Safety control method and system for hoisting equipment

A technology for safety control and lifting equipment, applied in cranes, load hanging components, transportation and packaging, etc., can solve complex operation characteristics, difficult to maintain the balance of lifting equipment and other problems, and achieve the effect of dynamic moment balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

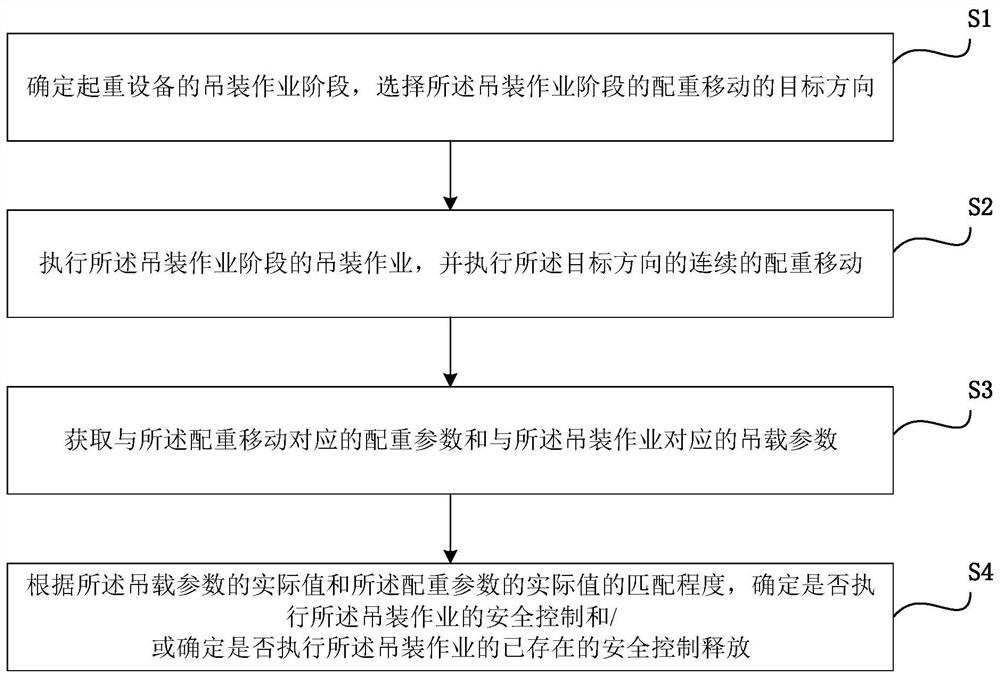

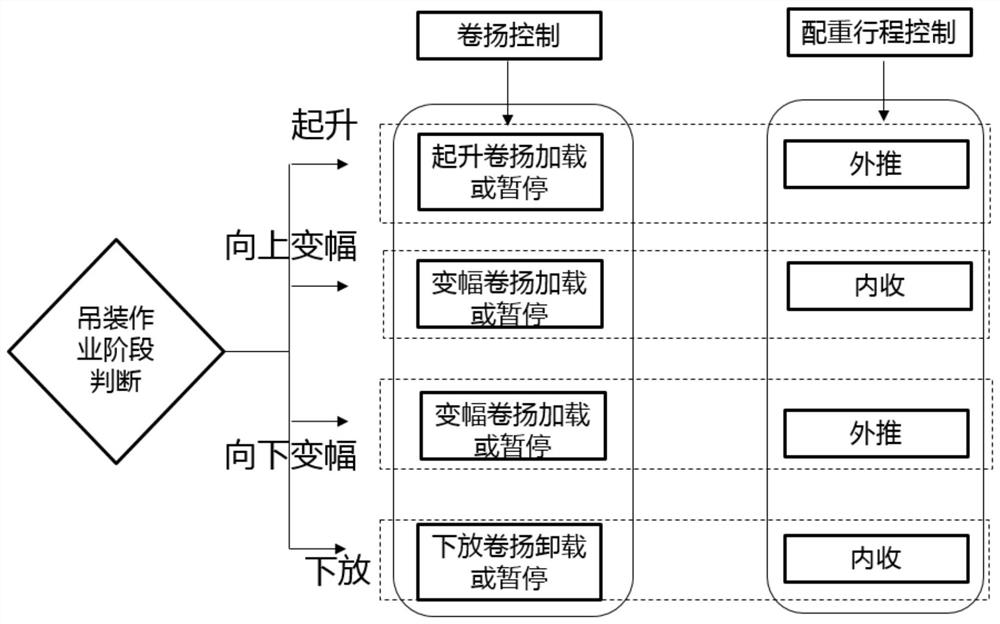

[0132] The embodiment of the present invention aims at the hoisting operation of current cranes using mobile counterweights in order to improve the lifting capacity and improve the stability of hoisting, which requires efficient and safe control, and it is difficult to hoist according to the stage characteristics of hoisting, lowering, and luffing in the hoisting process Linkage control with counterweight (lifting can refer to the process of increasing the load from 0 to the total weight of the hoisted object, and lowering can refer to the process of the hoisting weight from the total weight of the heavy object to the total weight of the hoisted object on the ground to 0) , it is difficult to complete the continuous movement and continuous operation control of the counterweight. A safety control scheme for the dynamic balance of the counterweight under the continuous operation of the crane based on the characteristics of the operation stage is proposed. Load and counterweight d...

Embodiment 2

[0223] An embodiment of the present invention provides a safety control system for lifting equipment, the safety control system may include:

[0224] The main control module is used to determine the hoisting operation stage of the lifting equipment, and select the target direction of the counterweight movement in the hoisting operation stage;

[0225] a counterweight control module, configured to perform continuous counterweight movement in the target direction;

[0226] a hoisting control module, configured to perform the hoisting operation in the hoisting operation phase;

[0227] The hoisting control module is used to obtain counterweight parameters corresponding to the movement of the counterweight and hoisting parameters corresponding to the hoisting operation;

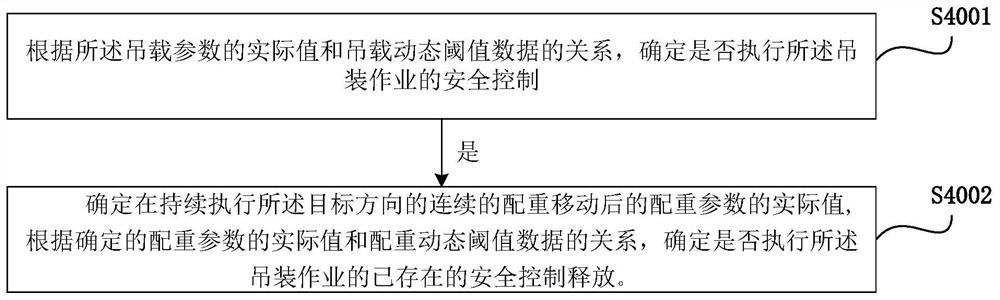

[0228] The hoisting control module is used to determine whether to execute the safety control of the hoisting operation and / or determine whether to execute the hoisting operation according to the matching degree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com