Dynamic balance shank device

A dynamic balancing and tool holder technology, applied in positioning devices, devices for fixing grinding wheels, accessories of tool holders, etc., can solve problems such as rotational imbalance, and achieve the effects of ensuring machining accuracy, reducing mechanical failures and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

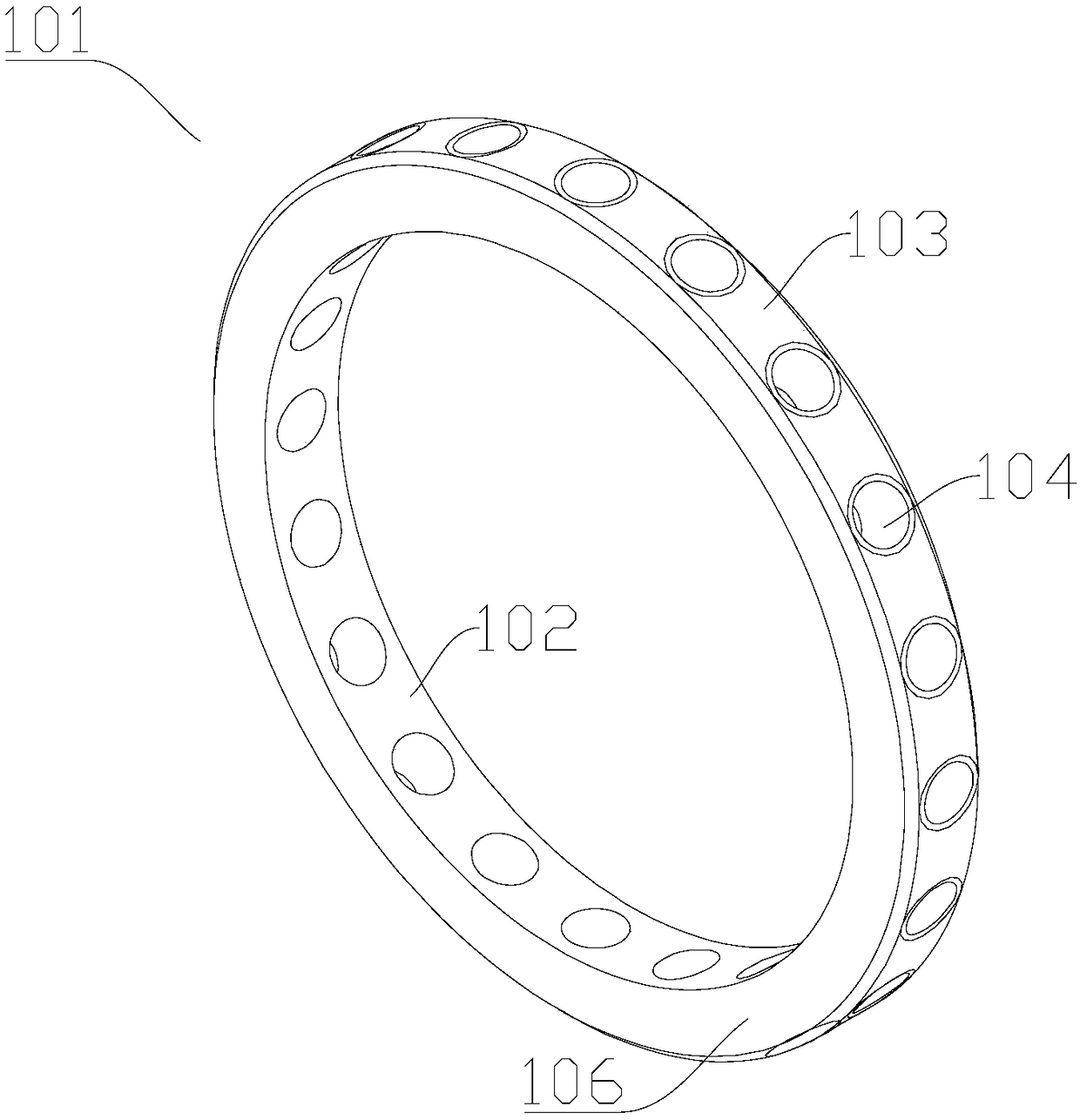

[0052] see Figure 1 to Figure 10 As shown, Embodiment 1 of the present invention provides a dynamic balance knife handle device, which includes a handle body 600 and a dynamic balance ring; the dynamic balance ring is installed on the handle body 600 .

[0053] The handle body 600 includes a main shaft installation part 601 and a balance ring installation part 602. The main shaft installation part 601 and the balance ring installation part 602 are connected.

[0054] One end of the spindle installation part 601 is used to connect with the machine tool spindle, the other end of the spindle installation part 601 is connected to one end of the balance ring installation part 602, and the other end of the balance ring installation part 602 is used to connect with the cutterhead or grinding head . The diameter of one end of the spindle mounting part 601 in the shape of a circular platform is smaller than the diameter of the other end, that is to say, one end of the balancing ring ...

Embodiment 2

[0078] see Figure 11 to Figure 19As shown, the second embodiment also provides a dynamic balance knife handle device. The dynamic balance knife handle device in this embodiment describes another implementation scheme in which the dynamic balance ring is installed on the handle body 600. In addition The technical solution of the first embodiment also belongs to this embodiment and will not be described again.

[0079] In this embodiment, the dynamic balance ring is installed on the handle body 600 through an ultrasonic transducer. There is no positioning boss in the first embodiment on the handle body.

[0080] In the optional solution of this embodiment, after the cylindrical boss 607 on the end surface of the other end of the balance ring installation part 602 in the first embodiment is omitted, an installation cavity is opened on the end surface of the other end of the balance ring installation part 602 , for installing the ultrasonic transducer; the installation cavity e...

Embodiment 3

[0103] The dynamic balancing knife handle device in the third embodiment is an improvement on the basis of the first or second embodiment, and the technical content disclosed in the first or second embodiment will not be described repeatedly. The disclosed content also belongs to the content disclosed in the third embodiment.

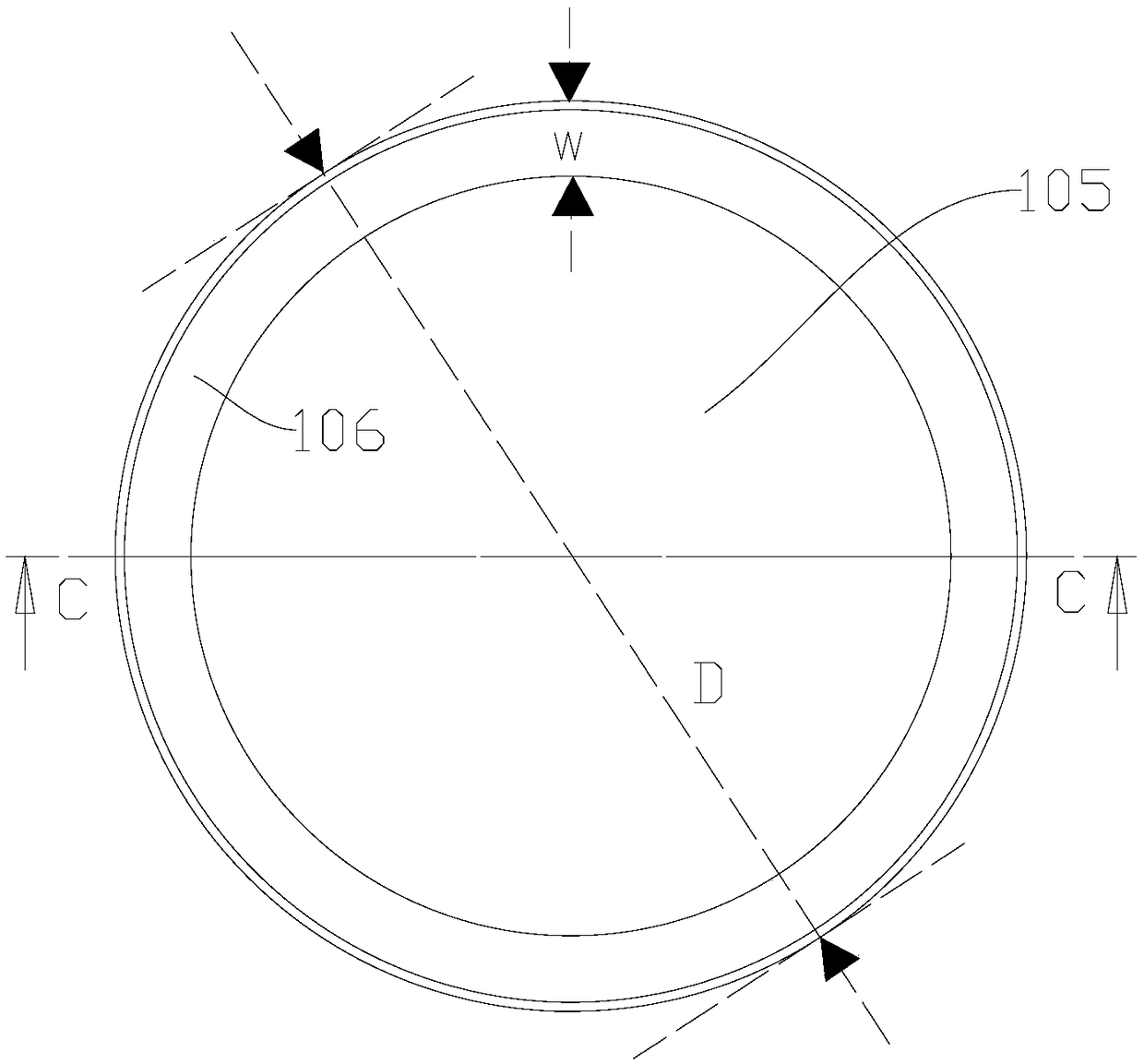

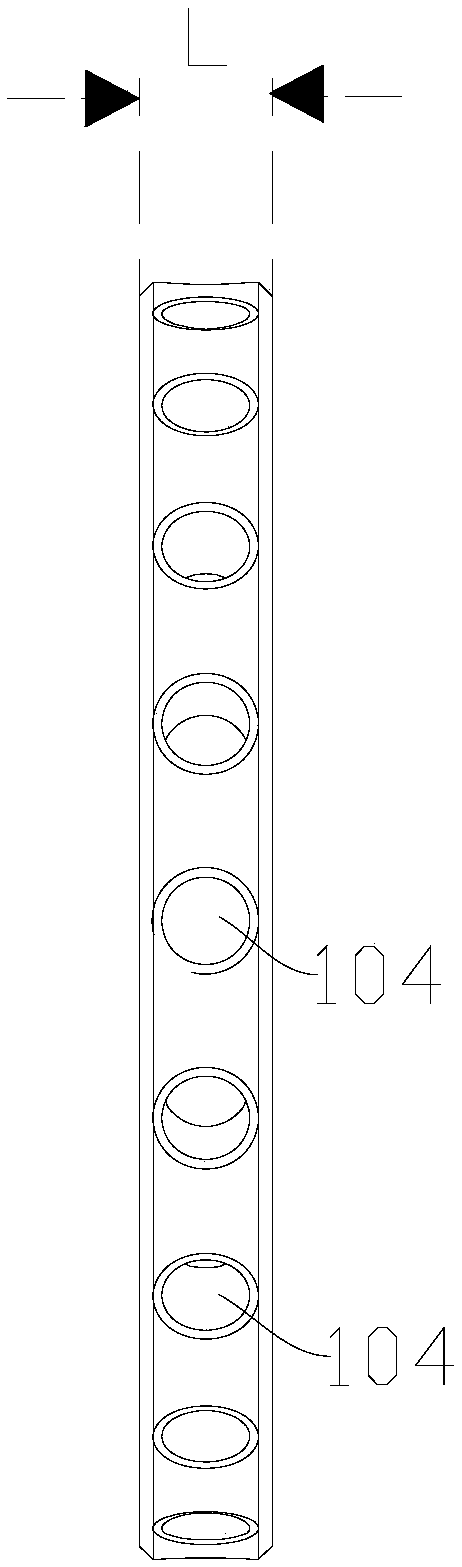

[0104] In this embodiment, the dynamic balance ring is mainly improved; the aperture of the counterweight hole 104 of the dynamic balance ring is linearly related to the outer diameter of the ring body 101, the axial length of the ring body 101 and the ring width of the ring body 101. It is estimated that when linearly related, it is convenient to configure the corresponding adjustment device, and it is beneficial to quickly adjust the balance.

[0105] Specifically, the diameter of the counterweight hole 104 satisfies the following formula:

[0106] d=xD+yL+zW+C,

[0107] Among them, d represents the aperture diameter of the counterweight hole 104 (b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com