Full-automatic multifunctional solar photovoltaic brewing machine

A solar photovoltaic, multi-functional technology, applied in biochemical instruments, biochemical equipment and methods, food science, etc., can solve the problems of inability to accurately grasp the fermentation temperature and time, high labor intensity, inaccurate control, etc., and achieve a convenient location. And the light receiving angle adjustment, to prevent flies and dust from falling, does not affect the effect of shading sunlight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

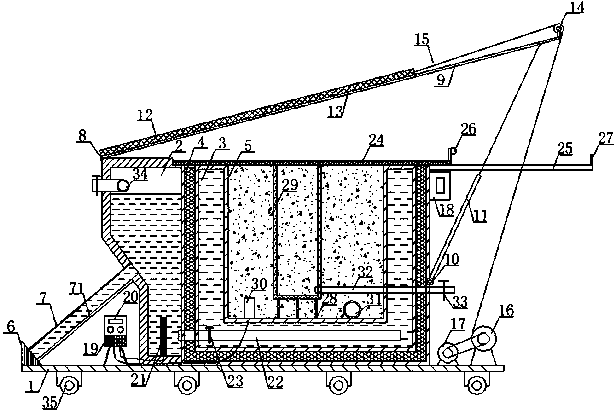

[0036] Such as figure 1As shown, a fully automatic multifunctional solar photovoltaic brewing machine of the present invention includes a chassis 1, a high temperature water tank 2, a constant temperature water tank 3, a heat insulation layer 4, a fermentation tank 5, a triangular pad 6, a solar vacuum tube 7, and a solar reflective Plate 71, first rotating shaft 8, inclined guide rail 9, second rotating shaft 10, telescopic rod 11, photovoltaic module 12, moving wheel 13, steering pulley 14, pulling rope 15, winder 16, winding motor 17, inverter Device 18, battery 19, control box 20, heating rod 21, diversion tube 22, water guide solenoid valve 23, glass cover plate 24, cover plate slide rail 25, push-pull handle 26, limit plate 27, support frame 28, penetration Filter screen 29, temperature probe 30, cleaning discharge port 31, dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com