Metal fuel battery and fuel battery system thereof

A metal fuel cell and metal powder technology, which is applied in the direction of fuel cell half-cells and primary battery-type half-cells, can solve the problems of increasing battery cost, cumbersome operation and waste of replacing metal electrodes, and prolongs the service life and Use efficiency, ensure long-term stable operation, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

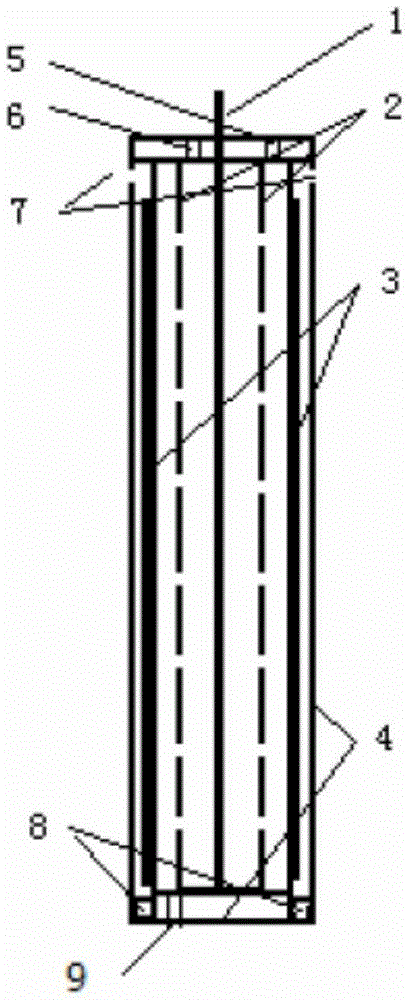

[0035] Embodiment 1: metal oxygen (empty) fuel cell unit

[0036] The active metal powder negative electrode of the metal fuel cell is composed of a polyester mesh negative electrode frame with a feed inlet in the middle and upper part of the single cell casing, a negative electrode collector fixed on the top cover of the battery casing and positioned in the middle of the negative electrode frame, and a metal The metal fuel cell is composed of a metal powder negative electrode sealed in the battery casing, an electrolyte, and an air positive electrode arranged in parallel on both sides of the negative electrode frame and fixed on both sides of the battery casing.

[0037] The above-mentioned battery casing is assembled by sealing and assembling the casing and the casing cover constructed of engineering plastics. The metal mesh or metal plate negative electrode current collector is fixed in the middle of the casing cover. The casing cover also has a metal powder negative electro...

Embodiment 2

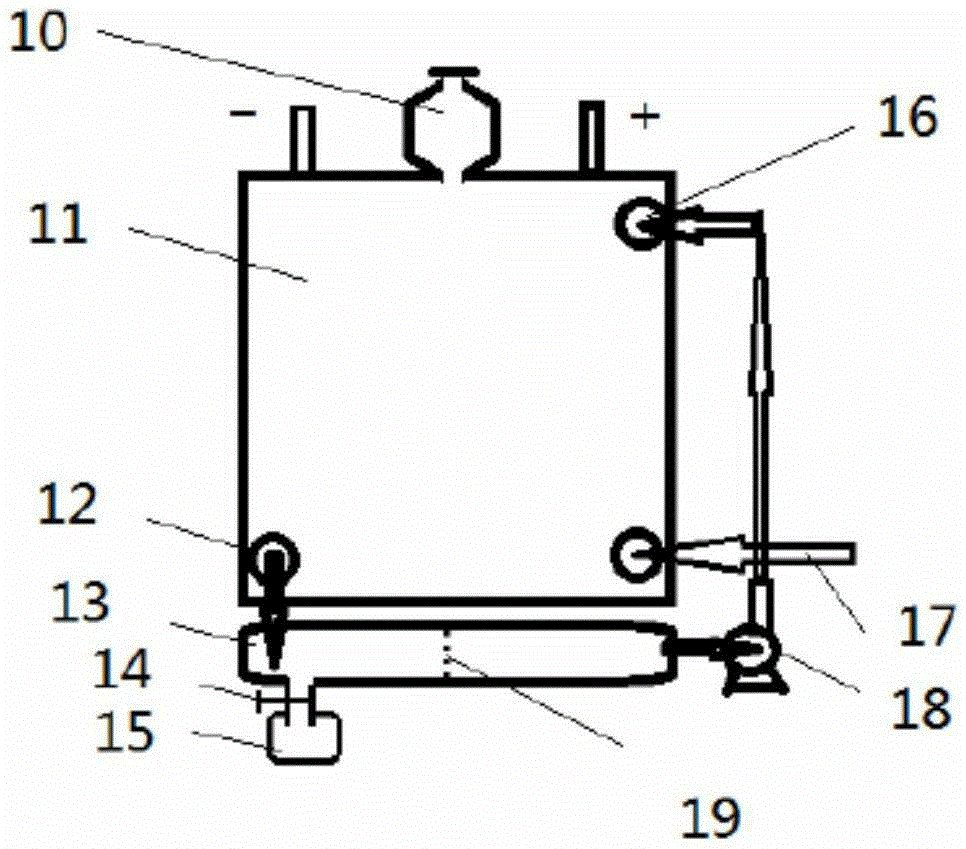

[0039] Example 2: Aluminum metal fuel cell unit

[0040] The aluminum metal fuel cell unit is composed of a negative electrode of 10-200 mesh aluminum metal powder sealed in a battery casing, an aqueous electrolyte, and air positive electrodes arranged in parallel on both sides of the negative electrode frame and fixed on both sides of the battery casing.

[0041] The above-mentioned battery case is composed of a polypropylene case and a case cover sealed and assembled. An aluminum metal mesh or a metal plate negative electrode current collector is fixed in the middle of the case cover. There is also an aluminum powder negative electrode material feeding port and an electrolyte inlet on the case cover. Liquid port, the lower part of the housing is provided with an air inlet, and the bottom is provided with an electrolyte outlet.

[0042] The aluminum metal powder negative electrode material feeding port on the above-mentioned battery case cover is connected with the aluminum m...

Embodiment 3

[0043] Example 3: Lithium metal fuel cell unit

[0044] The lithium metal fuel cell unit is composed of a 10-200 mesh lithium metal powder negative electrode sealed in a battery casing, a non-aqueous electrolyte, and air positive electrodes arranged in parallel on both sides of the negative electrode frame and fixed on both sides of the battery casing.

[0045] The above-mentioned battery casing is composed of a polypropylene casing and a casing cover sealed and assembled. A titanium metal mesh or a metal plate negative electrode current collector is fixed in the middle of the casing cover. At the same time, there is a lithium powder negative electrode material feeding port and an electrolyte inlet on the casing cover. Liquid port, the lower part of the housing is provided with an air inlet, and the bottom is provided with an electrolyte outlet.

[0046] The lithium metal powder negative electrode material feeding port on the above-mentioned battery case cover is connected wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com