Fluorine-silicon tri-block copolymer and preparation method thereof

A triblock and copolymer technology, applied in the field of technical materials, to achieve the effect of reducing side reactions, mild reaction conditions, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

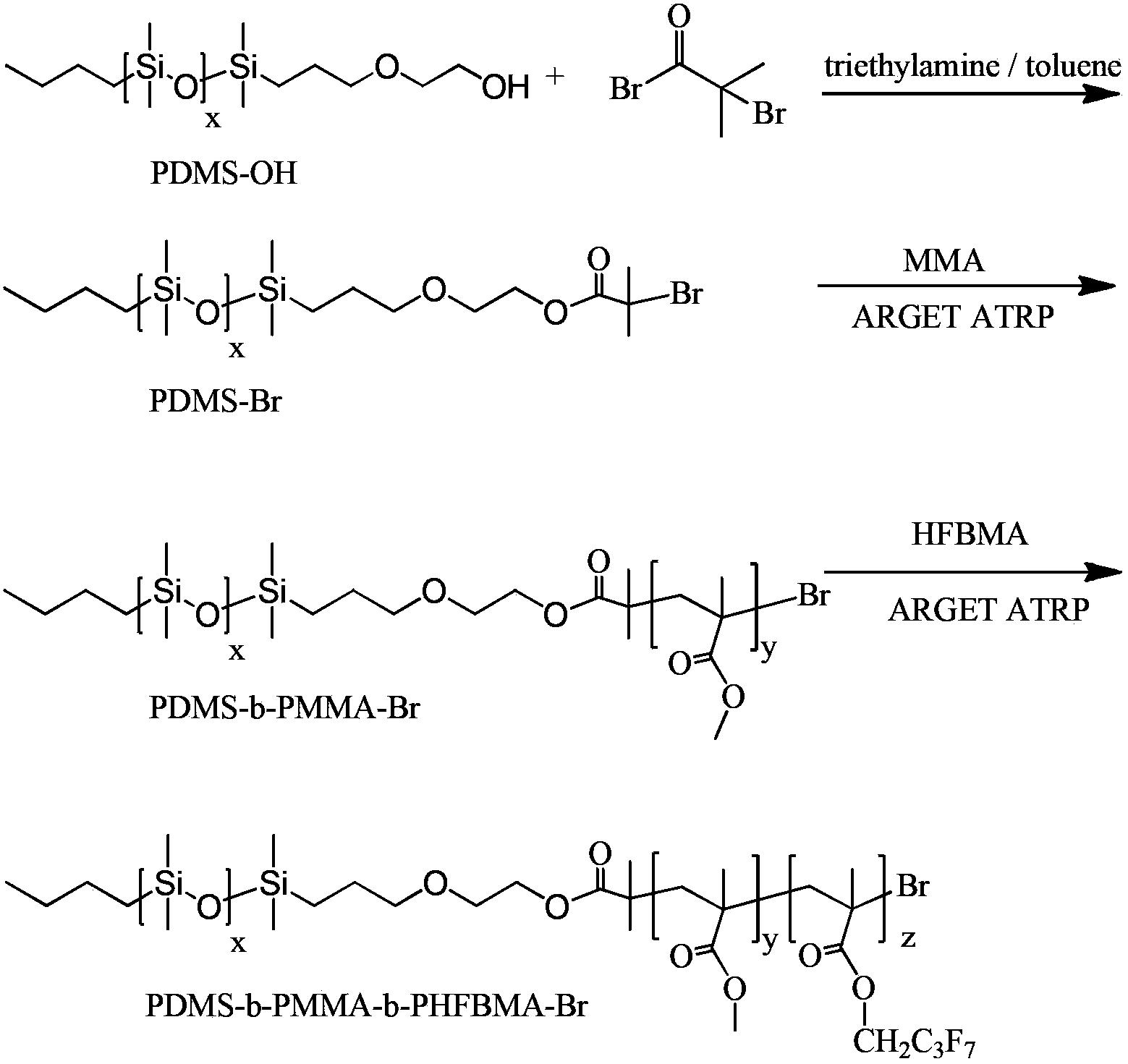

Method used

Image

Examples

Embodiment 1

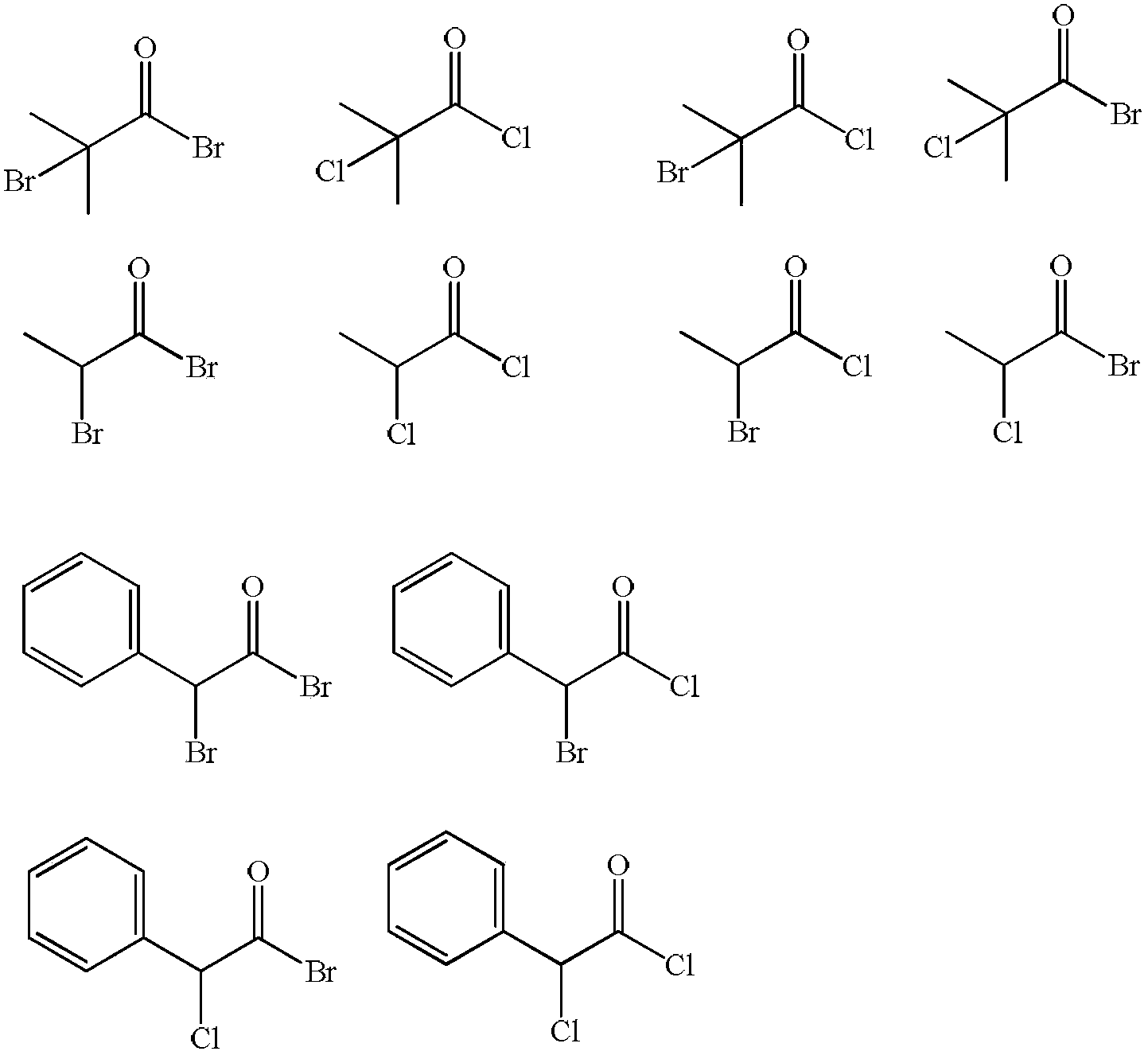

[0038] Step 1: Preparation of PDMS-Br

[0039] 1 mol of monohydroxyl-terminated polydimethylsiloxane and 1.1 mol of pyridine were added to 1 mol of toluene. 1.1 mol of 2-bromoisobutyryl bromide diluted with the same volume of toluene was slowly added dropwise at low temperature. After 1 hour, it was slowly raised to room temperature and stirred for another 1 hour. The mixture was concentrated, dissolved in dichloromethane, and washed successively with saturated aqueous sodium bicarbonate solution and sodium chloride aqueous solution. After drying the organic phase, it was concentrated and dried to obtain the product macroinitiator PDMS-Br.

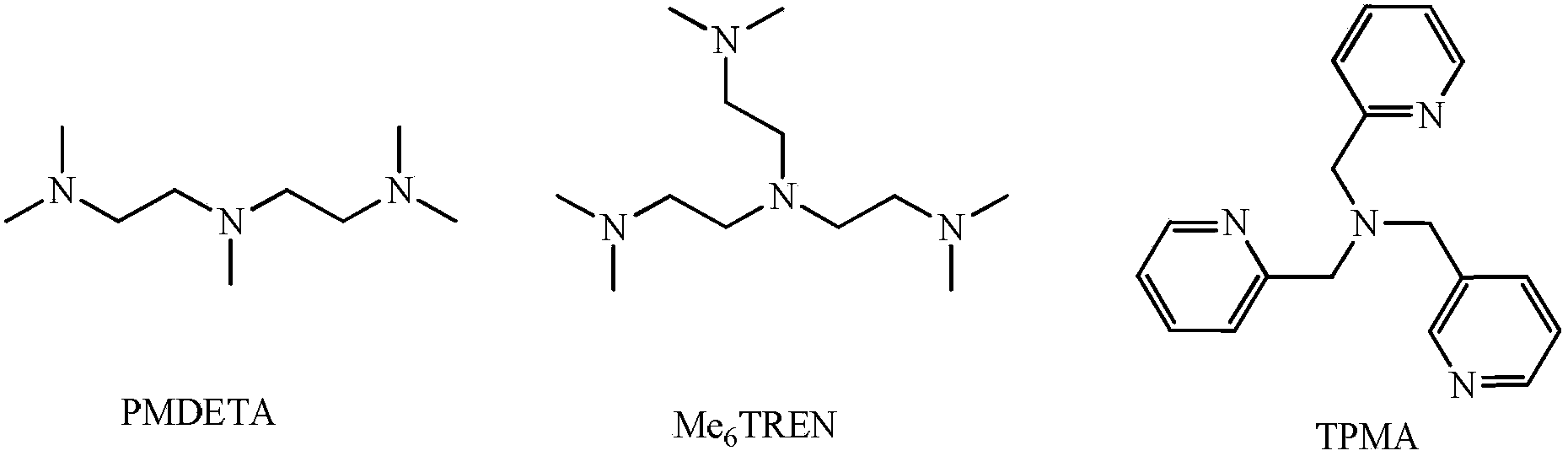

[0040] Step 2: Preparation of PDMS-b-PMMA-Br (the ratio of transition metal salt to monomer is 50ppm)

[0041] Add 1 mol macroinitiator PDMS-Br, 50 mol monomer methyl methacrylate, 0.0025 mol copper bromide, 0.01 mol tris(2-pyridyl)methylamine and 50 mol toluene into the reaction flask, stir at 60°C, Then add 0.025mol stannous octoate. ...

Embodiment 2

[0045] Step 1: Preparation of PDMS-Br

[0046] Add 1 mol of monohydroxyl-terminated polydimethylsiloxane and 10 mol of pyridine to 100 mol of toluene. At low temperature, 10 mol of 2-bromoisobutyryl bromide diluted with the same volume of toluene was slowly added dropwise. After 3 hours, it was slowly raised to room temperature, and stirred for another 24 hours. The mixture was concentrated, dissolved in dichloromethane, and washed successively with saturated aqueous sodium bicarbonate solution and sodium chloride aqueous solution. After drying the organic phase, it was concentrated and dried to obtain the product macroinitiator PDMS-Br.

[0047] Step 2: Preparation of PDMS-b-PMMA-Br (the ratio of transition metal salt to monomer is 200ppm)

[0048] Add 1 mol macromolecular initiator PDMS-Br, 500 mol monomer methyl methacrylate, 0.1 mol copper bromide, 0.4 mol tris(2-pyridyl)methylamine and 500 mol toluene into the reaction flask, and pass nitrogen gas for 60 minutes, stirre...

Embodiment 3

[0052] Step 1: Preparation of PDMS-Br

[0053] Add 1 mol of monohydroxyl-terminated polydimethylsiloxane and 2 mol of triethylamine to 2 mol of toluene. 2 mol of 2-bromoisobutyryl chloride diluted with the same volume of toluene was slowly added dropwise at low temperature. After 2 hours, it was slowly raised to room temperature and stirred for another 24 hours. The mixture was concentrated, dissolved in dichloromethane, and washed successively with saturated aqueous sodium bicarbonate solution and sodium chloride aqueous solution. After drying the organic phase, it was concentrated and dried to obtain the product macroinitiator PDMS-Br.

[0054] Step 2: Preparation of PDMS-b-PMMA-Br (the ratio of transition metal salt to monomer is 100ppm)

[0055] Add 1 mol macromolecular initiator PDMS-Br, 200 mol monomer methyl methacrylate, 0.02 mol copper bromide, 0.10 mol tris(2-pyridyl)methylamine and 200 mol toluene into the reaction flask, and blow nitrogen gas for 30 minutes, stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com