Drawing pressing equipment for computer image-text making

A graphic and drawing technology, applied in the field of drawing pressing equipment for computer graphic production, can solve problems such as troublesome fixing methods, high cost, and complicated equipment structure, and achieve the effects of reducing production costs, improving work efficiency, and simplifying equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

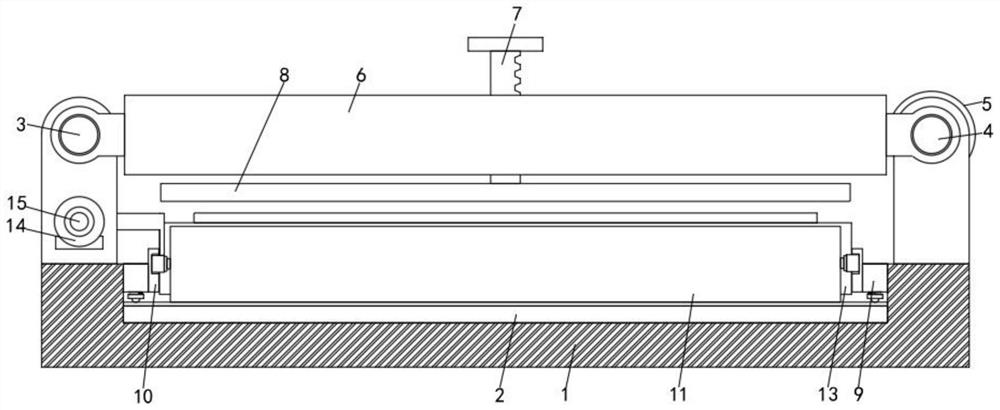

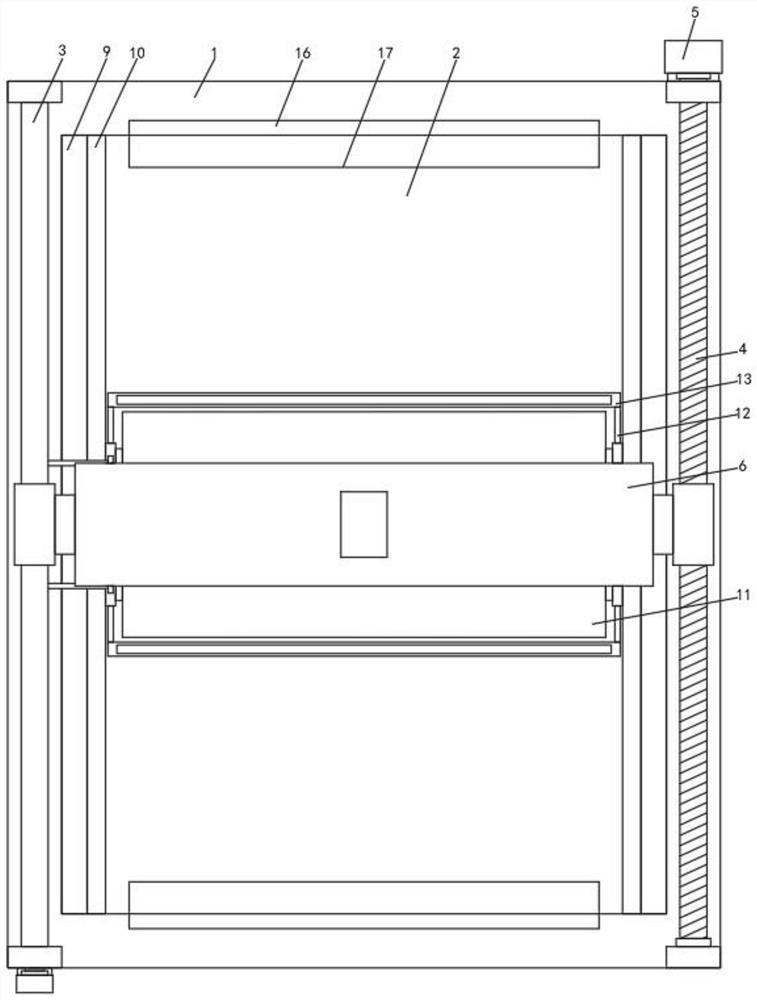

[0026] Such as figure 1 As shown, a kind of drawing pressing equipment for computer graphics and text production proposed by the present invention includes a base 1, a placement plate 2, a guide rod 3, a screw rod 4, a motor 5, a moving box 6, a tooth plate 7 and a scanner main body 8 . The top of the placement plate 2 is provided with a limiting mechanism 9 located on the inner walls of both sides of the base 1 , and the inner side of the limiting mechanism 9 is welded with a side plate 10 . A plurality of rollers 11 are movably connected between the symmetrically arranged side plates 10 , and clamping mechanisms 13 are arranged on the sides of the rollers 11 . A riser 16 is welded to the front and back of the top of the base 1, and a wedge 17 is fixedly connected to the top of the riser 16. The bottom of guide rod 3 is rotatably connected with the two-way screw mandrel 15 that is positioned at the symmetrical supporting plate of left side, and the front end of two-way scre...

Embodiment 2

[0029] Such as Figure 1-2 As shown, the present invention proposes a drawing pressing device for computer graphics and text production. Compared with Embodiment 1, this embodiment also includes: support plates are symmetrically arranged on both sides of the top of the base 1, and support plates are symmetrically arranged on the right side. A screw 4 is connected to the plate for rotation, a motor 5 is arranged at one end of the back of the screw 4, and a guide rod 3 is arranged between the support plates arranged symmetrically on the left side, and a connecting block is set on the guide rod 3 and the screw rod 4 , a moving box 6 is arranged between a plurality of connecting blocks, a toothed plate 7 is movably connected to the moving box 6, the bottom end of the toothed plate 7 passes through the top and bottom shell walls of the moving box 6, and a scanner main body 8 is installed, The bottom inner wall of the base 1 is provided with a placement plate 2, and a chute is provi...

Embodiment 3

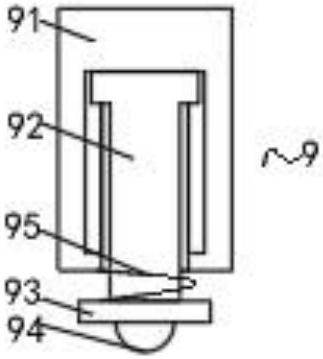

[0032] Such as Figure 3-4 As shown, the present invention proposes a drawing pressing device for computer graphics and text production. Compared with Embodiment 1 or Embodiment 2, this embodiment also includes: the limit mechanism 9 includes a limit plate 91, an adjustment rod 92, a stopper Plate 93, ball 94 and back-moving spring one 95, the inside of limit plate 91 is slidingly connected with adjusting rod 92, the bottom end of adjusting rod 92 is welded with abutment plate 93, and the bottom of abutment plate 93 is rollingly connected with a plurality of balls 94, and Adjusting rod 92 is provided with back-moving spring one 95, and clamping mechanism 13 includes cavity plate 131, movable bar 132, wedge two 133, pressing plate 134 and back-moving spring two 135, and the inner sliding connection of cavity plate 131 has many A movable rod 132, the top of a plurality of movable rods 132 is welded with two wedges 133, and the bottom end of the movable rods 132 is fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com