Manufacturing method of impact-resistant food packaging tin

A technology of food packaging and manufacturing method, which is applied in the field of manufacturing impact-resistant food packaging cans, can solve the problems of low strength of the can body, poor fire and heat insulation effect of the food packaging can, deformation and the like, and achieves the effect of stabilizing the can body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

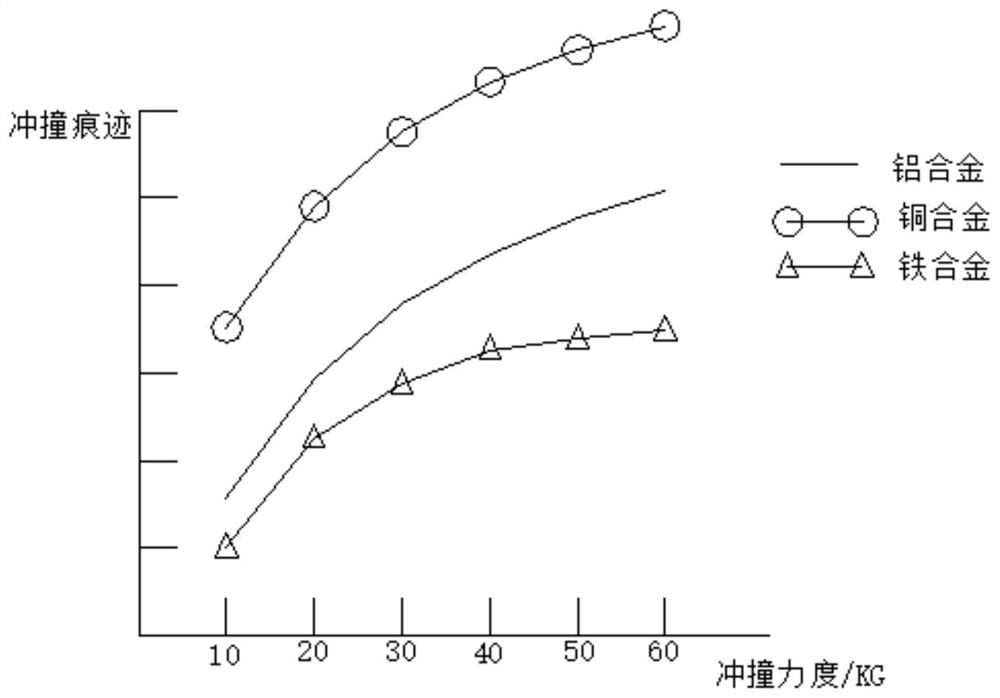

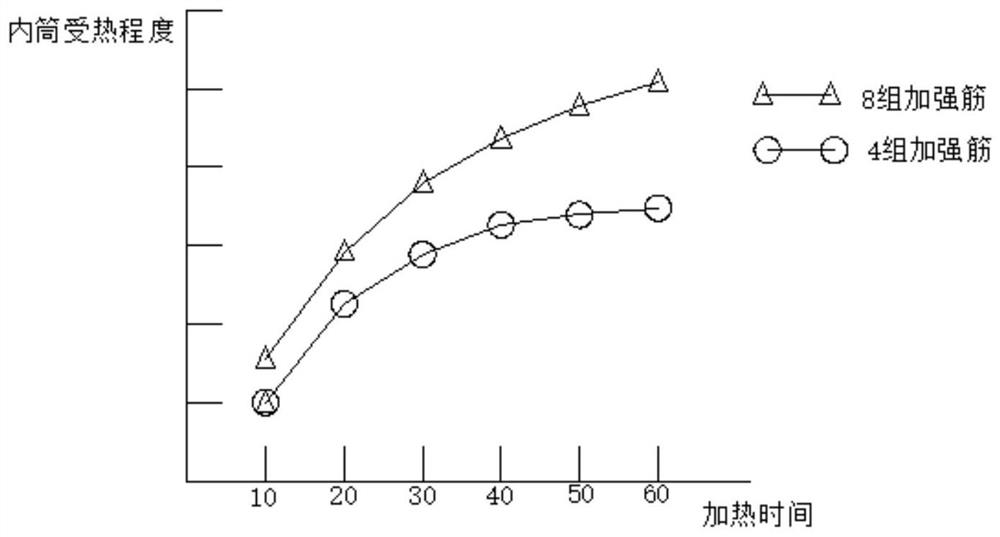

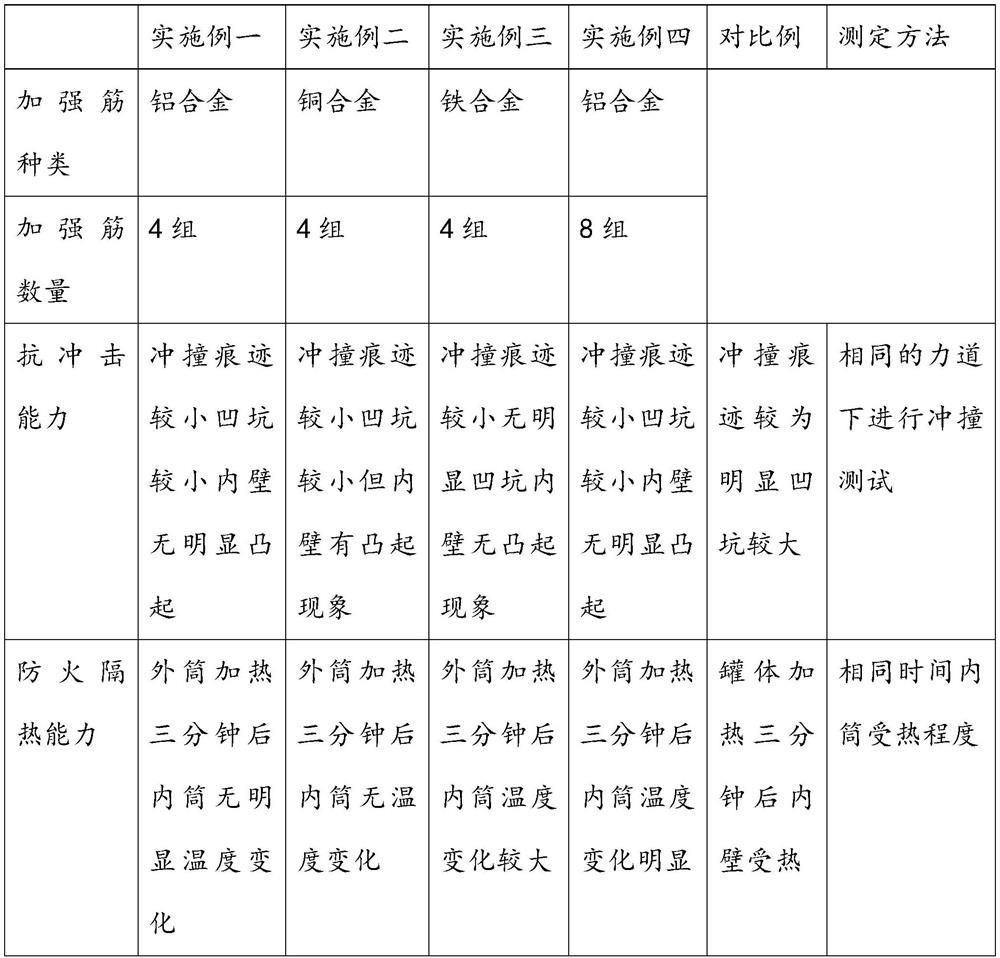

Embodiment 1

[0026] A kind of manufacturing method of impact-resistant type food packaging jar designed by the present invention, comprises the following steps:

[0027] a. The inner cylinder of the packaging can is made of aluminum plate, the outer cylinder is made of aluminum alloy, and the reinforcing rib is made of aluminum alloy.

[0028] b. Use a punching machine to stamp the aluminum plate and aluminum alloy plate into aluminum discs and aluminum alloy discs, and the diameter of the aluminum alloy discs is larger than that of the aluminum discs.

[0029] c. Draw the aluminum disc and the aluminum alloy sheet into a cylinder through the preliminary drawing die to form the preliminary outer cylinder and inner cylinder; d. After drawing the outer cylinder and the inner cylinder again through the secondary drawing die, the reduction Its diameter stretches its length; e. Repeat the above steps until the inner and outer cylinders reach the specified size.

[0030] f. Fix the inner cylind...

Embodiment 2

[0035] A kind of manufacturing method of impact-resistant type food packaging jar designed by the present invention, comprises the following steps:

[0036] a. The inner cylinder of the packaging tank is made of aluminum plate, the outer cylinder is made of aluminum alloy, and the reinforcing rib is made of copper alloy.

[0037] b. Use a punching machine to stamp the aluminum plate and aluminum alloy plate into aluminum discs and aluminum alloy discs, and the diameter of the aluminum alloy discs is larger than that of the aluminum discs.

[0038] c. Draw the aluminum disc and the aluminum alloy sheet into a cylinder through the preliminary drawing die to form the preliminary outer cylinder and inner cylinder; d. After drawing the outer cylinder and the inner cylinder again through the secondary drawing die, the reduction Its diameter stretches its length; e. Repeat the above steps until the inner and outer cylinders reach the specified size.

[0039] f. Fix the inner cylinde...

Embodiment 3

[0044] A kind of manufacturing method of impact-resistant type food packaging jar designed by the present invention, comprises the following steps:

[0045] a. The inner cylinder of the packaging tank is made of aluminum plate, the outer cylinder is made of aluminum alloy, and the reinforcing rib is made of iron alloy.

[0046] b. Use a punching machine to stamp the aluminum plate and aluminum alloy plate into aluminum discs and aluminum alloy discs, and the diameter of the aluminum alloy discs is larger than that of the aluminum discs.

[0047] c. Draw the aluminum disc and the aluminum alloy sheet into a cylinder through the preliminary drawing die to form the preliminary outer cylinder and inner cylinder; d. After drawing the outer cylinder and the inner cylinder again through the secondary drawing die, the reduction Its diameter stretches its length; e. Repeat the above steps until the inner and outer cylinders reach the specified size.

[0048] f. Fix the inner cylinder ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap