High-applicability electricity testing self-detection warning device based on electrical equipment

A technology for warning devices and power equipment, applied in the directions of measuring devices, measuring device casings, measuring current/voltage, etc., can solve the safety hazards of electric sparks in inconvenient equipment and devices, real-time monitoring of the live condition of difficult power equipment, and inconvenient fault location location. and other problems to achieve the effect of increasing the scope of detection, preventing potential safety hazards and preventing electric shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

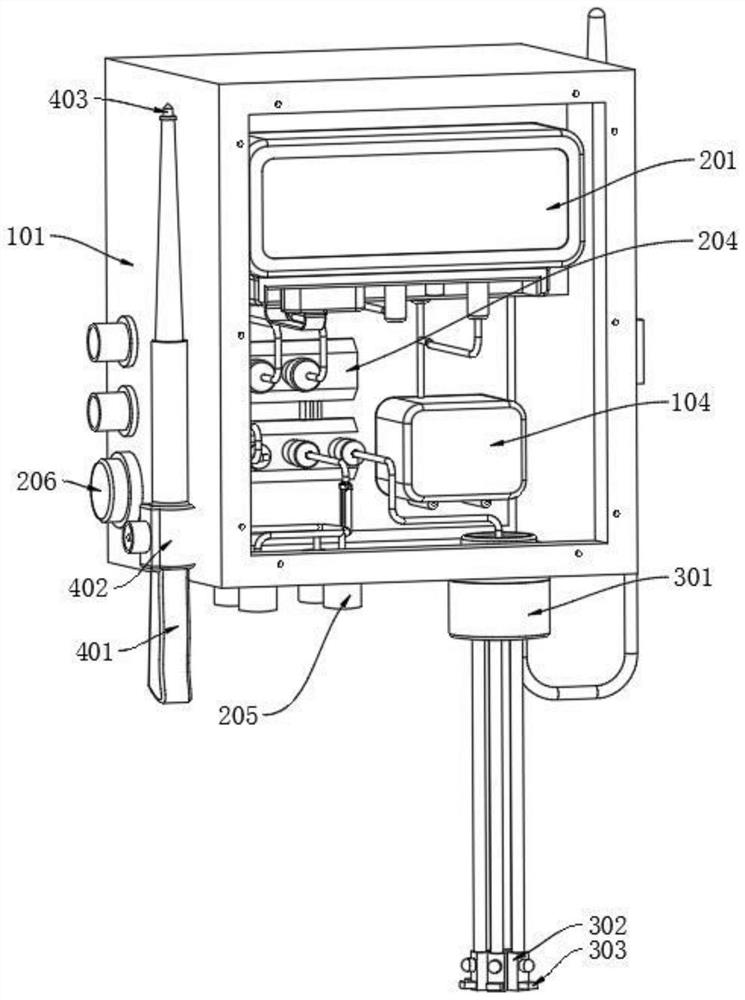

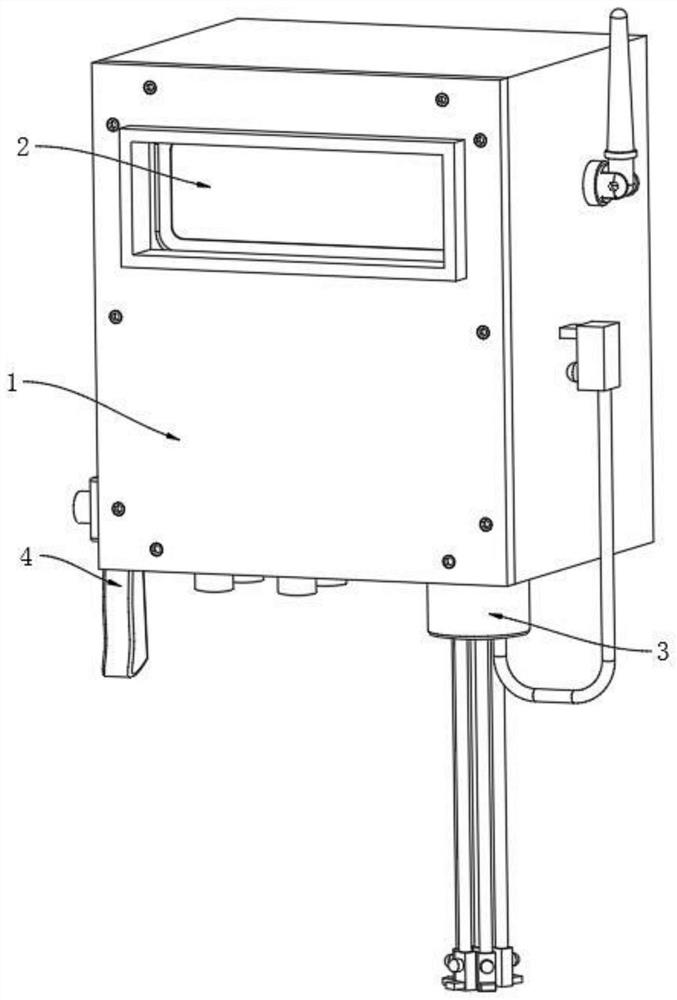

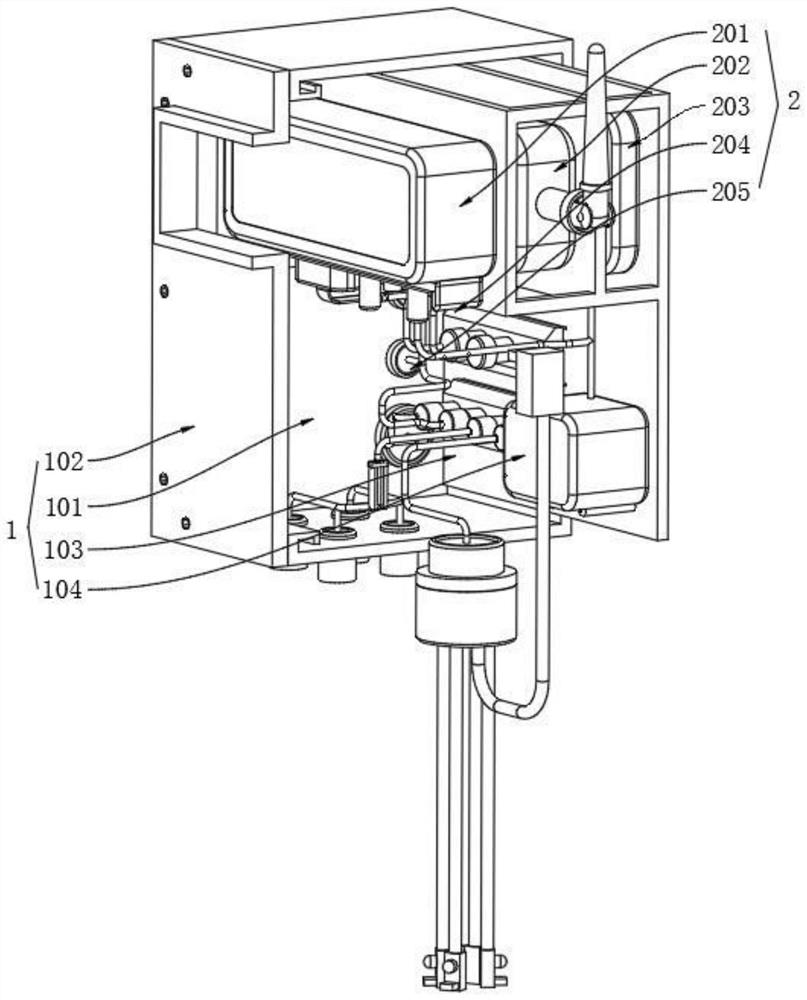

[0033] Example: Please refer to Figure 1 to 9 :

[0034] The present invention is based on the high applicability of the proposed test device from the electrical power detecting warning device, comprising: a mounting means; an internally mounted mechanism attached to the control mechanism 2, the controller 2 and the display control means and the mounting mechanism 201 of the seal 1 the cover through hole 102 is aligned; means a lower mounting means 3 is attached to the self-test, self-test means and the connecting member 3 is connected via a line 301 to the control means 2 of merged element 204; the left mounting mechanism 1 is mounted detecting means 4, the telescopic rod 4 and the detecting means 402 mounted on the card body 101 is mounted on the left side.

[0035] Further, according to an embodiment of the present invention, such as figure 1 , image 3 , The mounting mechanism 1 comprising: mounting the housing 101, the housing 101 is mounted in a rectangular configuration, mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com