A mechanical claw for mechanical manufacturing

A technology of machinery manufacturing and mechanical jaws, applied in the field of machinery manufacturing supporting equipment, can solve the problems of reducing the production efficiency of the production line, poor mechanical strength of the mechanical jaws, and high cost, and can increase the connection stability, increase the mechanical strength, and reduce the failure rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

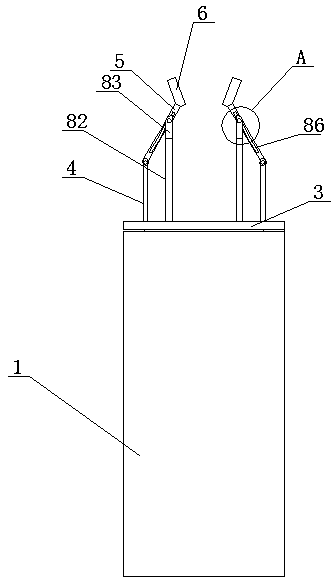

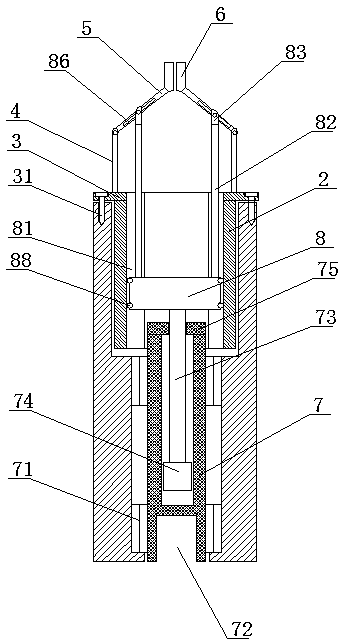

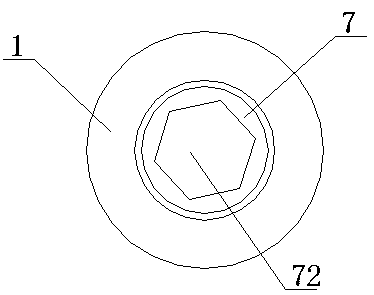

[0027]A mechanical gripper for mechanical manufacturing, comprising an outer sleeve 1, a first inner cavity is arranged at the front end of the outer sleeve 1, and an inner sleeve 2 is arranged in the first inner cavity, and the inner sleeve 2 and the outer sleeve 2 are connected to each other. The sleeve 1 is screwed, the inner sleeve 2 protrudes from the outer sleeve 1 and is provided with a mounting seat 3, and also includes a screw 31, and the mounting seat 3 and the outer sleeve 1 are fixedly connected by the screw 31. The mounting base 3 is provided with a column 4, and the end of the column 4 away from the mounting base 3 is provided with a mechanical clamp arm 5. The clamping block 6 is provided with anti-slip lines 61 on the clamping side of the clamping block 6 , and the anti-slip lines 61 are wave-shaped, and the wave-shaped anti-slip lines 61 on the two clamping blocks 6 are alternately arranged. The rear end of the outer sleeve 1 is provided with a second inner ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com