Biomass gasification furnace using furnace interlayer structure for decoking

A sandwich structure and biomass technology, applied in the manufacture of combustible gas, petroleum industry, etc., can solve the problems of energy loss contained in tar, high ash content of combustible gas, high tar content, etc., to reduce temperature, reduce tar content, and reduce pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

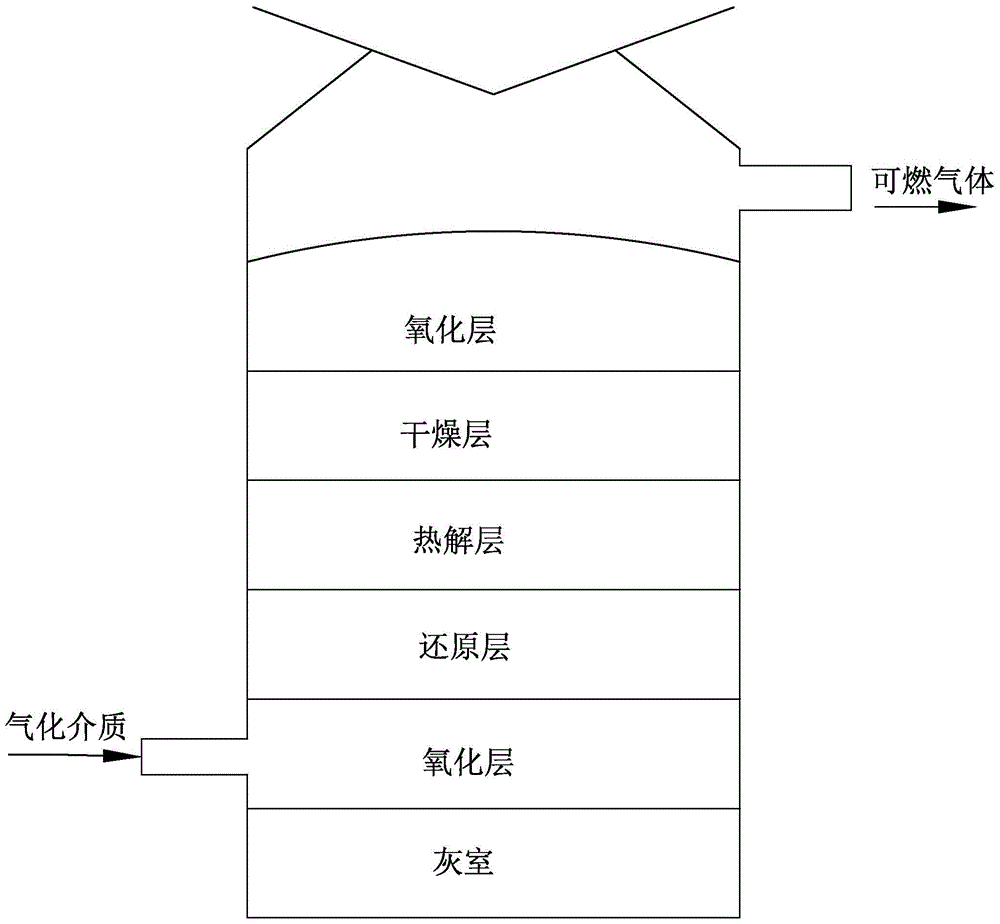

Embodiment 1

[0045] Such as Figure 4 As shown, the furnace body 10 includes a first furnace body 101 and a second furnace body 102 . The lower end of the first furnace body 101 is open, the upper end of the second furnace body 102 is open, and the radius or cross-sectional size of the second furnace body 102 is larger than that of the first furnace body 101 . The second furnace body 102 is sleeved in the middle or middle lower part of the first furnace body 101 , and its interiors are interconnected, and the side walls are spaced apart, thereby forming a sandwich structure with gas passages 15 . The first furnace body 101 and the second furnace body 102 can be integrally formed, or separate parts can be sealed and connected into one body by a known method. The feeding port 11 is provided on the top of the first furnace body 101 . The fire grate 14 is arranged in the second furnace body 102 , which can be a known automatic fire grate 14 . The drying layer and the pyrolysis layer are arr...

Embodiment 2

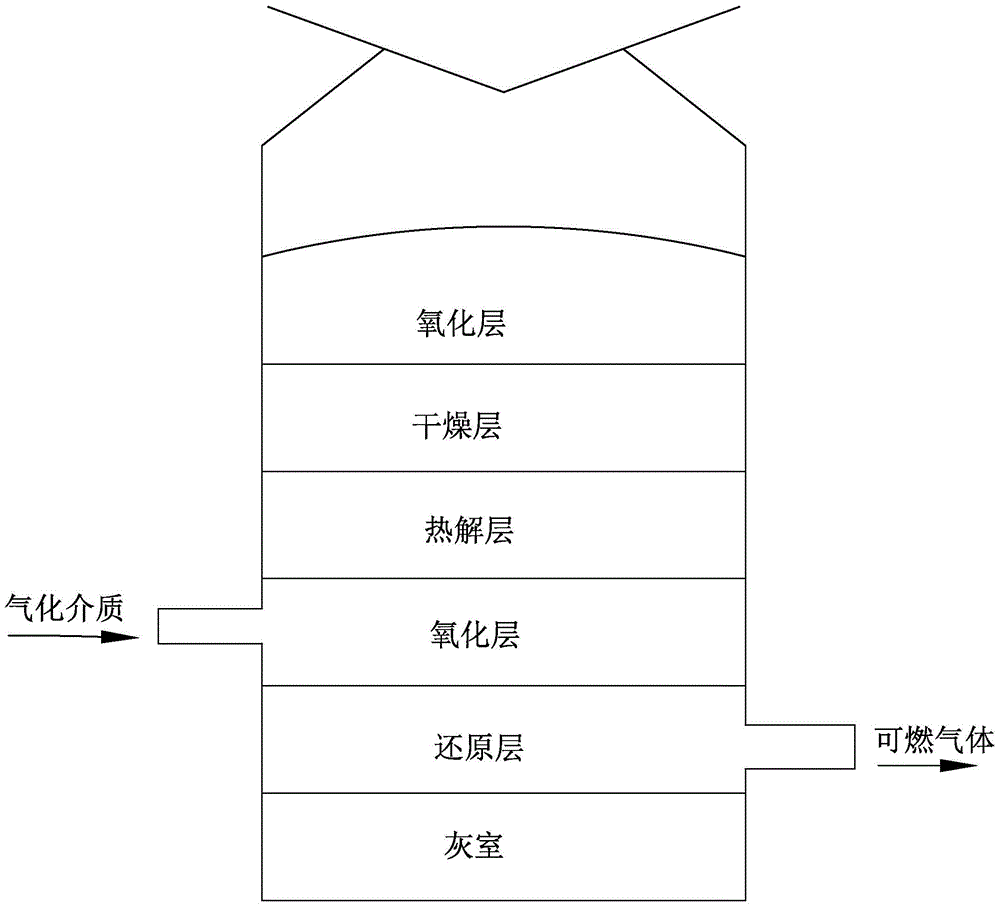

[0048] Such as Figure 5 As shown, the furnace body 10 of this embodiment includes a first furnace body 101 , a second furnace body 102 , and a third furnace body 103 , which are internally connected to each other. The lower end of the first furnace body 101 is open, and the upper and lower ends of the second furnace body 102 are open, and the second furnace body 102 is sheathed in the middle or lower part of the first furnace body 101 . The upper end of the third furnace body 103 is open, and it is sheathed in the middle or lower part of the second furnace body 102 . The first furnace body 101, the second furnace body 102, and the third furnace body 103 are nested in sequence to form a sandwich structure with gasification channels, wherein a gasification gas is formed between the side walls of the first furnace body 101 and the second furnace body 102. The gasification medium channel 16, through which the gasification medium passes into the oxide layer. A gas channel 15 is ...

Embodiment 3

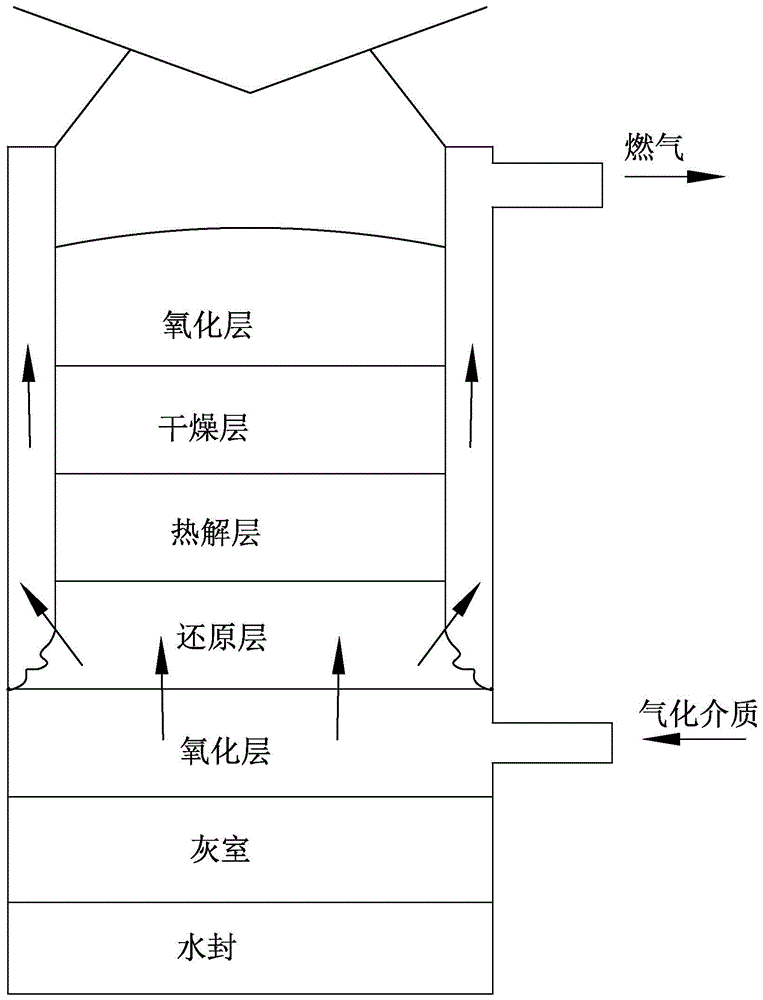

[0050] Such as Image 6 As shown, the furnace body 10 of this embodiment includes a first furnace body 101 and a second furnace body 102 . The first furnace body 101 is a hermetic furnace body 10, which is divided into a drying layer, a pyrolysis layer, a reduction layer and an oxidation layer from top to bottom. The second furnace body 102 is the furnace body 10 with upper and lower ends open, which is arranged in the first furnace body 101 , its lower end opening is located in the reducing layer, and its upper end opening is connected with the gas outlet 13 through the communication pipe 17 . The gas outlet 13 can be arranged on the side wall of the first furnace body 101 at any height. The fire grate 14 is arranged in the first furnace body 101 and is located under the oxide layer. The feeding port 11 is arranged on the top of the first furnace body 101 , and the gasification medium inlet 12 is arranged under the fire grate 14 , which feeds the gasification medium into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com