Floating bed equipment for cleaning sewage

A sewage purification and floating bed technology, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of low filter operating flow rate, water ecological damage, high operating flow rate, etc. To achieve the effect of solving high energy consumption problems, saving energy and promoting recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

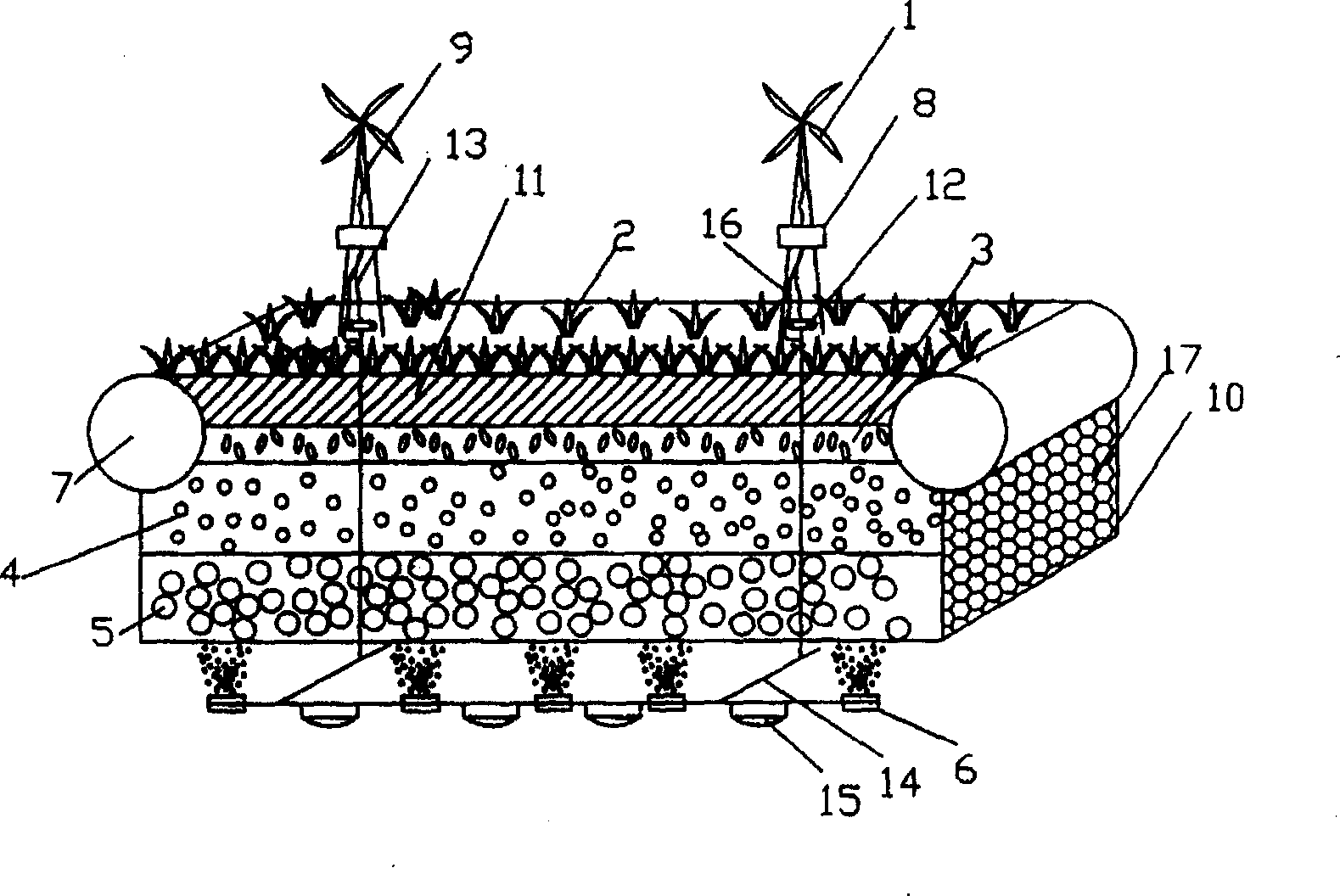

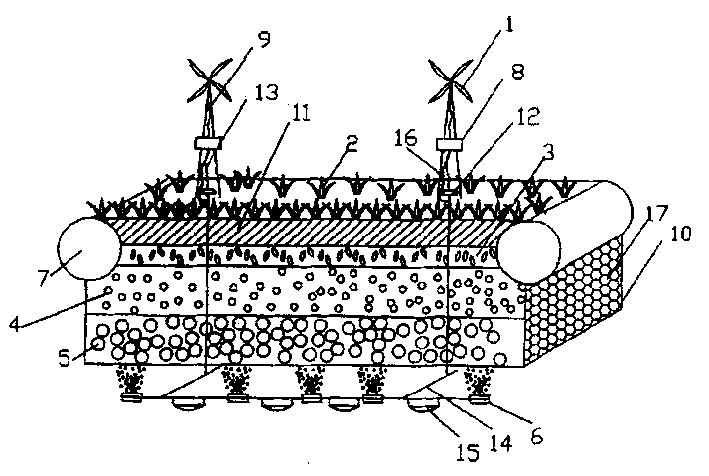

[0008] Such as figure 1 As shown, the present invention mainly comprises: wind power generator (1), amphibious plants (2) of high nitrogen and phosphorus removal varieties, algae-inhibiting biological filter material (3), denitrification biological filter material (4), nitrification biological filter material (5), aeration device (6), hollow buoy (7), storage battery (8), steel frame A (9), steel frame B (10), plant root support (11), air pump (12), electric wire A (13), air pipe (14), underwater lighting lamp (15), electric wire B (16), wind-driven generator (1) is arranged on the top of steel frame A (9), in the middle of steel frame A (9) A storage battery (8) is installed, and an air pump (12) is installed under the steel frame A (9). The storage battery (8) is connected to one end of the electric wire A (13), and the other end of the electric wire A (13) is connected to the air pump (12). , the air pump (12) is connected to one end of the air pipe (14), the other end of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap