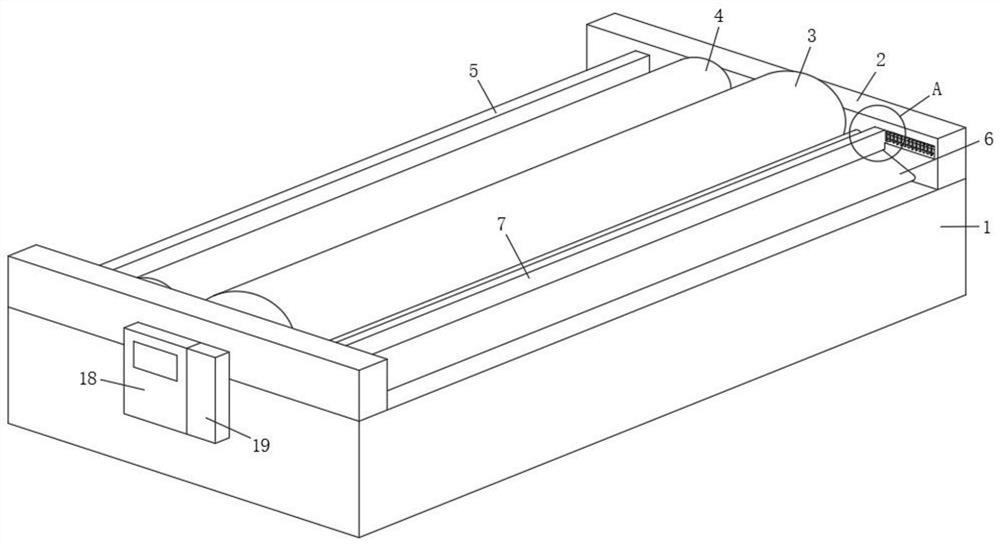

Wallpaper blade coating mechanism for wallpaper production line

A production line and wallpaper technology, applied in the field of wallpaper scraping mechanism for wallpaper production line, can solve the problems of paint splashing, poor coating thickness uniformity and high cost, and achieve the effects of easy processing and installation, reduction of paint waste, and simple and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

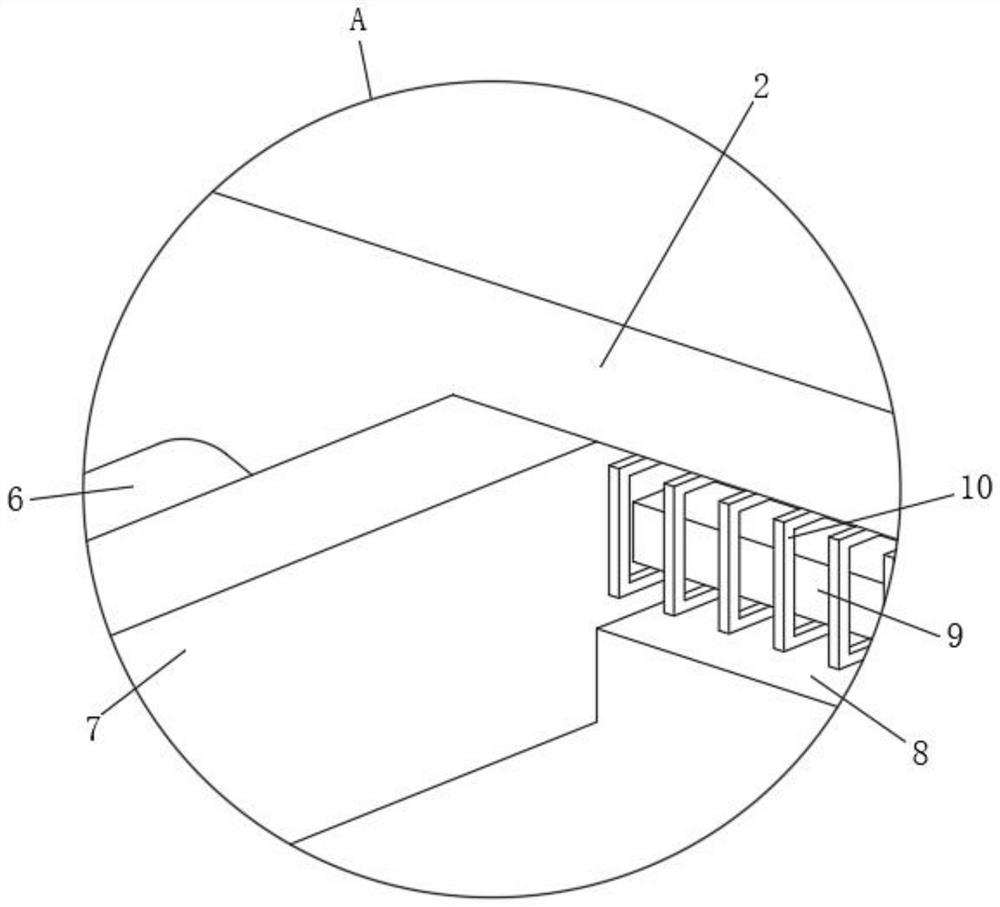

Image

Examples

Embodiment 1

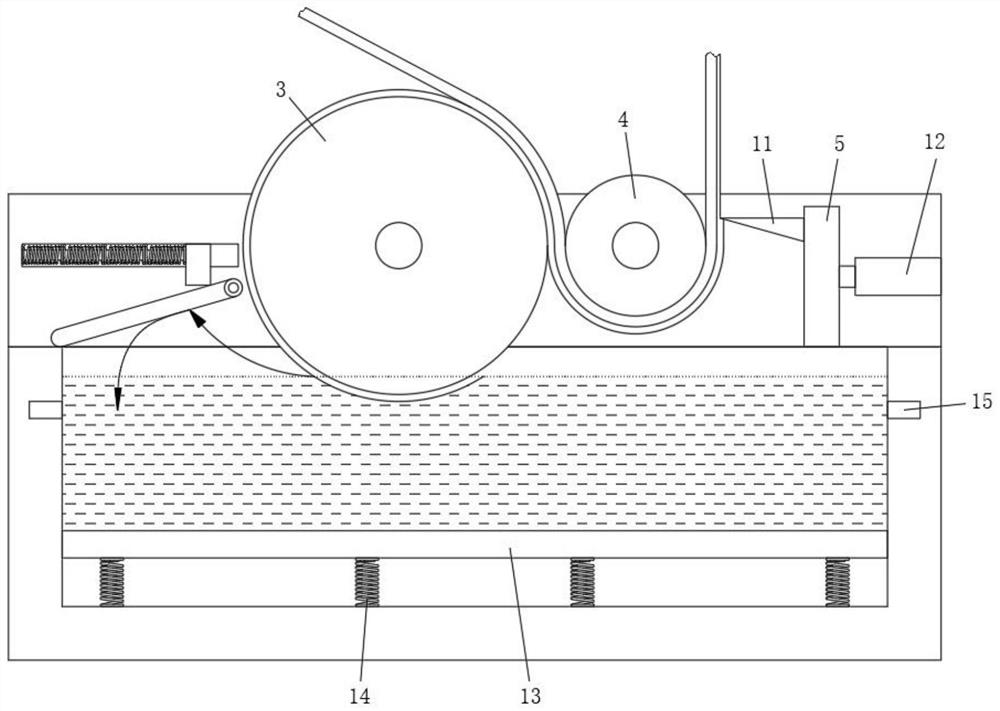

[0059] see Figure 3-Figure 4 As shown, the lifting drive assembly includes at least one lifting spring 14 , and the lifting piston plate 13 is welded to the top of the lifting spring 14 .

[0060] Specifically, in this embodiment, based on the weight (gravity) of the paint stored in the material storage box 1 and the elastic force of the lifting spring 14 to form a support balance; in the continuous scraping process, the paint in the material storage box 1 gradually decreases, and the corresponding weight (Gravity) descends, thereby support balance is destroyed, elastic force>gravity, realizes the rising of lifting piston plate 13; Thus, the lifting drive of the lifting piston plate 13 can be effectively satisfied.

Embodiment 2

[0062] see Figure 5 As shown, the lifting drive assembly includes a second electric push rod 16 and a liquid level sensor 17, the lifting piston plate 13 is fixed on the top of the second electric push rod 16, the liquid level sensor 17 is embedded on the inner wall of the material storage box 1, and the liquid level sensor The height of 17 is higher than coating roller 3 bottoms.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com