Light calcium carbonate husk combustion furnace husk feeding device

A light calcium carbonate, combustion furnace technology, applied in the combustion method, control combustion, combustion equipment and other directions, can solve the problems of high labor intensity, large environmental pollution, high energy consumption, achieve convenient feeding, ensure efficiency, and improve control The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

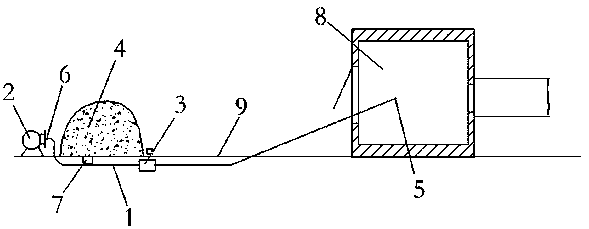

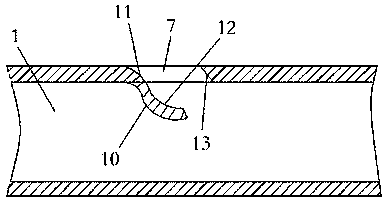

[0034] A chaff feeding device for a light calcium carbonate chaff burning furnace, comprising a conveying pipeline 1, an air blower 2 and a control valve 3, the conveying pipeline 1 is arranged under the chaff storage yard 4, and one end of the conveying pipeline 1 is provided with a blower 2, The air outlet of the blower 2 is docked with the inlet 6 of the conveying pipeline 1, and supplies air to the conveying pipeline 1, and the outlet 5 of the conveying pipeline 1 stretches into the hearth 8 of the chaff burning furnace, and is located in the chaff stacking field 4 in the middle of the conveying pipeline 1 The position below has a chaff inlet 7, and chaff enters in the delivery pipeline 1 at the chaff inlet 7, and is blown in the hearth 8 of the chaff burning furnace by blower 2.

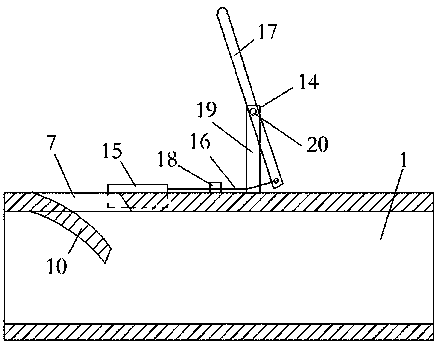

[0035] Further, between the chaff inlet port 7 of the conveying pipeline and the outlet 5 stretching into the hearth of the chaff burning furnace, a control valve 3 for controlling the delivery v...

Embodiment 2

[0042] The principle of embodiment two is the same as that of embodiment one, but the system device adopted is different, for comprising conveying pipeline 201, air blower 202 and control valve 203, conveying pipeline 201 is arranged on below the chaff storage yard 204, and conveying pipeline 201 One end is provided with blower 202, and the air outlet of blower 202 is docked with the inlet 206 of conveying pipeline 201, and feeds air to conveying pipeline 201, and the outlet 205 of conveying pipeline 201 stretches in the hearth 208 of chaff burning furnace, in the middle of conveying pipeline 201 Be positioned at the position below the chaff stacking field 204 to have a chaff inlet 207, chaff enters in the delivery pipeline 201 at the chaff inlet 207, and is blown in the hearth 208 of the chaff burning furnace by blower 202.

[0043] Further, a control valve 203 for controlling the conveying amount of chaff is arranged between the chaff inlet of the conveying pipeline and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com