Dry pressing molding equipment and method for silicon carbide composite ceramic processing

A composite ceramic and dry pressing molding technology, applied in the field of ceramic processing, can solve problems such as affecting work efficiency, and achieve the effects of improving the crushing effect, simple and convenient feeding, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

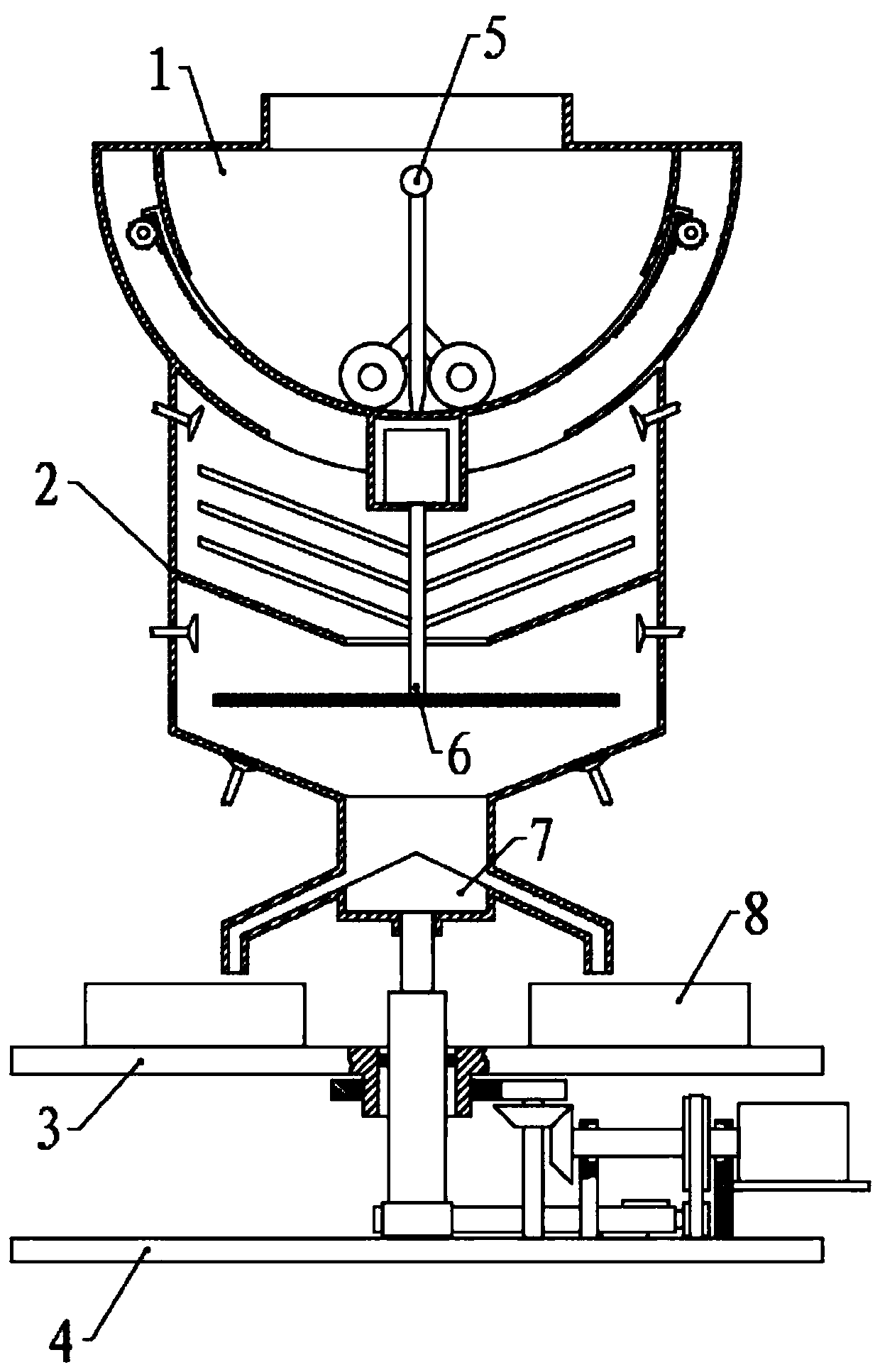

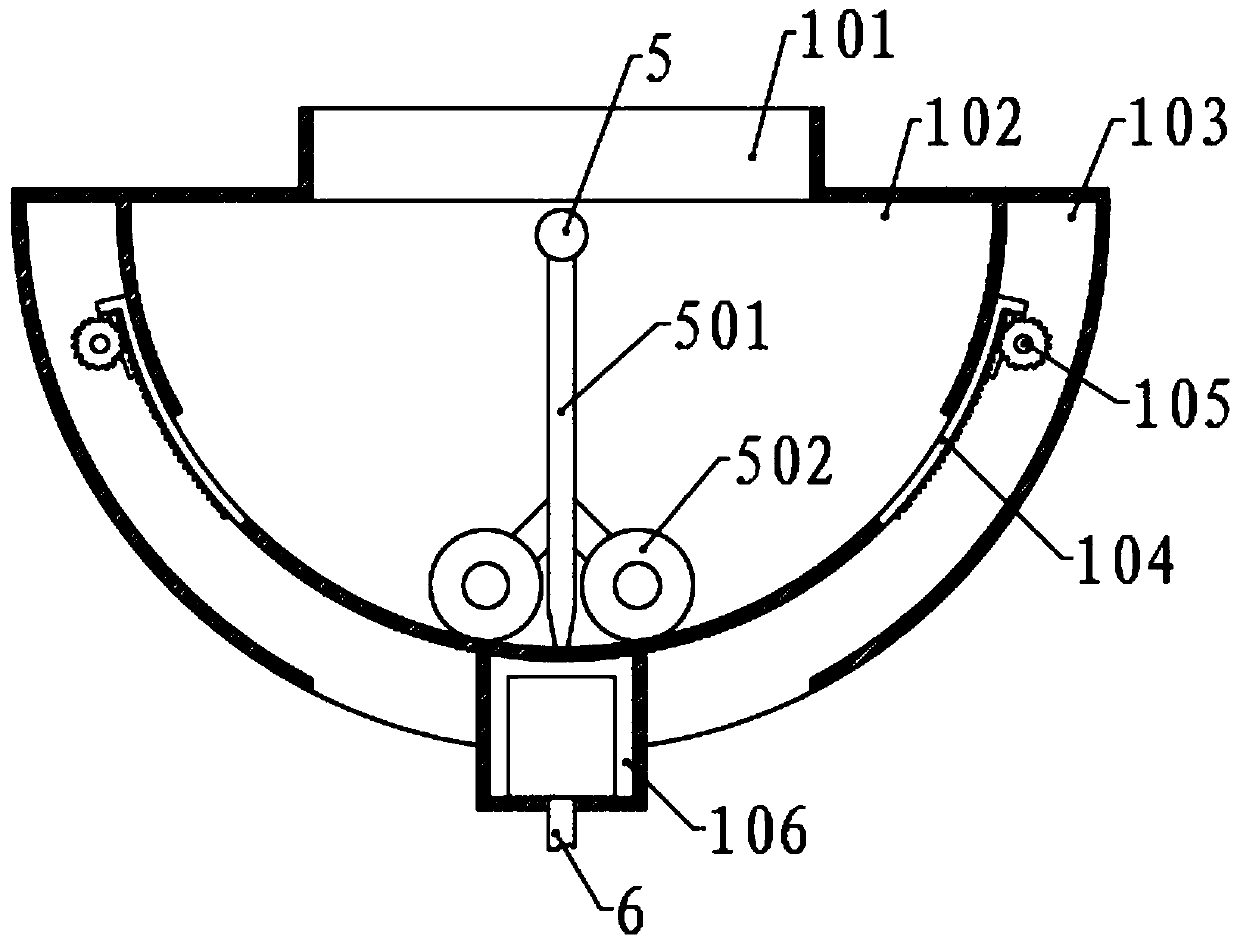

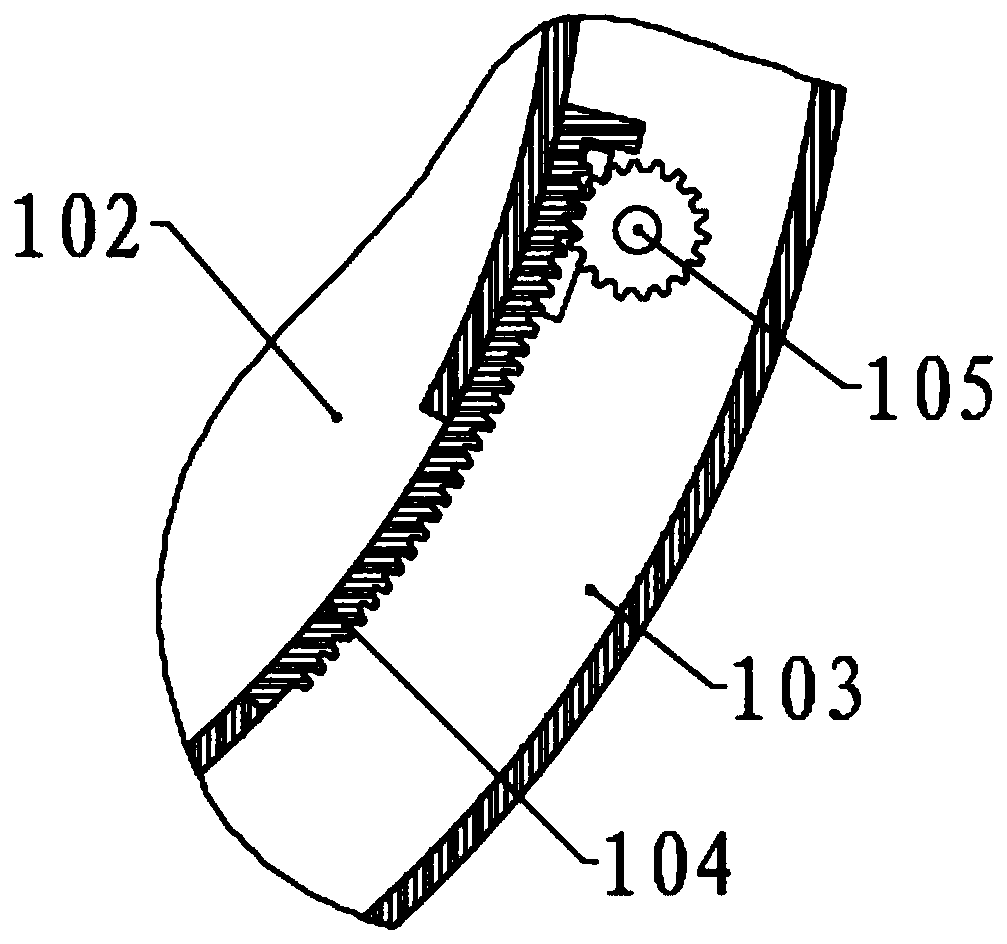

[0051] Please refer to the accompanying drawings, the present invention provides a technical solution: a dry pressing molding equipment for processing silicon carbide composite ceramics, including a crushing box 1, a granulation box 2, a rotary table 3 and a base 4 arranged in sequence from top to bottom, And the crushing box 1, the granulation box 2 are fixedly connected with the base 4, the turntable 3 is connected with the base 4 in rotation, the crushing box 1 is provided with a semicircular crushing chamber 102, the crushing chamber 102 is provided with a crushing assembly, and the crushing chamber 102 is provided with a feeding port 101 in the middle of the top surface, and an arc-shaped feeding chamber 103 is provided outside the bottom of the crushing chamber 102. Both sides of the crushing chamber 102 are symmetrically provided with communication ports, and communicate with the feeding chamber 103 through the communication ports. , and the connecting port is provided w...

Embodiment 2

[0067]The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the bottom end of the second rotating shaft 6 extends into the drying chamber 202, and a circular blanking plate 602 is fixed on it, and the blanking plate 602 is evenly arranged There are a plurality of air holes 603, and a plurality of second air ducts 207 are evenly fixed on the bucket-shaped bottom surface of the drying chamber 202, and the second air ducts 207 are connected with motors. The air inlet, and a screen is fixed in the air inlet to prevent the ceramic powder particles from being discharged from the air inlet when they fall.

[0068] After the powder is granulated by spraying, it falls into the drying chamber 202, and is dried through the first air pipe 205, and then the powder falls onto the blanking plate 602, which rotates with the second rotating shaft 6, and with the falling The rotation of the material plate 602 makes the powder move to the outside ...

Embodiment 3

[0070] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that a plurality of placement grooves 302 are uniformly arranged on the turntable 3 along the circumferential direction, the outer ends of the placement grooves 302 are set as open, and the inner ends are connected by springs. Spring plate 304, and the top of spring plate 304 is higher than the top surface of turntable 3, and two stoppers 303 are symmetrically fixed on the outer section of placement groove 302, and the top surface of stopper 303 is lower than the top surface of turntable 3, The bottom of the forming groove 8 extends into the placement groove 302 and is located between the stopper 303 and the spring plate 304 .

[0071] A cam 305 is rotatably connected on the outer section of the bottom surface of the placement groove 302, and the top surface of the cam 305 is lower than the top surface of the turntable 3, and the wheel surface of the cam 305 is in contact wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com