High-pressure distillation essential oil separation and purification treatment system

A processing system and essential oil technology, applied in the direction of oil/fat refining, fat production, etc., can solve the problems of lack of accurate measurement of material weight and purging function, single function of auxiliary mechanism, etc., to achieve a high degree of automation, improved effect, structure scientifically sound effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

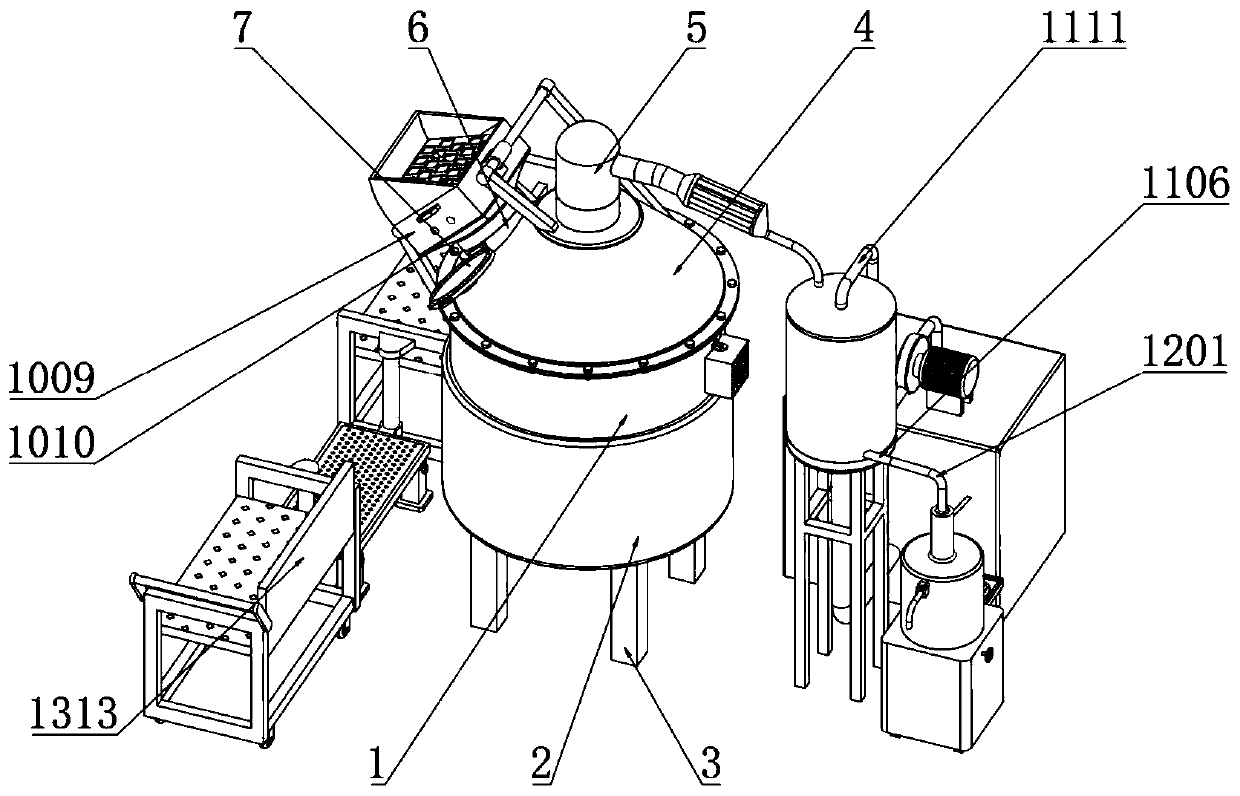

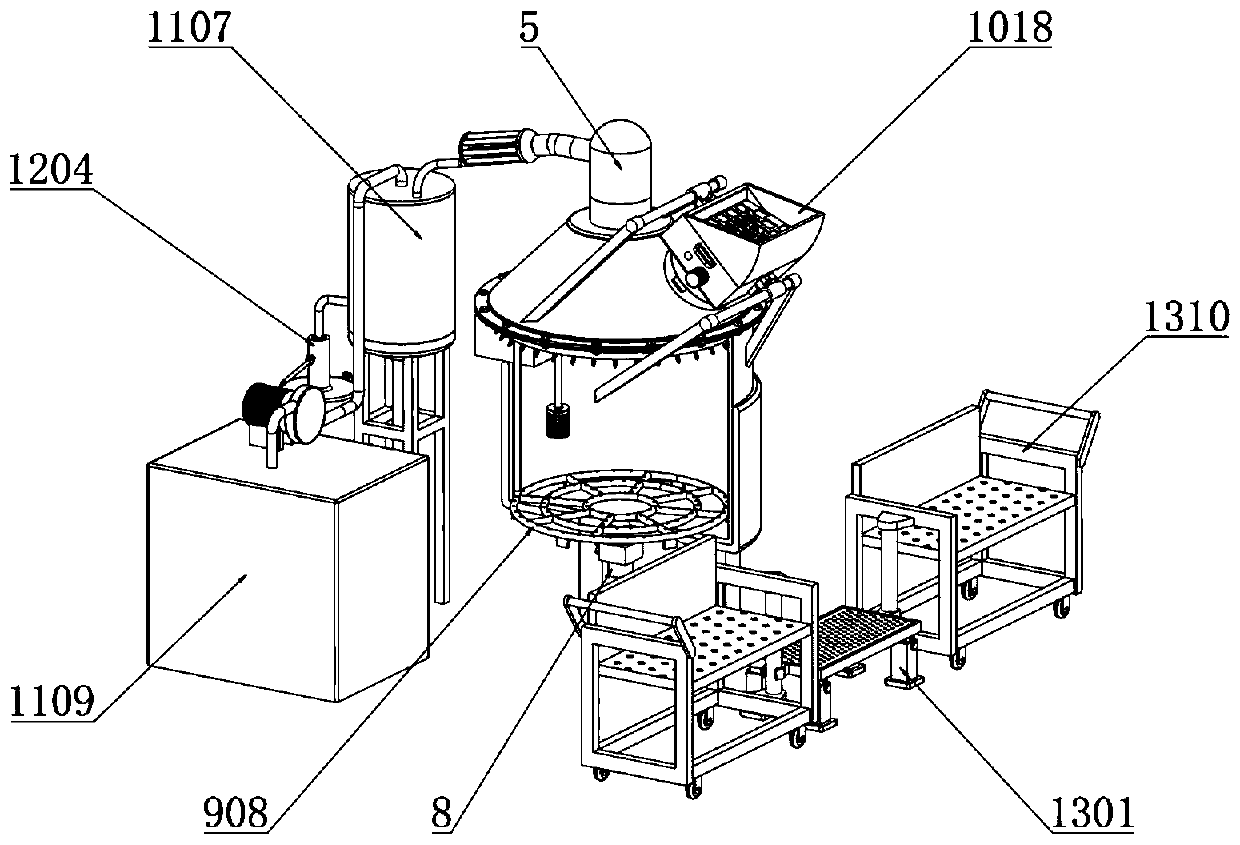

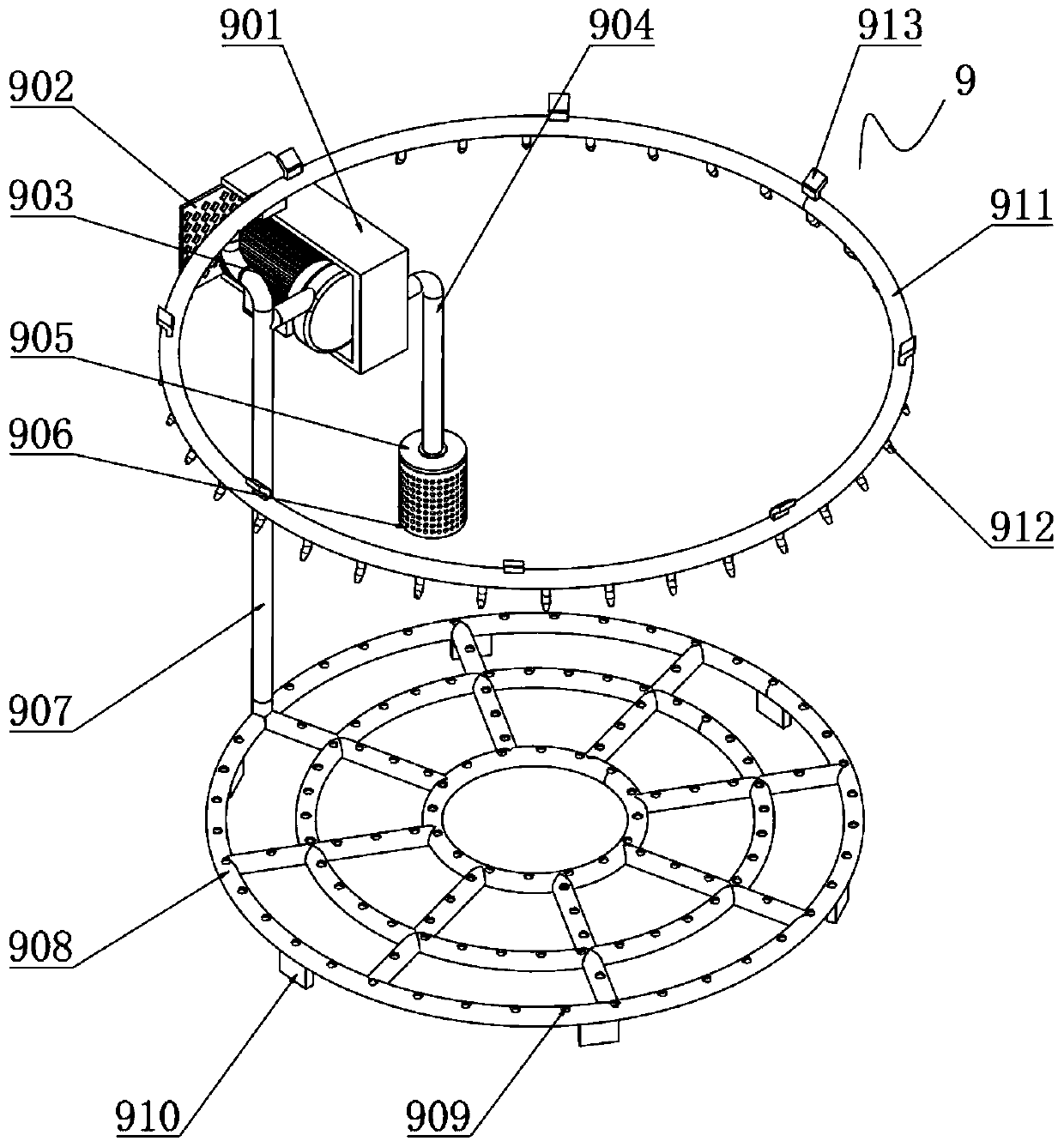

[0032] Example: such as figure 1 , 7 As shown in -10, a high-pressure distillation essential oil separation and purification treatment system includes a distillation barrel 1, an evaporation enhancement mechanism 9, a feeding mechanism 10, a cooling cycle mechanism 11, a separation and purification mechanism 12 and an auxiliary mechanism 13, at least one of the auxiliary mechanisms 13 The rear side of the protective vertical plate 1313 is fixedly connected with a tripod 1315, and the tripod 1315 is fixedly connected with a raw material purge box 1316 (the tripod and the raw material purge box are all made of light materials to reduce weight imbalance). The upper end of the purge box 1316 is provided with an electric flap door 1317, and the side of the raw material purge box 1316 is fixed with a blower fan 1318 and a control display 1319, and the outlet of the blower fan 1318 is fixed on the electric flap door through a hose 1320. The purge nozzle 1321 on the 1317 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com