Overhead structure for floor heating installation

An overhead structure and floor heating technology, which is applied in the field of engineering installation, can solve the problems of delayed pipeline discovery and affecting living experience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solution in this application will be described in further detail below in conjunction with the accompanying drawings.

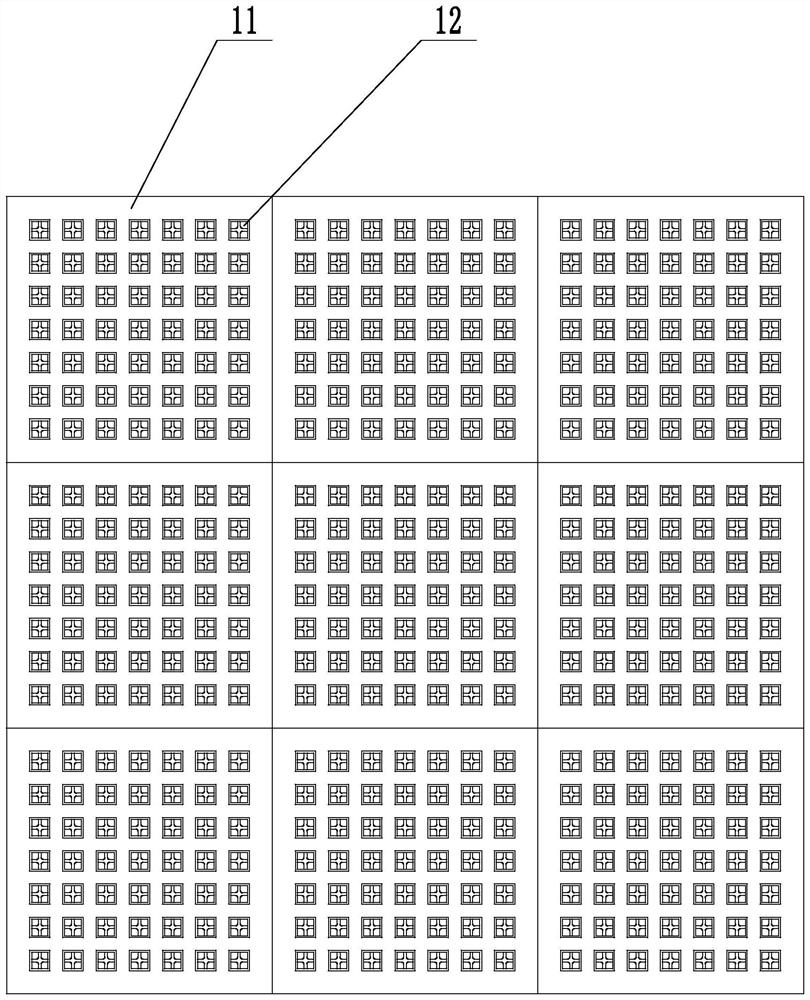

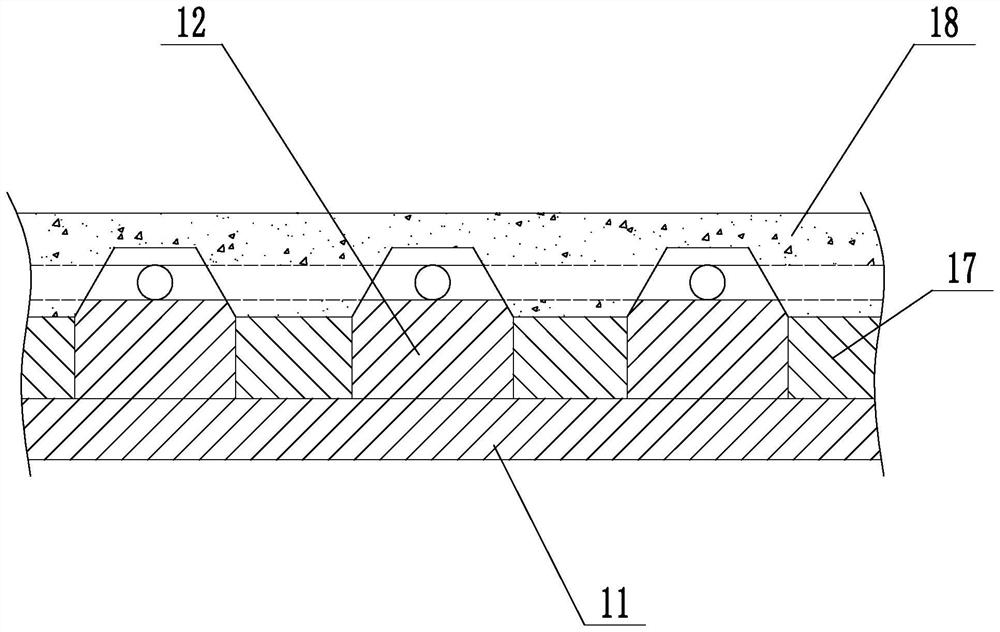

[0038] see figure 1 and figure 2 , is an overhead structure for floor heating installation disclosed in the embodiment of this application. In the above, taking the specific construction process as an example, after the ground in the room is leveled, the partitions 11 need to be laid on the ground in order, and the specific style can refer to the laying of ceramic tiles. A layer of adhesive can be applied between the bottom surface of the partition 11 and the ground, in order to improve the stability of the connection.

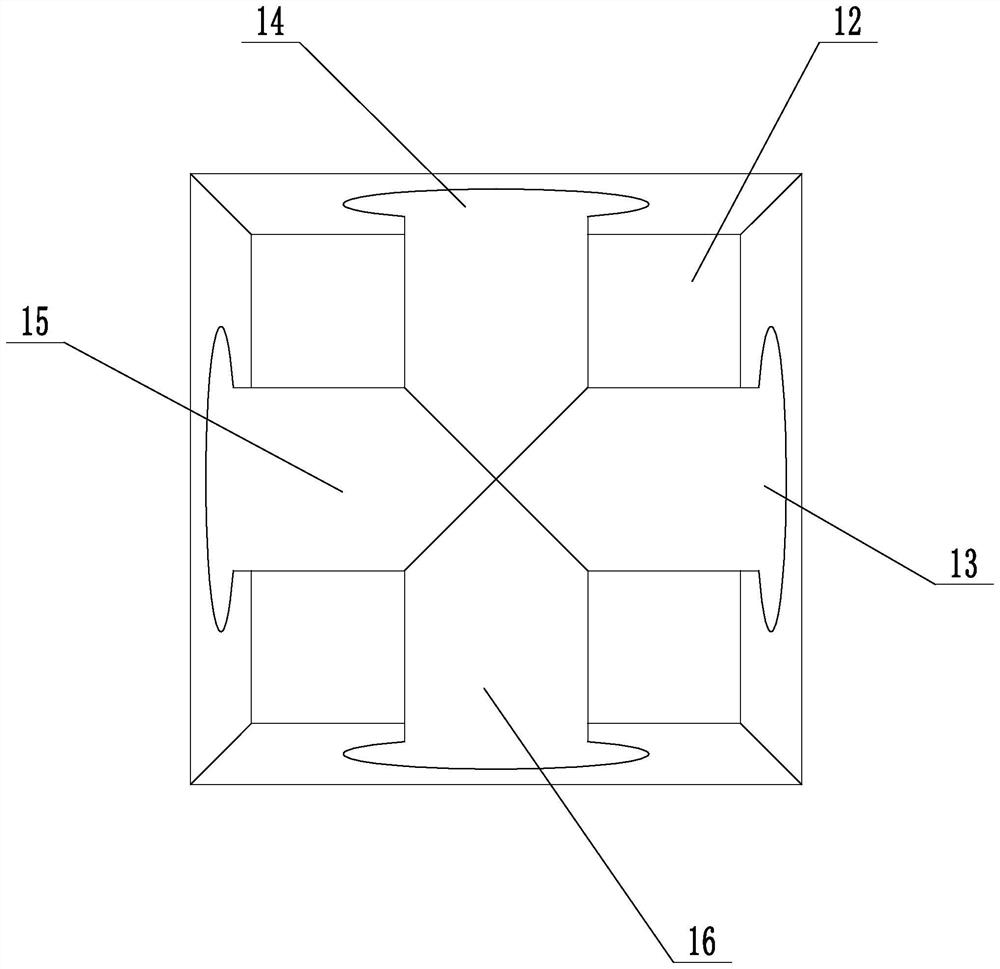

[0039] Connectors 12 are evenly distributed on the top surface of the separator 11, and the connectors 12 are arranged in a matrix form of MxN, where both M and N are natural numbers greater than zero. The connecting body 12 is provided with two fixed passages, which are respectively the first fixed passage 13 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com