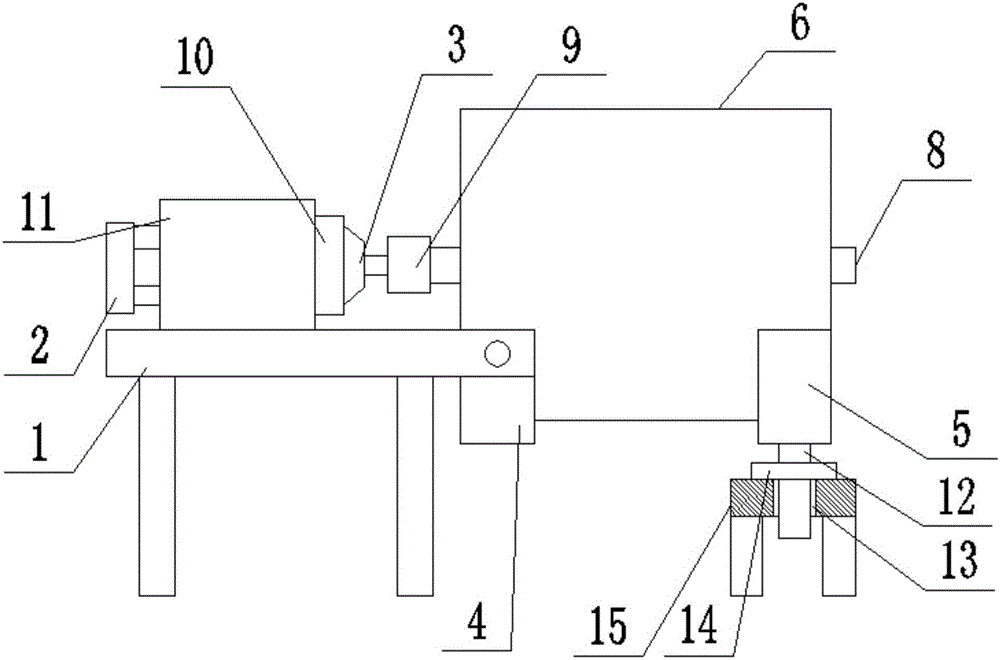

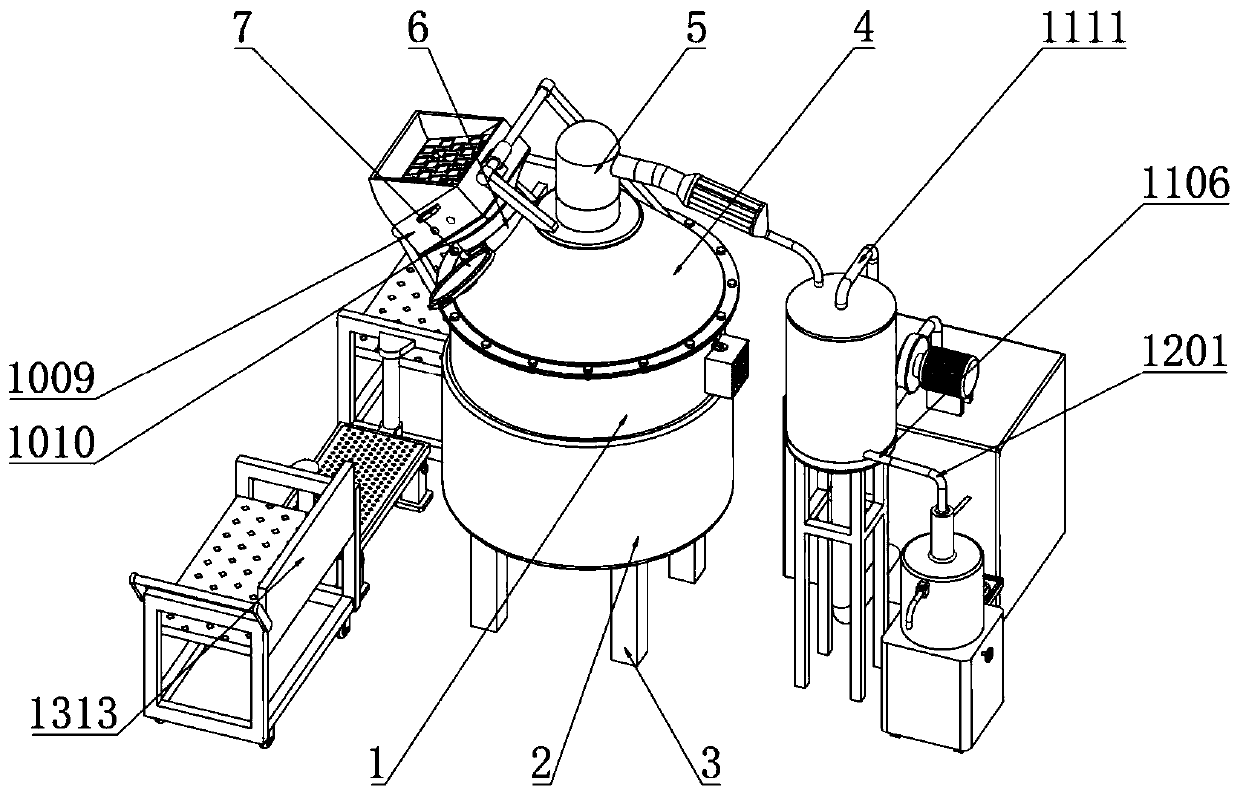

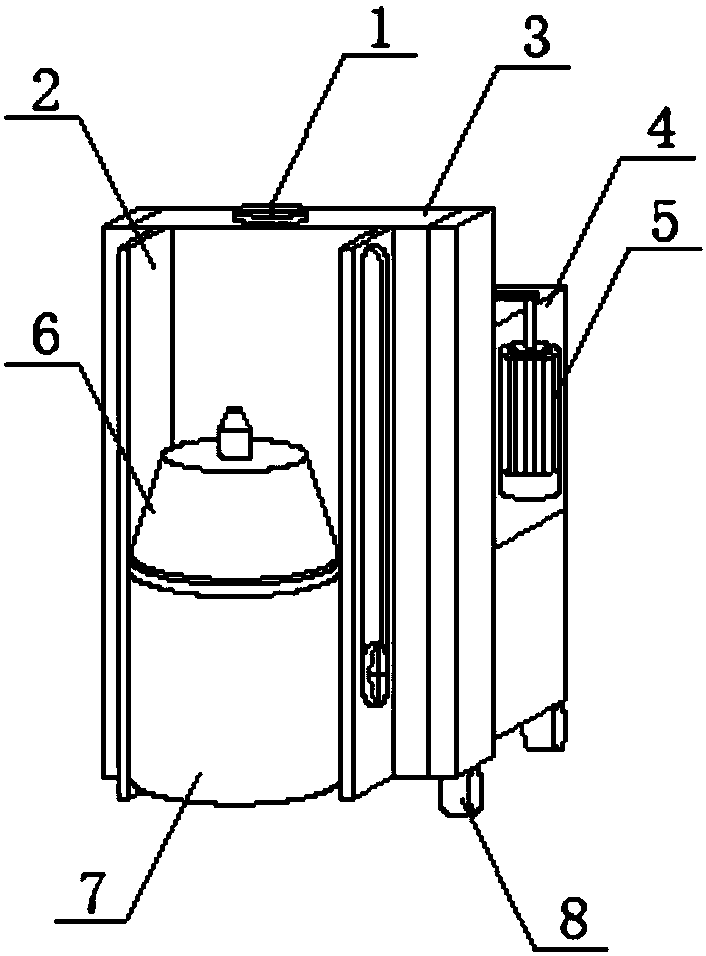

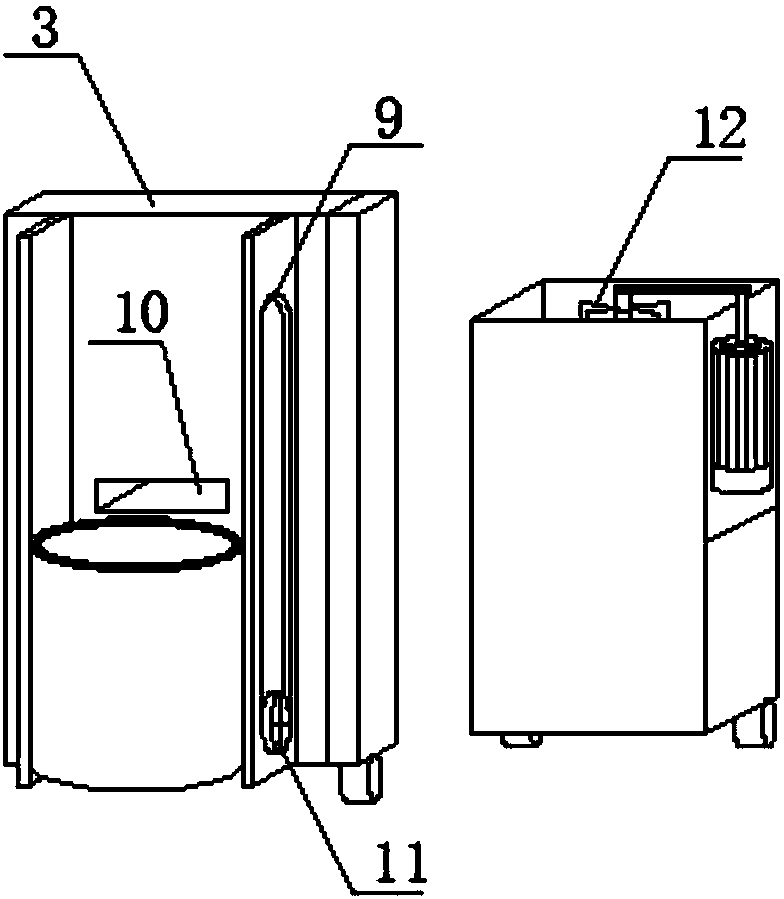

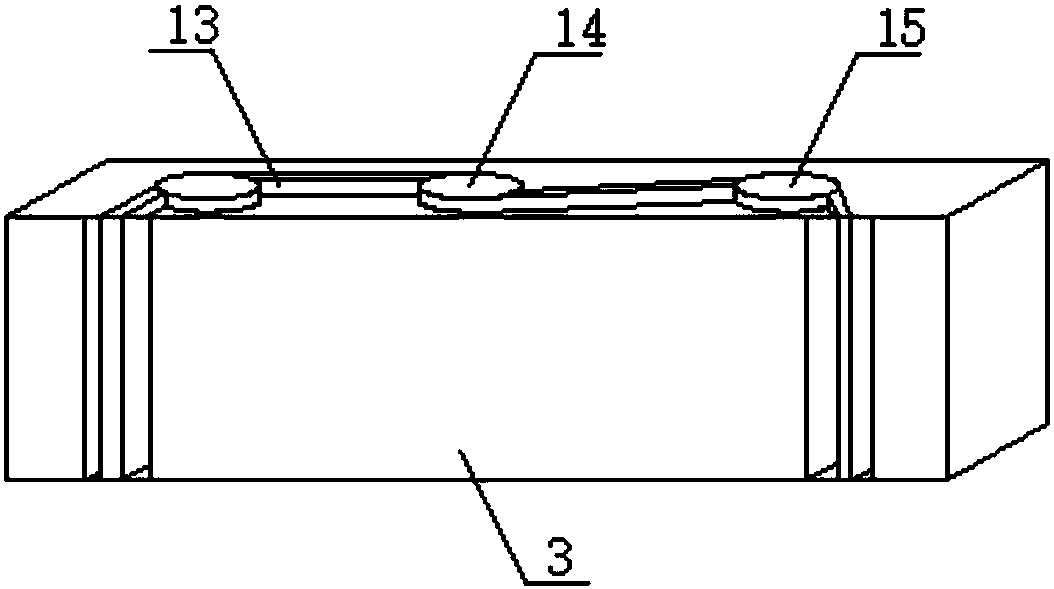

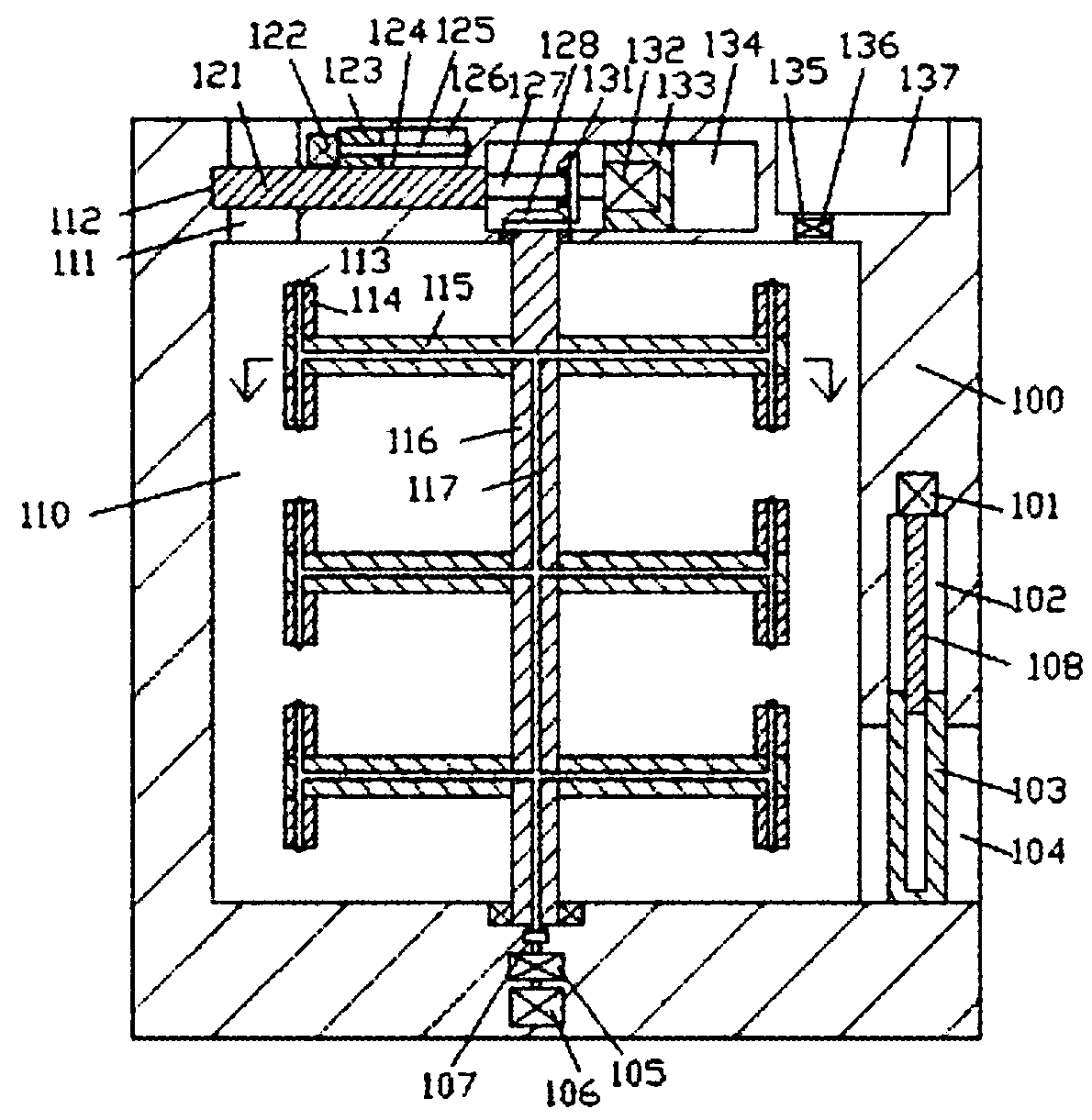

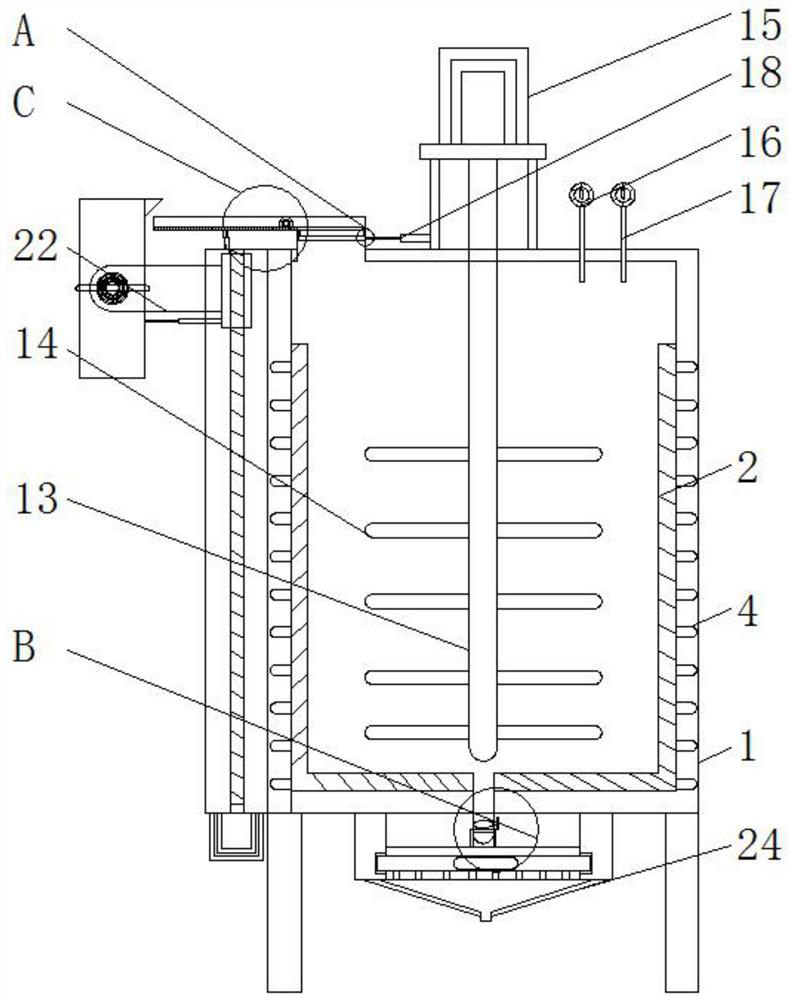

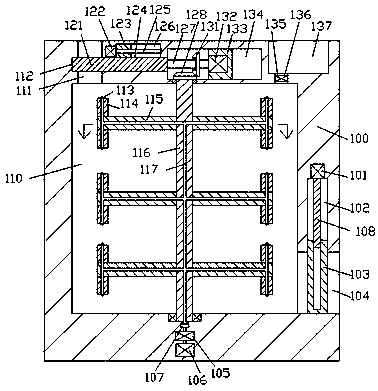

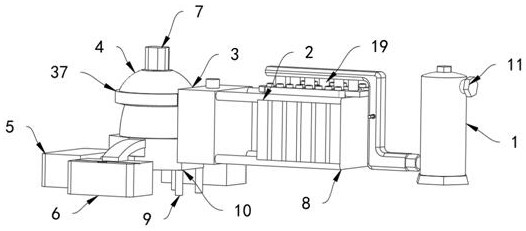

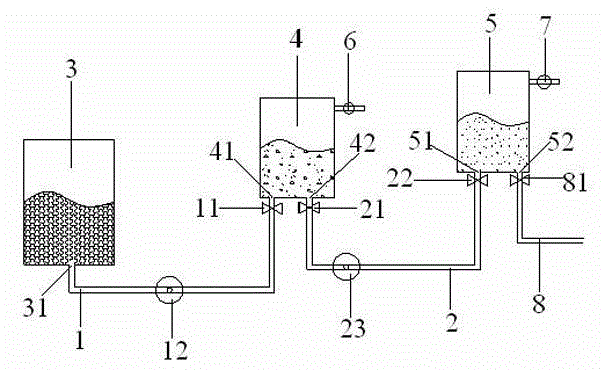

Preparation apparatus and method for lithium ion battery slurry

ActiveCN102824872AWell mixedReduce generationCell electrodesMixing methodsElectrical batteryEngineering

The invention belongs to the technical field of lithium ion batteries and especially relates to a preparation apparatus for lithium ion battery slurry. The apparatus comprises a solvent loading tank and a slurry agitator tank, wherein the slurry agitator tank is connected with a first vacuum pump; the apparatus further comprises a binder premixing tank, wherein the binder premixing tank is connected with a second vacuum pump; a discharge outlet of the solvent loading tank is connected with a feed inlet of the binder premixing tank through a first pipeline, and a discharge outlet of the binder premixing tank is connected with a feed inlet of the slurry agitator tank through a second pipeline. Compared with the prior art, the preparation apparatus provided by the invention has the following advantages: fluids like a solvent and a binder premixed liquid are added from the bottom of a tank to the top of the tank by using vacuum negative pressure, so it is guaranteed that there is only a two-phase interface of a liquid phase and a solid phase, maximum-efficiency mutual infiltration is realized, generation of bubbles in the slurry is reduced, dispersion is promoted, stirring time is shortened and operation is simple, which enables stirring time to be reduced and production efficiency to be improved. Furthermore, the invention also discloses a method of utilizing the apparatus for preparation lithium ion battery slurry.

Owner:DONGGUAN AMPEREX TECH

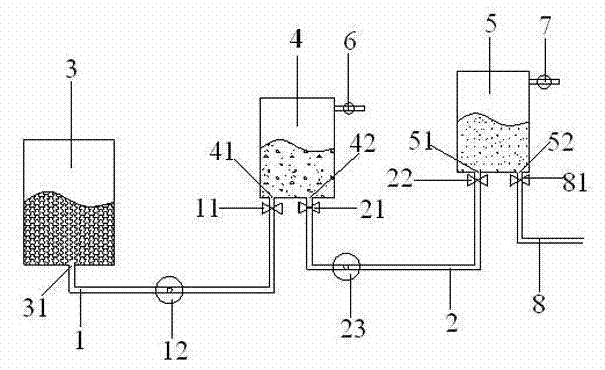

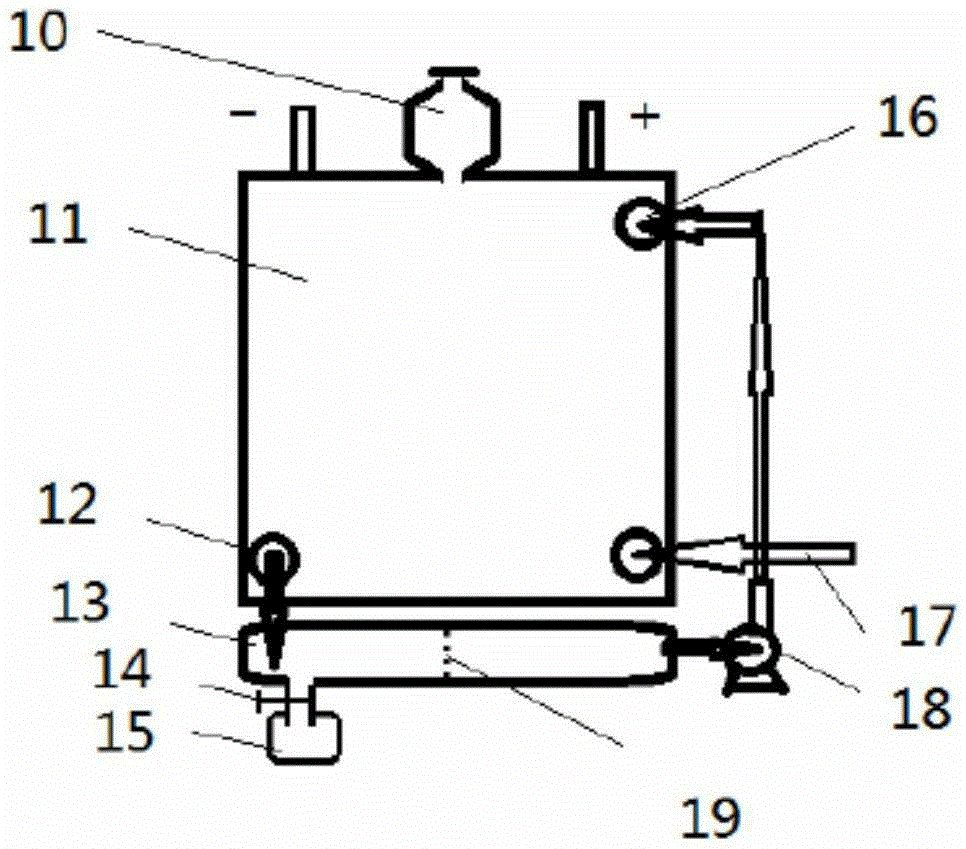

Metal fuel battery and fuel battery system thereof

InactiveCN105337003ASolve the problem of unsustainable power generationStable electric powerFuel and primary cellsFuel cellsEngineering

A metal fuel battery comprises a reactive metal powder negative electrode, air positive electrodes, an electrolyte and a battery shell. The metal fuel battery is characterized in that the metal powder negative electrode is composed of a negative electrode frame, metal powder and a negative electrode current collector, the negative electrode frame is arranged inside the battery shell, a metal powder charging opening is formed in the upper portion, the parallel air positive electrodes are arranged on the two outer sides of the negative electrode frame, a metal powder negative electrode material charging opening and an electrolyte feeding inlet are formed in the top of the battery shell, an electrolyte discharging outlet is formed in the bottom of the battery shell, and an air inlet and an air outlet are formed in the battery shell. A metal fuel battery system comprises a set of metal fuel batteries. The metal fuel batteries are connected in series or in parallel to form a fuel battery stack, battery monomers are connected with a metal powder charging groove and an electrolyte storage groove, and the electrolyte is circulated and filtered through a liquid flowing pump. The metal fuel battery is provided with the reactive metal powder negative electrode capable of achieving continuous charging, no metal electrode needs to be replaced, power generation can be continuously performed, the cost is low, and environmental protection is achieved.

Owner:WUHU HUAXINNUO ELECTROCHEM TECH

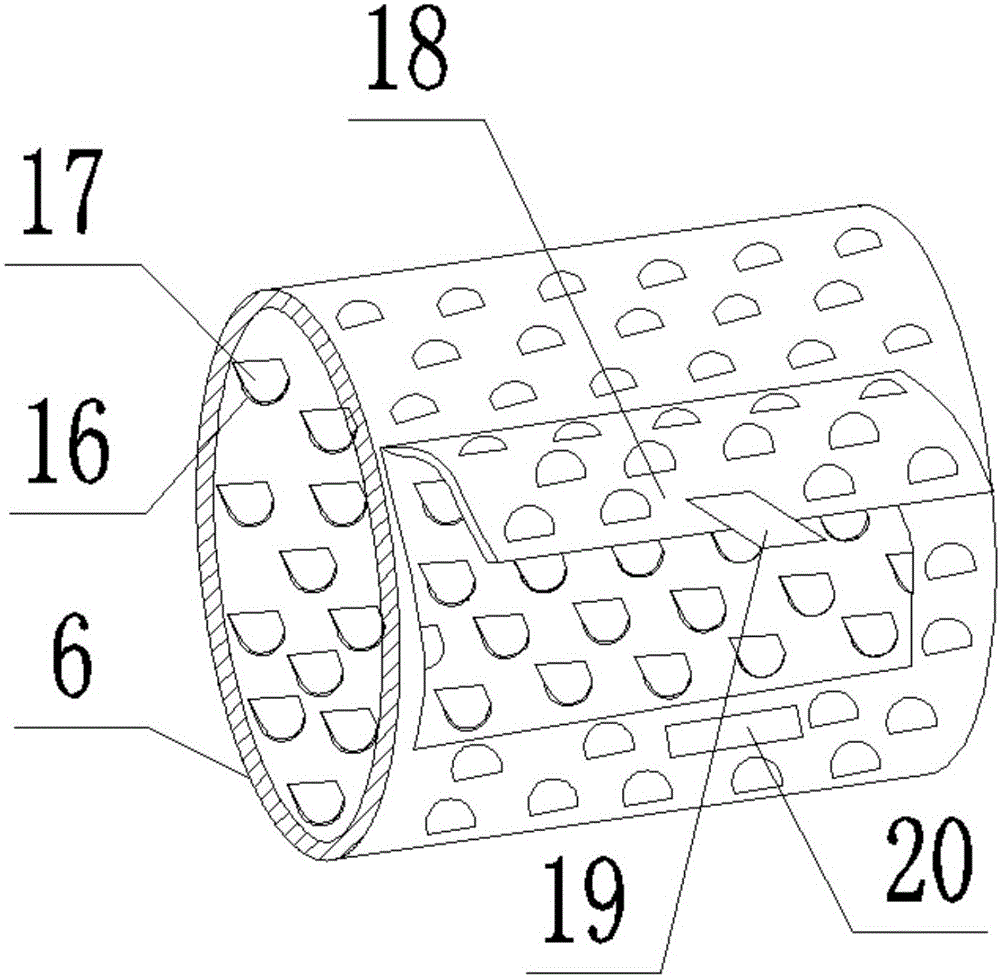

Traditional Chinese medicine cleaning machine

PendingCN106000962AImprove cleaning efficiencyEasy to adjustCleaning using liquidsDrive shaftWater filter

The invention relates to a traditional Chinese medicine cleaning machine which comprises a cleaning barrel and further comprises a turbine, wherein the cleaning barrel is connected to a drive device; the drive device comprises a drive shaft; the two ends of the drive shaft penetrate through and extend out of the cleaning barrel; the drive shaft is connected to a drive motor through a speed reducer; the drive motor is provided with an electromagnetic brake; a universal coupler is arranged between the speed reducer and the drive shaft; a water conveying tube is arranged in the drive shaft; the water conveying tube extends into the cleaning barrel; water spray devices are arranged on the drive shaft; each water spray device comprises a water spray tube; a plurality of water spray holes are formed in the side wall of each water spray tube; a connecting tube communicating with the water conveying tube is fixedly arranged on the drive shaft; the connecting tube is provided with reciprocating spiral slots; slide blocks are arranged in the water spray tube; the slide blocks are mounted in the reciprocating spiral slots in a sliding manner; the turbine is arranged in the connecting tube; the turbine is fixedly arranged on the water spray tube; the barrel wall of the cleaning barrel is provided with water filter holes; and elastic baffle plates are arranged over the water filter holes. Stirring effect on traditional Chinese medicines on different positions in the cleaning barrel is good, water adding is uniform, cleaning efficiency is high and cleaning quality is good. The traditional Chinese medicine cleaning machine is convenient to operate.

Owner:YULONG JINWANG CHINESE MEDICINAL HERBS PLANTING CO LTD

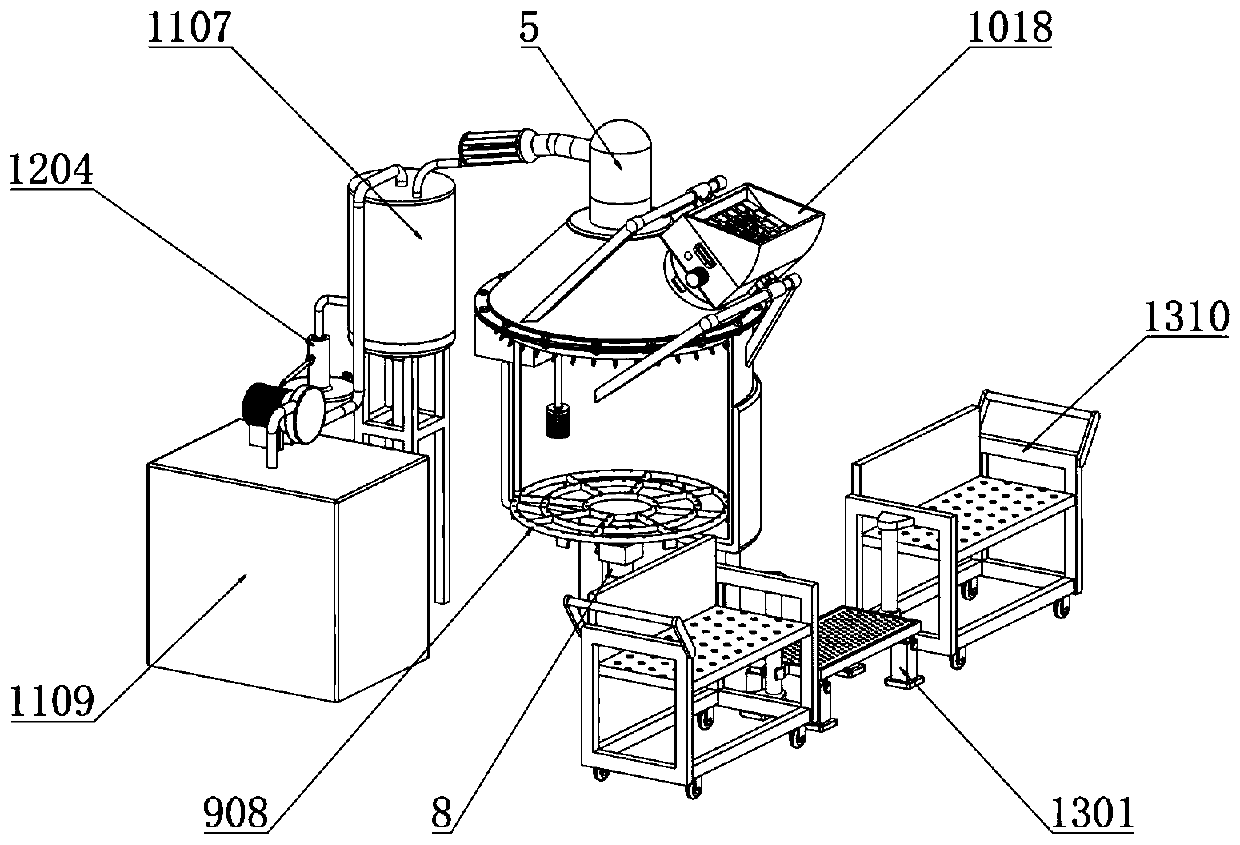

High-pressure distillation essential oil separation and purification treatment device and separation and purification method

InactiveCN111304002AScientific and reasonable structureEasy to useEssential-oils/perfumesThermodynamicsPurification methods

The invention discloses a high-pressure distillation essential oil separation and purification treatment device and separation and purification method. The device comprises a distillation barrel, andthe edge part of the bottom end of the outer side of the distillation barrel is sleeved with an electromagnetic heater. The bottom end of the distillation barrel is in threaded connection with a sealed conical top. The middle part of the top end of the sealed conical top is fixedly connected with a steam discharge pipe. A feeding opening is formed in one side of the outer part of the sealing conical top. A sealing cover plate is rotationally connected to one side of the feeding opening. The bottom end of the distillation barrel is fixedly connected with a slag discharging opening. An evaporation enhancement mechanism is fixedly connected to one side, corresponding to the top of the electromagnetic heater, of the distillation barrel. Liquid enters an annular pipe from the top of a liquid outlet pipe and is sprayed out of a drainage nozzle, the contact area between liquid in the distillation barrel and air is increased, the evaporation rate of the liquid is further increased, meanwhile,fixed raw materials attached to the inner wall of the distillation barrel can be flushed to the bottom of the distillation barrel, the distillation process of essential oil production is optimized, and the essential oil extraction efficiency is improved.

Owner:陈国全

Biomass direct combustion furnace

InactiveCN104132369ABurn fullyImprove utilization efficiencyDomestic stoves or rangesLighting and heating apparatusCombustion chamberDirect combustion

The invention discloses a biomass direct combustion furnace which comprises a furnace pipe, a furnace end, a furnace frame, a feeding device and an air supply mechanism. The biomass direct combustion furnace is characterized in that the furnace end is fixedly connected with the furnace pipe, air supply holes are formed in the furnace end, the feeding device is fixedly arranged below the furnace pipe, the feeding device is fixedly connected with the furnace frame, the feeding device comprises a feeding barrel and a lifting mechanism, the lifting mechanism is fixedly connected with the feeding barrel, a furnace grate is arranged on the upper portion of the feeding barrel, the furnace grate is hinged to the feeding barrel, and ventilation holes are formed in the furnace grate. Biomass fuel is directly combusted through the biomass direct combustion furnace, after the upper portion is ignited, the biomass fuel is combusted from top to bottom, and when the fuel in a combustion chamber formed by the furnace pipe and the furnace grate is burnt out, secondary feeding can be carried out from the lower portion of the furnace through the feeding device.

Owner:金桂方

Intermediate frequency smelting furnace building technology

The invention discloses an intermediate frequency smelting furnace building technology. The intermediate frequency smelting furnace building technology includes the following steps that 1 asbestos cloth is tailored in advance according to the size of an electric furnace, and a quartz sand mixture is prepared according to the size of an intermediate frequency furnace; 2 the asbestos cloth tailored in advance is arranged on a coil from top to bottom, wherein the coil is arranged in a cavity of a furnace body to be built; 3 daubing is conducted; 4 furnace baking and sintering are conducted. The intermediate frequency smelting furnace building technology is reasonable in process, simple to operate and low in production cost. After quartz sand and appropriate water are stirred and mixed, the adhesion is high, charging and daubing are convenient and simple, a furnace lining is high in compacting degree, and the service life of the furnace is prolonged. Furnace building is conducted by using the technology, the furnace building cost each time is 15000 RMB, the service life of a furnace built each time is about 430 years, the furnace building cost consumed by fusion per ton iron liquid on average is 11.63 RMB, the furnace building labor cost, the furnace building shut-down cost and the like are not included, and therefore the furnace building technology saves the furnace building cost and lowers the overall casting cost.

Owner:GUANGDONG HENGCHENG TECH

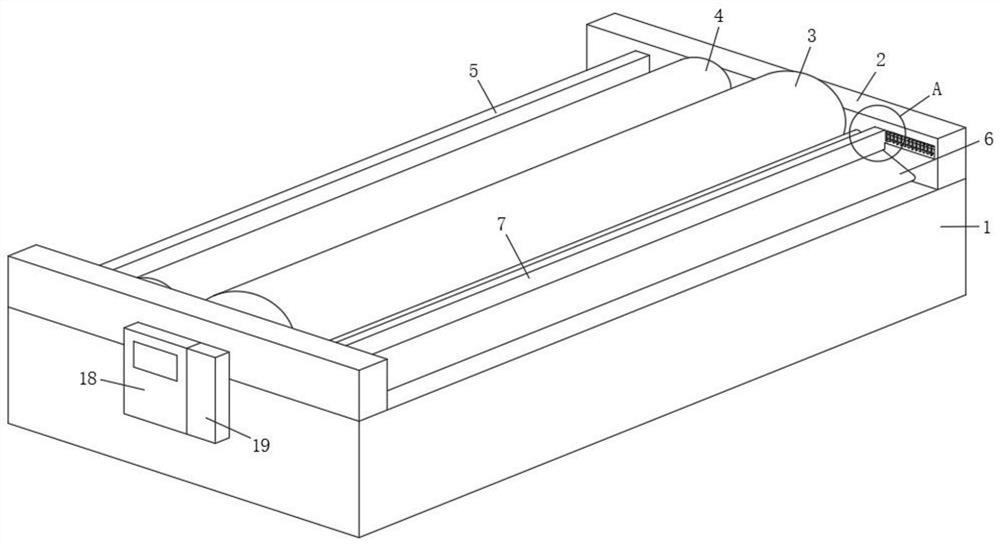

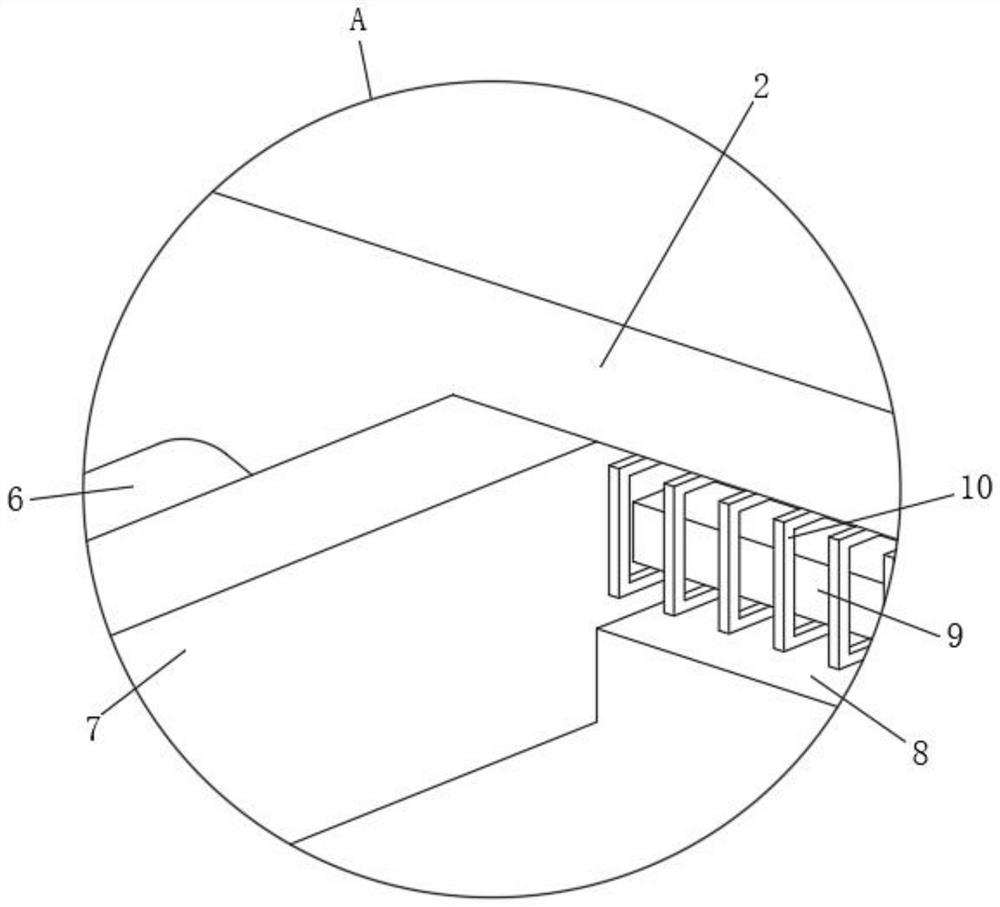

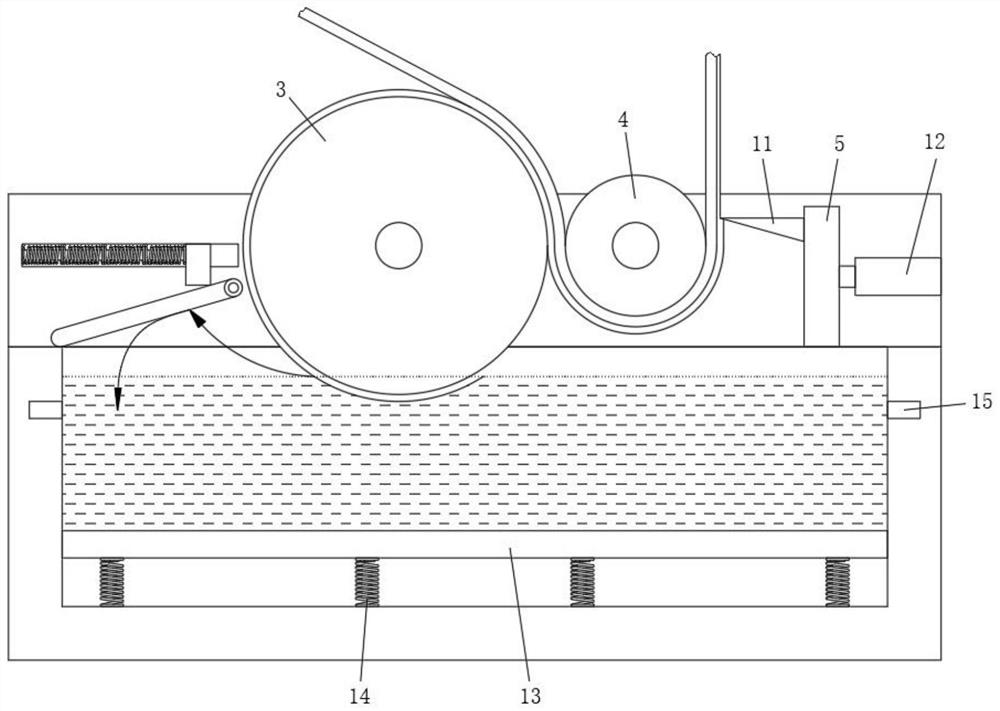

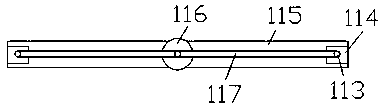

Wallpaper blade coating mechanism for wallpaper production line

PendingCN112048941AEffective adjustment of coating thicknessUniform coatingSpecial paperPaper/cardboardStructural engineeringMaterial storage

The invention belongs to the technical field of wallpaper production, and discloses a wallpaper blade coating mechanism for a wallpaper production line. The wallpaper blade coating mechanism comprisesa material storage box with an open top, wherein two fixed side plates are symmetrically welded to the top of the material storage box; a coating roller which is rotationally installed between the two fixed side plates, wherein the bottom of the coating roller is located in the storage box; a pressing roller which is rotationally installed between the two fixed side plates and located on one sideof the coating roller, wherein the bottom of the pressing roller is located above the storage box; and a movable scraper which is arranged between the two fixed side plates in a sliding mode, whereinpressing roller is located between the scraper and the coating roller, and wallpaper sequentially penetrates through the gap between the coating roller and the pressing roller and the gap between thepressing roller and the scraper in the coating process; in conclusion, uniform coating of the wallpaper is effectively achieved based on the arrangement of the coating roller, the pressing roller andthe scraper, the coating thickness of the coating can be effectively adjusted, and the wallpaper blade coating mechainsm has the advantages of being simple and reasonable in structure, low in cost and convenient to machine and install.

Owner:天津市艺恩装饰材料有限公司

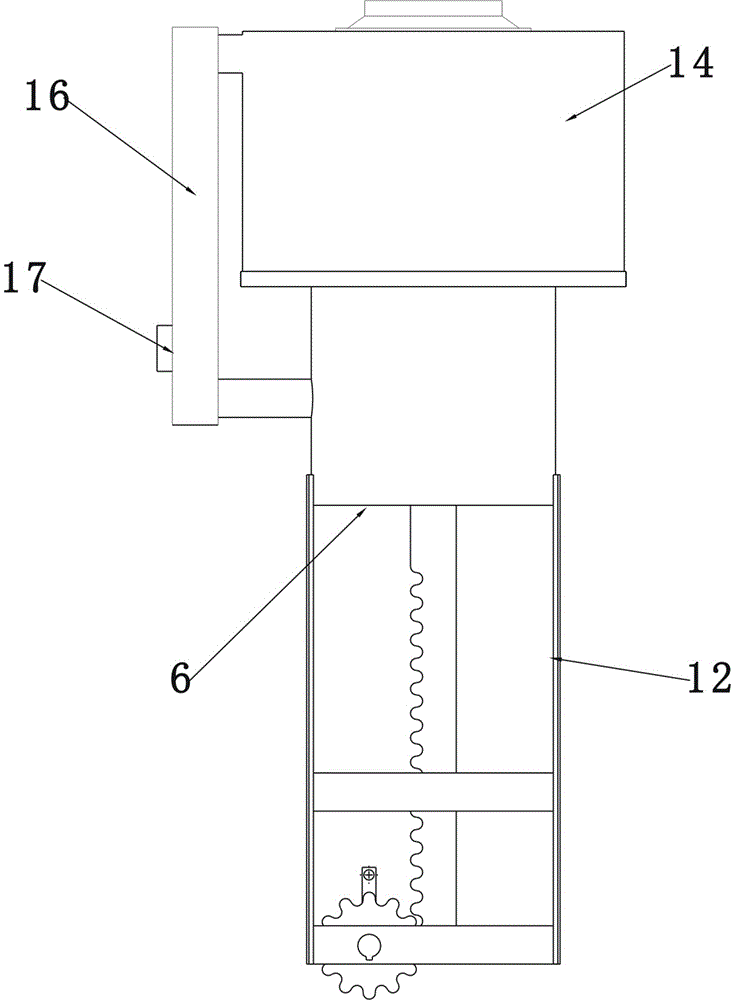

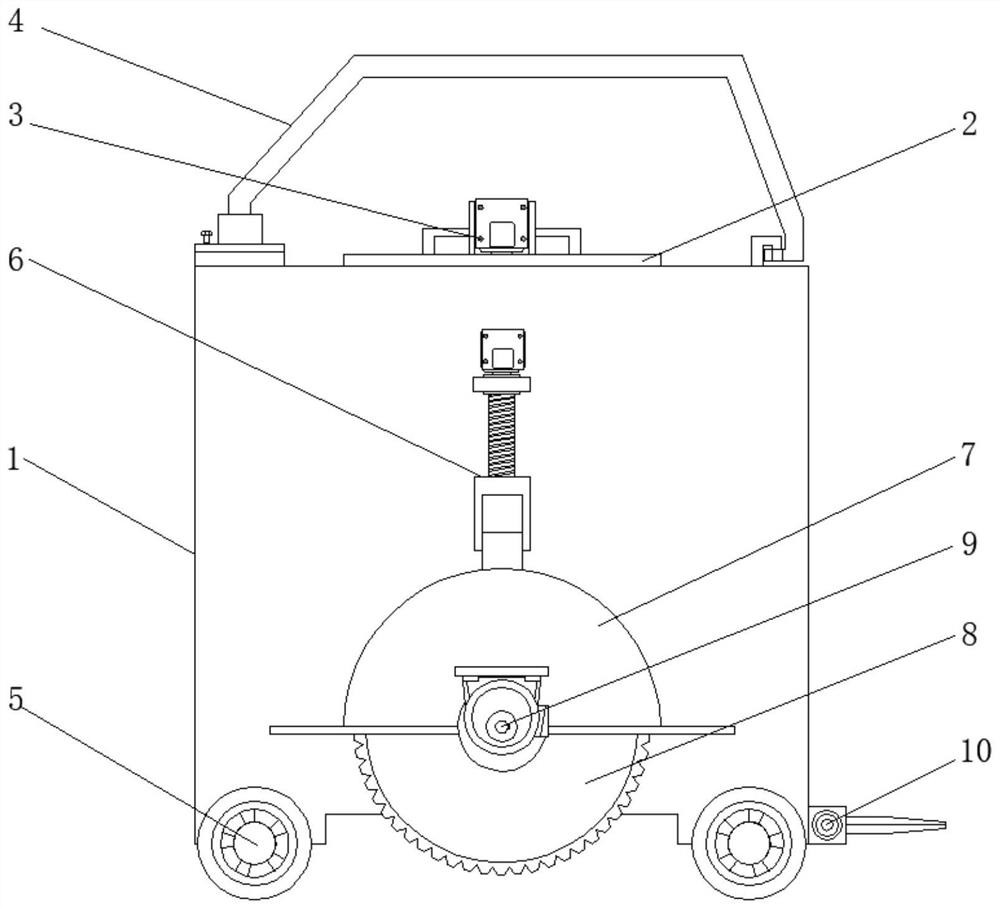

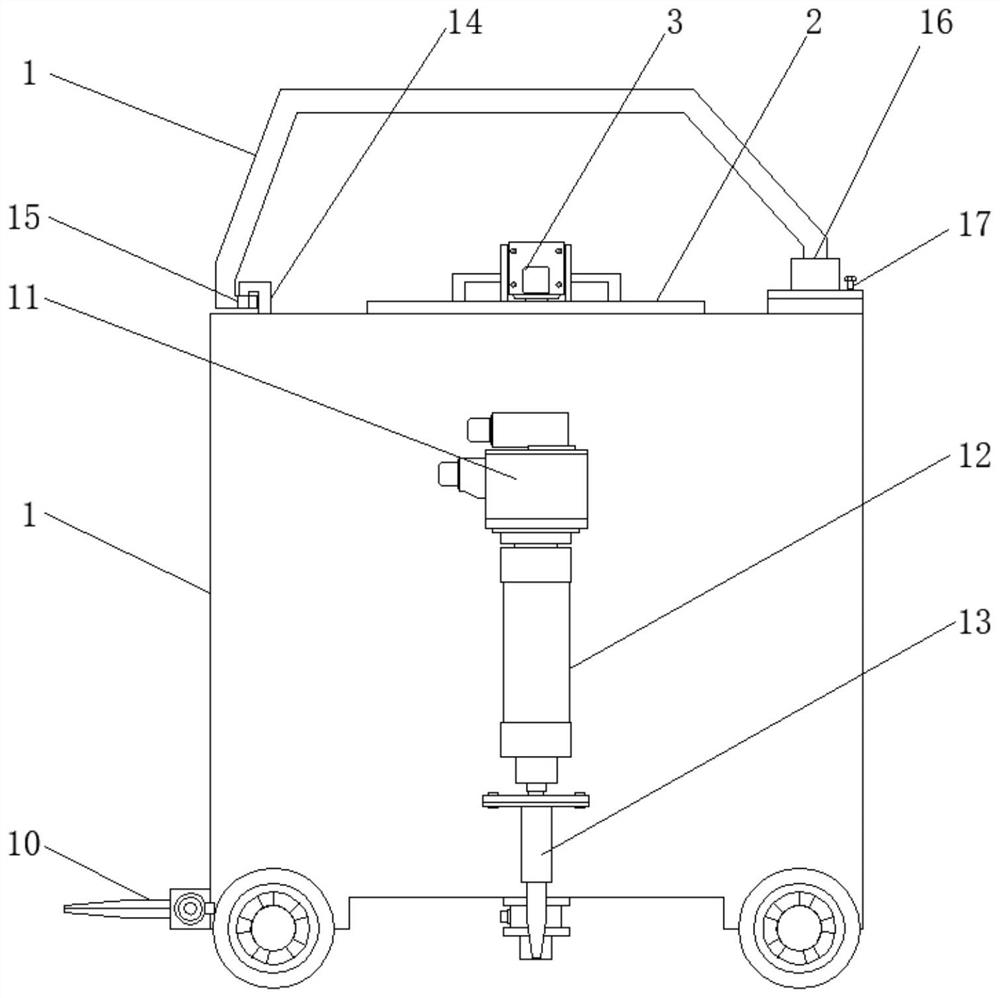

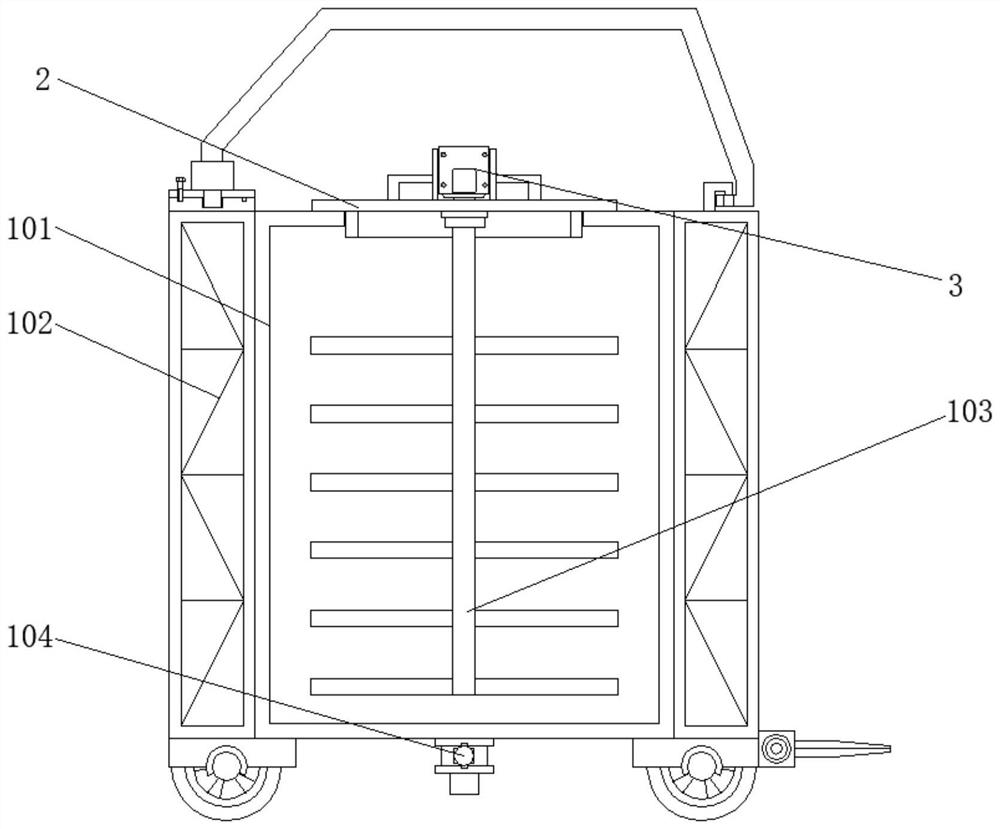

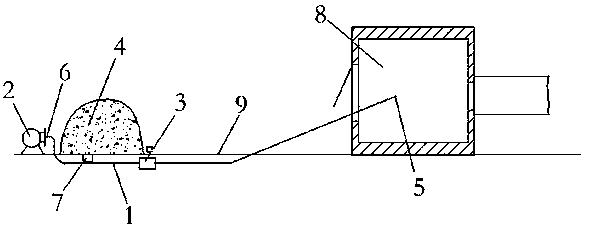

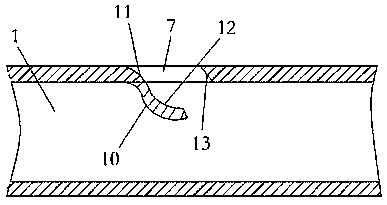

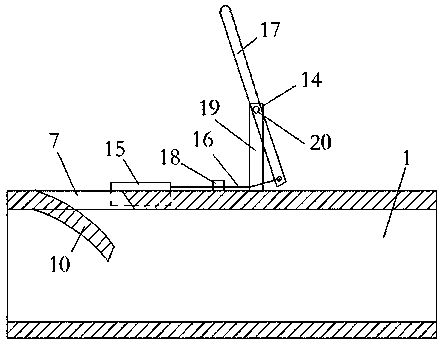

Portable repairing equipment integrating municipal traffic and pavement cutting and filling

InactiveCN112176840AReduce the burden onSolve the trouble of moving three different devices for use at the same timeRoads maintainenceArchitectural engineeringAir pump

The invention discloses portable repairing equipment integrating municipal traffic and pavement cutting and filling. The portable repairing equipment comprises a main body box, a lifting assembly anda scraping assembly, a gland is installed at an opening in the upper end of the main body box, a first motor is fixed above the gland, a push rod is installed above the first motor, and the push rod is connected with the lifting assembly. Idler wheels are arranged on the left side and the right side of the bottom of the main body box, the lifting assembly is installed on the outer wall of the front face of the main body box, a protective shell is arranged on the front face of the lifting assembly, a cutting wheel is installed in the protective shell, a second motor is installed in the middle of the cutting wheel, and the scraping assembly is installed at the lower right corner of the main body box. And an air pump is fixed to the back face of the main box, an air cylinder is connected to the lower portion of the air pump, and a punching head is installed below the air cylinder. The whole device integrates the functions of road surface cutting, road surface crushing and road surface filling, and the trouble that in the prior art, three kinds of different equipment need to be carried at the same time for use is effectively solved.

Owner:彭丽辉

Large paperboard cement smearing device for fine brushing

The invention discloses a large paperboard cement smearing device for fine brushing. The large paperboard cement smearing device comprises a telescopic button, fixing plates, a main box, a feeding box, a motor, an injection nozzle, a material storage barrel, universal wheels, clamping grooves, a discharging port, lifting buttons, a stirring wheel, soft plates, a driving roller and driven rollers.The large paperboard cement smearing device has the beneficial effects that the longitudinal height of the discharging port is greater than the longitudinal height of the top of the material storage barrel, cement from the discharging port can be completely received by the material storage barrel, and the situation of cement wasting is avoided; the injection nozzle is of a stepped circular table type structure, the cement can be better concentrated by the injection nozzle step by step, and therefore the fineness of the ejected cement is high; the lifting buttons installed in the clamping grooves are located in the middle of the side wall of the material storage barrel, the material storage barrel can freely rotate between the fixing plates, and labor is better saved in the rotating process; and threads corresponding to each other are formed in the top of the material storage barrel and the bottom of the injection nozzle correspondingly, the material storage barrel and the injection nozzle are convenient to dismount and mount, and the raw material adding process and the cleaning process of the material storage barrel are facilitated.

Owner:广东五月花网络科技有限公司

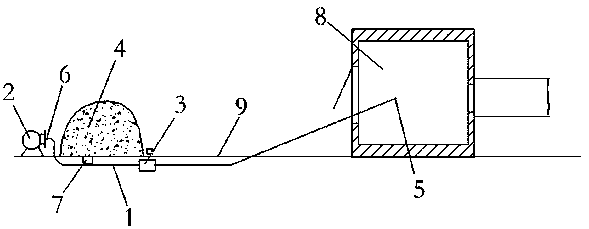

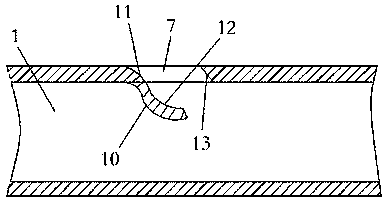

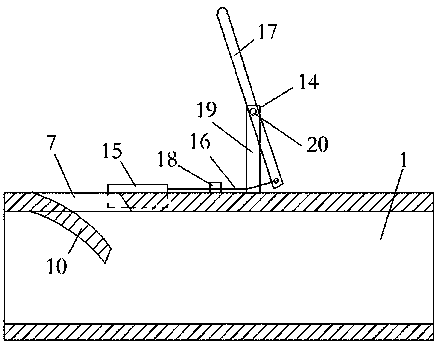

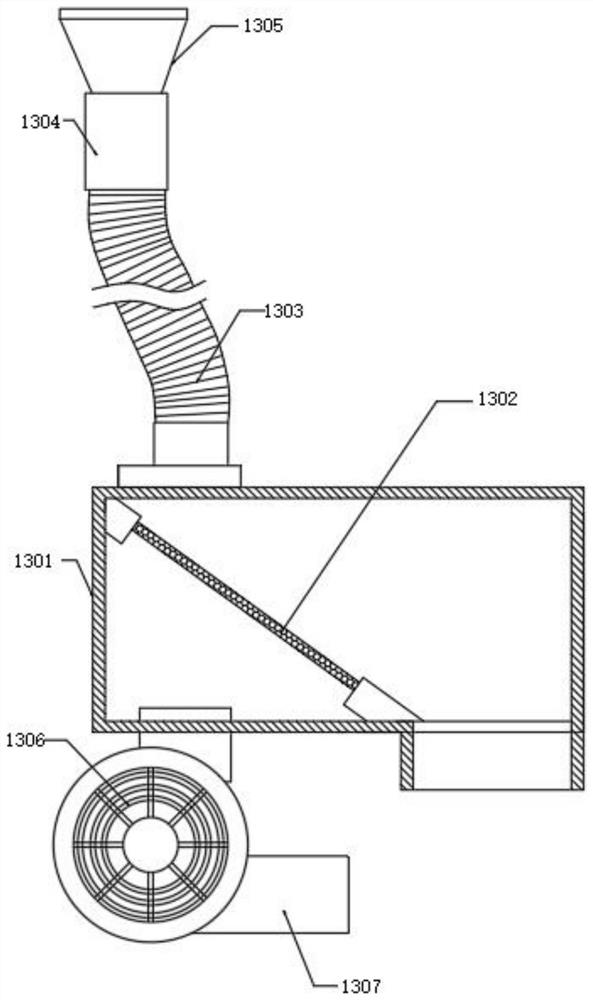

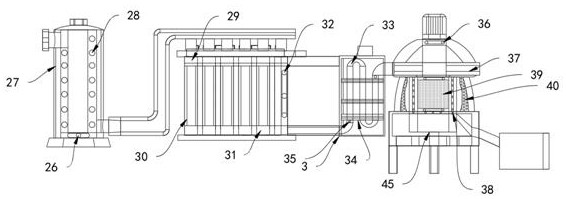

Light calcium carbonate husk combustion furnace husk feeding device

InactiveCN107917436AEasy to add ingredientsAdding materials and saving energyFuel supply regulationFuel feeding arrangementsCombustionButt joint

A light calcium carbonate husk combustion furnace husk feeding device comprises a conveying pipeline, an air blower and a control valve; the conveying pipeline is arranged below a husk stacking site;one end of the conveying pipeline is provided with the air blower, an air outlet of the air blower is in butt joint with an inlet of the conveying pipeline, and the air blower supplies air to the conveying pipeline; an outlet of the conveying pipeline stretches into a hearth of a husk combustion furnace; a husk inlet is formed in the position, located below the husk stacking site, of the middle ofthe conveying pipeline, and husk enters the conveying pipeline through the husk inlet and is blown into the hearth of the husk combustion furnace through the air blower; and the position between thehusk inlet of the conveying pipeline and the outlet, stretching into the hearth of the husk combustion furnace, of the conveying pipeline is provided with the control valve used for controlling the husk conveying amount, and the amount of the husk entering the husk combustion furnace is controlled by the control valve so that the combustion temperature and the generated heat of the husk combustionfurnace can be controlled.

Owner:湖南恒旺碳酸钙有限公司

Method for extracting theanine from tea leaves

InactiveCN109096141AEasy to addEasy to add ingredientsCarboxylic acid amide separation/purificationTheanineEngineering

The invention discloses a method for extracting theanine from tea leaves. The device comprises a fermentation frame body, wherein the inner wall body of the fermentation frame body is internally provided with a fermentation cavity; a transmission cavity is arranged inside the fermentation frame body on the top of the fermentation cavity in a left-and-right extending manner; a sliding seat is mounted inside the transmission cavity in a sliding fit manner; a first motor is fixedly arranged inside the left side fracture surface of the sliding seat; a first bevel gear is mounted at the left end ofthe first motor in a power fit manner; a left-and-right extending connecting rod is mounted at the left end of the first bevel gear in a normal running fit manner; a second bevel gear is arranged atthe bottom of the first bevel gear in an intermeshing manner; a main rotating shaft is fixedly arranged at the bottom of the second bevel gear; the main rotating shaft extends downwards into the fermentation cavity and is connected with the upper and lower end walls of the fermentation cavity in the normal running fit manner; a plurality of groups of stirring rods are fixedly arranged on the outersurface of the main rotating shaft in the circumferential direction; and stirring paddles are symmetrically and fixedly arranged on the upper and lower end faces of the stirring rods on the side awayfrom the main rotating shaft.

Owner:湖南冯河大龙山茶业有限公司

Biomass direct combustion furnace

InactiveCN104132369BBurn fullyImprove utilization efficiencyDomestic stoves or rangesLighting and heating apparatusCombustion chamberDirect combustion

Owner:金桂方

Method and device for feeding rice husks into rice husk combustion furnace for light calcium carbonate

PendingCN107702130AEasy to add ingredientsAdding materials and saving energyCalcium/strontium/barium carbonatesFuel feeding arrangementsProcess engineeringAir blower

The invention discloses a method and a device for feeding rice husks into a rice husk combustion furnace for light calcium carbonate. The method is characterized in that a conveying pipeline is arranged below a rice husk stacking site, an air blower is arranged at an end of the conveying pipeline, an air outlet of the air blower is butted to an inlet of the conveying pipeline, air can be deliveredto the conveying pipeline, an outlet of the conveying pipeline extends into a hearth of the rice husk combustion furnace, a rice husk inlet is formed in the middle of the conveying pipeline and is particularly formed in a position below the rice husk stacking site, and the rice husks can be fed into the conveying pipeline from the rice husk inlet and can be blown into the hearth of the rice huskcombustion furnace; a control valve for controlling the conveying quantities of the rice husks is arranged between the rice husk inlet of the conveying pipeline and an outlet in the hearth of the ricehusk combustion furnace, and the quantities of the rice husks which are fed into the rice husk combustion furnace can be controlled by the control valve, so that the combustion temperatures of the rice husk combustion furnace and generated heat can be controlled.

Owner:湖南恒旺碳酸钙有限公司

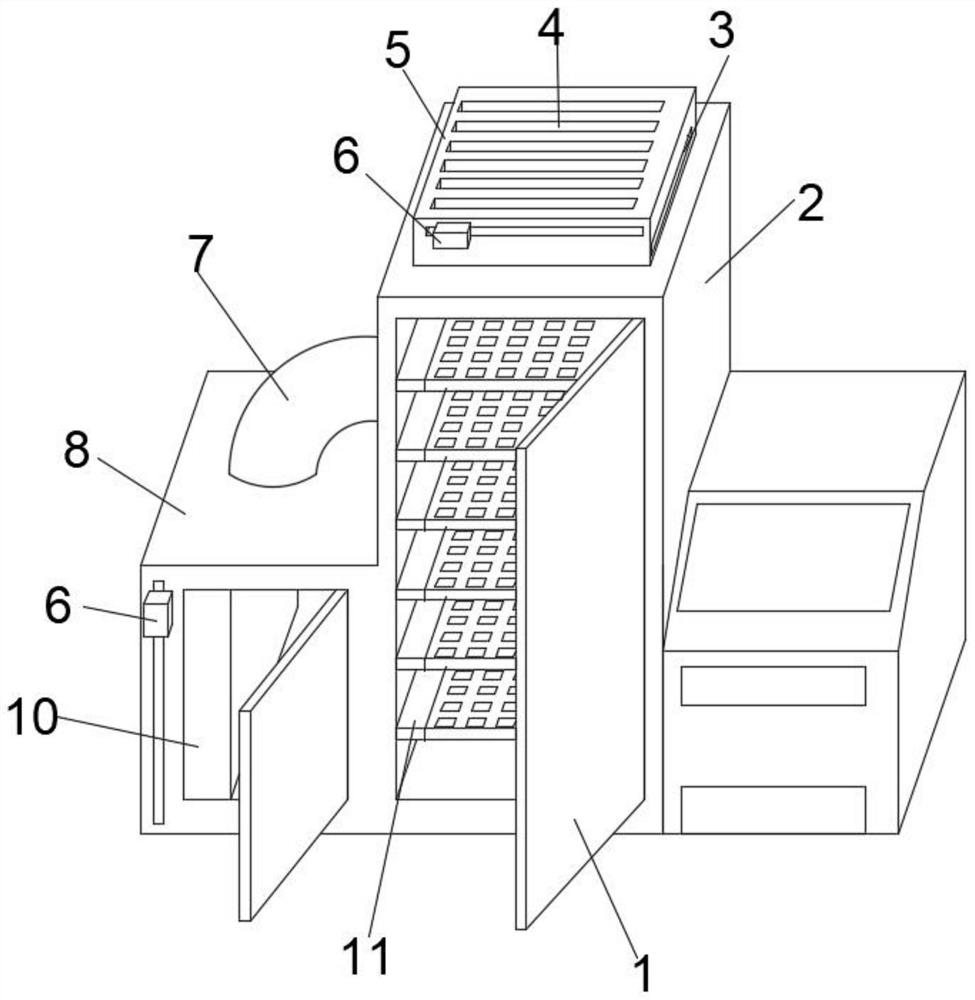

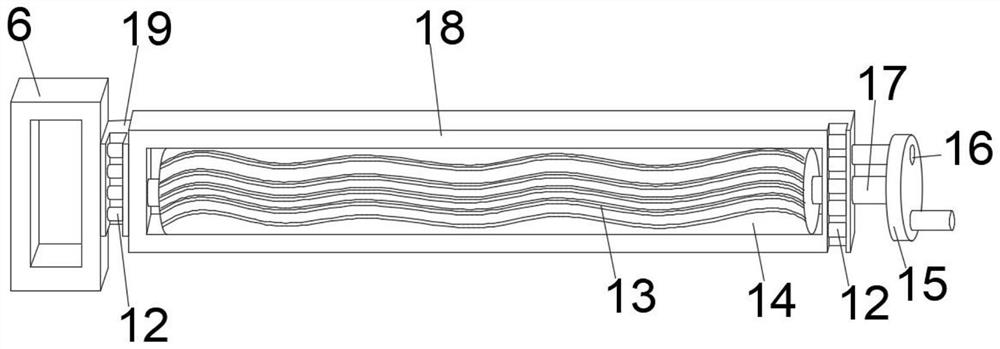

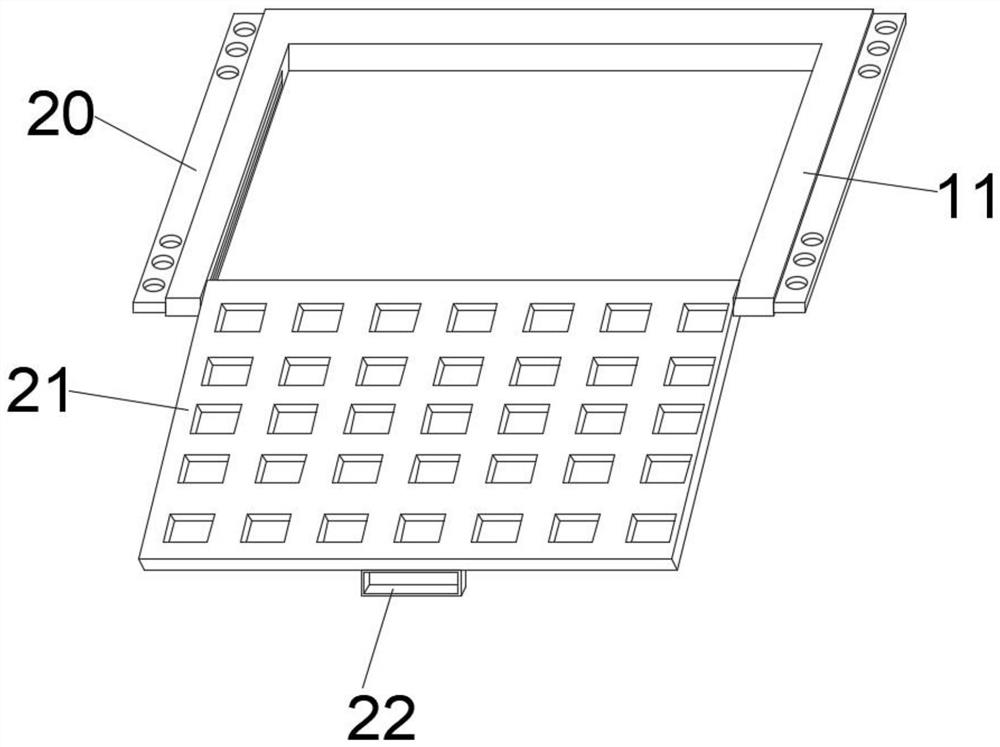

Chip resistor conductor layer drying equipment and using method thereof

InactiveCN113539593APrevent rotationReduce frictionResistor chip manufactureCleaning using toolsElectrical conductorDust control

The invention discloses chip resistor conductor layer drying equipment and a using method thereof. The chip resistor conductor layer drying equipment comprises a drying cabinet and a fixed side box. The fixed side box is fixedly installed on the outer surface of one side of the drying cabinet, a communicating pipe is arranged between the fixed side box and the drying cabinet, and an exhaust hood is fixedly installed on the outer surface of the upper end of the drying cabinet. Push-pull buckles are movably installed on the outer surfaces of the side edges of the exhaust hood and the fixed side box, a movable sliding frame is fixedly installed at one end of each push-pull buckle, the movable sliding frames are movably installed on the inner sides of the exhaust hood and the fixed side box, and a rolling brush rod is movably installed in the middle of the inner side of each movable sliding frame. The movement of the movable sliding frames is matched with the rolling brush rods in a fixed state to conduct dust removal operation on the interior of the equipment, and meanwhile the movement of the movable sliding frames is matched with the rolling brush rods in a rotating state to discharge cleaned dust from a dust discharging groove, so that dust removal operation on the interior of the equipment is completed under the condition that the equipment is not disassembled, and the phenomenon that the equipment is blocked due to accumulated dust is avoided.

Owner:安徽省富捷电子科技有限公司

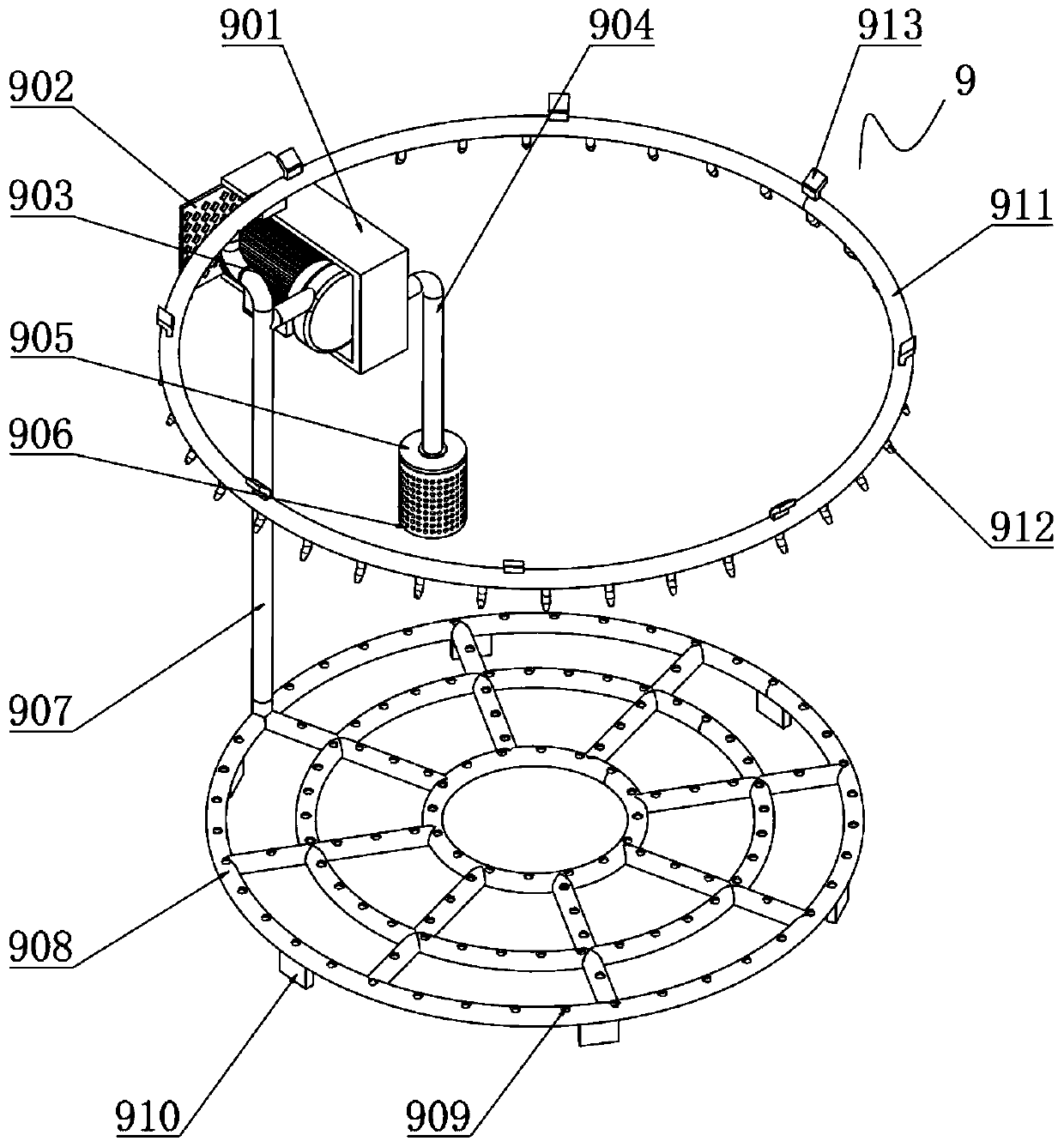

Subcritical water reaction device for automatically preparing organic fertilizer

InactiveCN110668849AEvenly distributedAvoid accumulationClimate change adaptationExcrement fertilisersAgricultural engineeringElectric machinery

The invention discloses a subcritical water reaction device for automatically preparing an organic fertilizer, which comprises a base, an air outlet valve and a magnet, wherein two sides of the top ofthe base are fixed with rotating frames; one side of the rotating frame, which is far away from the base, is rotationally connected with a roller; one side of the base which is close to the rotatingframes is fixed with a first motor; the first motor is in transmission connection with the roller through a belt; a reaction chamber is formed in the roller; a feed pipe is communicated with the top of the roller; a discharge pipe is communicated with the side of the roller which is far away from the feed pipe; a rotating rod penetrates through the inside of the reaction chamber; and a stirring rod is fixed on the rotating rod and is positioned outside the reaction chamber. The subcritical water reaction device for automatically preparing the organic fertilizer is provided with the roller andthe first motor, the feed pipe is closed, a second motor stops rotating, the first motor drives the roller to rotate through the belt, so that materials roll in the reaction chamber, and the high-pressure steam and the materials are uniformly mixed through the rotation of the roller to perform full sterilization.

Owner:汪娟

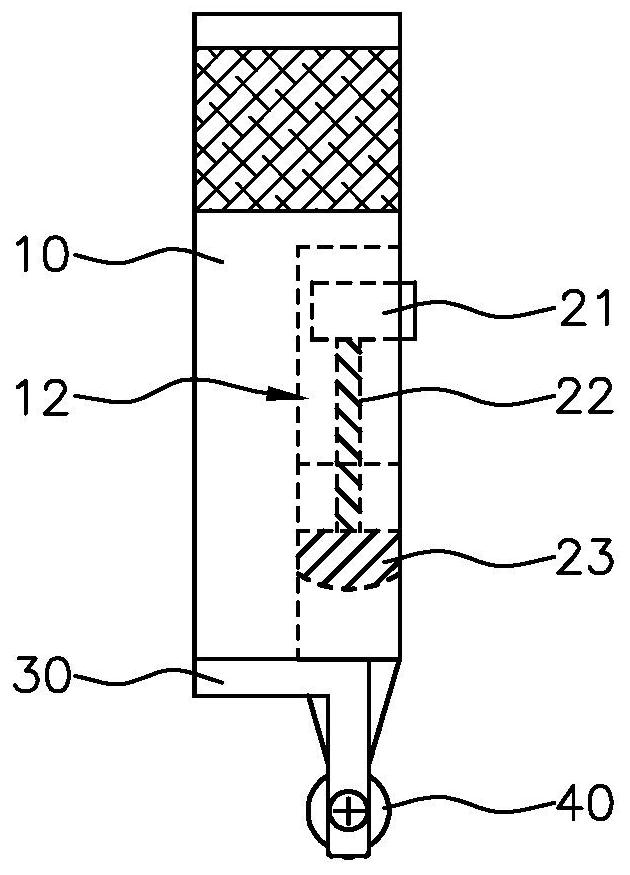

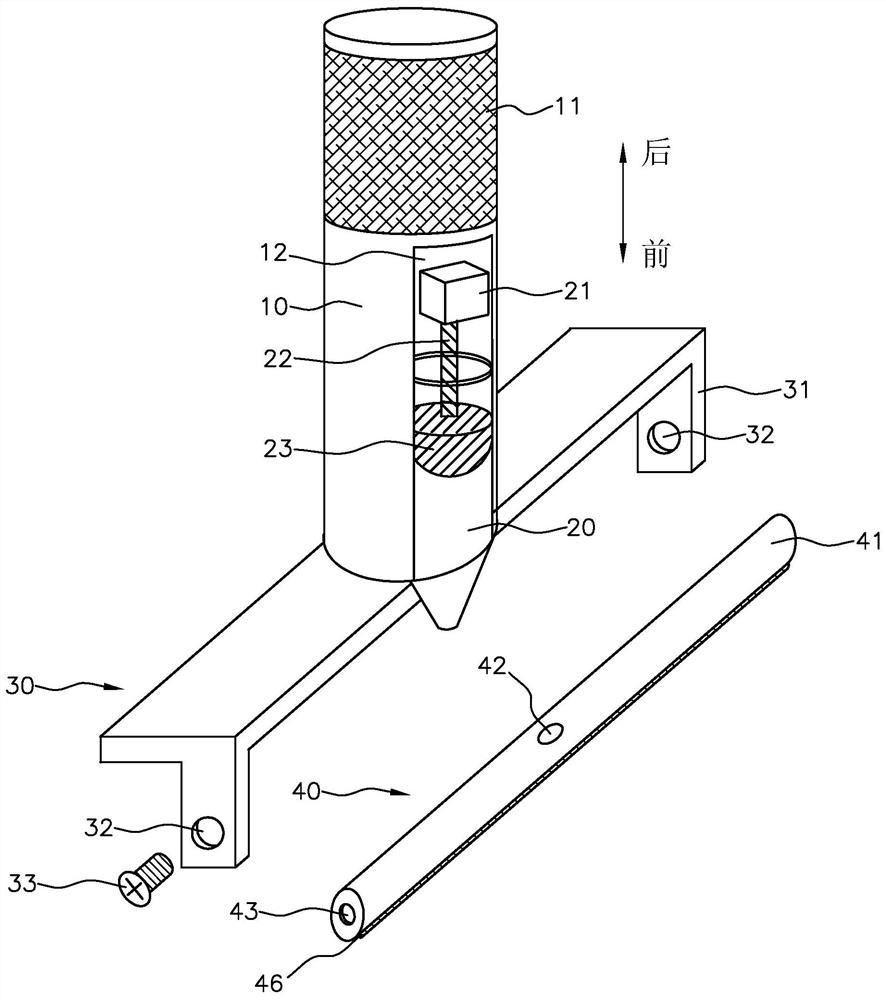

Coil bar coater capable of controlling coating weight

PendingCN113499965AImprove efficiencyAvoid uneven applicationLiquid surface applicatorsCoatingsElasterellMechanical engineering

The invention discloses a coil bar coater capable of controlling the coating weight, and relates to the technical field of coil bar coater. The coil bar coater comprises a coating assembly, a handle and a charging barrel, the coating assembly comprises a coating body internally provided with a coating liquid groove, the coating body is provided with a feeding hole and a discharging groove which communicate with the coating liquid groove, a bar body is arranged in the coating liquid groove, an elastic piece connected with the rod body is mounted in the coating body, and the elastic piece applies elastic force for enabling the rod body to move towards the direction of the discharging groove, so that the rod body clamps the discharging groove; the handle is connected with the coating assembly; and the charging barrel is provided with a discharging hole communicating with the feeding hole, and a piston is arranged in the charging barrel and used for outputting the coating in the charging barrel from the discharging hole. According to the coil bar coater capable of controlling the coating weight, materials can be conveniently and uniformly added on the surface of a base material, and the problems of non-uniform coating thickness and the like caused by human factors can be solved.

Owner:SOUTH CHINA UNIV OF TECH

Feeding and proportion control equipment for scale inhibitor and adhesive of sintered carbon rod

InactiveCN114311820AImprove the efficiency of rod makingImprove efficiencyRotary stirring mixersTransportation and packagingProportional controlAdhesive

The invention discloses a feeding and proportion control device for a scale inhibitor and an adhesive of a sintered carbon rod. The feeding and proportion control device comprises a workbench; the extrusion forming cylinder is arranged on the upper end face of the workbench, and a forming opening is formed in one side of the extrusion forming cylinder. According to the device, a scale inhibitor and an adhesive can be directly placed into a charging barrel for storing the scale inhibitor and the adhesive through the two material suction ports, then raw materials can be directly sucked into the hopper through the two air pumps to be mixed, the mode that in the prior art, the raw materials need to be poured into an added material from a high position is changed, material adding is more convenient and rapid, and during continuous feeding operation, the material adding efficiency is improved. The carbon rod extrusion equipment does not need to be shut down to wait for feeding operation, continuous feeding operation can be achieved by sequentially placing the suction ports of the carbon rod extrusion equipment into different storage equipment, the rod manufacturing efficiency of a factory is improved, meanwhile, the exhaust end of the air pump can feed air into the hopper through the exhaust pipe, raw materials accumulated in the hopper can be blown into the extrusion device, and the production efficiency is improved. And the condition of accumulation of residual materials is prevented.

Owner:江西中科高博科技服务有限公司

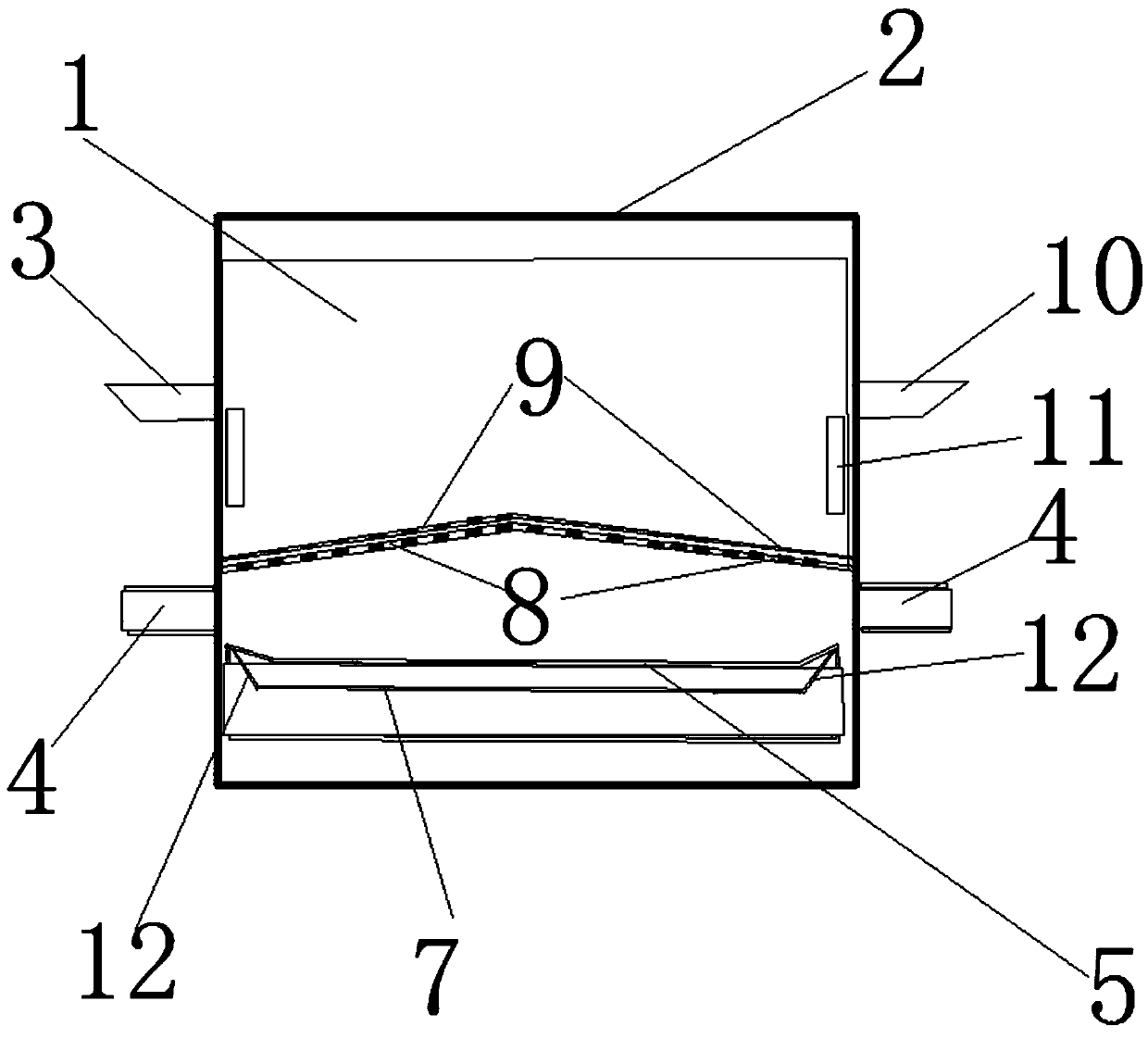

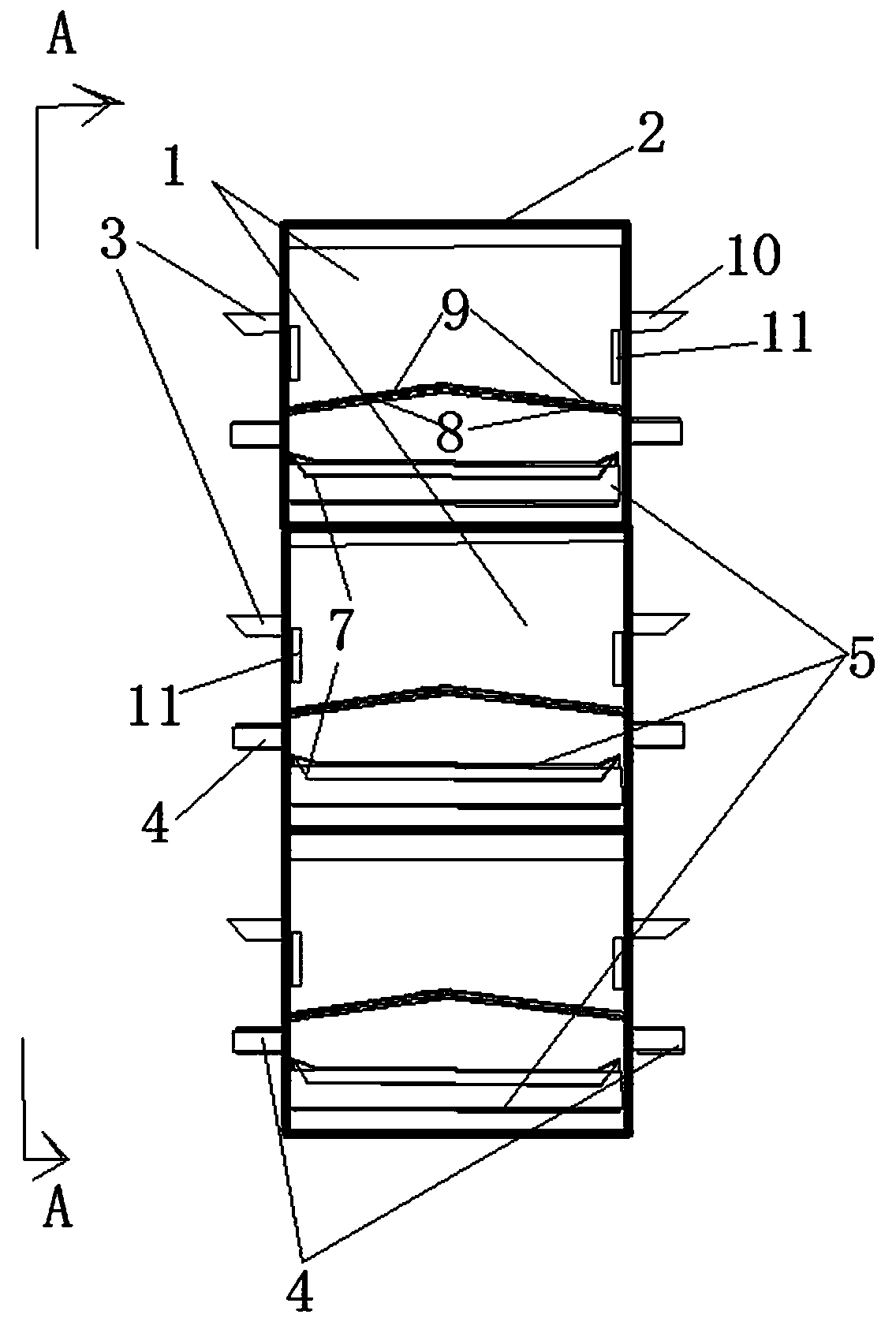

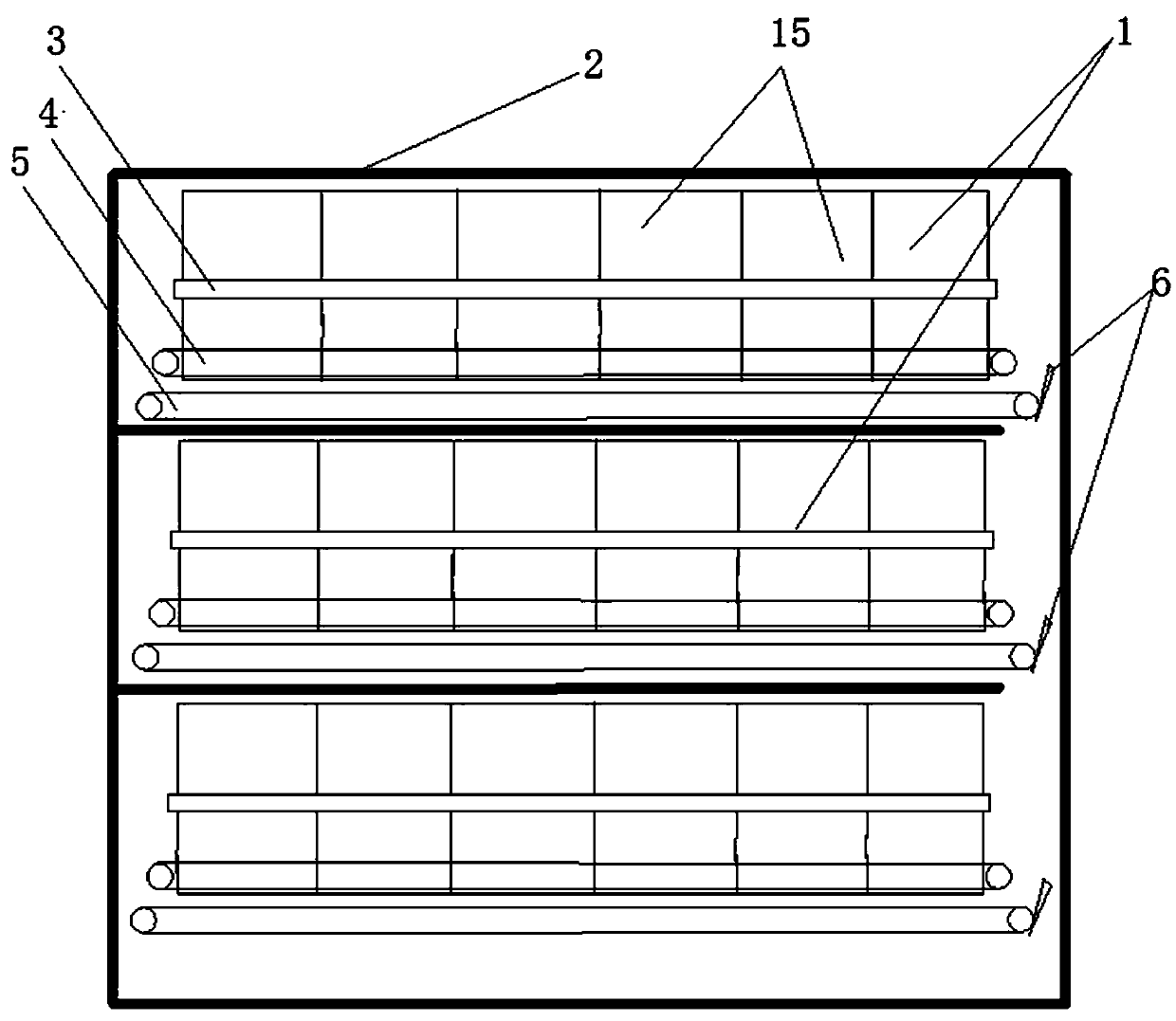

Layered duck breeding method

The invention provides a layered duck breeding method. Duck cages are arranged on a machine frame layer by layer. Water troughs and feed troughs are distributed on the two sides of the machine frame from bottom to top respectively. Longitudinal plates divide the duck cages into one or more chambers. The average cage occupation area of a duck in each chamber is not smaller than 450 cm<2>. The artificial illumination time kept in a duck house is not shorter than 12 hours. The water level in each water trough is kept above the threshold so that the ducks can drink water freely. The feed amount ineach feed trough is set so that the ducks can freely eat. A duck cage floor is an inverted-V-shaped egg collecting mesh piece with duck excrement leaking holes. A soft mesh cushion with holes is arranged on each edge collecting mesh piece so that the irritation on duck flippers can be reduced and the duck flippers can be protected. An excrement and urine collecting conveying belt is arranged under each egg collecting mesh piece. Each excrement and urine collecting conveying belt is placed between the upper layer of duck cages and the lower layer of duck cages so that excrements can be isolated. The duck cages in each layer share the corresponding excrement and urine collecting conveying belt. Laying ducks can adapt to the layered cage breeding, the space utilization rate of the duck cagesis large, the safe collection of egg products is facilitated, and the rapid cleaning of the excrements of the laying ducks is facilitated.

Owner:福建光阳蛋业股份有限公司

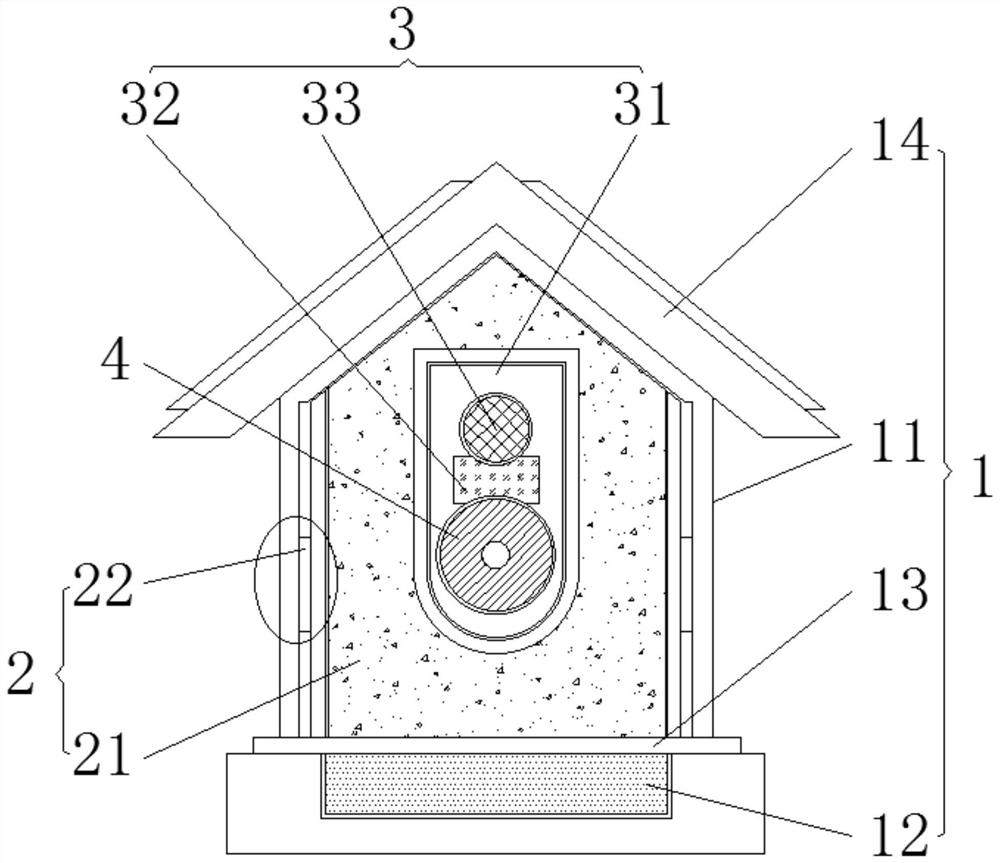

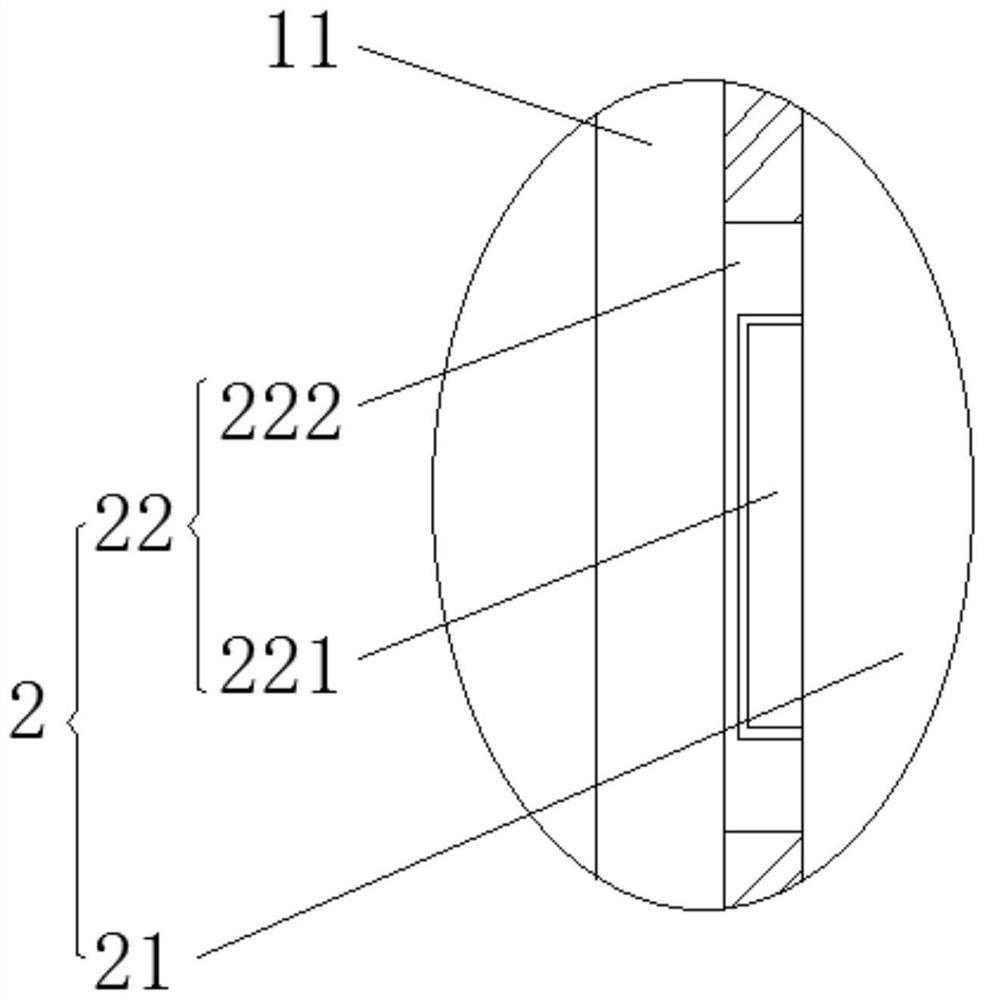

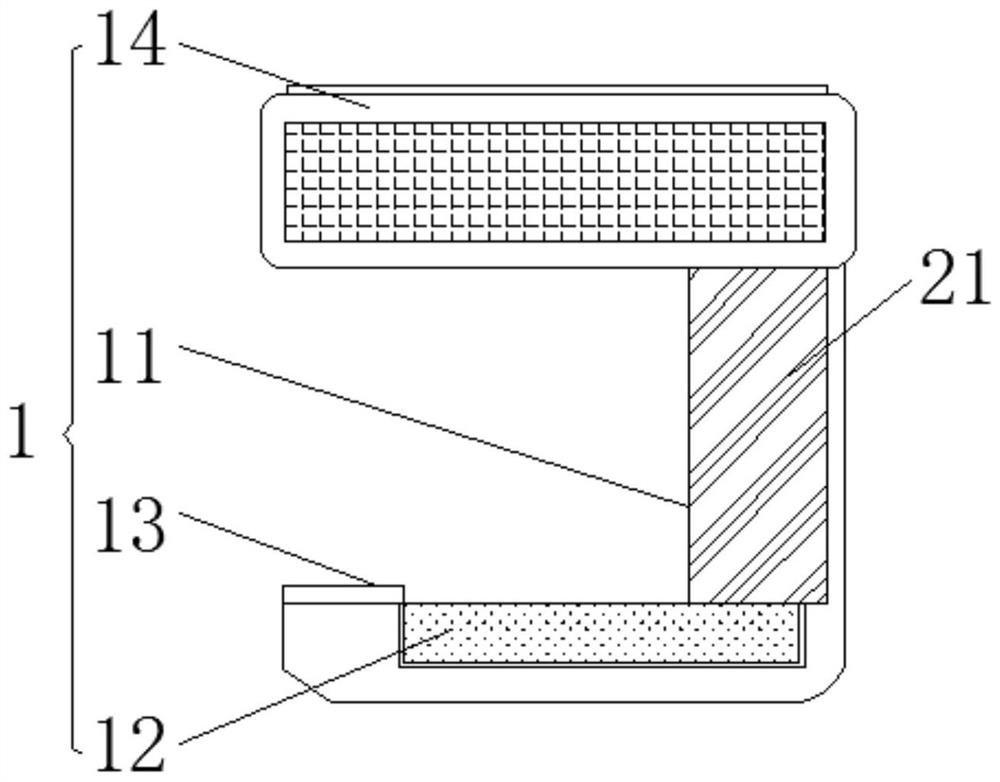

Feeding device with suction function and feeding system thereof

InactiveCN113678756ACapture in timeWith feeding target selection functionClosed circuit television systemsAvicultureAnimal scienceEngineering

The invention relates to a feeding device with a suction function and a feeding system thereof. The feeding device comprises a shell, a food storage structure, a sound release structure and a camera probe, wherein the sound release structure and the camera probe are fixedly installed in the shell. The shell comprises an L-shaped loading frame, a trough formed in the L-shaped loading frame, a grabbing plate and a rainproof cover. The sound release structure comprises a host fixedly installed in the L-shaped loading frame, a communication chip arranged in the host, and a trumpet projector fixedly installed at the portion, opposite to the L-shaped loading frame, of the host. The feeding device is of a house structure, animal eating can be facilitated, birds are attracted for feeding by making a sound, target animals can be attracted by selecting the sound corresponding to the birds wanting to be fed, and the feeding device has the functions of attraction feeding and feeding target selection. The feeding system can flexibly record image information of needed species, has the attracting function to attract feeding and the driving function, and can release sound to attract a certain specific species according to needs.

Owner:柠檬智能深圳有限公司

Epoxy resin processing reaction kettle facilitating material adding

PendingCN113385129AEasy to add ingredientsAvoid containingChemical/physical/physico-chemical stationary reactorsFeed devicesManufacturing engineeringEpoxy

The invention discloses an epoxy resin processing reaction kettle facilitating material adding. The epoxy resin processing reaction kettle comprises a kettle body, a feeding pipe, a sealing cover, a discharging pipe, a stirring shaft, a barometer, a thermometer, a first telescopic air cylinder, a material guiding plate, an auxiliary feeding device, a third telescopic air cylinder and a filtering device, a ceramic wall is fixedly embedded in the inner wall of the kettle body, and a first sliding groove is formed in the right side of the feeding pipe; A sealing gasket is fixedly embedded in the left side of the sealing cover, and a discharging valve is installed on right side of the discharging pipe. According to the epoxy resin processing reaction kettle facilitating material adding, the filtering device is arranged, a finished product in the kettle body is conveyed into the connecting pipe through the discharging pipe, and then the finished product is conveyed to the filtering plate through the connecting pipe. Therefore, the finished product is filtered through the filter plate, and the problems that the finished product contains a small amount of impurities after being processed, and meanwhile, the finished product passing through the discharging pipe needs to be subjected to impurity filtering treatment, so that troubles are caused, and the overall working efficiency is reduced are solved.

Owner:江苏宏景电气有限公司

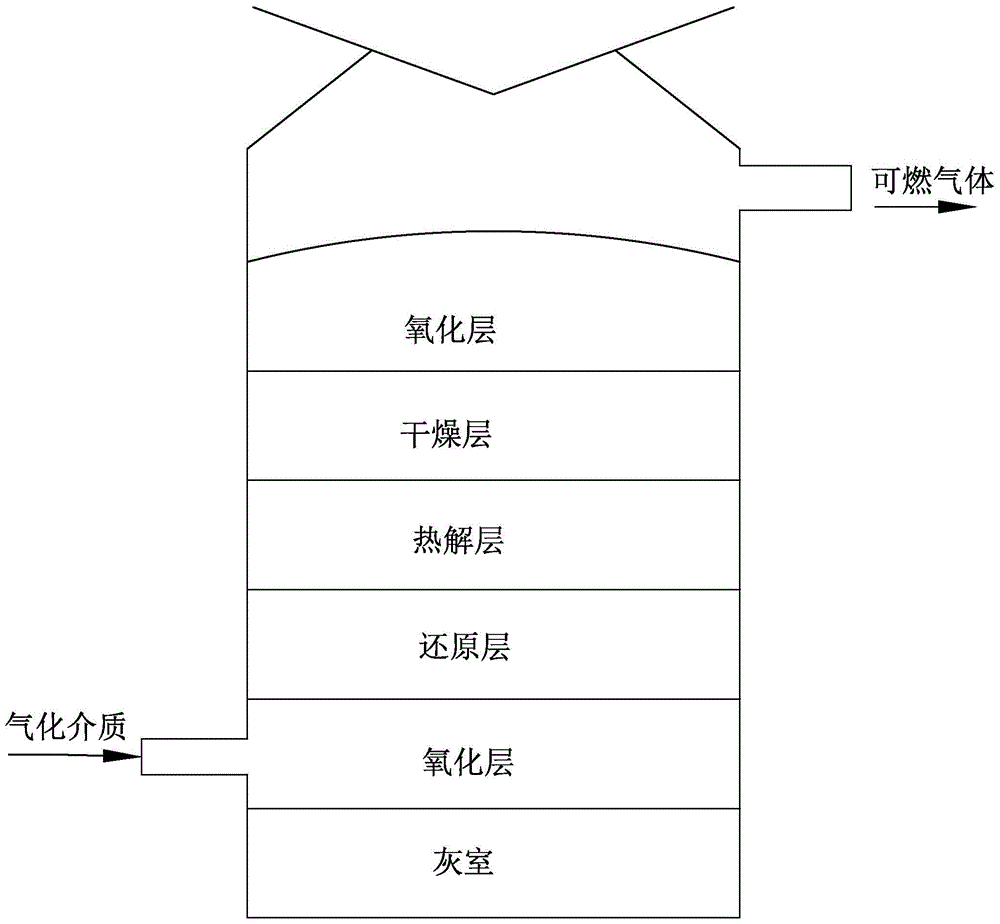

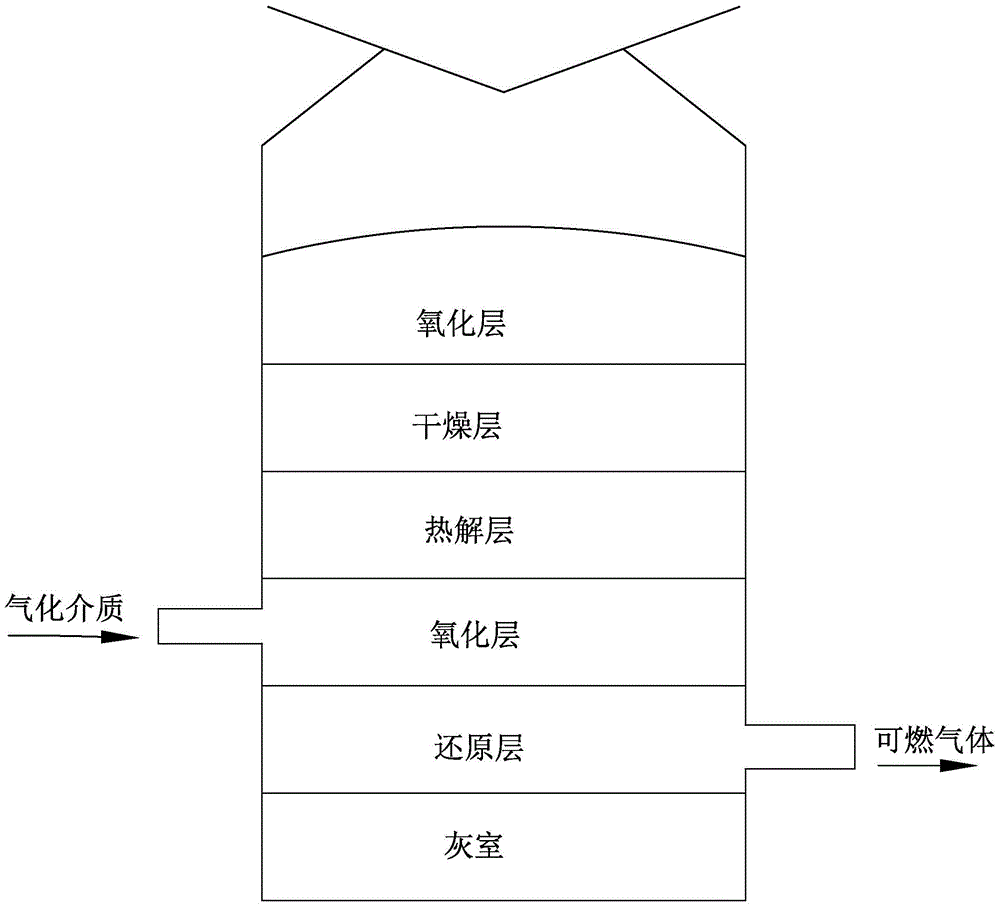

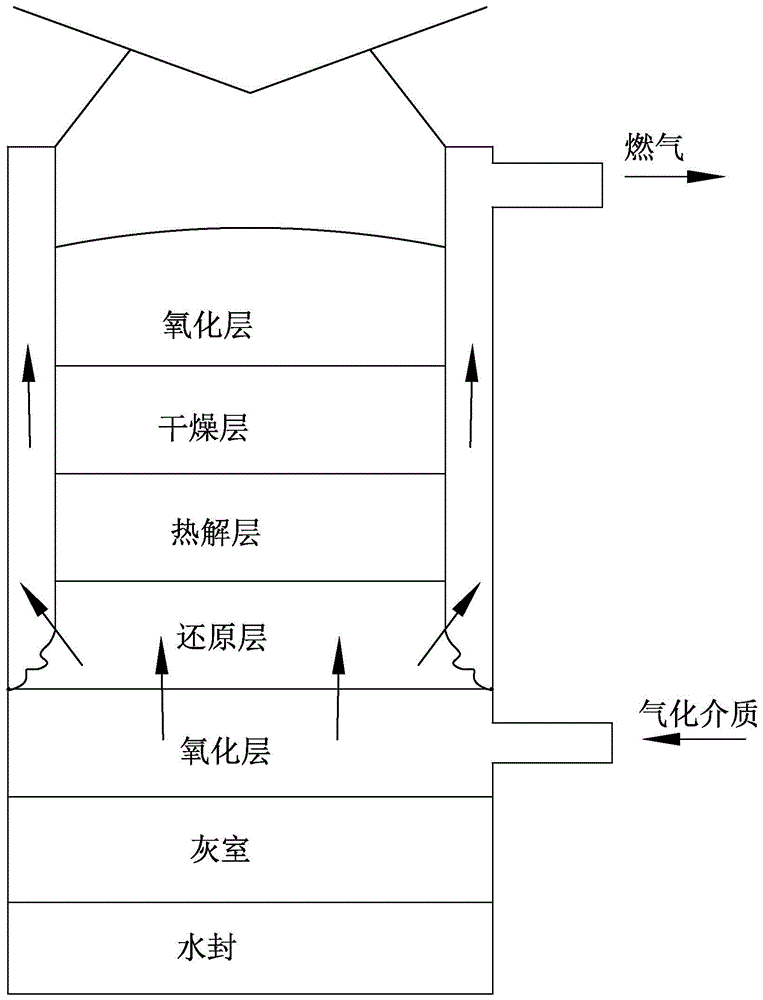

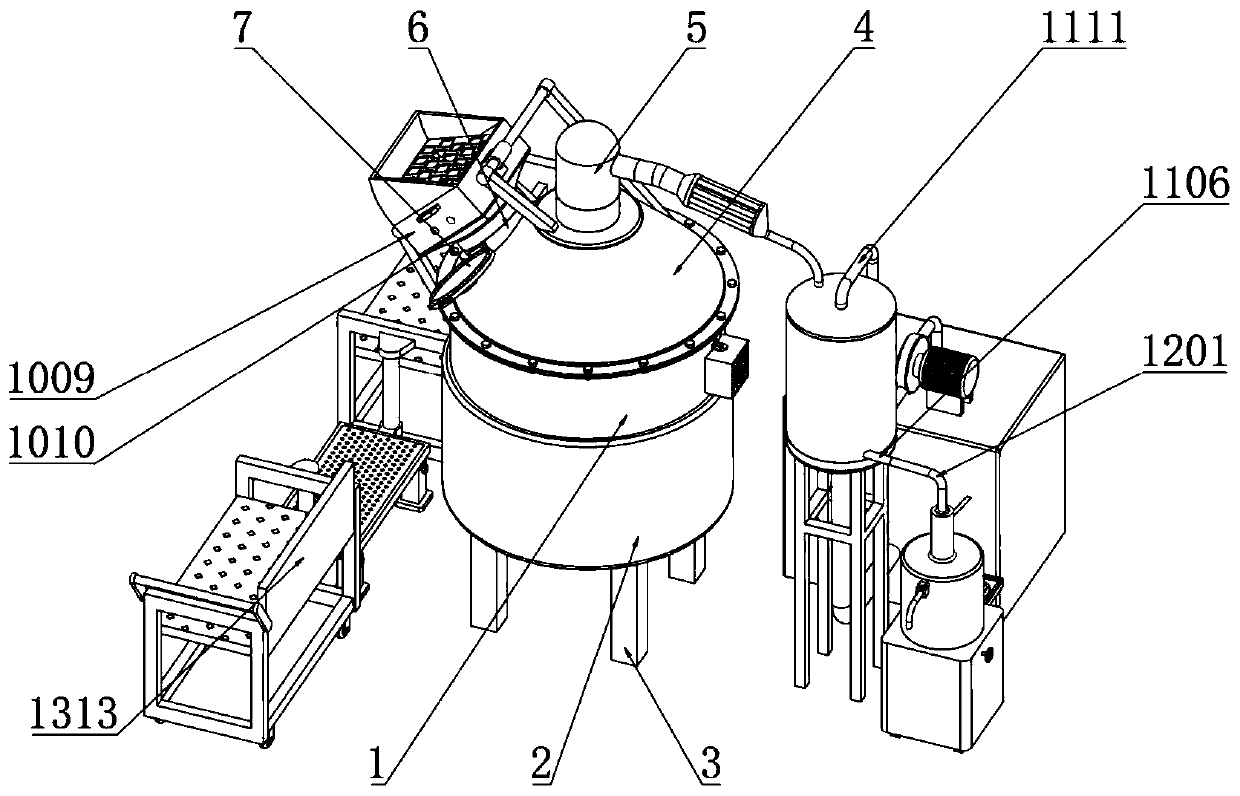

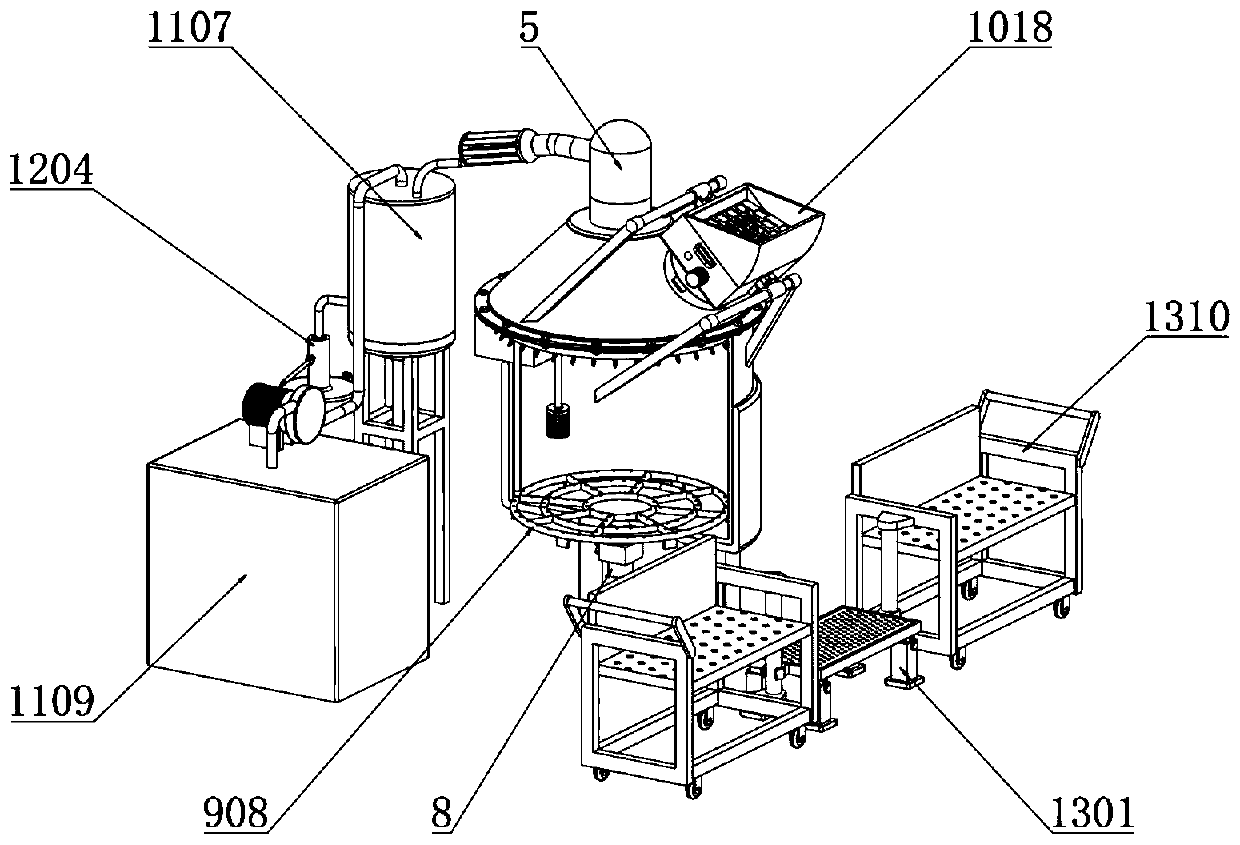

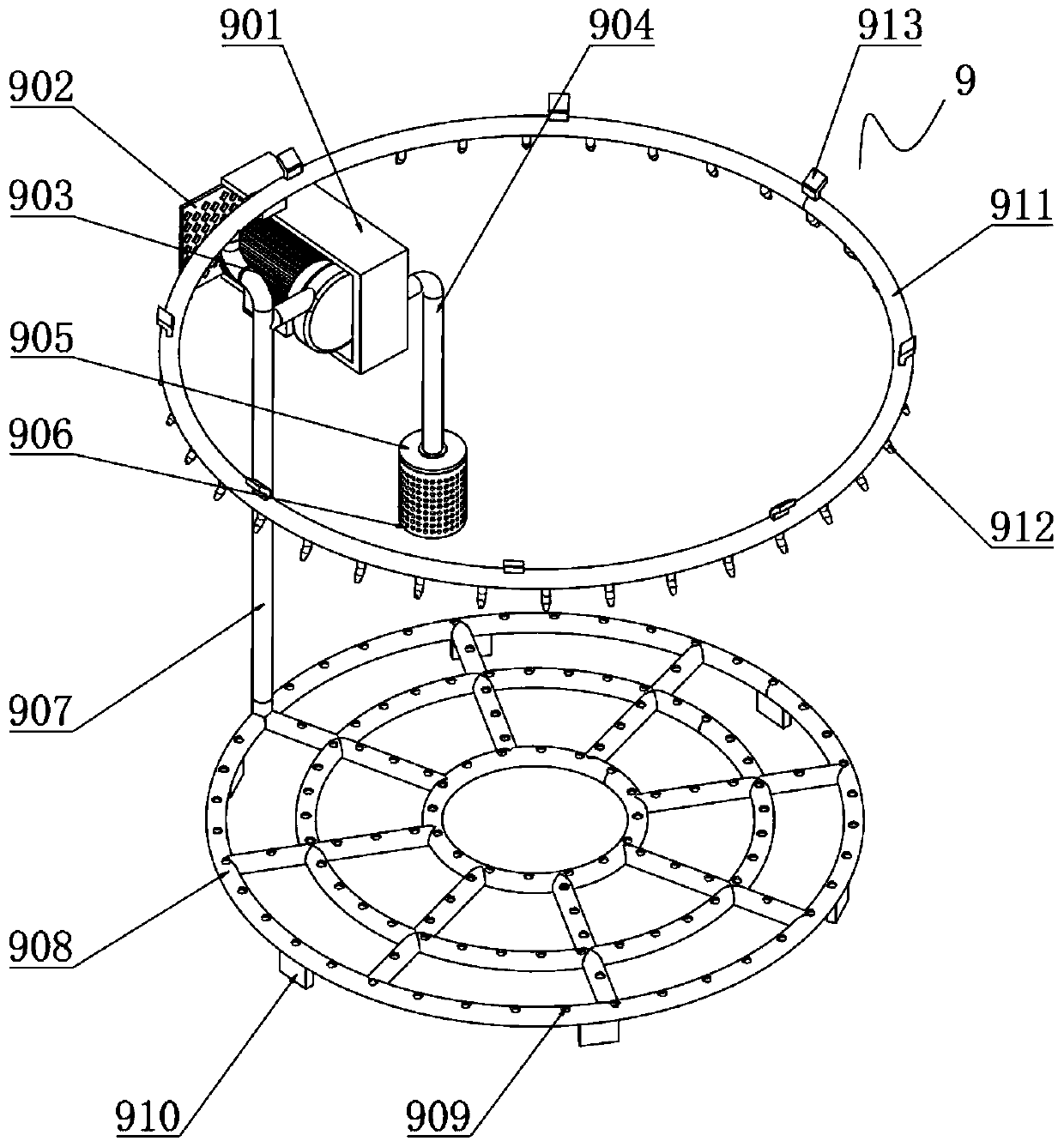

Biomass gasification furnace using furnace interlayer structure for decoking

A biomass gasification furnace that utilizes the interlayer structure of the furnace body for decoking, which includes a furnace body provided with a drying layer, a pyrolysis layer, a reduction layer and an oxidation layer, and the furnace body is provided with a feeding port, a gasification medium inlet and a The gas outlet is provided with a fire grate in the furnace body, which is characterized in that the furnace body is constructed as a sandwich structure with a gasification channel, and the gasification channel includes a gas channel and a gasification medium channel, wherein one end of the gas channel communicates with the reducing layer, and the other One end is connected with the gas outlet, so that the combustible gas generated in the furnace is forced to flow through the reducing layer and discharged, and the high temperature of the reducing layer is used to further crack the tar in the combustible gas to reduce the tar content. The invention overcomes the shortcomings of traditional gasifiers and effectively combines its advantages, solving the problems of high tar content of combustible gas discharged from the updraft gasifier and inconvenient addition of materials, and difficulty in gas extraction of the downdraft gasifier question. In addition, the present invention uses the structure of the furnace body to construct channels, which can increase the flow rate of air intake / exit, which is beneficial to maintain the stability of the reaction in the furnace.

Owner:深圳市科陆绿能节能环保有限公司

High-pressure distillation essential oil separation and purification treatment system

InactiveCN111440660AScientific and reasonable structureEasy to useFatty-oils/fats refiningOil separationDisplay device

The invention discloses a high-pressure distillation essential oil separation and purification treatment system, wherein a triangular frame is fixedly connected to the rear side of at least one protective vertical plate in an auxiliary mechanism, and is fixedly connected with a raw material purging box, an electric flap door is arranged at the upper end of the raw material purging box, a purging fan and a control display device are fixed on the side surface of the raw material purging box, the outlet of the purging fan is communicated with a purging nozzle embedded and fixed on the electric flap door through a hose, an electric telescopic rod is fixedly connected to the bottom wall of the raw material purging box, the output shaft of the electric telescopic rod is fixedly connected with atray, a first weight sensor is fixedly connected to the bottom end of the tray, a plurality of dust exhaust holes are formed in the protection wall of the tray, at least one exhaust hole is formed inthe left side of the raw material purging box, and a second weight sensor is arranged on the bottom surface of the pedal of the auxiliary mechanism.

Owner:陈国全

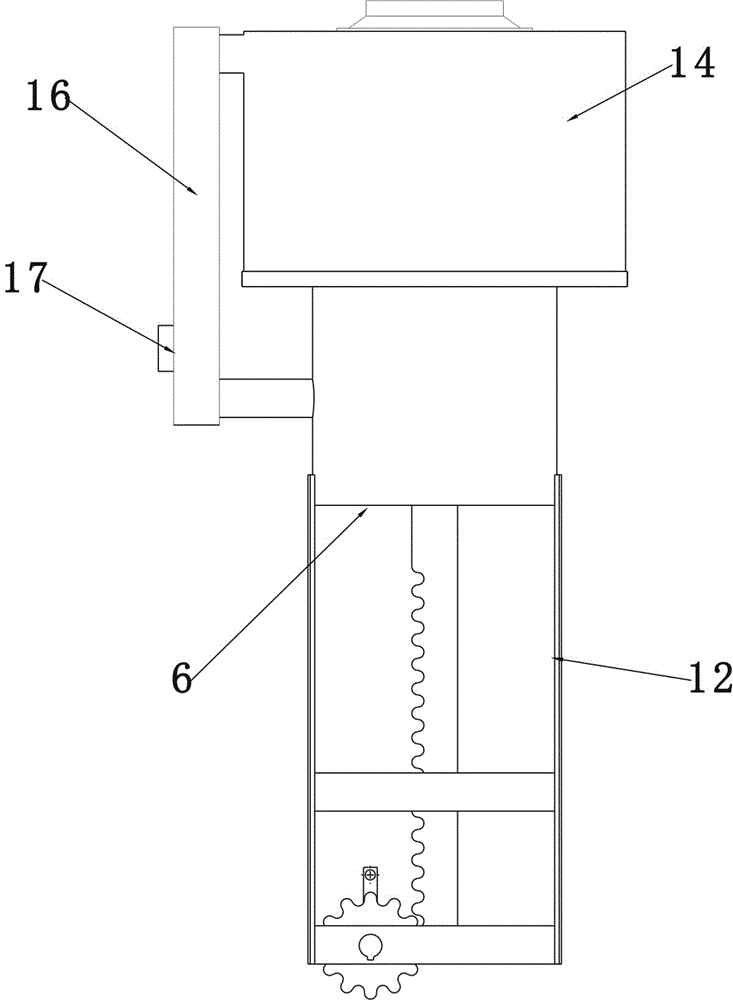

Multi-layer weighing device for feed milll

PendingCN112027133AEasy to add ingredientsEasy to take outSolid materialElectric machineryAgricultural engineering

The invention discloses a multi-layer weighing device for a feed mill, and relates to the technical field of agricultural and sideline product production. The device comprises a bottom plate, whereina side plate is perpendicularly fixed to the upper wall of the rear side of the bottom plate, a top plate is fixed in front of the top of the side plate, a second electric push rod is perpendicularlyfixed to the right side below the top plate, a first electric push rod is transversely arranged on the left side below the top plate, and a weighing sensor is arranged above the bottom plate. Throughthe multi-layer arrangement, a turnover box is arranged above a weighing plate, feeding and taking operation is more convenient, the feeding and taking operation can be correspondingly conducted on feed in a bag through the arrangement of the first electric push rod, a spiral blade and a motor, and the problems that in the prior art, when feed is weighed, a worker needs to go back and forth between a feed weighing position and a feed turnover position, weighing is inconvenient, and in the prior art, the labor intensity of workers is increased due to the fact that feeding and taking operation is conducted on the weighed feed manually are solved.

Owner:江门市恒胜实业有限公司

Method for extracting theanine from tea leaves

InactiveCN108546640AEasy to addEasy to add ingredientsBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringTheanine

The invention discloses a method for extracting theanine from tea leaves. The method is characterized by comprising a fermentation rack body, wherein an inner wall body of the fermentation rack body is provided with a fermentation cavity; the fermentation rack arranged at the top end of the fermentation cavity is provided with a transmission cavity in a left-right extension manner; a sliding baseis mounted in the transmission cavity in a sliding fit manner; a first motor is fixedly arranged in the left-sided cross section of the sliding base; a first bevel gear is mounted at the left end of the first motor in a dynamic fit manner; a connecting rod which extends leftwards and rightwards is mounted on the left side of the first bevel gear in a rotation fit manner; the bottom end of the first bevel gear is provided with a second bevel gear in a mutual meshing manner; a main rotating shaft is fixedly arranged at the bottom end of the second bevel gear; the main rotating shaft extends downwards and stretches into the fermentation cavity, and is connected with an upper end wall and a lower end wall of the fermentation cavity in a rotation fit manner; multiple groups of stirring rods arefixedly and circumferentially arranged on the outer surface of the main rotating shaft; stirring paddles are symmetrically and fixedly arranged at the upper ends and the lower ends of the stirring rods away from one side of the main rotating shaft.

Owner:YICHANG HUIYIXING NEW ENERGY TECH CO LTD

Biological reaction separation device with high stability

PendingCN112457964AQuality improvementEasy to handleBioreactor/fermenter combinationsBiological substance pretreatmentsRotary valveReactive separation

The invention discloses a biological reaction separation device with high stability, relates to the technical field of biological reaction separation devices, and aims to solve the problem of low reaction separation effect due to single structural performance when an existing biological reaction separation device is used. A bacterium impurity filtering structure is installed on one side of a primary filtering structure; a circulating precipitation structure is arranged on one side of the bacterium impurity filtering structure; a biological reaction separation treatment structure is installed on one side of the circulating precipitation structure; a water tank is arranged on one side of the biological reaction separation treatment structure; a special liquid sealing storage cabinet is installed on one side of the water tank; a protective jacket structure is arranged outside the biological reaction separation treatment structure; a rotary valve is installed above the primary filtering structure; a feeding port is formed in the outer wall of the primary filtering structure; and the feeding port is fixedly connected with the outer wall of the primary filtering structure.

Owner:周振华

A kind of device and method for preparing lithium-ion battery slurry

The invention belongs to the technical field of lithium ion batteries and especially relates to a preparation apparatus for lithium ion battery slurry. The apparatus comprises a solvent loading tank and a slurry agitator tank, wherein the slurry agitator tank is connected with a first vacuum pump; the apparatus further comprises a binder premixing tank, wherein the binder premixing tank is connected with a second vacuum pump; a discharge outlet of the solvent loading tank is connected with a feed inlet of the binder premixing tank through a first pipeline, and a discharge outlet of the binder premixing tank is connected with a feed inlet of the slurry agitator tank through a second pipeline. Compared with the prior art, the preparation apparatus provided by the invention has the following advantages: fluids like a solvent and a binder premixed liquid are added from the bottom of a tank to the top of the tank by using vacuum negative pressure, so it is guaranteed that there is only a two-phase interface of a liquid phase and a solid phase, maximum-efficiency mutual infiltration is realized, generation of bubbles in the slurry is reduced, dispersion is promoted, stirring time is shortened and operation is simple, which enables stirring time to be reduced and production efficiency to be improved. Furthermore, the invention also discloses a method of utilizing the apparatus for preparation lithium ion battery slurry.

Owner:DONGGUAN AMPEREX TECH

A kind of automatic extraction equipment and method of extracting theanine from tea leaves

ActiveCN108517292BEasy to addEasy to add ingredientsBioreactor/fermenter combinationsBiological substance pretreatmentsTheanineFermentation

The invention discloses a method for automatically extracting theanine from tea. A fermenting rack body is included. A fermentation chamber is arranged inside the internal wall of the fermenting rackbody. A transmission chamber extends to left and right sides at the top of the fermentation chamber inside the fermenting rack body. A sliding seat is in sliding fit inside the transmission chamber. Afirst motor is fixedly arranged in the left cross section of the sliding seat. The left end of the first motor is in power fit with a first bevel gear. The left end of the first bevel gear is in running fit with a connecting rod which extends towards left and right sides. The bottom of the first bevel gear is engaged with a second bevel gear, the bottom of which is fixedly provided with a main rotating shaft. The main rotating shaft extends downwards into the fermentation chamber to be in running fit with upper and lower walls of the fermentation chamber. Agitator arms are circumferentially and fixedly arranged on the external surface of the main rotating shaft. Agitating valves are symmetrically and fixedly arranged at upper and lower end faces of the agitator arms, far from one side ofthe main rotating shaft.

Owner:金威宝(广东)健康产业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com