Water-cooled multi-split heat recovery floor heating device

A multi-connection, heat recovery technology, applied in hot water central heating systems, household heating, heating methods, etc., can solve the problems of radiation source heat reduction, temperature difference, energy waste, etc. Effects of high radiation levels and high ambient temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

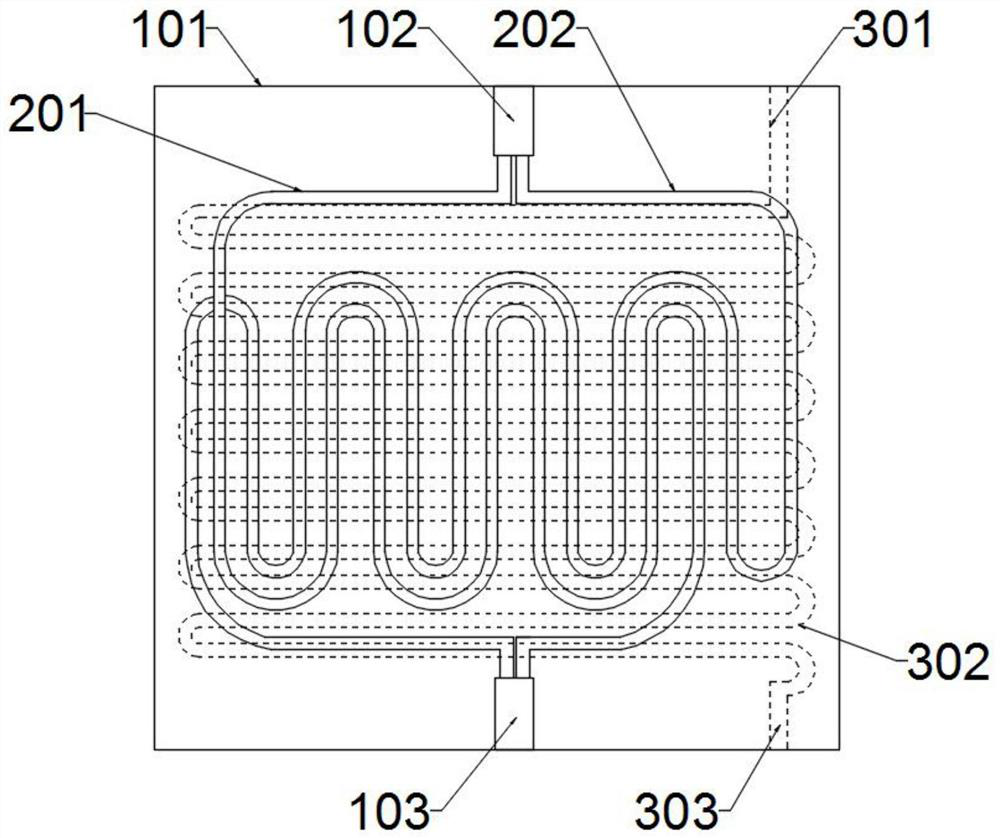

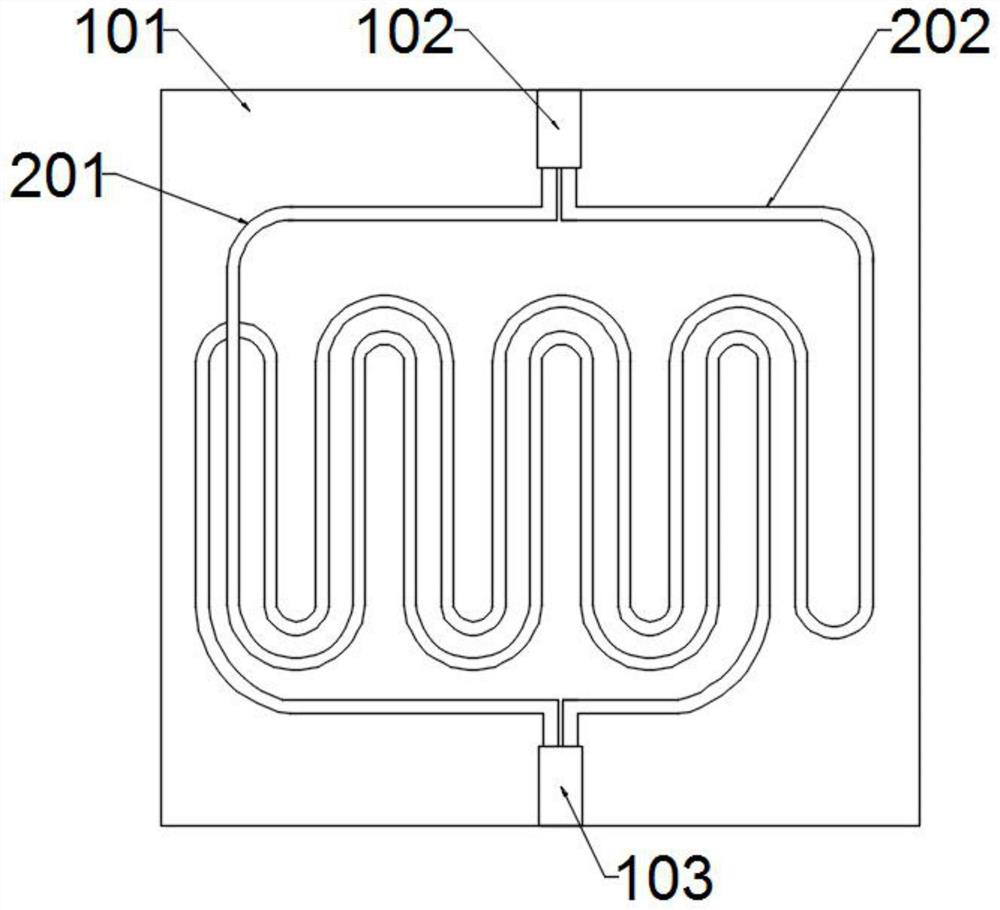

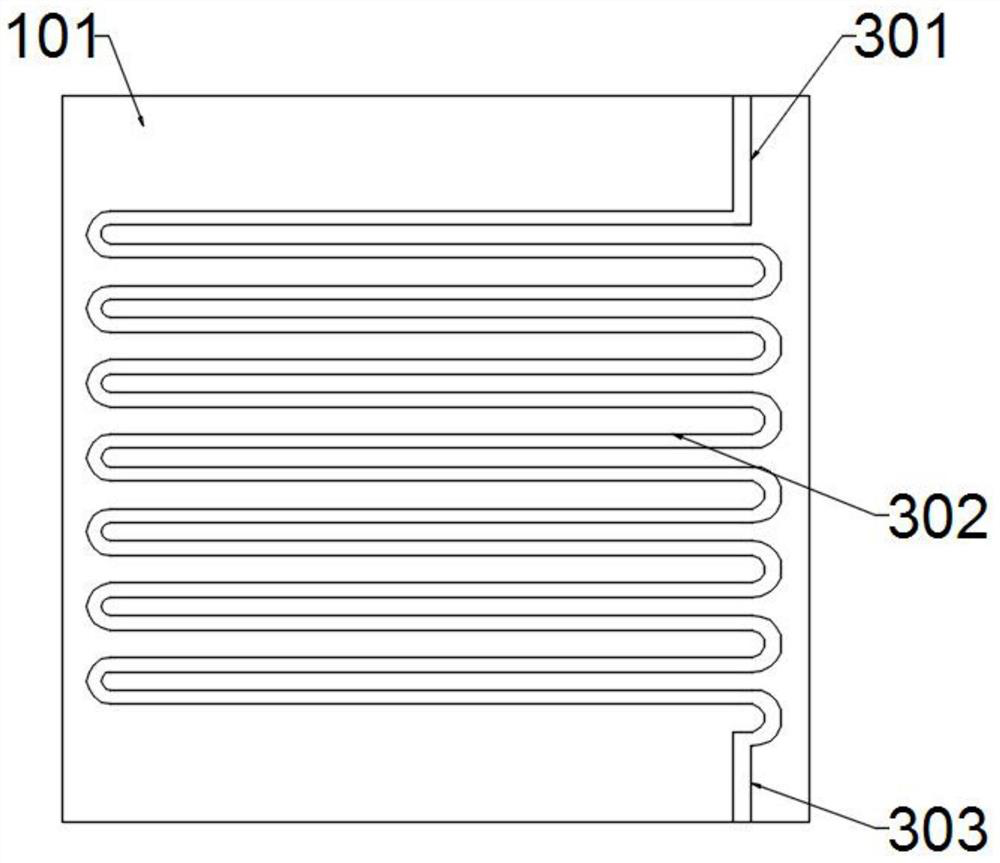

[0027] Example: such as Figure 1~6 As shown, the water-cooled multi-connected heat recovery floor heating device includes a basic support component, a heat compensation component, a heat absorption component, an air intake component, an exhaust component, and a water flow drive component. The role of other components in the support device. The basic support component is equipped with a thermal compensation component. The thermal compensation component plays the role of compensating and balancing the regional temperature difference of the heating. There is a heat absorption component under the thermal compensation component. The heat absorption component plays a timely role. The function of absorbing heating heat for energy storage, the side of the thermal compensation component is provided with an air intake component, and the intake component plays the role of distributing the intake air into the thermal compensation component, and the end of the thermal compensation componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com