Abrasive belt cutting structure

An abrasive belt and center shaft technology, applied in the field of vertical abrasive belt slitting machines, can solve the problems of prolonged non-working time, troublesome next process, low stability of the slitting machine, etc., so as to reduce rotation and tool movement. Influence, ensure work stability, and shorten the effect of non-working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

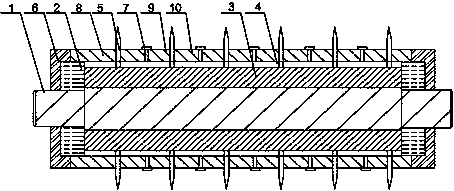

[0022] Such as figure 1 with figure 2 As shown, the abrasive belt cutting structure 5 of the present invention includes a central shaft 1, and the two ends of the central shaft 1 are rotated and arranged on the bearing seat 2. There are a plurality of trapezoidal grooves 4 distributed in an annular array, the trapezoidal grooves 4 are coaxial with the central axis 1, and also include a plurality of knives 5 and fixed blocks 8, the fixed blocks 8 are installed at both ends of the tool shaft 3, The cutter 5 is slidingly arranged in the trapezoidal groove 4, and the bottom end of the cutter 5 cooperates with the trapezoidal groove 4, and a spacer is installed between two adjacent cutters 5, and a threaded blind hole is provided on the cutter shaft 3, and the spacer The sleeve is fixed on the tool shaft 3 through the threaded blind hole through the bolt 7, and the two ends of the spacer are in contact with the end face of the cutter 5. When the present invention works, the cent...

Embodiment 2

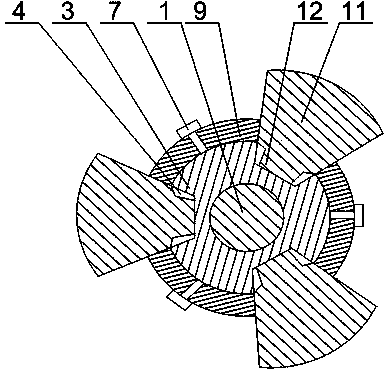

[0024] Such as figure 2 As shown, in this embodiment, on the basis of Embodiment 1, the cutter 5 includes an arc-shaped cutter head 11 and a support portion 12 connected to each other, the support portion 12 is trapezoidal, and the support portion 12 cooperates with the trapezoidal groove 4 . The arc-shaped cutter head 11 can ensure a longer contact time with the abrasive belt during cutting, and the trapezoidal support part 12 cooperates with the trapezoidal groove 4, so that the tool 5 is stressed during high-speed rotation and in contact with the abrasive belt. It has strong stability during operation, and avoids the quality reduction of the cutting abrasive belt caused by the loosening of the cutter 5 during work.

Embodiment 3

[0026] Such as figure 1 As shown, on the basis of Embodiment 1, the present embodiment includes the spacer A9 arranged at intervals and the spacer B10 matched with the spacer A9, and the spacer A9 and the spacer B10 are respectively fixed during operation. On both sides of the cutter 5. When the required width of the cut strips is the same, the spacer A9 is the same as the spacer B10 to ensure that the distance between the blades is equal; when the width of the spacer A9 is smaller than the spacer B10, the adjacent two knives 5 The distances between them are not equal, and the widths of the sand strips obtained after cutting the abrasive belts are also not the same, ensuring that the present invention can produce sand strips of different widths without changing the cutter 5, greatly increasing its applicability. scope.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com