Method and device for detecting reliability of flash memory chip

A flash memory chip and detection method technology, applied in reliability/availability analysis, error detection/correction, static memory, etc., can solve problems such as insufficient information, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The following is attached Figure 1-7 The application is described in further detail.

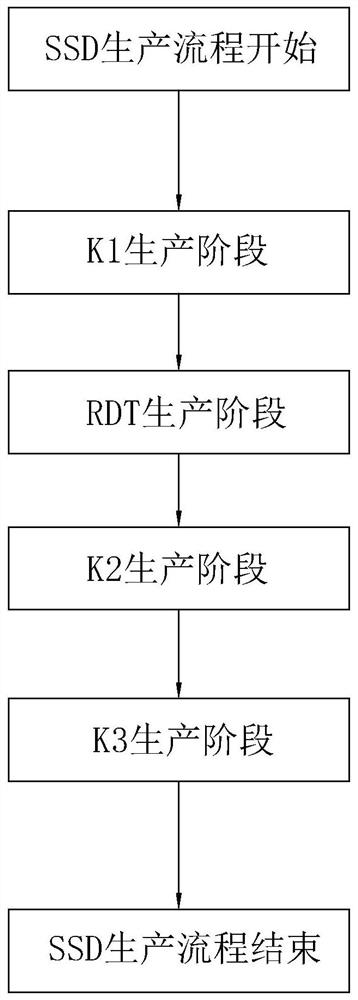

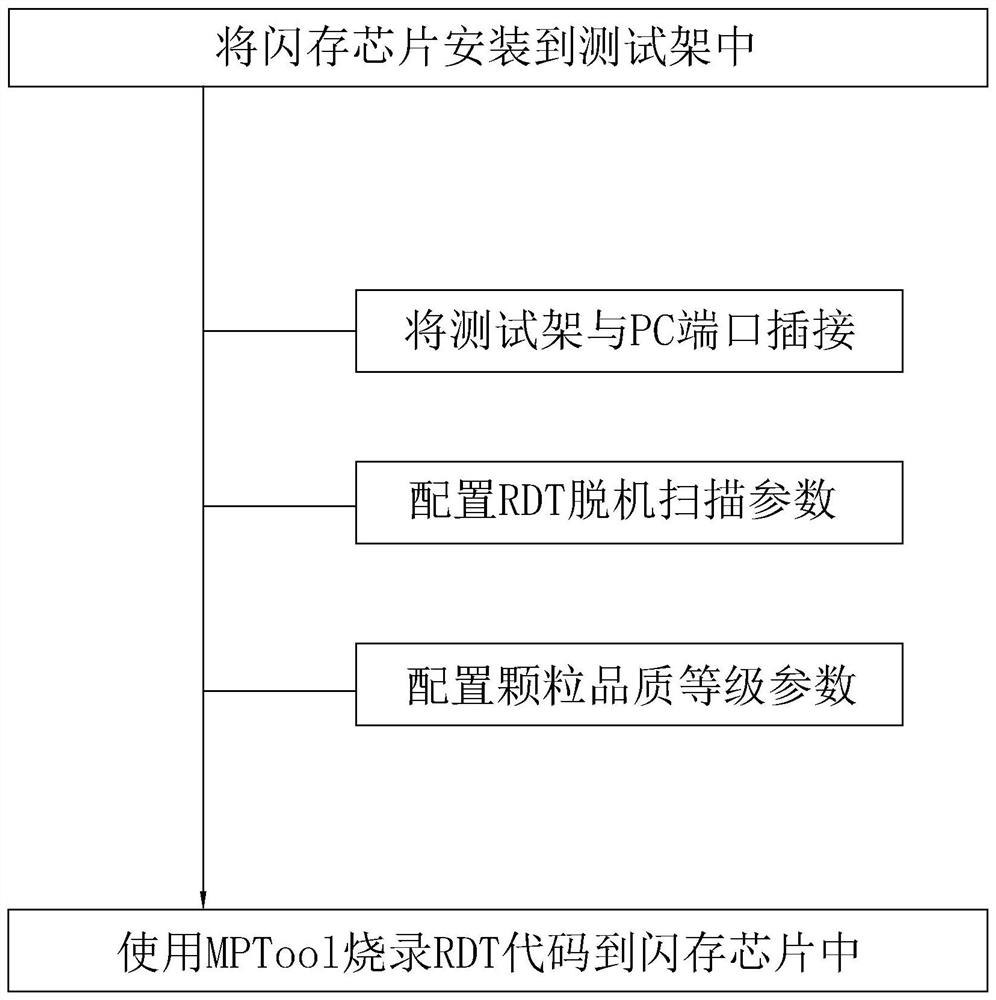

[0051] refer to figure 1 , the production process of solid-state drives (SSD) can be divided into K1 production stage, RDT production stage, K2 production stage, and K3 production stage. The K1 production stage refers to the practical MPTool burning RDT code into the flash memory chip. The K2 production stage refers to using MPTool for mass production of an SSD product, using the bad block information analyzed in the RDT stage to generate a corresponding bad block table, and the SSD mass-produced through the K2 production stage is a usable SSD solid state drive. The K3 production stage refers to the SSD solid-state hard disk that has been mass-produced in the K2 production stage. After the customer test stage, the "blocks" in the flash memory chip have been worn out, and new bad blocks may be generated. When the SSD is delivered to the customer, it needs to It is an unused factory ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com