Physical training belt sorting and conveying mechanism

A conveying mechanism and physical fitness technology, which is applied in the field of physical training belt sorting and conveying mechanisms, can solve problems such as low efficiency, webbing stuck in the gap, and webbing confusion, etc., and achieve the effect of fast line collection and overcoming the broken webbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

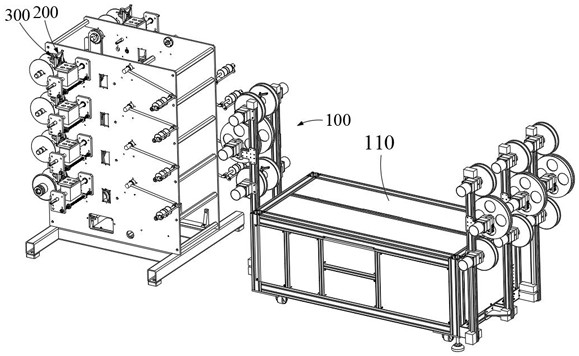

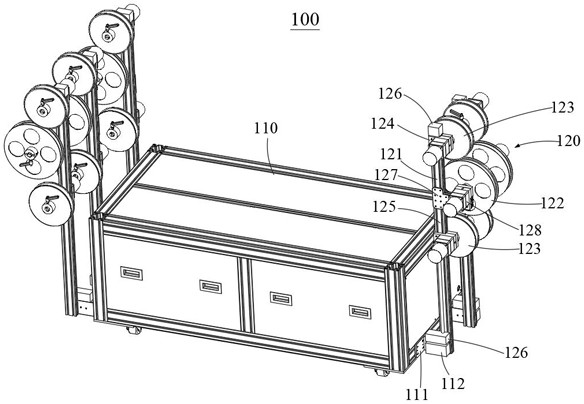

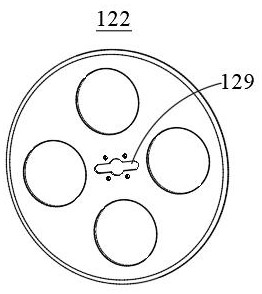

[0053] Such as Figure 1 ~ 10 As shown, a physical training belt sorting transport mechanism, including, twisting mechanism, a winding mechanism 100 disposed on the side of the twisting mechanism, the winding mechanism 100 including a storage box 110 and a rotation setting in the The collecting unit 120 on both sides of the box 110 includes a link 121 that is secured to the active roller 122 and a lifting roller 123 on the link 121, wherein The viscosity roller 123 is located at both ends of the active roller 122;

[0054]The twisted mechanism includes a wire device 400, a distribution device 200, and a line device 300 in sequential, wherein the wire wire device 400 is adapted to output each of the web to cause each ribbon to pass through the distribution device. 200, and in the intersection device 300, that is, the hinge device 300 is adapted to drive each of the ribbons to rotate to screw each zone into a webbing.

[0055] Wound mechanism 100

[0056] The winding mechanism 100 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com