Split type butterfly cable

A split type, butterfly cable technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of low effective utilization rate of butterfly cable, difficulty in splitting operation, shortened service life, etc., and achieve good sealing, reasonable overall structure design, and complete structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

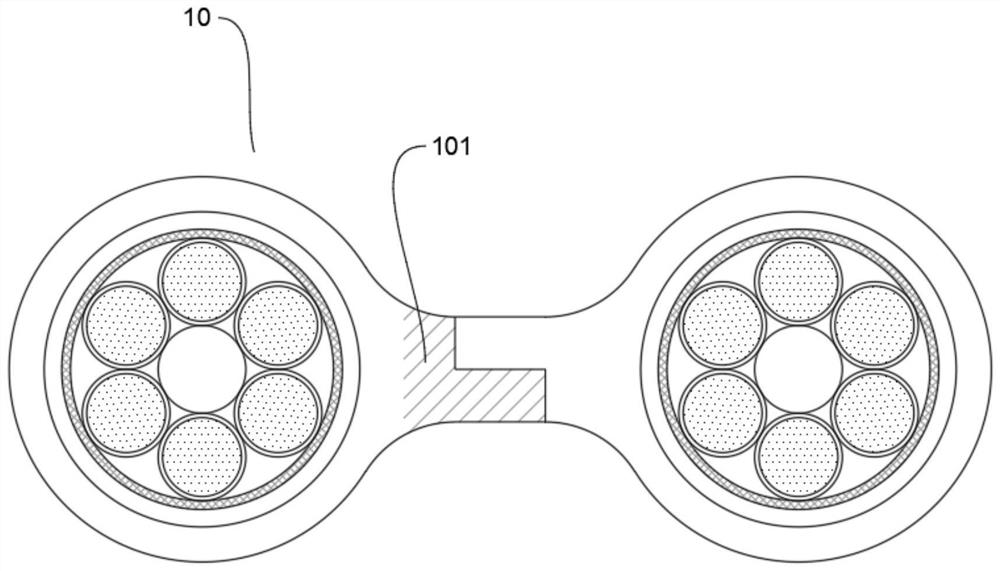

[0049] a kind of like figure 1 The split butterfly cable shown specifically includes:

[0050] Two cable units 10 are fitted together to form a complete butterfly cable;

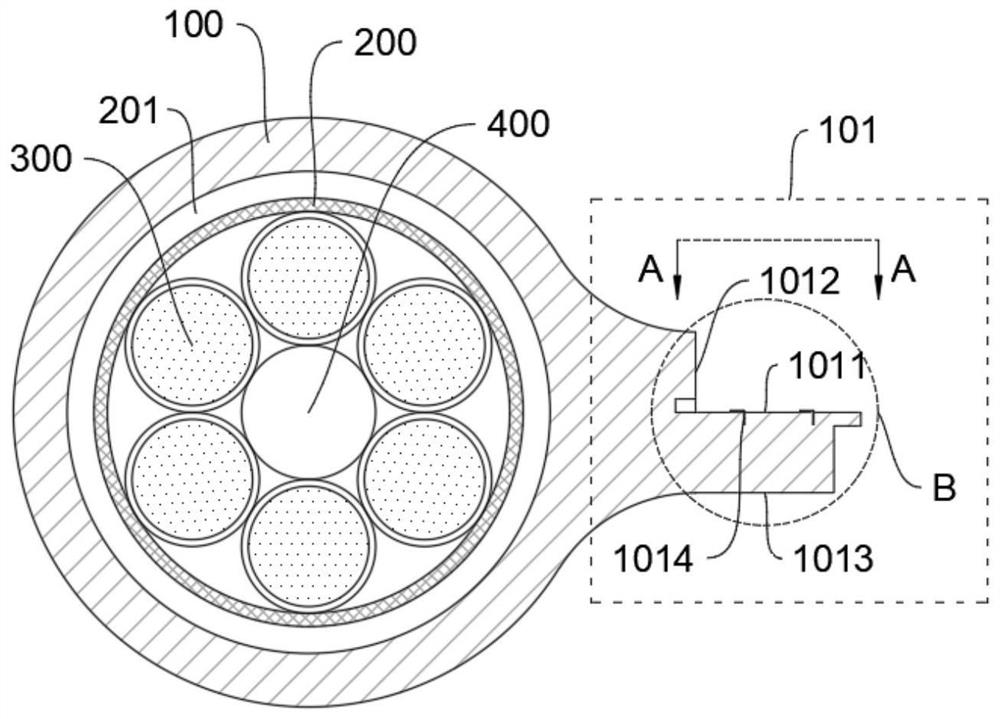

[0051] The cable unit 10 is specifically as figure 2 As shown, it includes a sheath 100, a waterproof protective layer 201, a tape layer 200 and an optical fiber 300, and optionally a strengthening member 400, and the sheath 100 is made of elastic PE material;

[0052] The sheath 100 is provided with a cavity for accommodating the tape layer 200 and the optical fiber 300, the optical fiber 300 is arranged in the cavity and fixed by the tape layer 200, and the waterproof protective layer 201 is arranged on the outer surface of the tape layer 200, In this embodiment, a strengthening member 400 is provided at the axis of the tape layer 200 of the cable unit 10, and the optical fiber 300 is evenly arranged outside the strengthening member 400 in the circumferential direction;

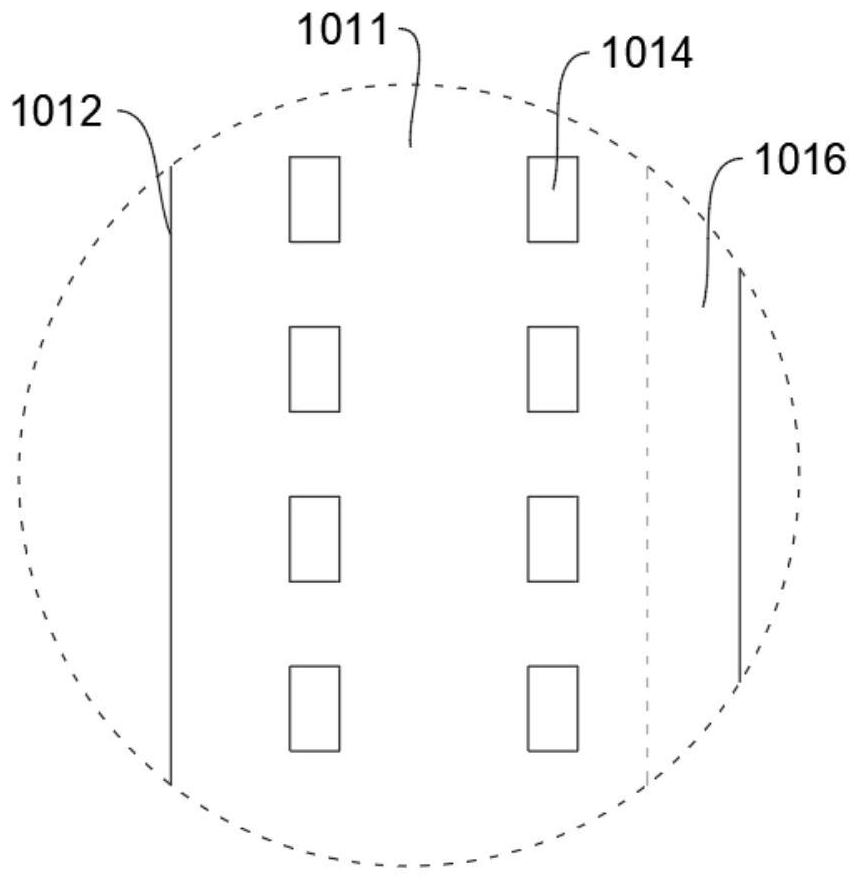

[0053] The sheath 100 is exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com