Battery fault detection device and method

A battery fault detection and battery technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problems of battery explosion life, the inability to obtain accurate open circuit voltage of the battery, and no accurate and effective battery fault detection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In the following, the components, steps and effects of the battery fault detection device and method of the present invention will be described by listing corresponding preferred embodiments in conjunction with the accompanying drawings. However, the components and dimensions of the battery fault detection device and method in each accompanying drawing The appearance and appearance are only used to illustrate the technical characteristics of the present invention, but not to limit the present invention.

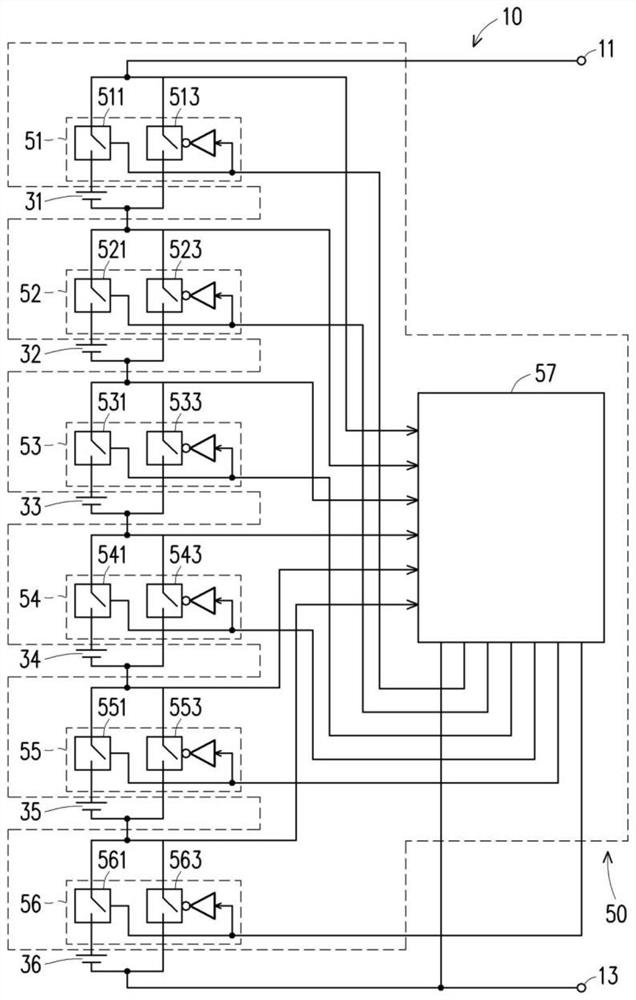

[0022] refer to figure 1 An embodiment is shown, and the figure is a block diagram of the charging / discharging system 10 with M batteries in the present invention. In this embodiment, M is 6. The charging / discharging system 10 with M batteries in the present invention is applied to an electric power The power system can be a variety of devices that need to be powered by batteries, such as portable computers, mobile phones, electric vehicles, electric locomotives, and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com