A rapid packaging device for light-emitting diodes

A technology for light-emitting diodes and packaging devices, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of damage to the pulling force of light-emitting diodes, failure to fix light-emitting diodes, and reduce the practicability of packaging devices, etc., to achieve flexible design of packaging molds, Prevents displacement and improves productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

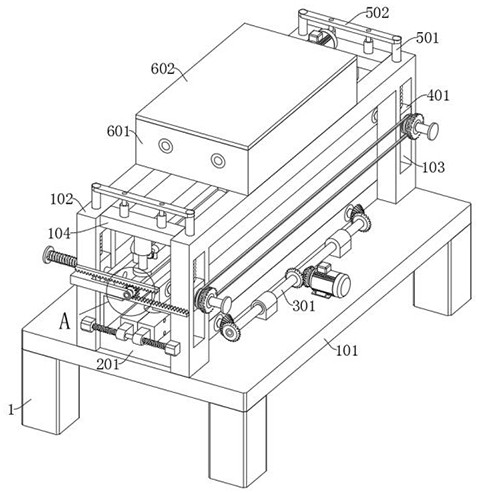

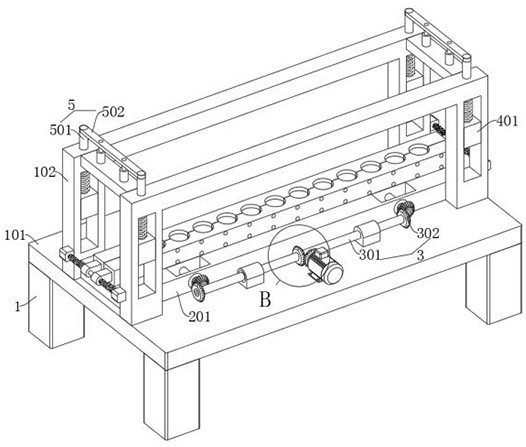

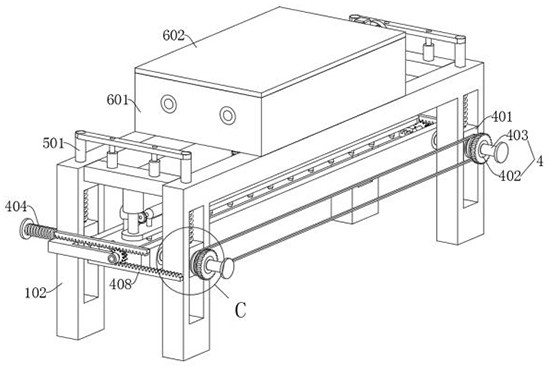

[0029] Example 1: Please refer to Figure 1 to Figure 12 :

[0030] The present invention provides a fast packaging device for light emitting diodes, comprising: a support body 1, the support body 1 includes: a support table 101, a support frame 102, a connecting groove 103 and a support column 104, and the support table 101 is fixedly arranged on the support body 1. The top; the support frame 102 is fixedly arranged on the top of the support table 101, and the main body of the support frame 102 is set to a U-shaped structure; The connecting groove 103 completely penetrates the support frame 102; the support column 104 is fixedly arranged between the two sets of support frames 102, and the number of the support column 104 is set to two groups; A mold mechanism 2 is installed on the top; a control mechanism 3 is installed on the top of the support body 1, and a fixing device 4 is installed on the top side of the support body 1; the control mechanism 3 includes: a control shaft...

Embodiment 2

[0034] Example 2: Please refer to Figure 13; In this embodiment, the mold mechanism 2 includes: a mold table 201, a double-ended screw 202, a connecting block 203, a mold piece 204, an auxiliary hole 205, a baking rack 206, a fixed block 207, a fixed rod 208 and a synchronous wheel A209, the mold The table 201 is fixedly arranged on the top of the support table 101, and two sets of square grooves are opened inside the mold table 201; the outer side of the double-ended screw 202 is fitted with a bearing, and the bearing is fitted inside the mold table 201; the top of the double-ended screw 202 is fixedly provided with a bearing. Synchronizing wheel, and the number of double-ended screws 202 is set to two groups; the connecting blocks 203 are arranged on both sides of the double-ended screw 202 through screw connection, and the number of connecting blocks 203 is set to four groups; the two groups of connecting blocks 203 are arranged in a symmetrical structure The mold piece 20...

Embodiment 3

[0035] Example 3: Please refer to Figure 14 ; In this embodiment, the glue filling mechanism 7 includes: glue filling frame 701, glue filling head 702, connecting pipe 703, screw rod 704, bevel gear C705, positioning rod 706 and positioning cylinder 707, glue filling frame 701 through hydraulic rod The glue filling head 702 is fixedly arranged at the bottom of the support column 104; the glue filling head 702 is fixedly arranged inside the glue filling frame 701, and the glue filling head 702 is fixed in a path array; the connecting pipe 703 is fixedly arranged on the top of the glue filling head 702, and the connecting tube 703 is connected with the telescopic soft The tube 605 is connected; the outer side of the screw rod 704 is fitted with a bearing, and the bearing is fitted inside both ends of the connecting tube 703; the top of the screw rod 704 is fixedly provided with a bevel gear; the bevel gear C705 is fixedly arranged at the shaft end of the motor device, and The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com