Method for controlling grouping interlocking time of separators of large sugar refineries

A control method and separator technology, applied to centrifuges and other directions, can solve the problems of affecting production capacity, difficulty in achieving the level of speed-up and down-speed coordination, and inaccurate two-unit groups, so as to achieve the effect of stable electric power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further illustrate the technical scheme of the control method of the group interlocking time of the large-scale sugar factory separators of the present invention, the specific implementation manner of the control method of the group interlocking time of the large-scale sugar factory separators of the present invention is illustrated in conjunction with the accompanying drawings as follows:

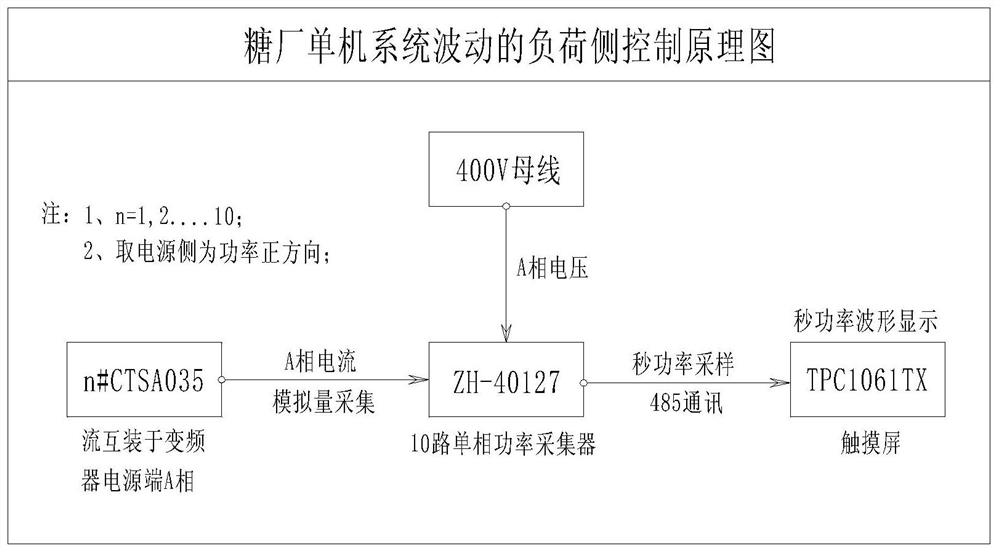

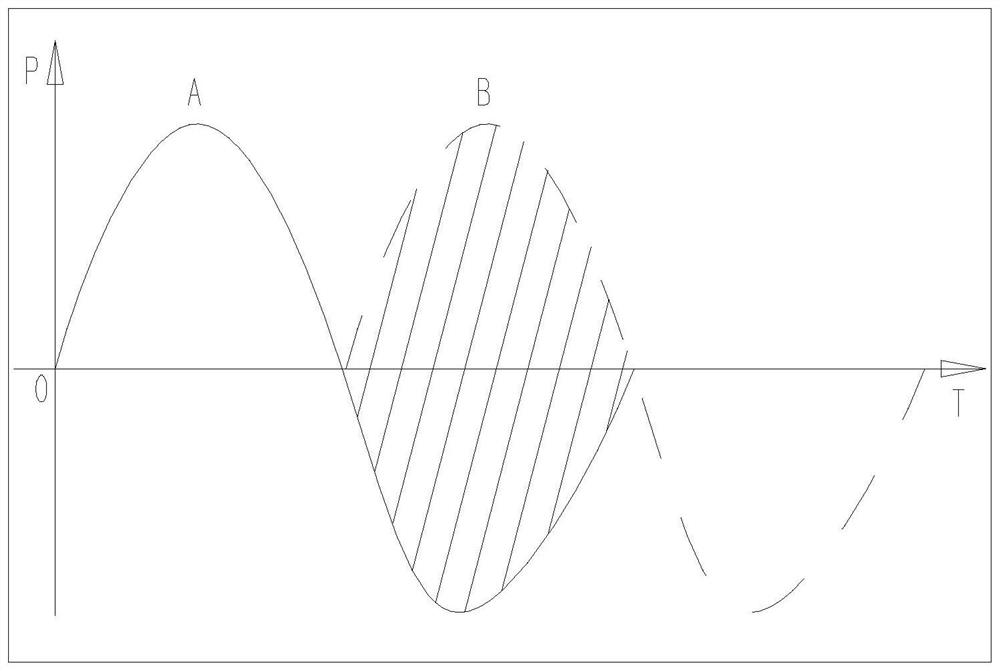

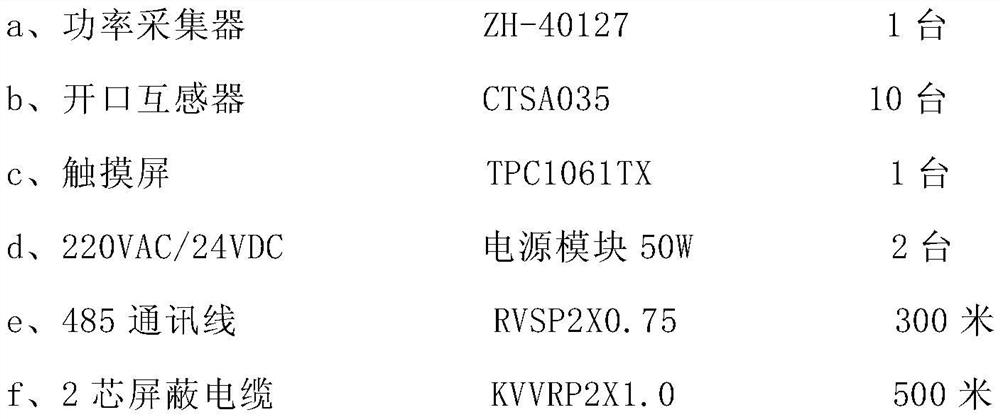

[0020] Such as figure 1 The technical scheme of the control method for the group interlocking time of the separators in the large sugar factory shown, a control method for the group interlocking time of the separators in the large sugar factory, including a power collector device, a phase A current transformer and a touch screen, Connect the power collector device to the 400V busbar, and connect the power supply 24VDC, so that the input rated phase voltage is 220VAC, and the rated phase current is 160mA. Each set has 12 current acquisition channels, 1 voltage acquisition ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com