A high precision optical fiber icing sensor, system and method

An icing sensor, high-precision technology, applied in the field of wind tunnel testing, can solve the problems of detection limitations, inaccurate measurement, and no protection considerations, etc., to achieve the effect of ensuring no icing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

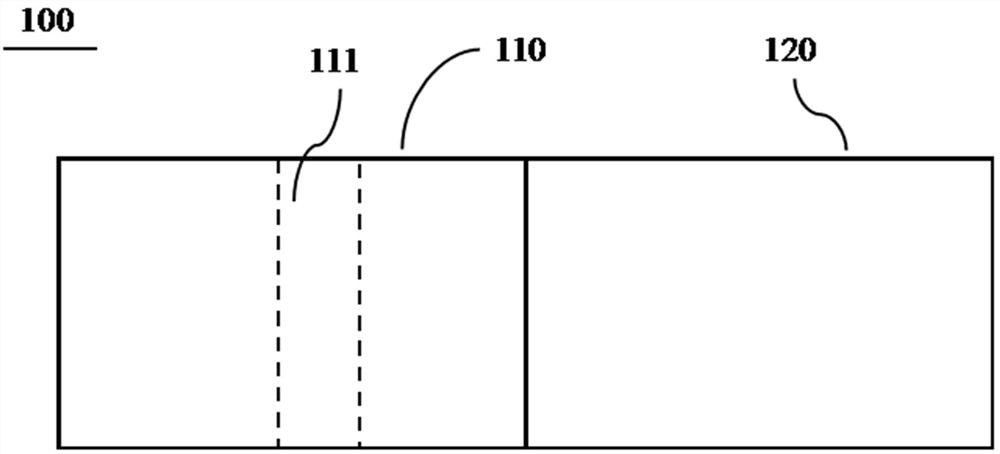

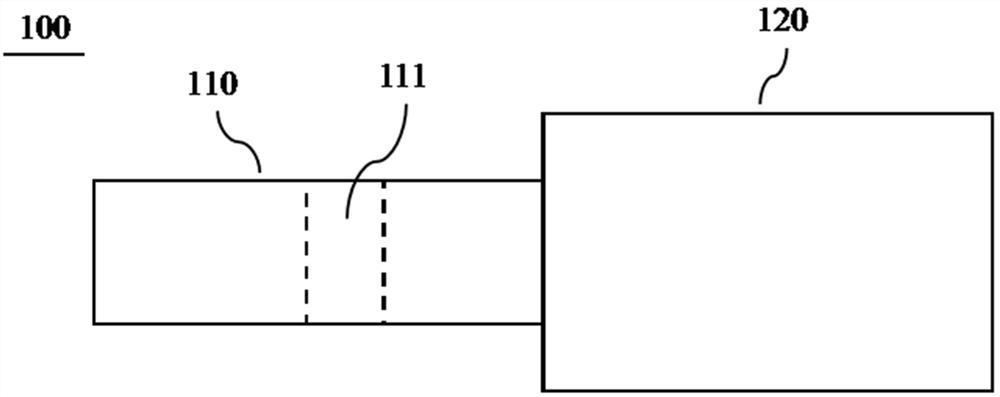

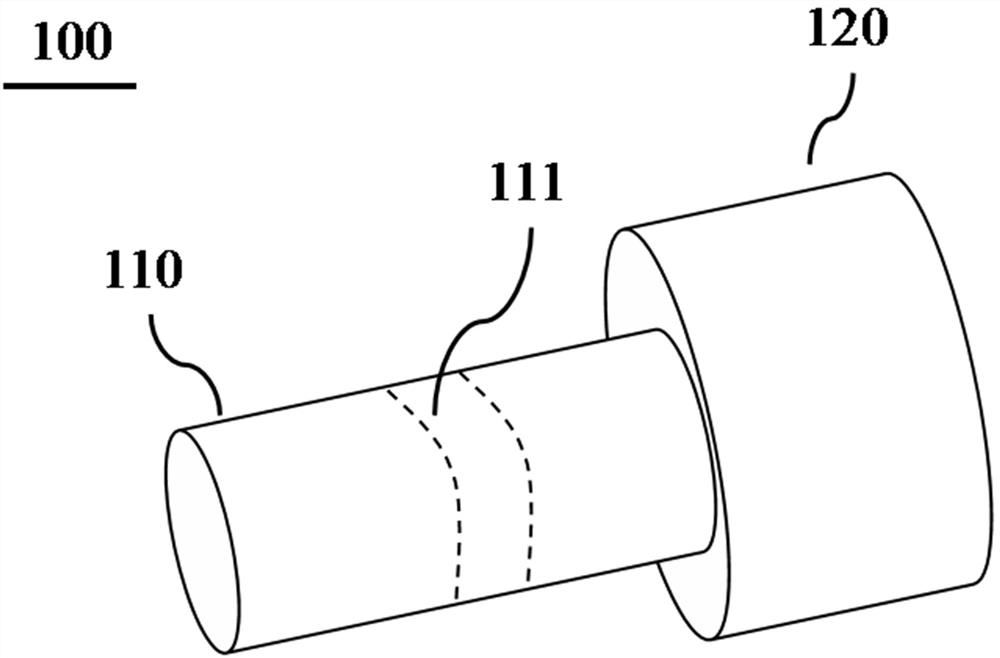

[0039] Such as figure 1 , figure 2 , image 3 As shown, Embodiment 1 of the present invention provides a high-precision optical fiber icing sensor 100, which includes a sensing part 120 and a non-sensing part 110 connected to each other. The non-sensing part 110 is provided with a temperature measurement area 111, and the The temperature measurement area 111 is arranged on the windward surface 112 of the non-sensing part, and the temperature measurement area 111 is used to obtain temperature information on the surface of the non-sensing part 110 .

[0040] After many tests and observations, the applicant combined with the applicant's own practical experience found that: the main reason for the inaccurate measurement of the optical fiber icing sensor 100 is that the non-sensing part 110 other than the sensing part 120 will freeze in the freezing environment The icing of the non-sensing part 110 will change the icing environment of the optical fiber icing sensor 100, affect t...

Embodiment 2

[0051] Such as Figure 5 As shown, Embodiment 2 of the present invention provides an anti-icing temperature control system, including a temperature measurement system, a control system, and an anti-icing system. The control system is connected to the temperature measurement system and the anti-icing system. The temperature system includes the optical fiber icing sensor 100 described above.

[0052] The temperature measurement system and the anti-icing system are connected through the control system, so that the temperature value and / or temperature change obtained by the temperature measurement system can be fed back and adjusted in time through the control system, and the anti-icing system is controlled by the temperature measurement system to control the optical fiber icing sensor 100 surfaces for effective and precise deicing.

[0053] Further, the control system is connected to the temperature measurement area 111, specifically, the control system is respectively connected...

Embodiment 3

[0059] Such as Figure 6 As shown, Embodiment 3 of the present invention provides an anti-icing temperature control method, including the following steps:

[0060] Step S10: Turn on the anti-icing temperature control system;

[0061] Step S20: When the temperature in the temperature measurement area 111 is lower than the preset temperature value, increase the anti-icing power until the temperature in the temperature measurement area 111 meets the preset temperature value, and the temperature in the temperature measurement area 111 is the temperature value of all temperature measurement points the mean value of

[0062] Step S30: Enter the freezing environment.

[0063] When the optical fiber icing sensor 100 enters the icing environment, the temperature on the surface of the non-sensing part 110 drops rapidly to the freezing temperature, such as 0°C; There will be rapid changes. In most cases, the temperature rise slope is large, that is, the temperature change in the freez...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap