High-pressure distillation essential oil separation and purification treatment device and separation and purification method

The technology of a processing device and a purification method is applied in the directions of essential oils/fragrance, fat generation, etc., which can solve the problems of reducing the efficiency of essential oil extraction, increasing the time of high-pressure distillation, slow steam, etc., achieving safe and convenient use, improving efficiency, and improving The effect of evaporation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

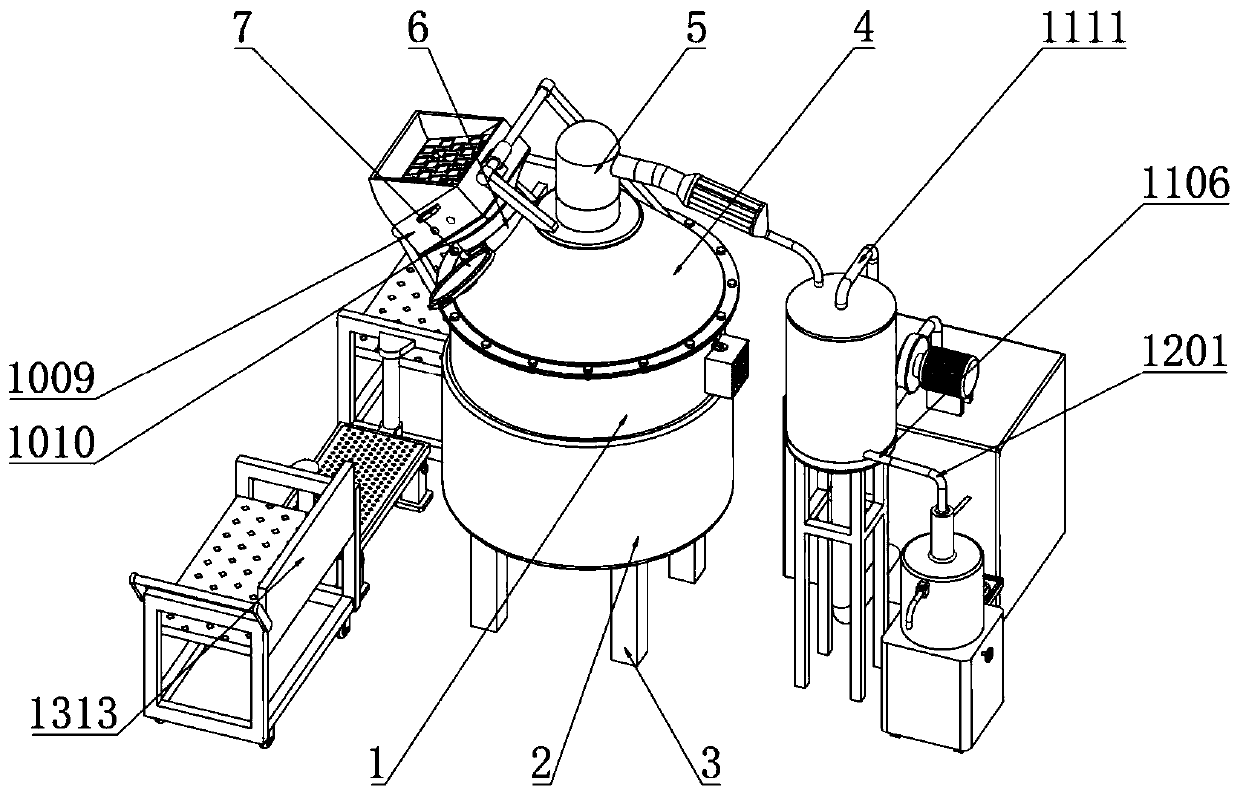

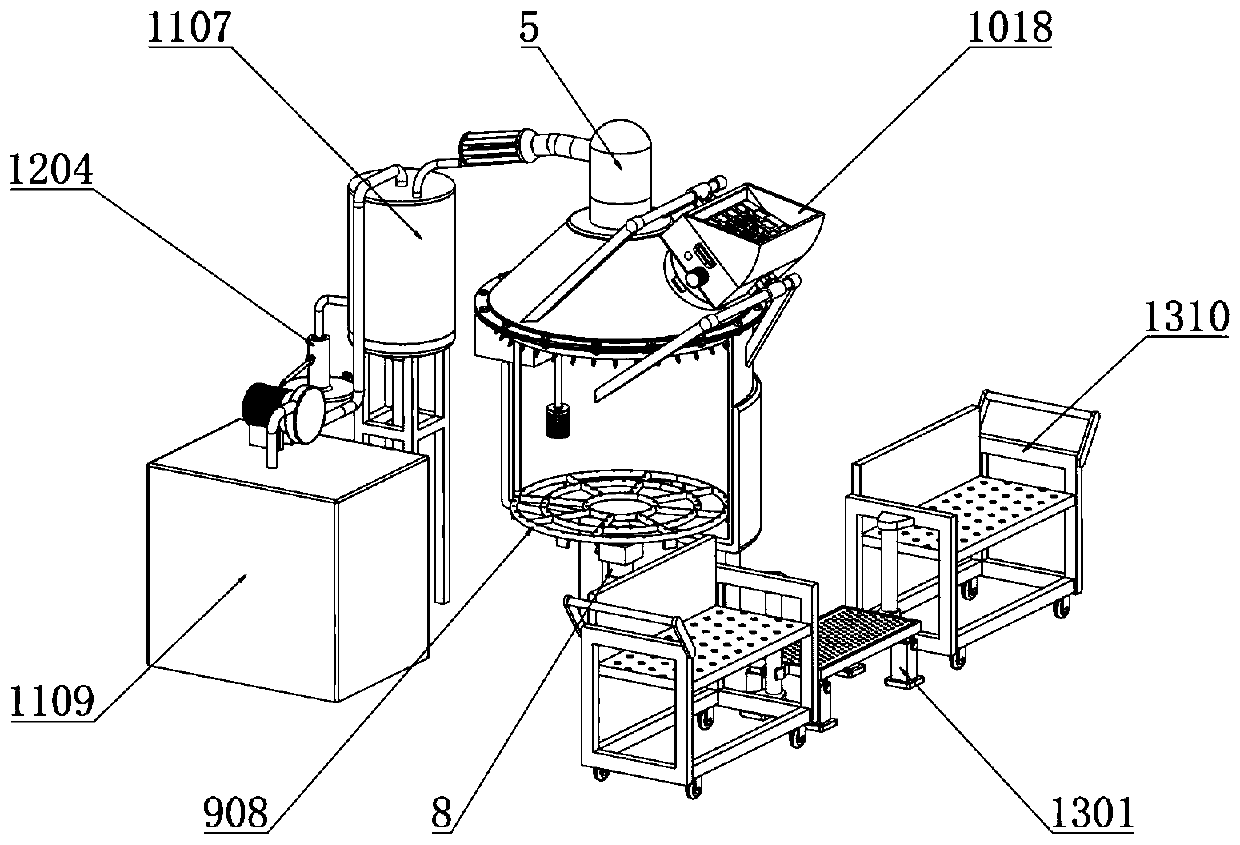

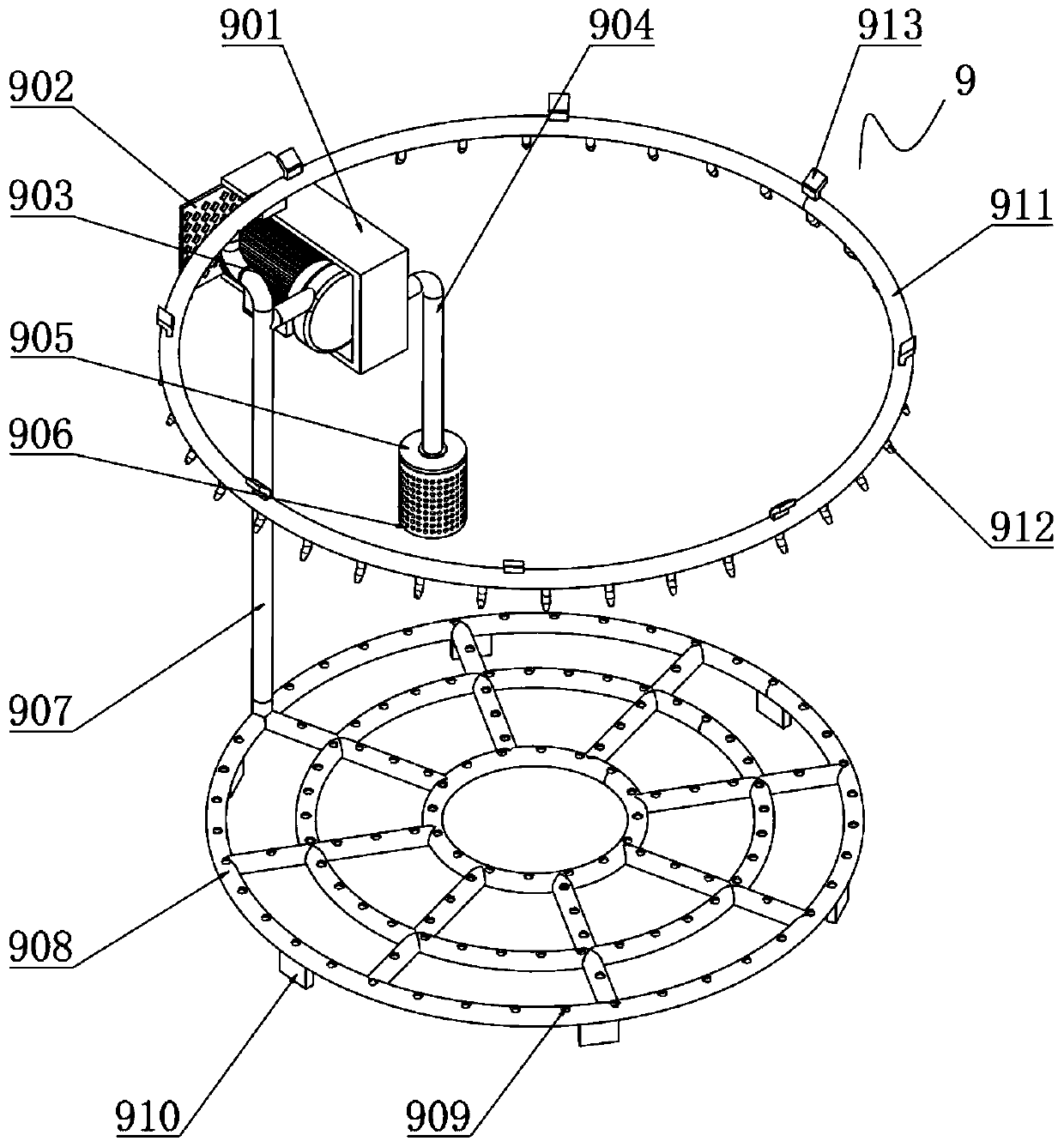

[0054] Example: such as Figure 1-7 As shown, the present invention provides a technical solution, a high-pressure distillation essential oil separation and purification treatment device, comprising a distillation barrel 1, an electromagnetic heater 2 is sleeved on the bottom edge of the outer side of the distillation barrel 1, and the input end of the electromagnetic heater 2 is connected to the market. The output end of the electricity is electrically connected, the bottom end of the electromagnetic heater 2 is evenly and fixedly connected with the support leg 3, the bottom end of the distillation barrel 1 is connected with a sealing cone top 4 through threads, and the middle part of the top end of the sealing cone top 4 is fixedly connected with a steam discharge pipe 5. The outer side of the sealed conical top 4 is provided with a feeding port 6, and one side of the feeding port 6 is rotatably connected with a sealing cover 7, and the bottom of the distillation tank 1 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com